Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Stability lobes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

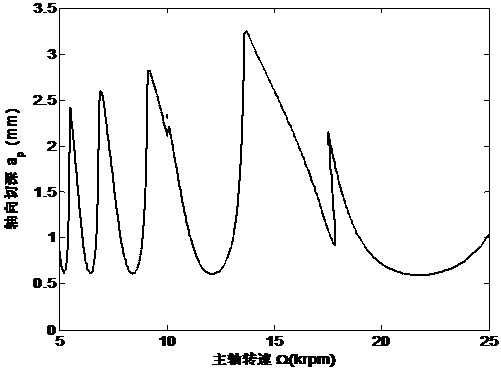

Flutter stability domain modeling approach for face cutting process

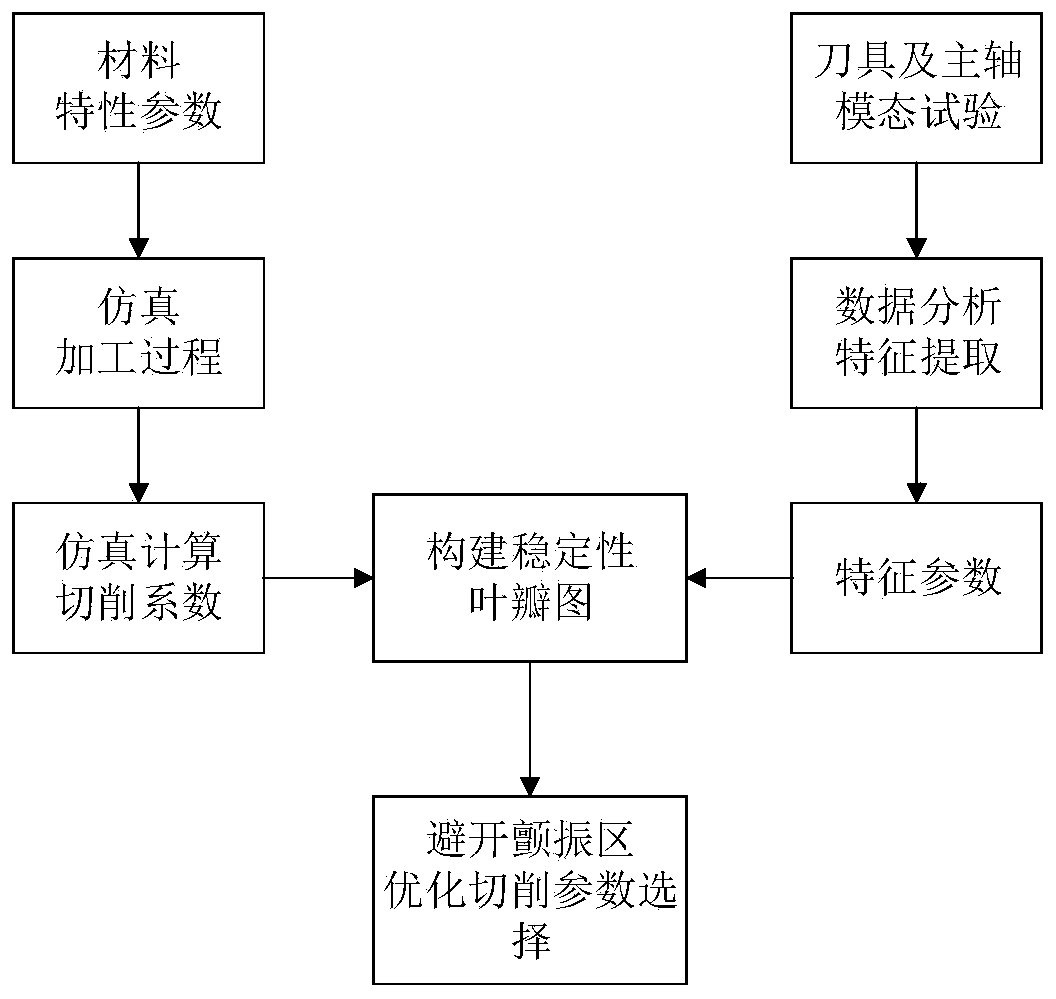

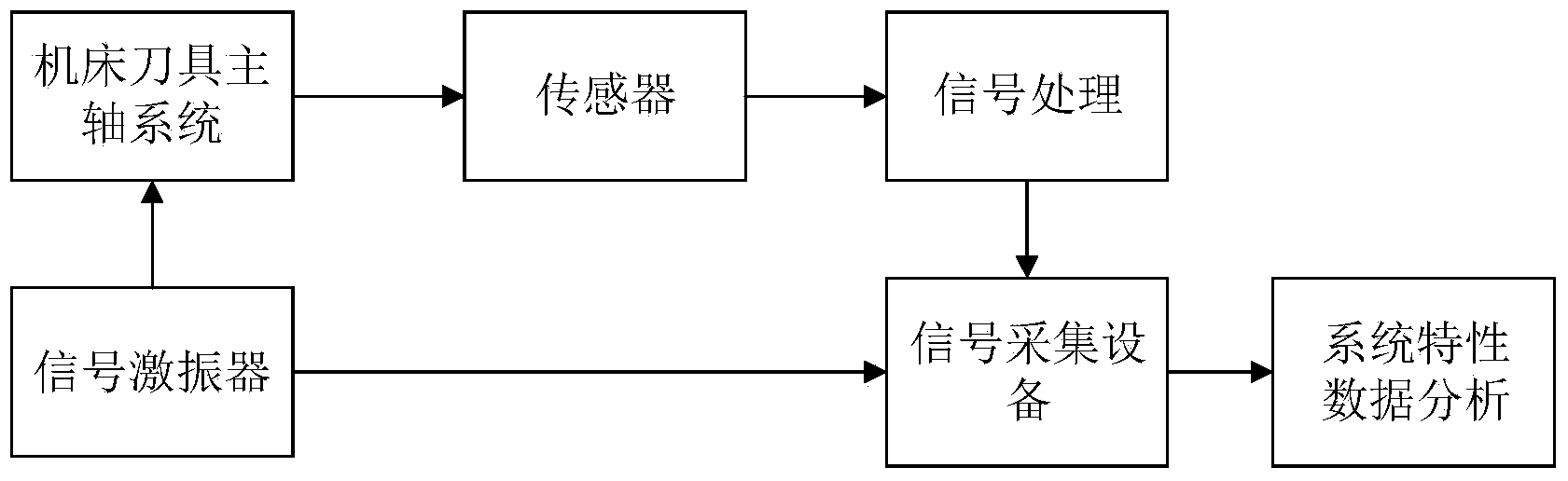

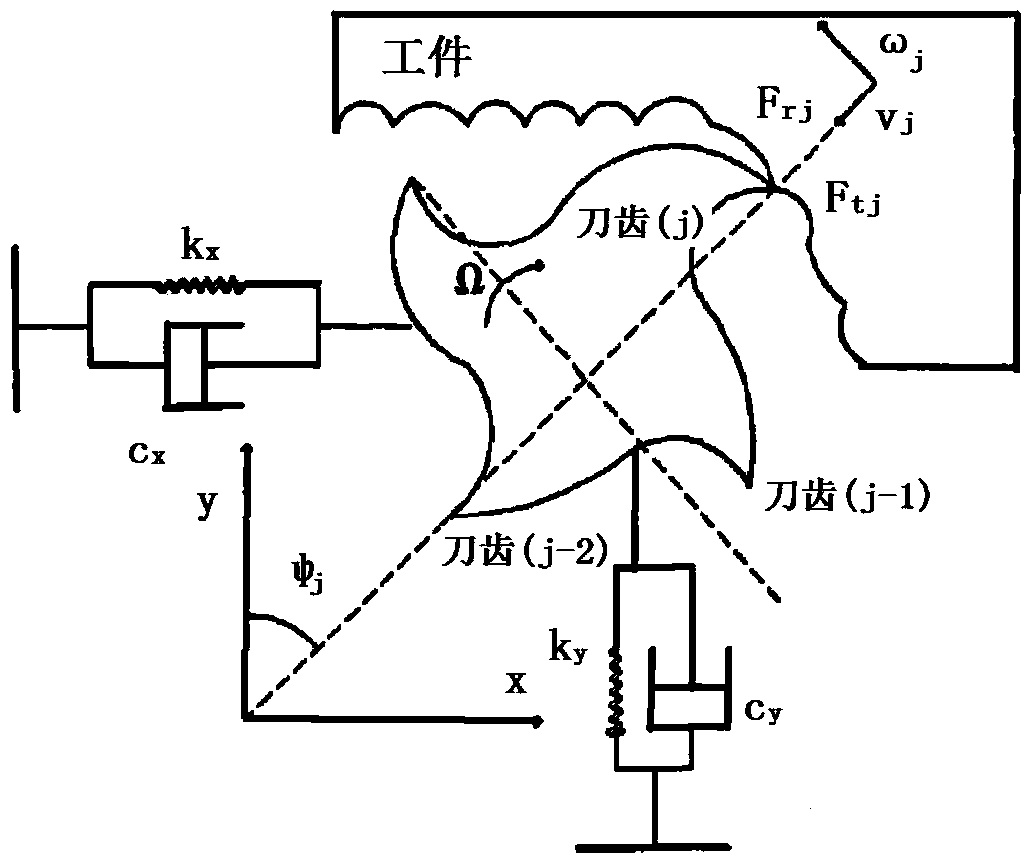

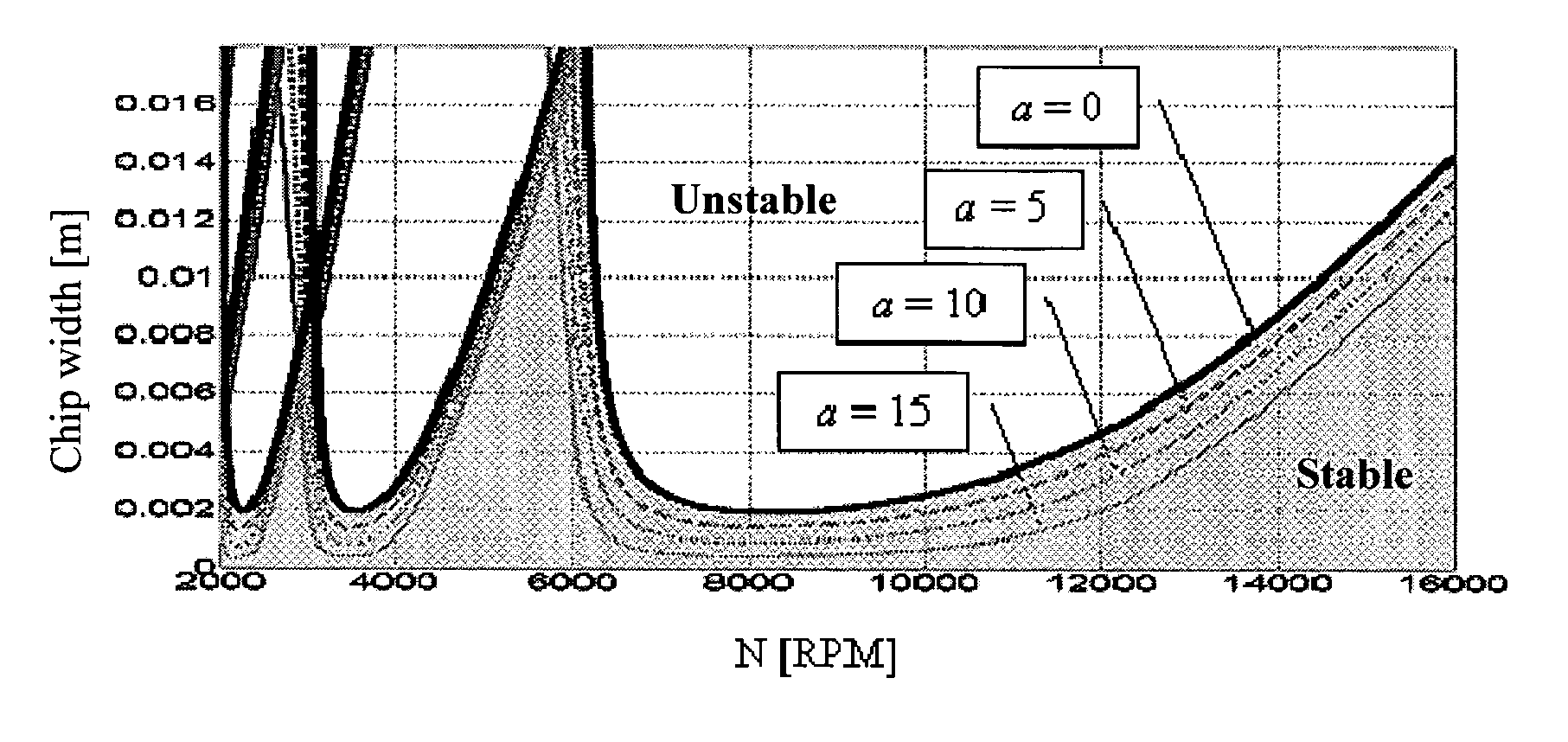

The invention belongs to the technical fields of simulating computational analysis and modal testing, and relates to a flutter stability domain modeling approach for a face cutting process. After all kinds of characteristic parameters of a material are known, a computer simulates a machining cutting process, calculates the cutting force in the machining process and analyzes the corresponding cutting coefficient. After the cutting coefficient is obtained, a modal experiment is utilized, modal testing is carried out on a machine tool spindle tool system, and the modal characteristic parameters of the machine tool spindle tool system are analyzed and comprise a multiple-order inherent frequency, a damping ratio, dynamic stiffness and the like. According to a flutter cutting theory, a stability lobe graph is drawn through combining the cutting coefficient and the system characteristic parameters and utilizing a computer assemble program, and is used for selecting the reasonable cutting parameter to avoid a flutter region, the processing precision and quality are improved, and a machine tool system is protected.

