Automatic strip-cutting machine

A slitter and automatic technology, applied in metal processing and other directions, can solve the problems of low work efficiency, low degree of automation, slow moving speed, etc., and achieve the effect of high cutting efficiency, high precision and fast cutting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

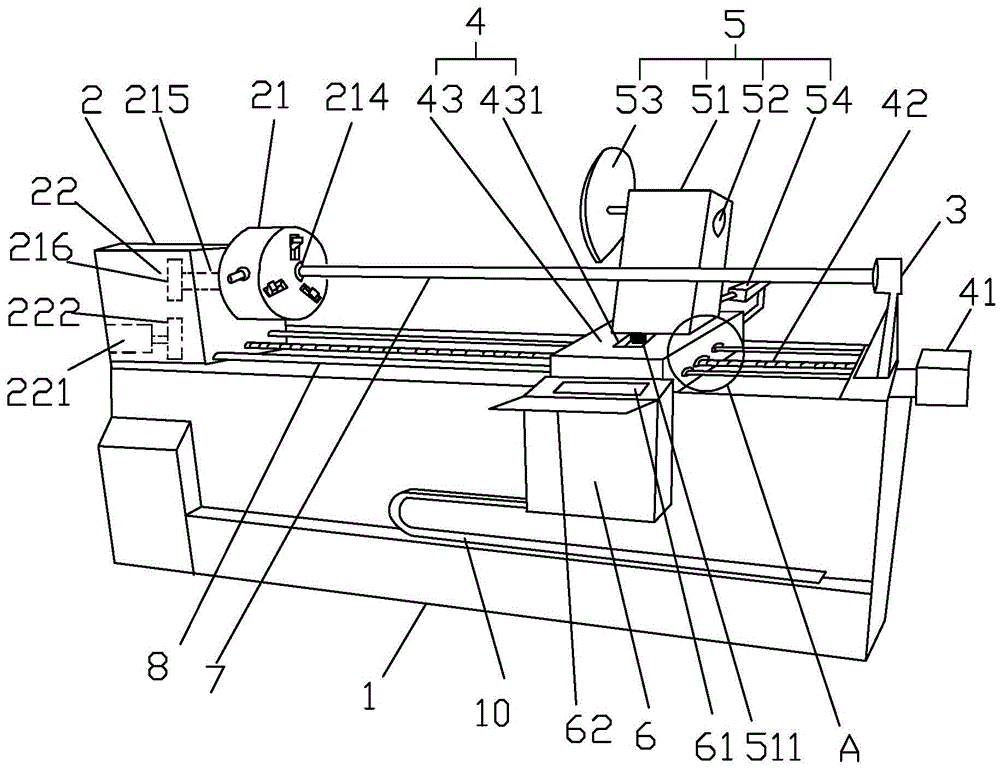

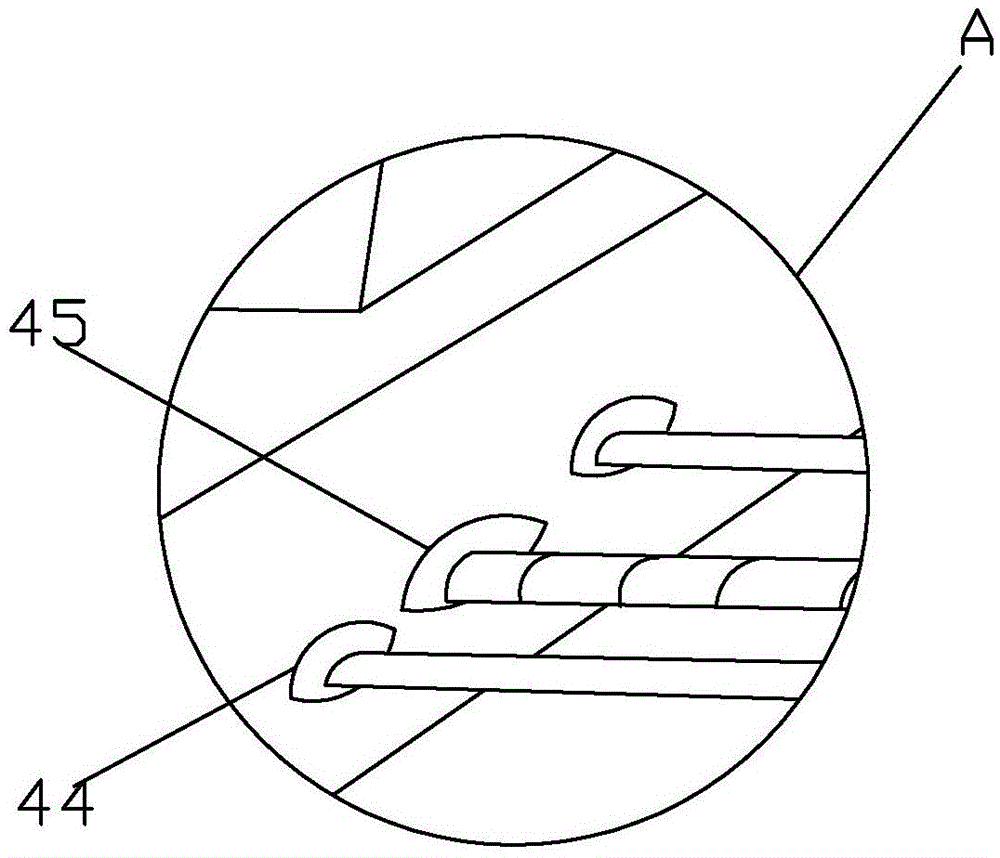

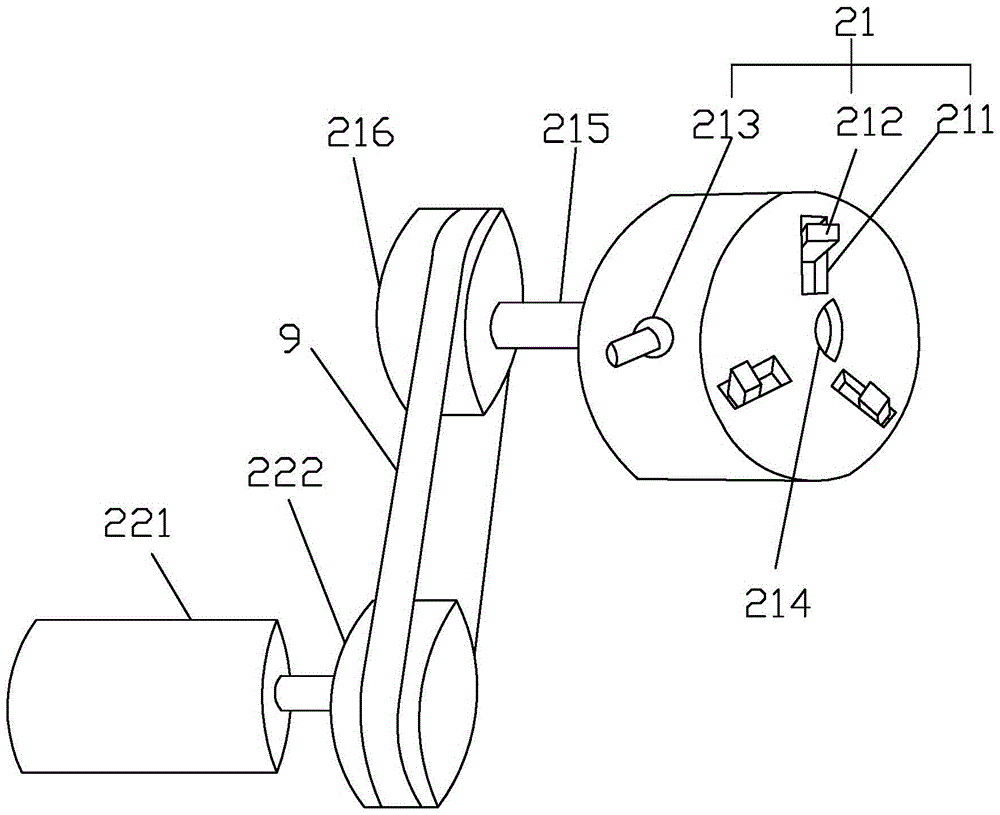

[0015] Such as Figure 1-3 Described a kind of automatic strip cutting machine, comprises frame 1, machine head 2, machine tail 3, moving device 4, cutting device 5 and PLC control box 6, and described machine head 2 and machine tail 3 are respectively positioned at bit frame 1 on both sides, the machine head 2 includes a clamping chuck 21 and a driver 22 that drives the clamping chuck 21 to rotate. The driver 22 adopts a second motor 221, and the main shaft of the second motor 221 is provided with a drive wheel 222, the connecting shaft 215 is provided with a driven wheel 216, and a belt 9 is provided between the driving wheel 222 and the driven wheel 216, which has a simple structure and is convenient to drive. A sleeve rod 7 is arranged between the clamping chuck 21 and the tail 3 , one end of the sleeve rod 7 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com