Rotary centrifugal multi-blade cutting machine

A rotary centrifugal and cutting machine technology, applied in metal processing and other directions, can solve the problems of complex transmission system structure, high cost of machinery and equipment, and high precision of parts manufacturing, and achieve the effects of low cost, good cutting quality, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the invention will be described in detail below with reference to the accompanying drawings. The description of the embodiments is for the purpose of illustration only, and in no way limits the invention and its application or use.

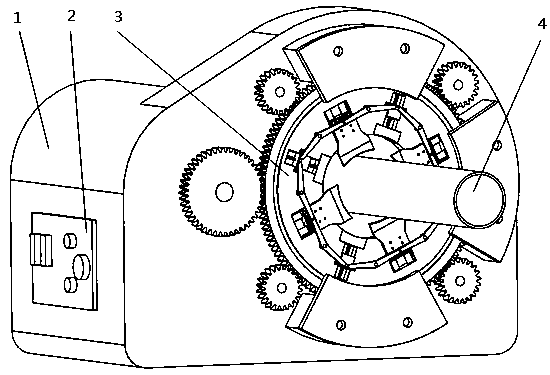

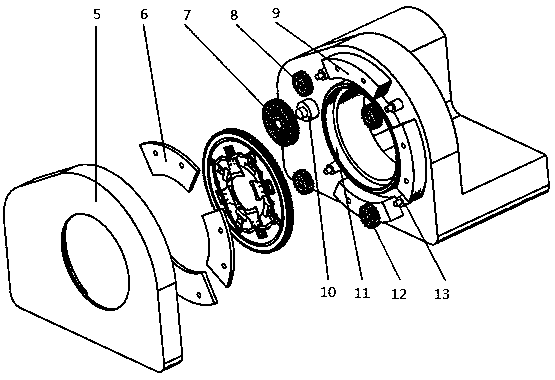

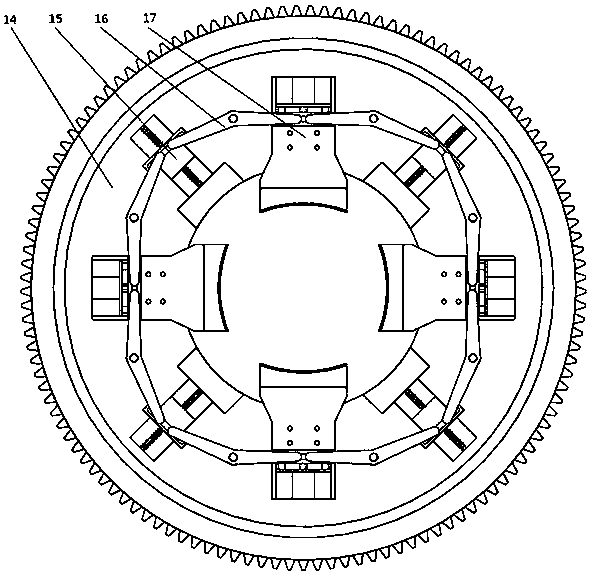

[0026] Such as figure 1 and figure 2 As shown, the rotary centrifugal multi-blade cutting machine provided by the present invention is used for pipe cutting. The cutting machine includes: a machine base 1, a control panel 2 arranged on the side of the machine base 1, a dust cover 5, and a cutting unit 3; The panel 2 is used to control the operation of the motor inside the machine base. The motor provides power for the cutting machine. The motor spindle 10 is exposed outside the end surface of the machine base 1; the end surface of the machine base 1 has a circular channel, which is convenient for the pipe 4 to enter the cutting unit 3 Cutting; the dust cover 5 is used to prevent dust and cuttings from entering the meshing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com