Owner:DALIAN UNIV OF TECH +1

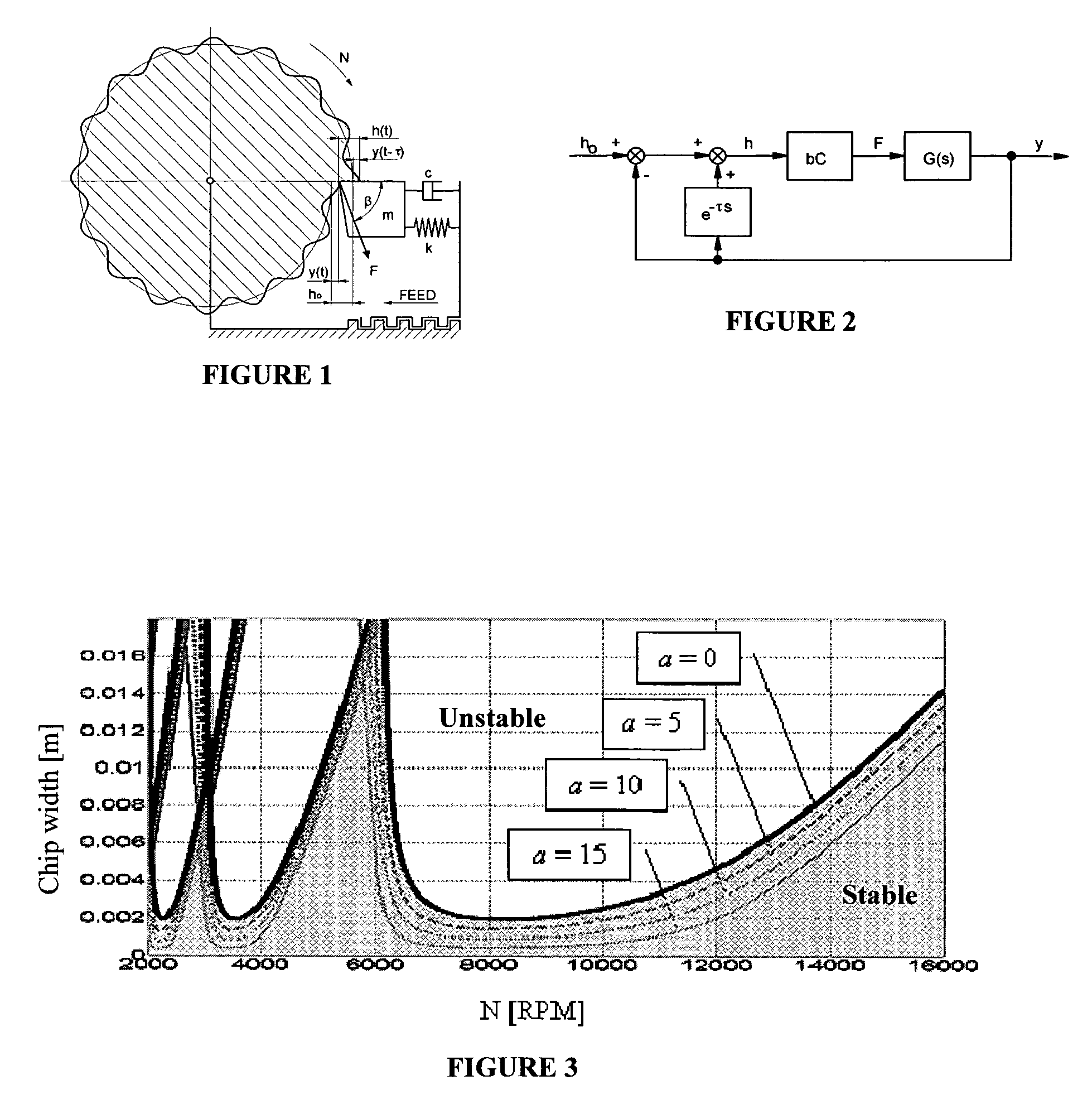

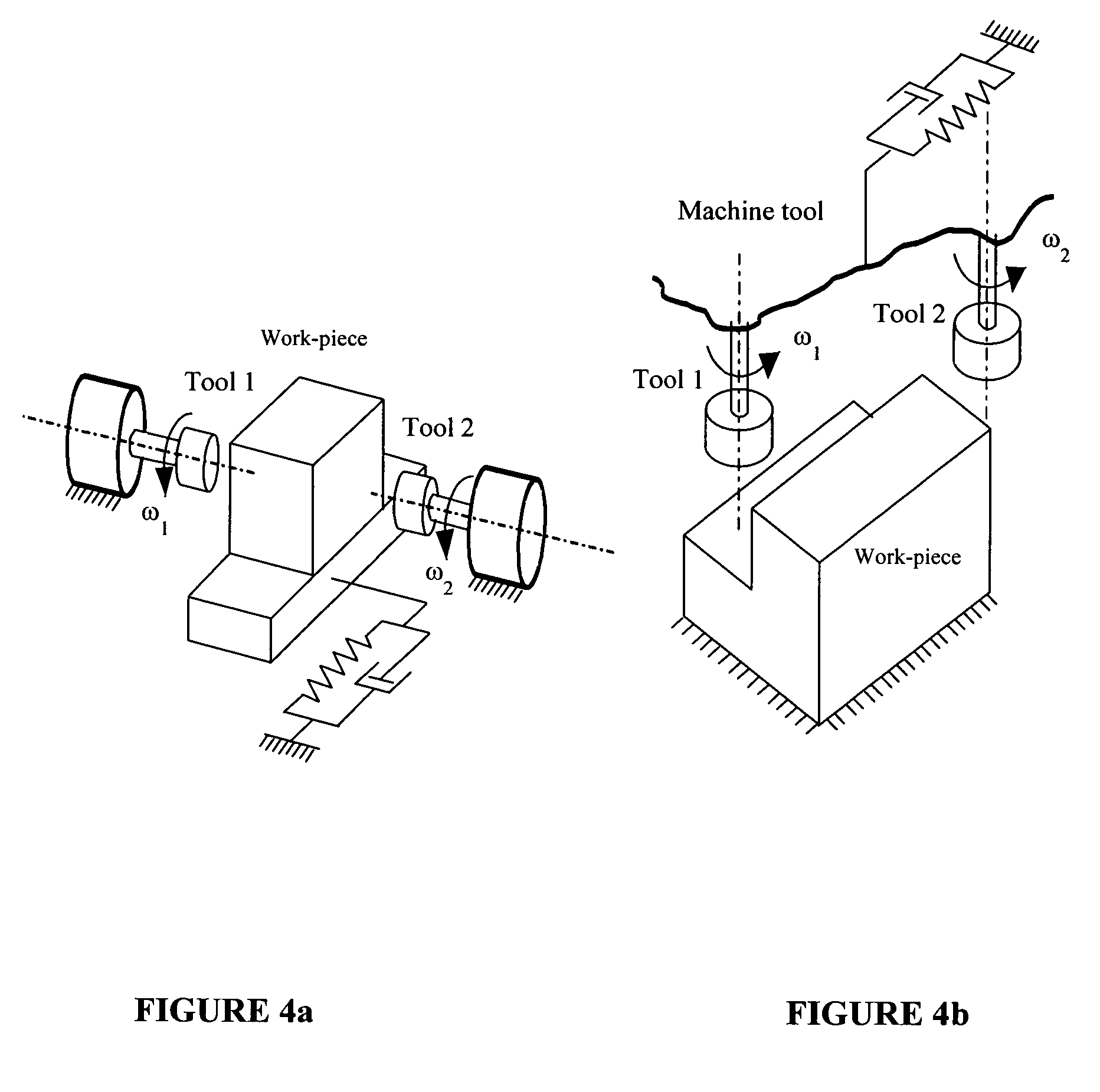

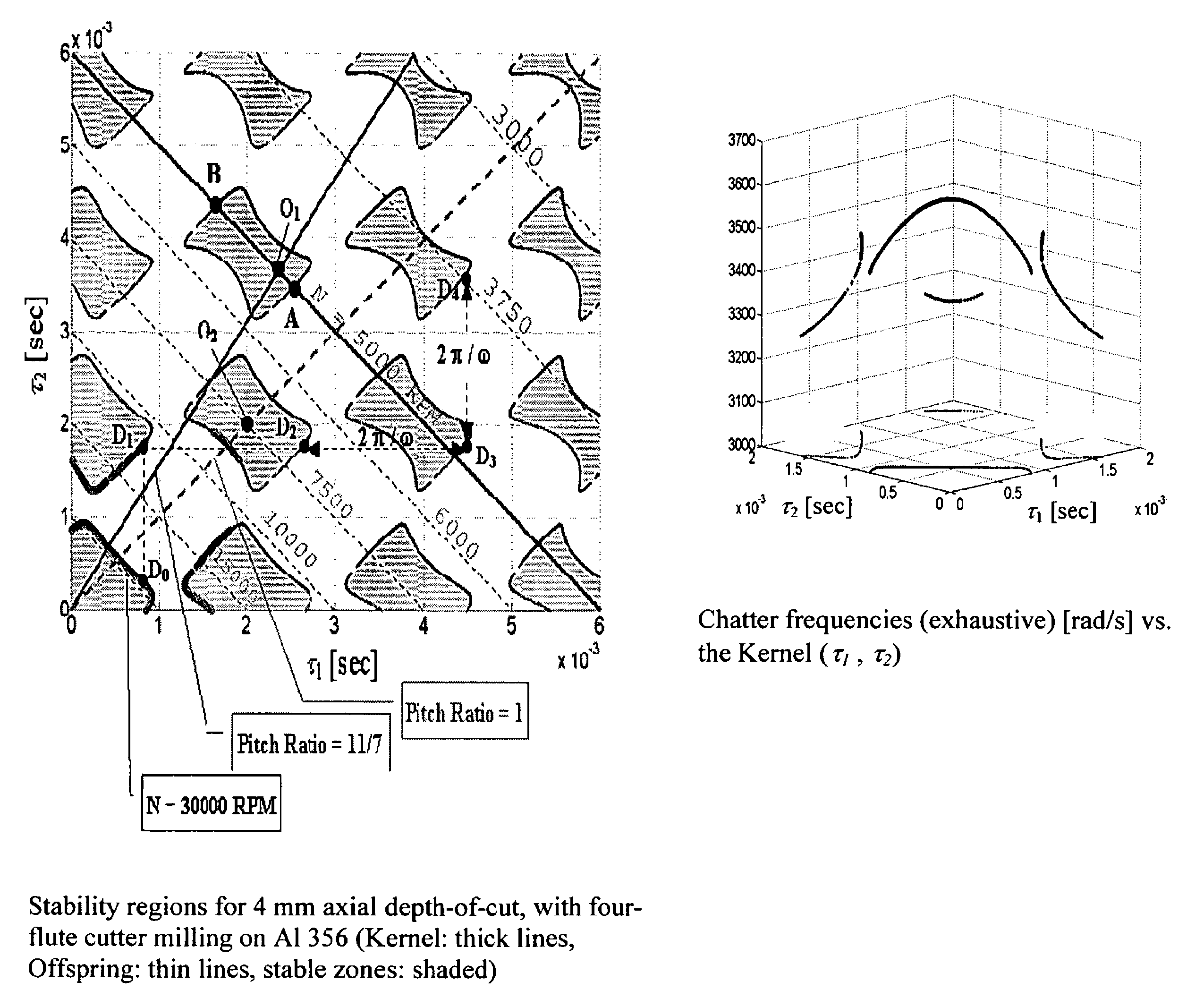

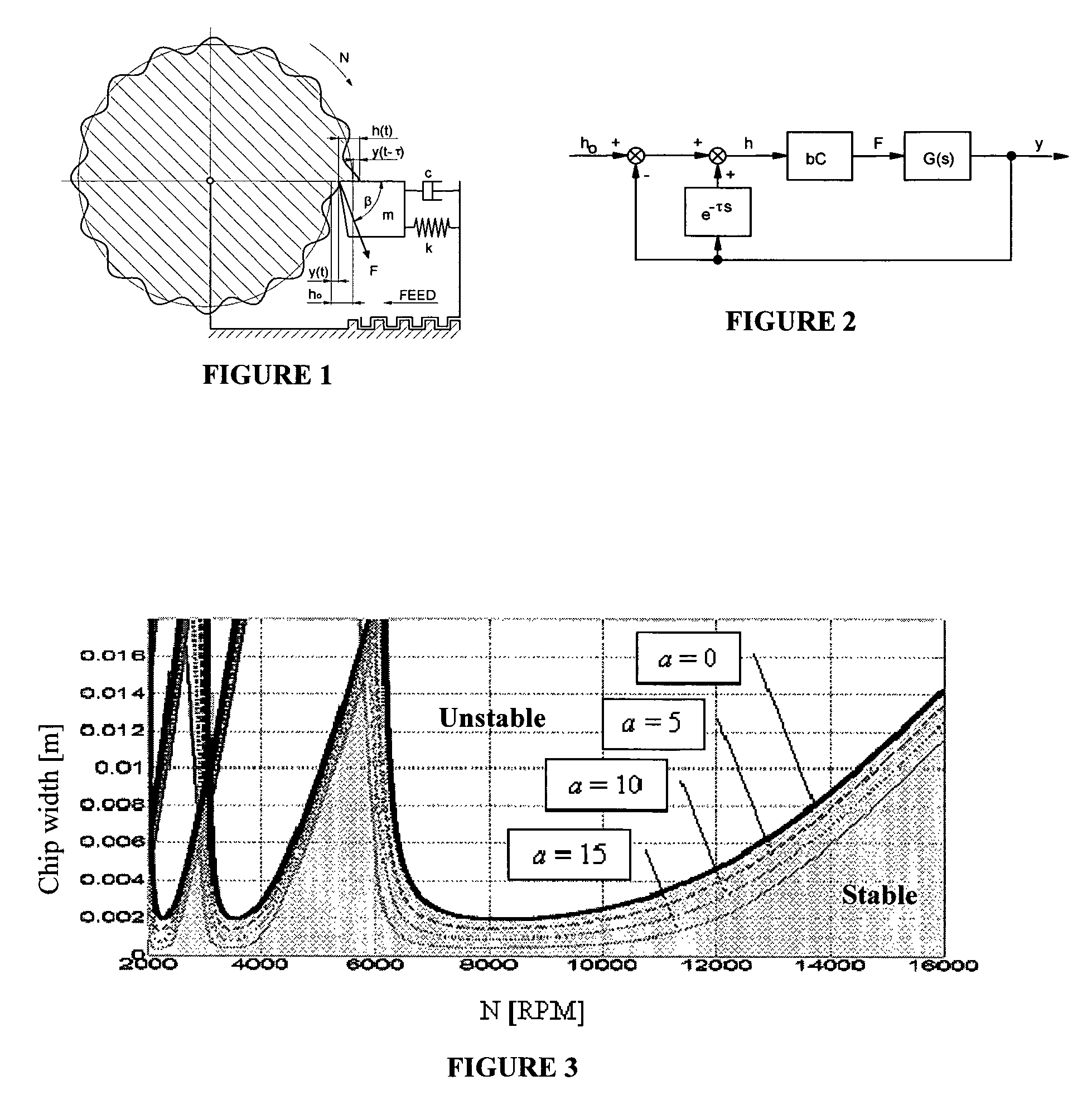

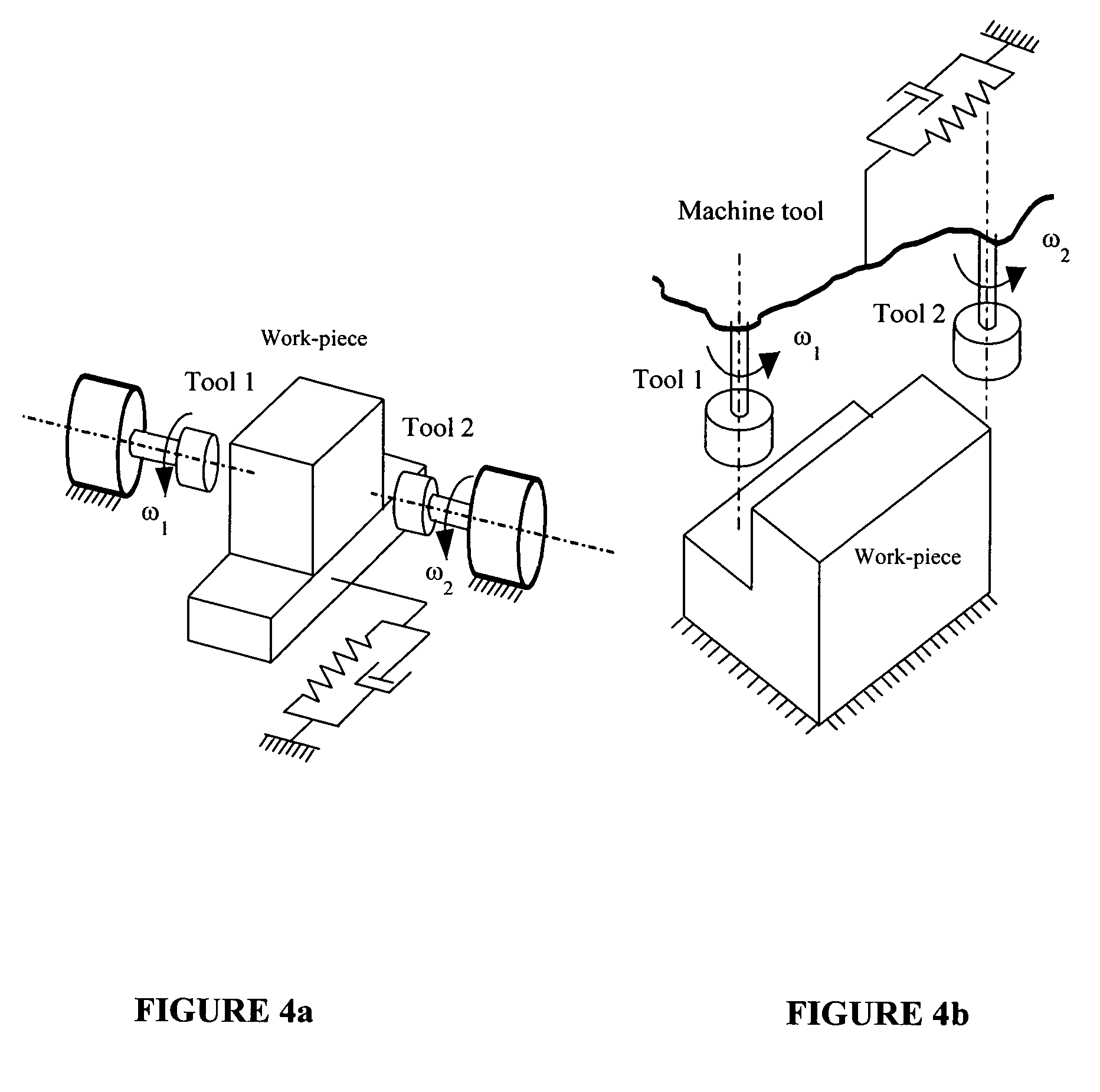

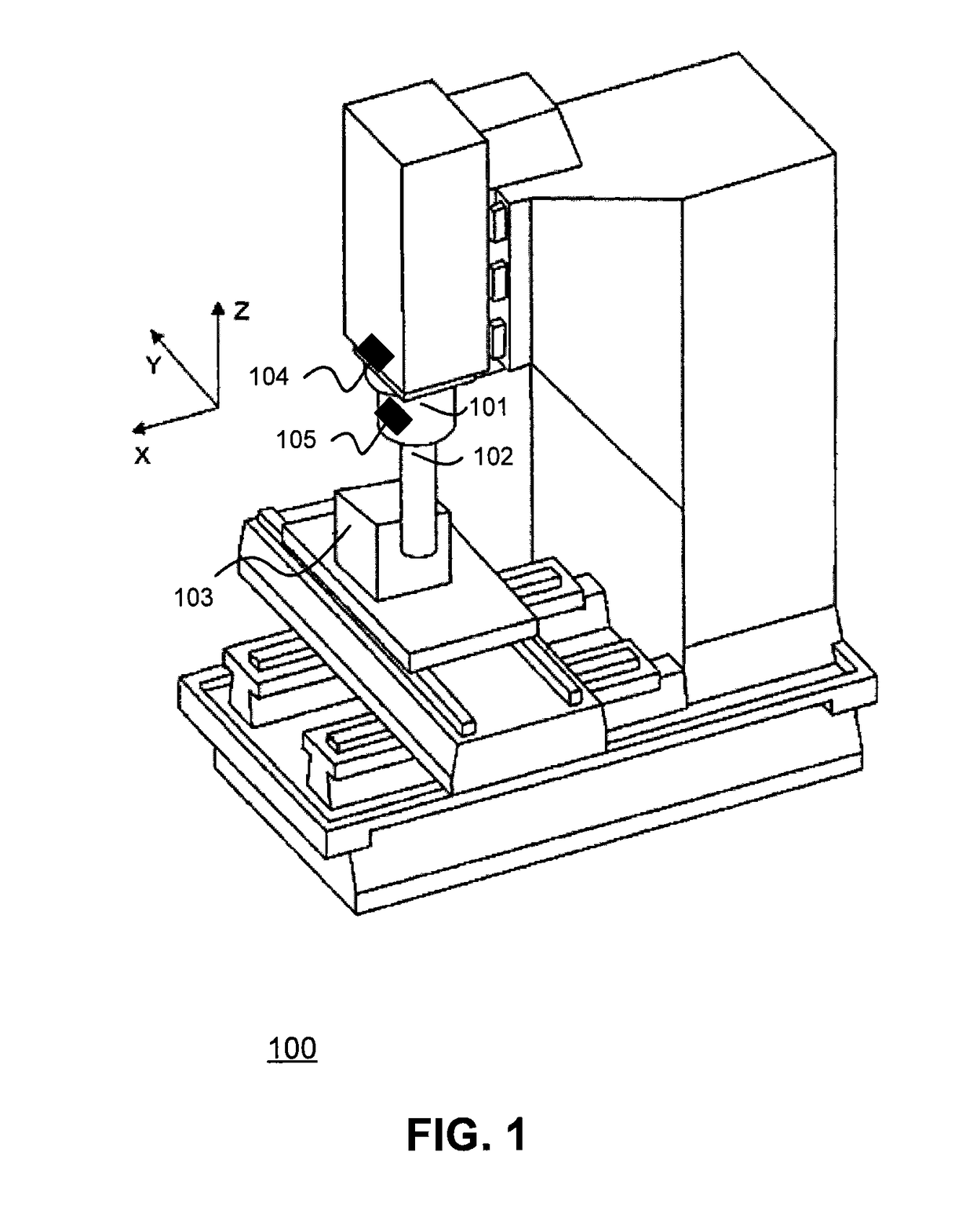

System and method for chatter stability prediction and control in simultaneous machining applications

InactiveUS20060271231A1Reducing and controlling machine tool chatterReduce controlProgramme controlLathesMilling cutterMachined surface

Systems and methods are provided for use in assessing the stability of simultaneous machining (SM) dynamics (which is also known as parallel machining). In SM, multiple cutters, which are generally driven by multiple spindles at different speeds, operate on the same work-piece. In an alternative implementation of SM, single milling cutters with non-uniformly distributed cutter flutes operate on a work-piece. When SM is optimized in the sense of maximizing the rate of metal removal constrained with or by the machined surface quality, “chatter instability” phenomenon appears. The present disclosure declares the complete stability picture of SM chatter within a mathematical framework of multiple time-delay systems (MTDS). A cluster treatment of characteristic roots (CTCR) procedure determines the regions of stability completely in the domain of the spindle speeds for varying chip thickness, thereby replicating the well-known “stability lobes” concept of STM for simultaneous machining.

