Double vertical clamping structure for finely adjusting double-worm-wheel fly cutter radially

A technology of double worm gears and flying knives, applied in the direction of worm gears, gear teeth, elements with teeth, etc., can solve the problems of reducing productivity, increasing cutting resistance, weakening the strength and rigidity of the tool bar, and achieving self-closing of positioning and clamping. Reliable, low rolling friction loss, flexible movement and anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

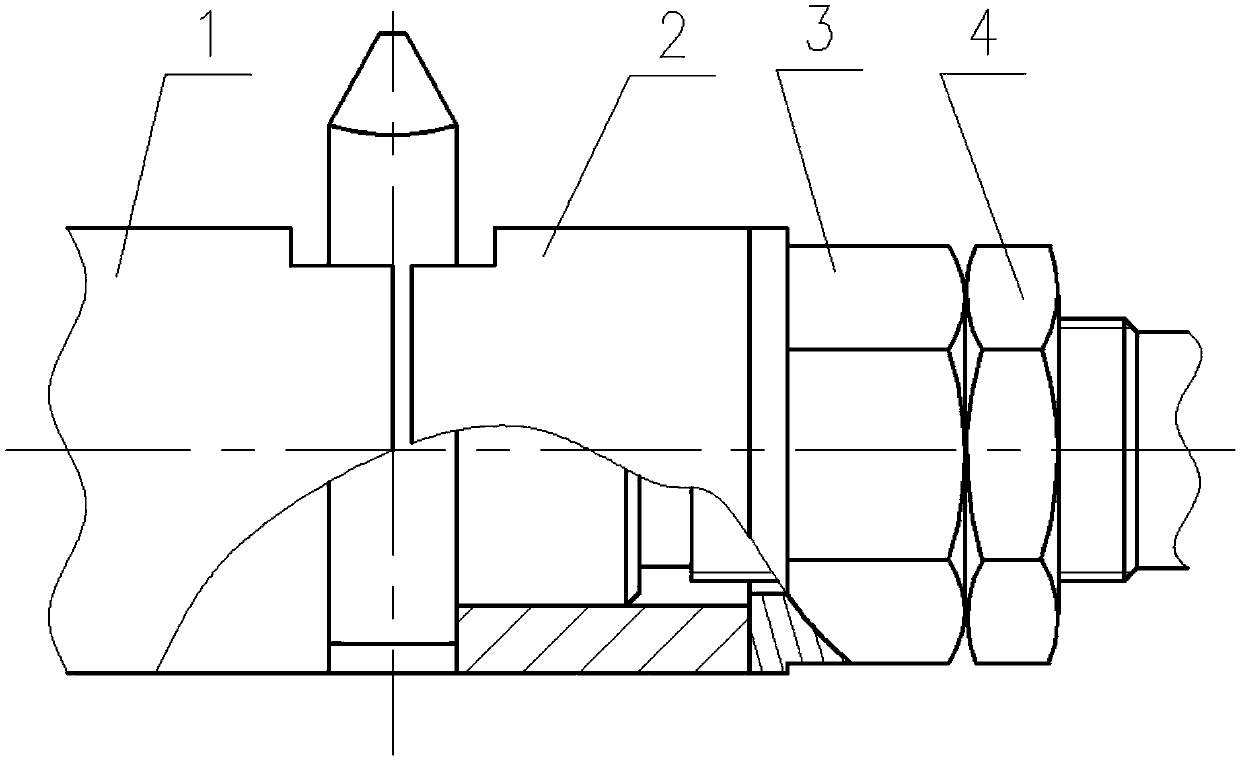

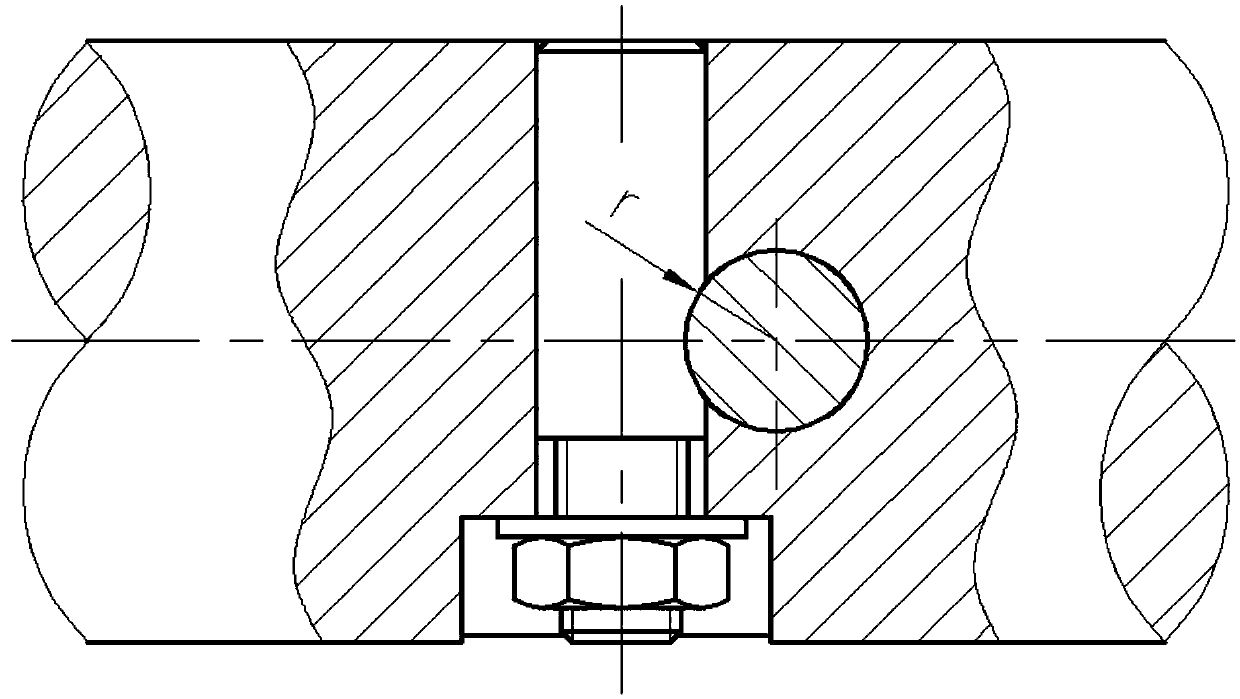

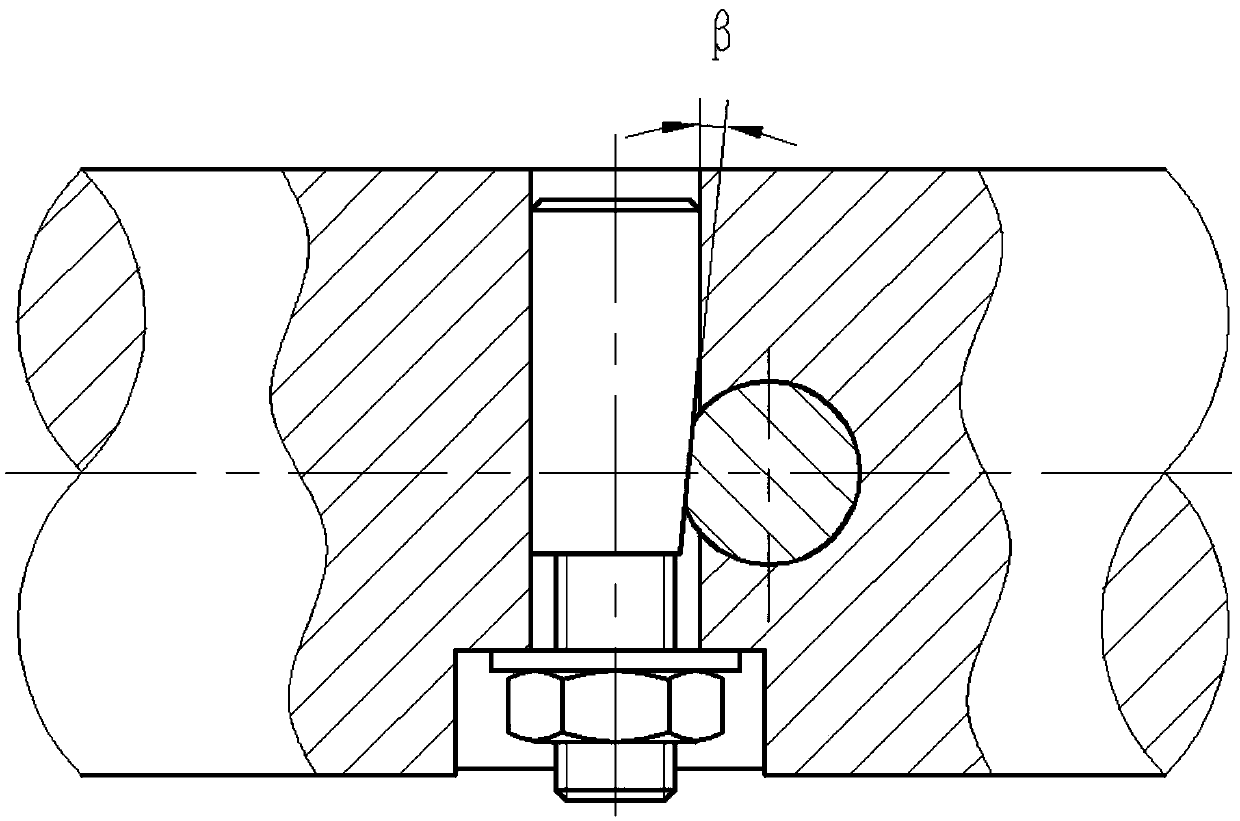

[0075] Such as Figure 4The shown clamping structure of a double worm gear flying knife includes a tool bar 1, which is composed of a driving end with a tapered shank (not shown in the figure) and a slender passive end. The passive end is provided with a central hole 4 facing the active end and concentric with the centerline of rotation of the tool bar 1, and a mounting and clamping device is provided radially along the center line of tool bar 1 rotation (in the axial direction) at a proper position in the middle of the tool bar 1. Tighten and fine-tune the two parallel, two-stage