High-precision furniture plate fixed-length cutting device

A technology for cutting devices and furniture boards, which is used in manufacturing tools, wood processing appliances, forming/shaping machines, etc., can solve the problems of long cutting time, narrow cutting range, and inability to block debris, and saves cleaning equipment. The effect of time, prevention of floating around, and high cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

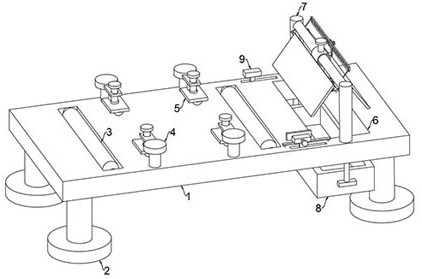

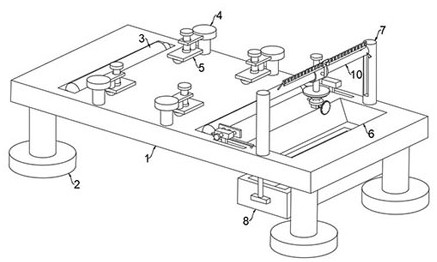

[0034] refer to Figure 1-4 , a high-precision fixed-length cutting device for furniture boards, comprising a platform 1 on which an auxiliary mechanism is installed;

[0035] The above points worth noting are as follows:

[0036] 1. The auxiliary mechanism includes two rolling grooves set up on the platform 1, and the roller rod 3 is installed in the two rolling grooves through the rotation of the rotating rod. The roller rod 3 in the rolling groove can rotate freely, which can reduce the distance between the furniture board and the The frictional resistance between the platforms 1 enables the furniture panels placed on the platforms 1 to quickly move horizontally.

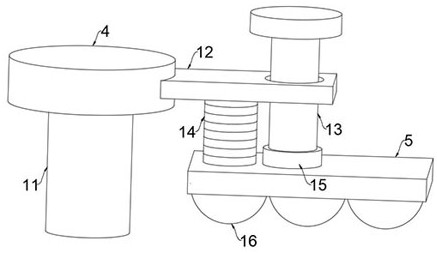

[0037] 2. A plurality of rotating columns 4 are installed on the platform 1 through a plurality of connecting rods 11. Each rotating column 4 is threaded with a threaded rod 13 through a rotating plate 12, and each threaded rod 13 is connected to the corresponding rotating plate 12. Each space is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com