Owner:UNIV OF CONNECTICUT

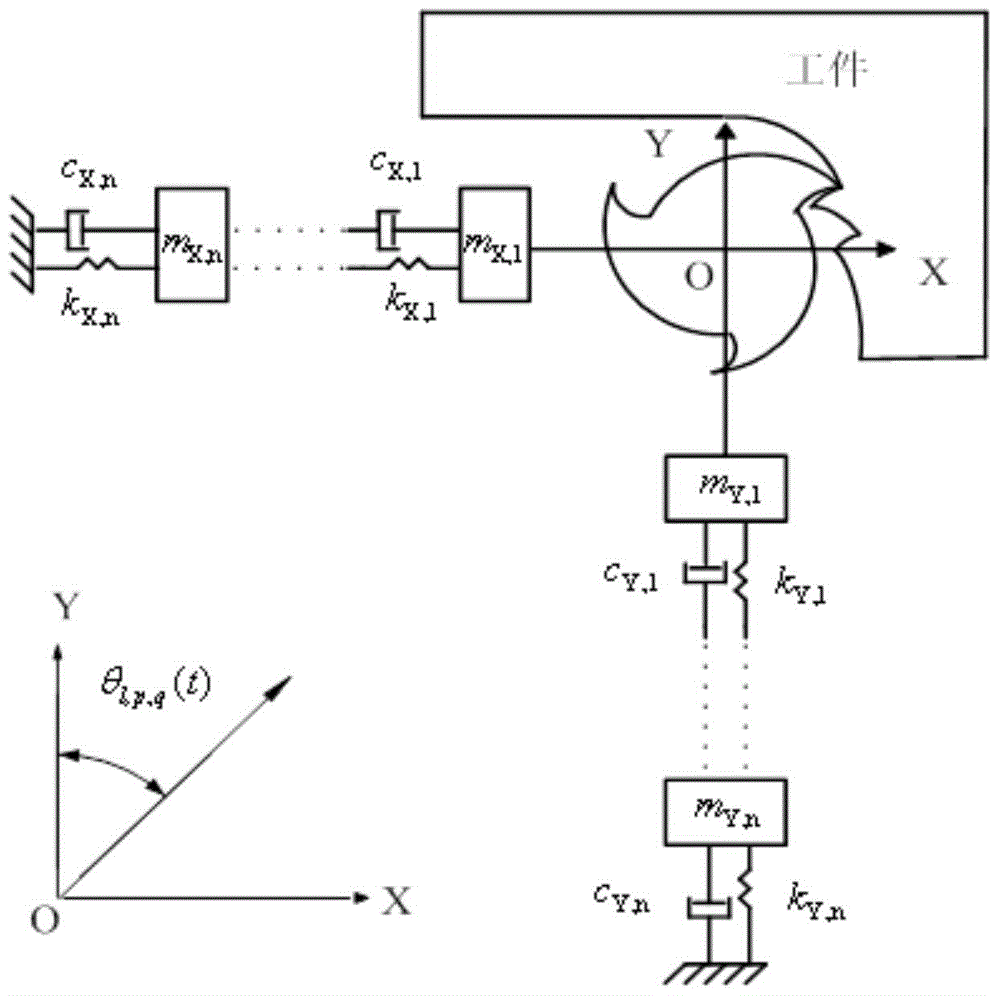

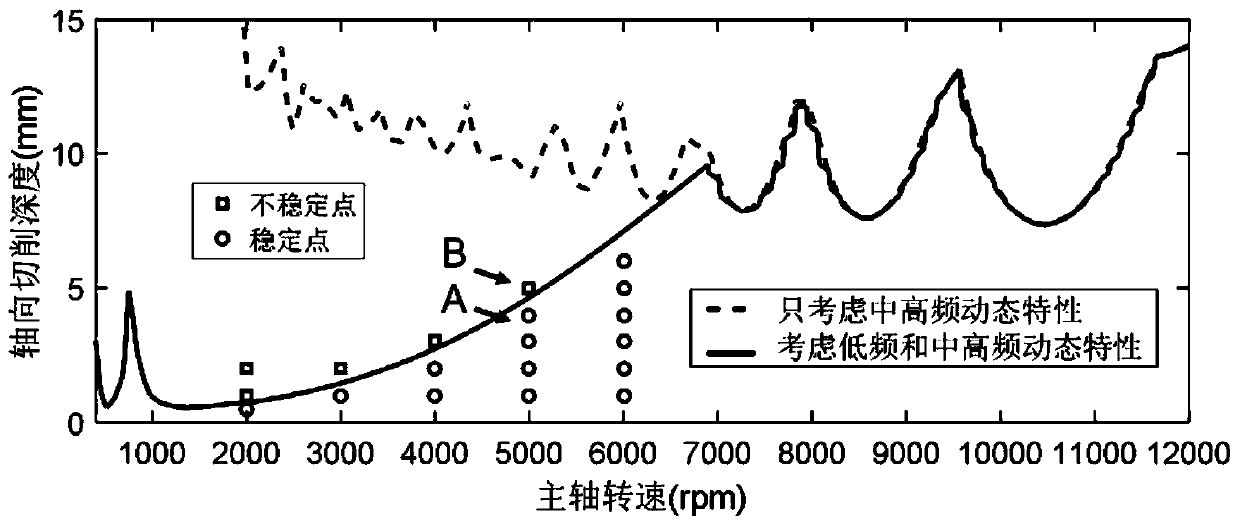

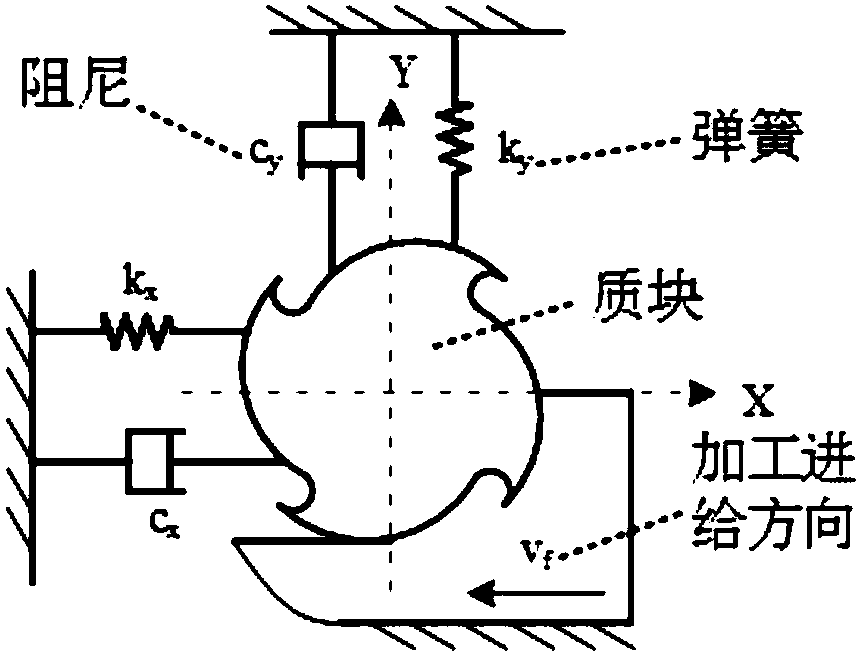

Milling stability domain prediction method under multi-modal coupling

ActiveCN103559550AImprove forecasting efficiencyImprove efficiencyForecastingProcess systemsModal testing

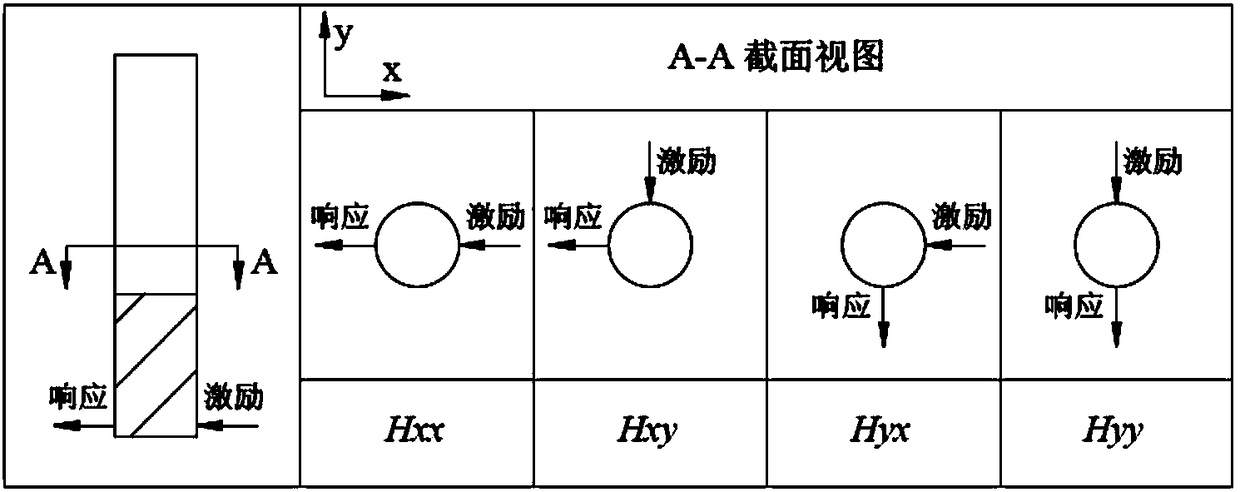

The invention discloses a milling stability domain prediction method under multi-modal coupling to solve a technical problem that the efficiency of an existing milling stability domain prediction method is low. The technical scheme is that firstly the transmission function of a process system is determined through a modal test experiment, then modal parameters are extracted from the transmission function and two orthogonal direction modal parameters are paired and combined, a milling test is carried out to calibrate a milling force coefficient, based on the milling force coefficient and each scale of modal parameters, an improved semi discrete method is employed to obtain a stability lobe diagram under each scale of modals, and finally lobe diagrams under obtained from each scale of modals are drawn in a same coordinate system to obtain a stable domain under multi modal coupling. Through a test, when a cutting cycle is divided into 40 sections, 80 sections and 120 sections, compared with a background technology method, the method can save time for 4949.6 seconds, 74200.4 seconds and 344699.5 seconds, and the efficiency is increased by 85.9%, 92% and 88.5%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