stepped concentric holes 2 of the large and small holes in the same direction of the straight handle 72 of the flying knife. The large holes of the two stages of the concentric holes 2 are cylindrical holes and the small holes are screw holes 22. The center distance between the two stages of stepped concentric holes 2 is the axial tooth pitch of a working worm πm, and the locking screw 8 is provided ...

Embodiment approach 2

[0125] Figure 5 Reflecting the specific structure of another embodiment of the present invention, this embodiment is different from Embodiment 1, mainly in that the force applying member 6 is an electro-hydraulic push rod or a hydraulic or pneumatic cylinder and a gas-hydraulic booster mechanism. Positioning and connection with the cutter bar 1; specifically, the larger diameter part of the central hole 4 (entry end) is a circular light hole 42, so as to facilitate the sliding positioning of the force applying member 6. On the passive end surface 11 There are several screw holes connected with the force applying member 6, and the hobbed worm wheel is left-handed.

[0126] A further technical solution is: the force-applying member 6 adopts an electro-hydraulic push rod or a hydraulic or pneumatic cylinder and a gas-hydraulic booster mechanism, and the axial force is generated by hydraulic, pneumatic or electric energy. The piston rod serves as a force application terminal 61,...

Embodiment approach 3

[0130] Image 6 Reflecting the specific structure of another embodiment of the present invention, this embodiment is different from Example 2 in that the force applying member 6, and δ=0°, specifically, the force applying member 6 adopts a spring or a spring assembly, Image 6 Shown in the central center hole 4 is the Belleville spring and adjusting flat washer.

[0131] A further technical solution is: the force applying mechanism member 6 adopts a spring or a spring assembly, and the spring is uniformly elastically deformed after being compressed by force, and the elastic force generates an axial force, which pushes the force applying terminal 61 to move axially, and adjusts the flat washer or screw Adjust the stretch.

[0132] When the spring is stressed and compressed, it deforms uniformly and elastically, and the force application terminal 61 moves axially to generate an axial force. Through several of the balls 9, the opposite ends of the first positioning push rod and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com