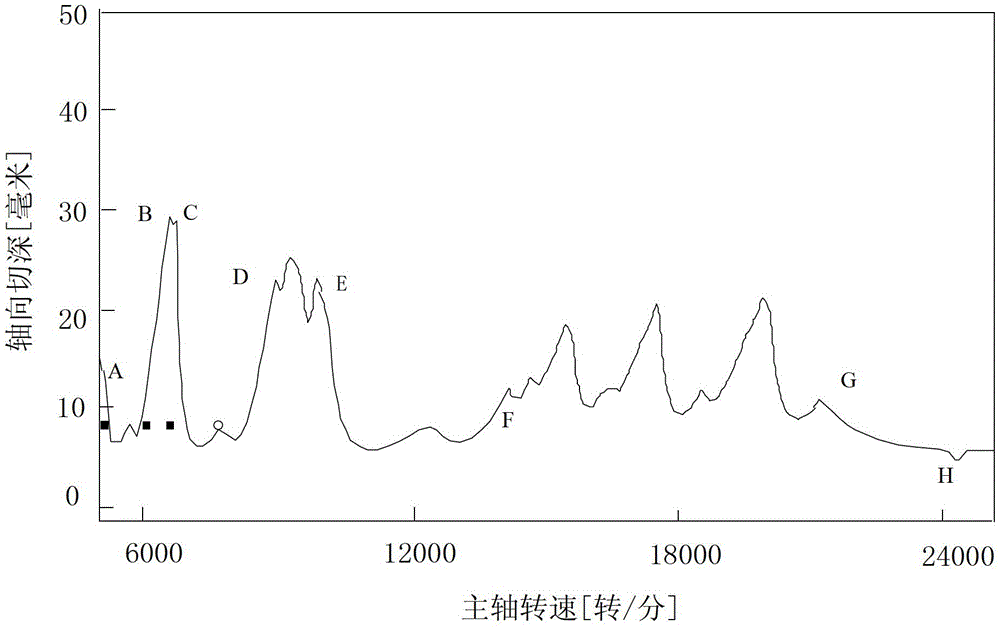

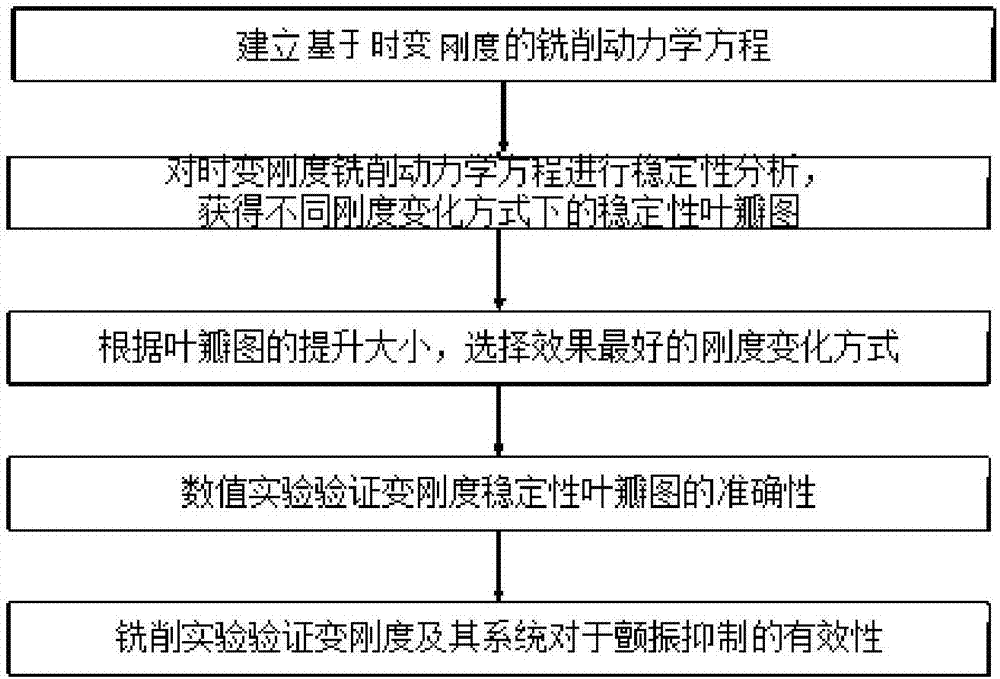

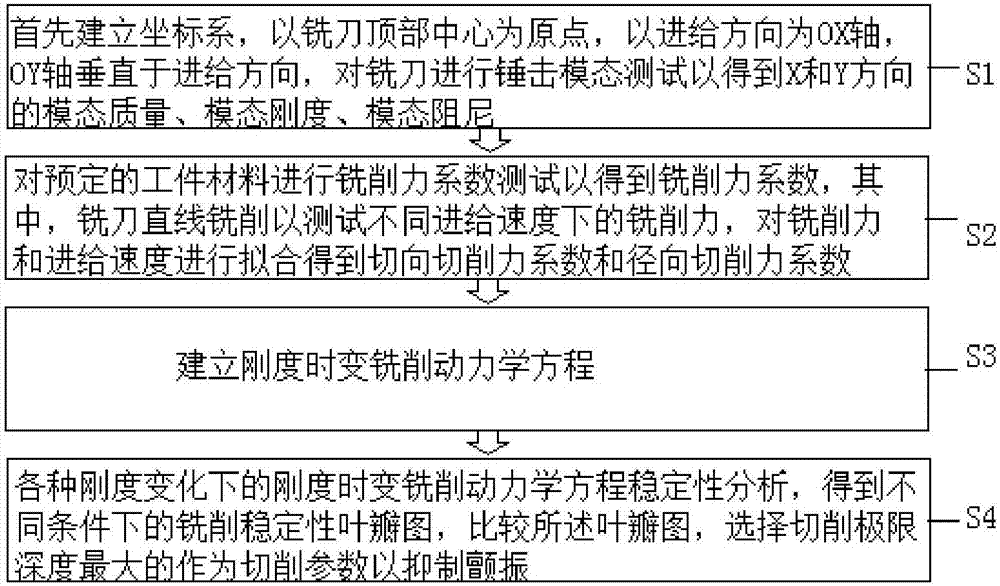

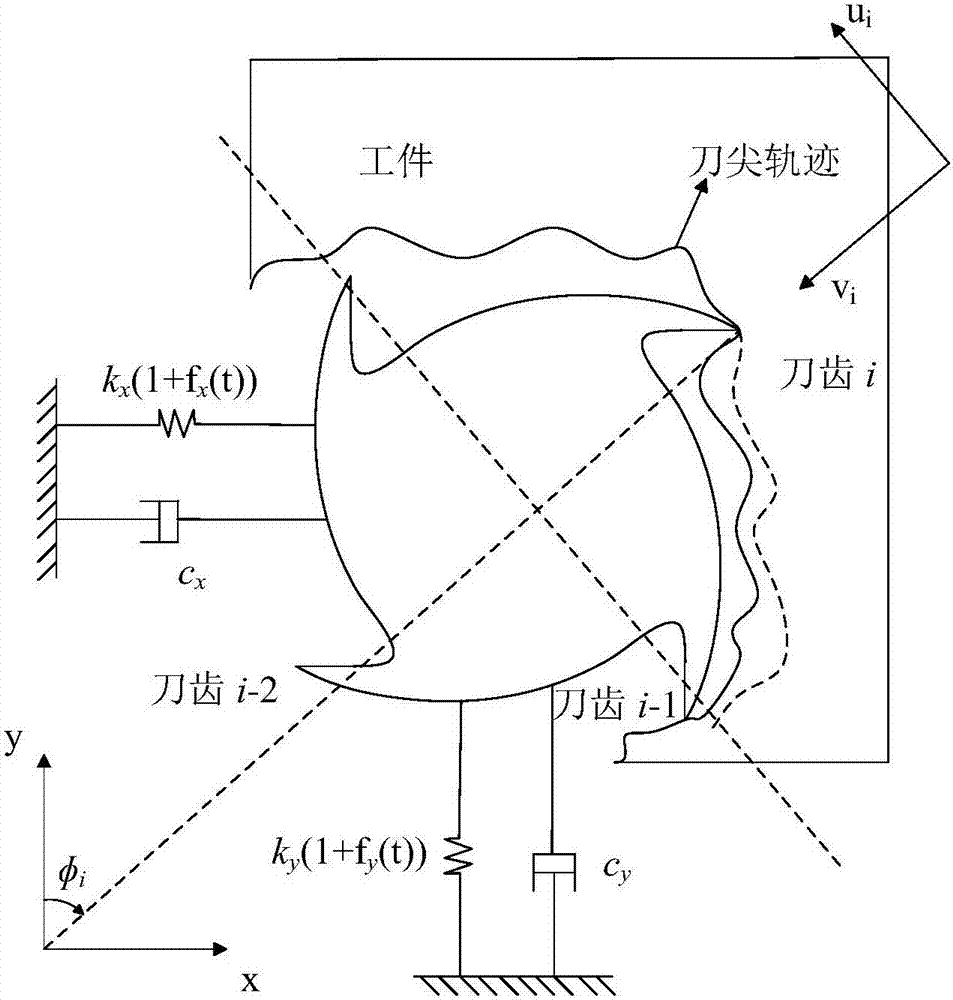

Rigidity-variation-based milling chatter suppression method and milling flutter optimization system

ActiveCN107457609AThe technical means are clearMeasurement/indication equipmentsMaintainance and safety accessoriesMilling cutterEngineering

The invention discloses a rigidity-variation-based milling chatter suppression method and a milling chatter optimization system. The method comprises the steps of carrying out a hammering modal experiment on a milling cutter to obtain modal parameters, such as modal mass, modal stiffness and modal damping, of the milling cutter; carrying out a milling force coefficient identification experiment on a predetermined workpiece material to obtain a milling force coefficient; establishing a stiffness time varying milling dynamical equation; conducting stability analysis of the stiffness time varying milling dynamical equation under various stiffness changes to obtain milling stability lobe graphs under different conditions, comparing the lobe graphs and selecting the maximum cutting limit depth as the cutting parameter to suppress chatter. By means of the method and system, milling chatter can be effectively suppressed, the milling stability lobe graphs are improved, and the machining quality and the machining efficiency are improved.

Owner:XI AN JIAOTONG UNIV

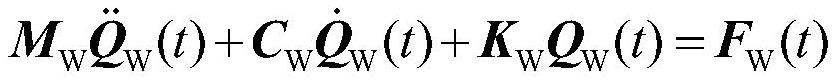

Three-dimensional stability modeling method for orthogonal turning-milling machining of helical endmill

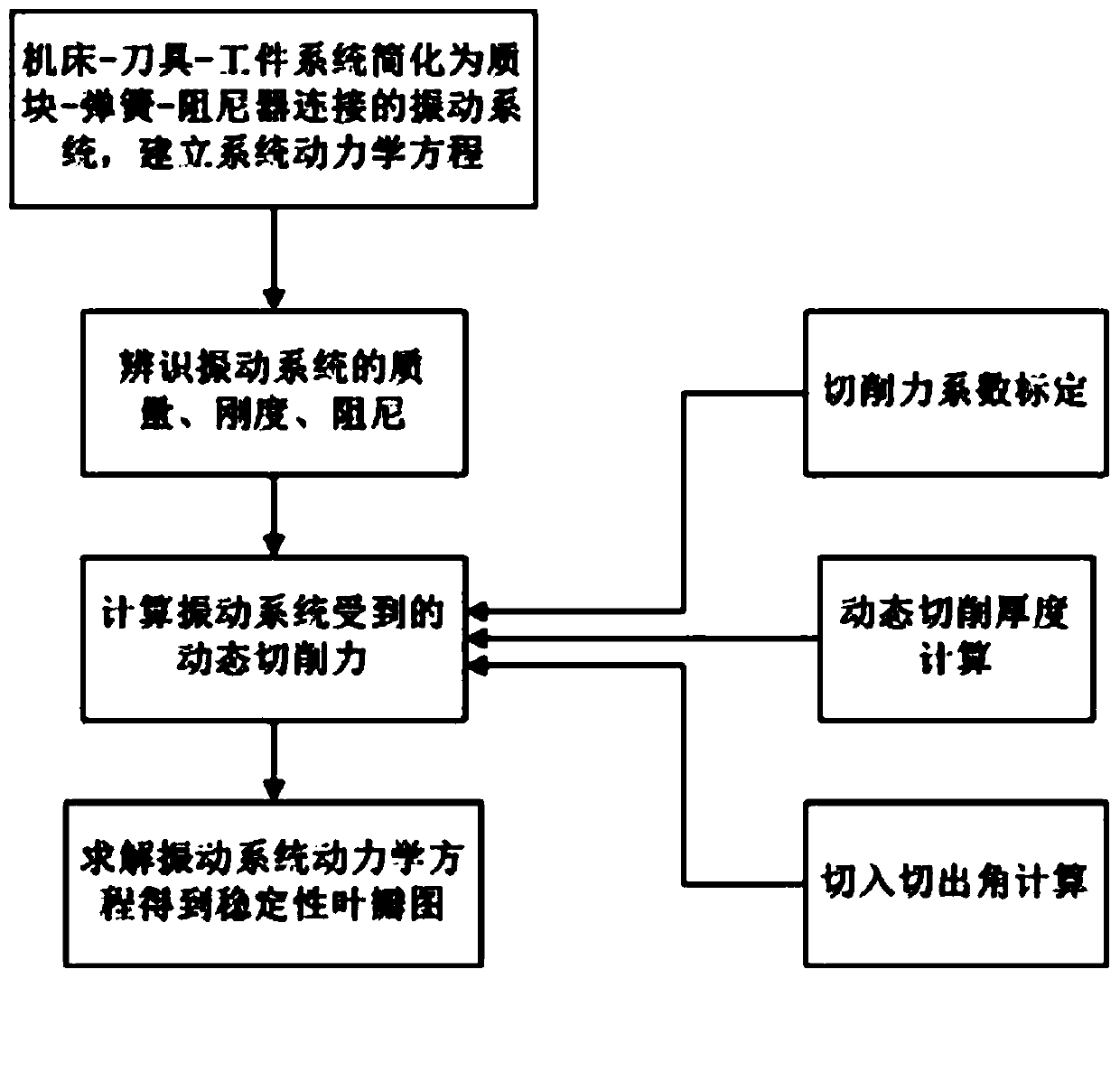

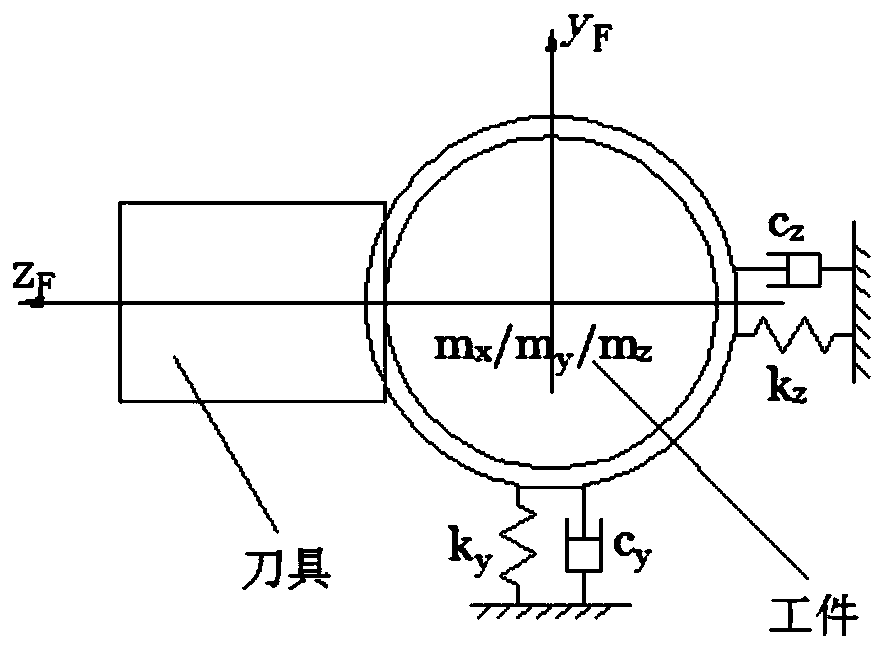

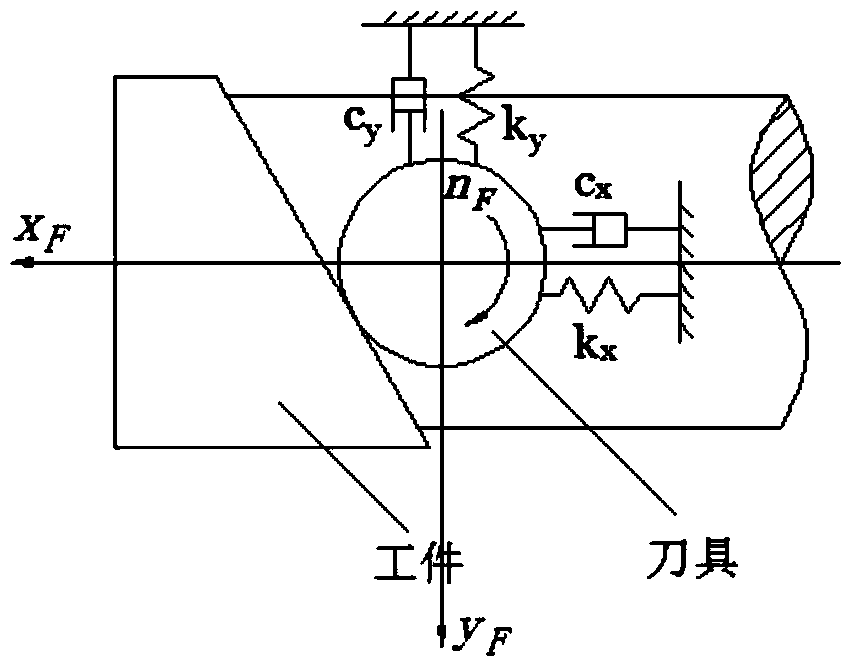

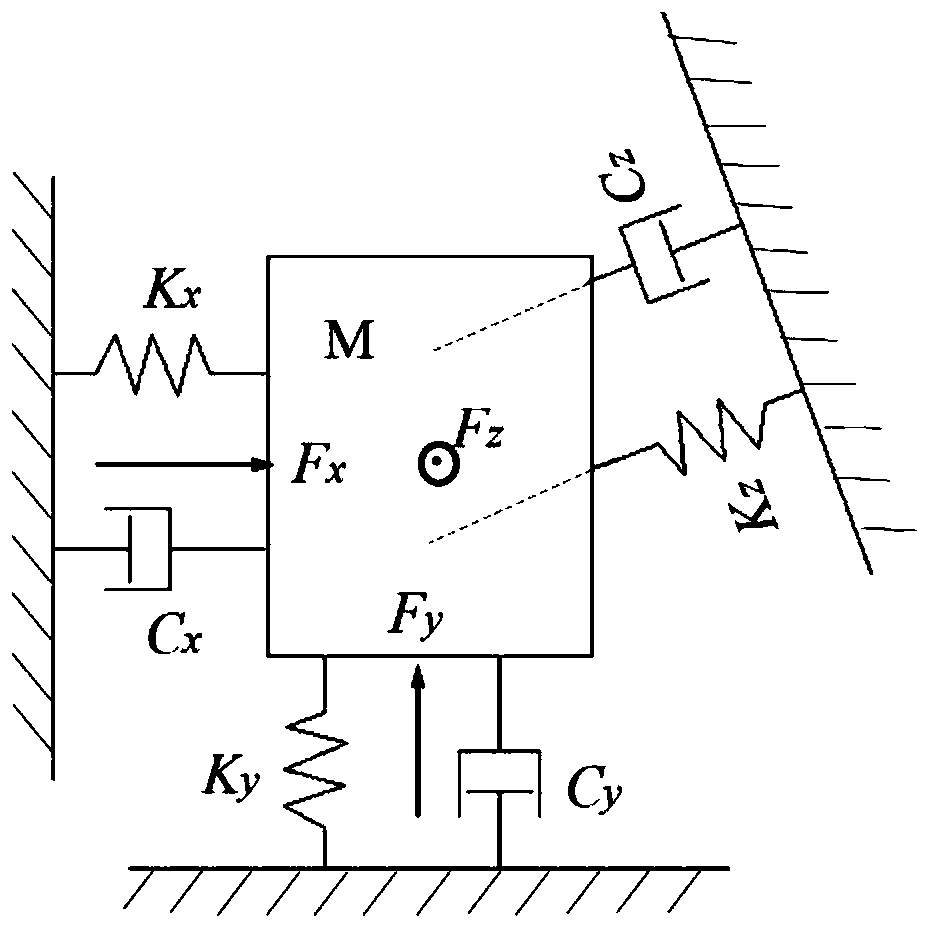

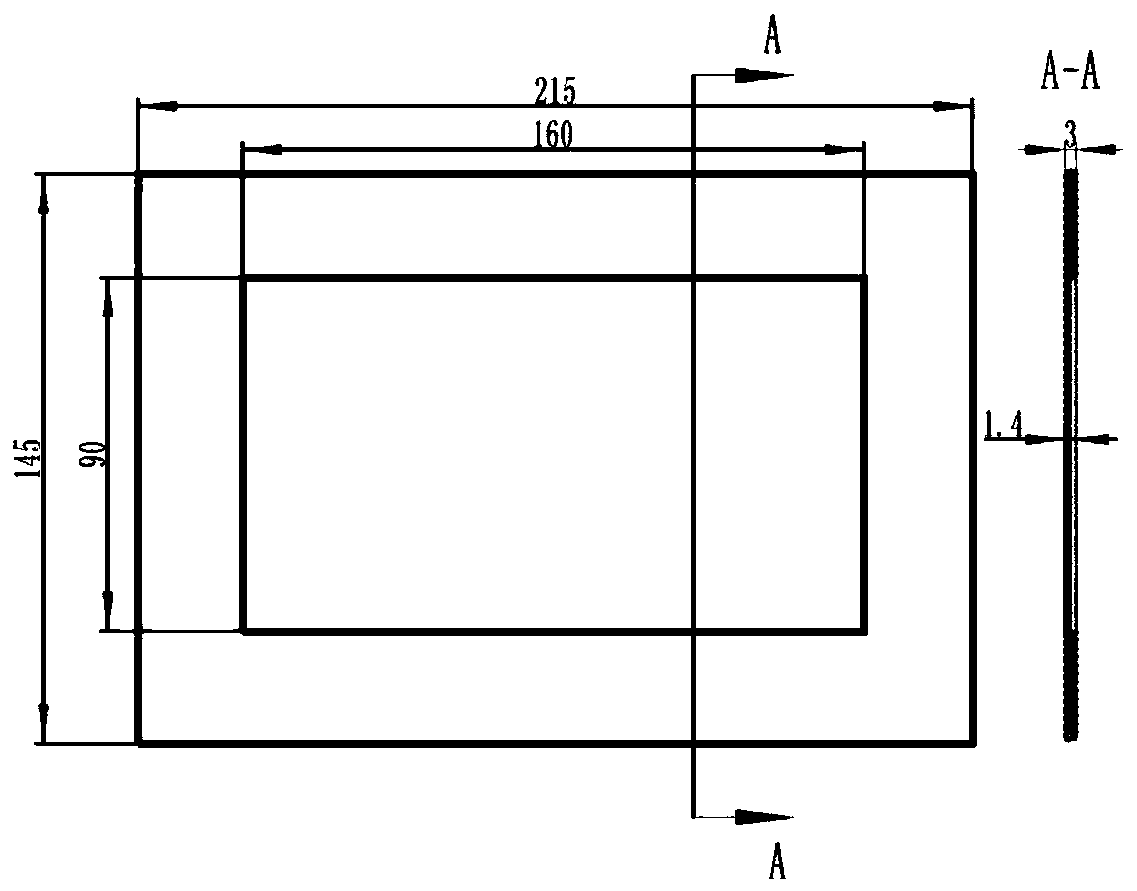

ActiveCN104778333AIn line with the actual processing situationExact modeling methodSustainable transportationSpecial data processing applicationsMass spring damperSpring force

The invention discloses a three-dimensional stability modeling method for orthogonal turning-milling machining of a helical endmill. The three-dimensional stability modeling method comprises the following steps: (1) simplifying a machine tool-cutter-workpiece system into a mass-spring-damper connected vibrating system, establishing a coordinate system xFyFzF, and establishing a kinetic equation of the vibrating system; (2) carrying out a hammering method modal test to obtain a frequency-response function of the vibrating system in each of xF, yF and zF directions, identifying the modal mass, the rigidity and the damping of the vibrating system, and calculating the inertia force, the spring force and the damping force of the vibrating system; (3) calculating a dynamic cutting force of the helical endmill; (4) solving the kinetic equation of the vibrating system to obtain a stability lobe graph of the vibrating system. The three-dimensional stability modeling method disclosed by the invention gives consideration to the three-dimensional dynamic cutting force of a circumference edge and a bottom edge of helical endmill, and simultaneously gives consideration to the dynamitic characteristics of a cutter side and a workpiece side, so that the stability modeling method is more accurate.

Owner:HUAZHONG UNIV OF SCI & TECH

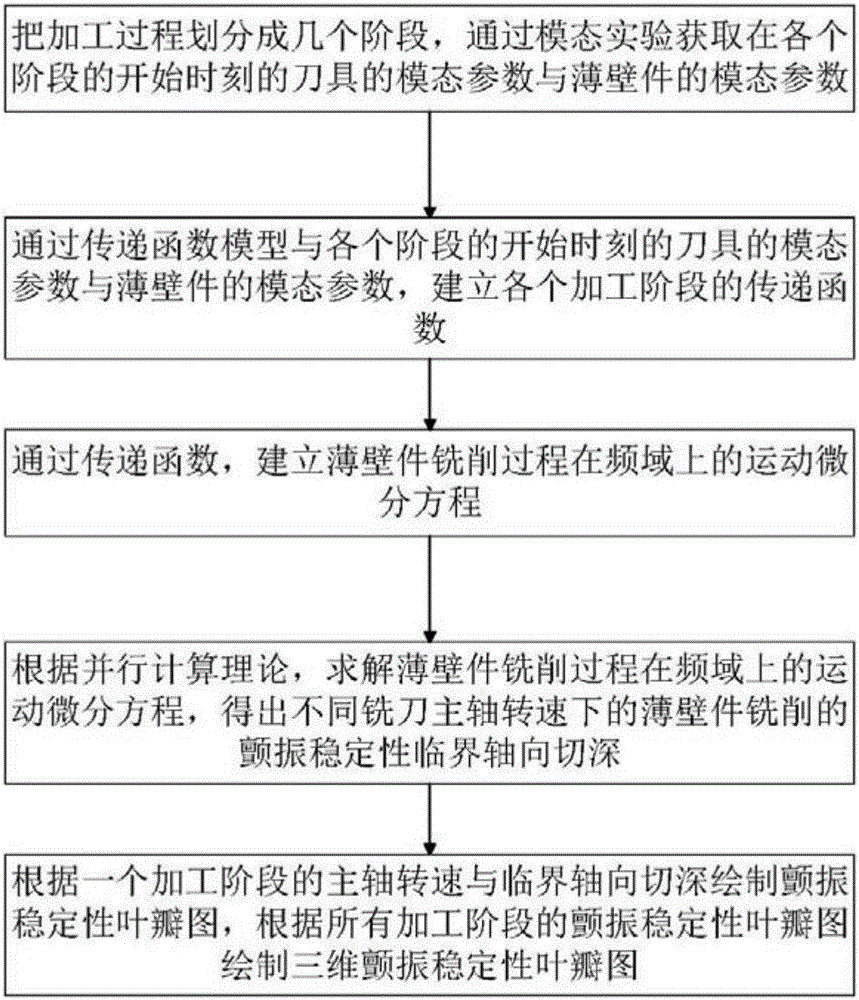

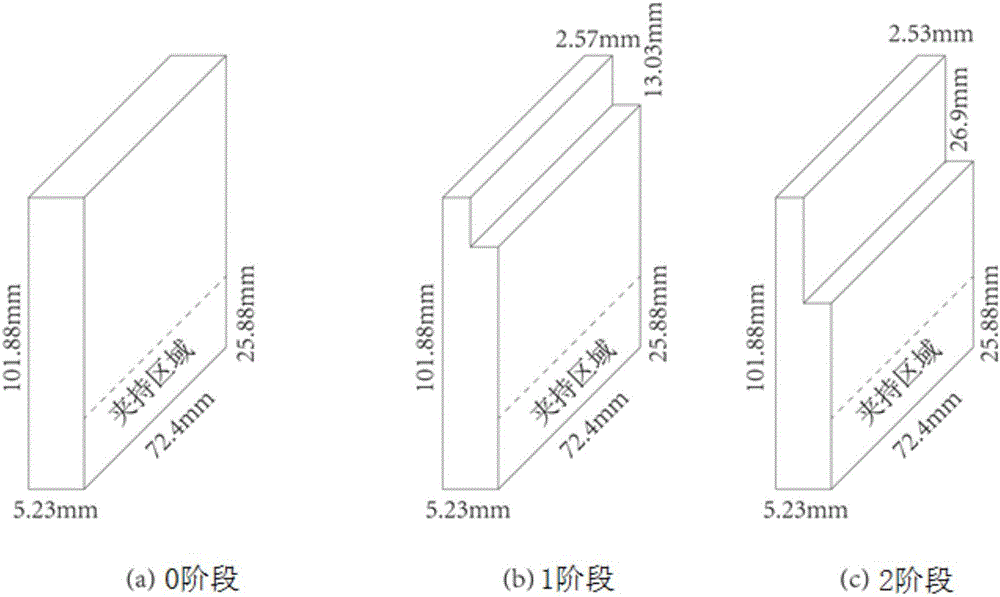

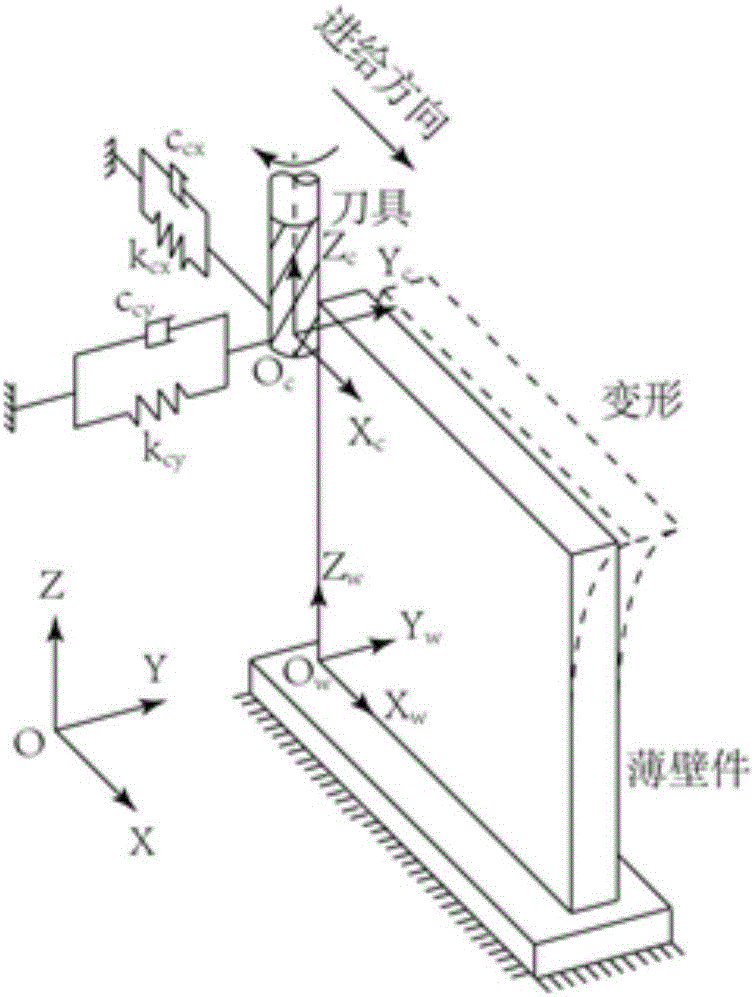

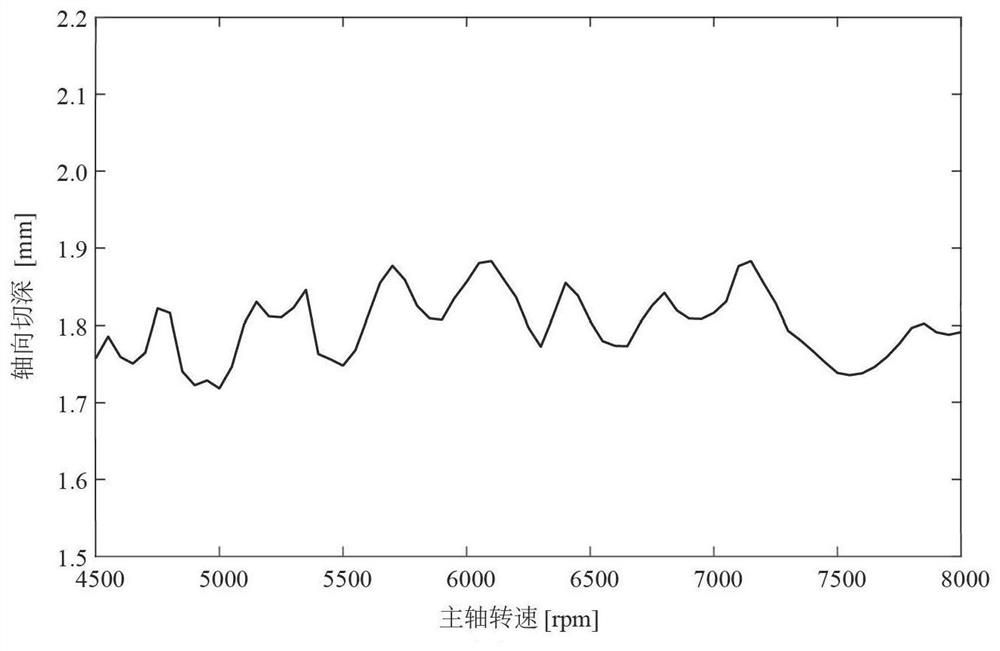

Parallel frequency domain method based on thin-wall workpiece milling flutter stability prediction

ActiveCN106802630AFlutter realReduce computing timeProgramme controlComputer controlMilling cutterDamping ratio

The invention discloses a parallel frequency domain method based on thin-wall workpiece milling flutter stability prediction. The method includes the following steps: obtaining modal parameters of a cutter and modal parameters of a thin-wall workpiece; establishing a transfer function; establishing a motion differential equation in a frequency domain during milling of the thin-wall workpiece; obtaining flutter stability critical axial cutting depths of milling of the thin-wall workpiece at different milling cutter main shaft rotating speeds; and drawing a flutter stability lobe graph and a three-dimensional flutter stability lobe graph. During the whole machining process, the method considers time variations of a milling process in one tooth period, time variations of all-order inherent frequencies, rigidity and damping ratios of the thin-wall workpiece, and modals of the cutter and the thin-wall workpiece. Therefore, the method can predict flutter of milling of the thin-wall workpiece in a more accurate and real manner. Through combination of the parallel computing theory, the computing time shortens by times along with increases of the number of threads. Therefore, the method is highly efficient.

Owner:NORTHEASTERN UNIV

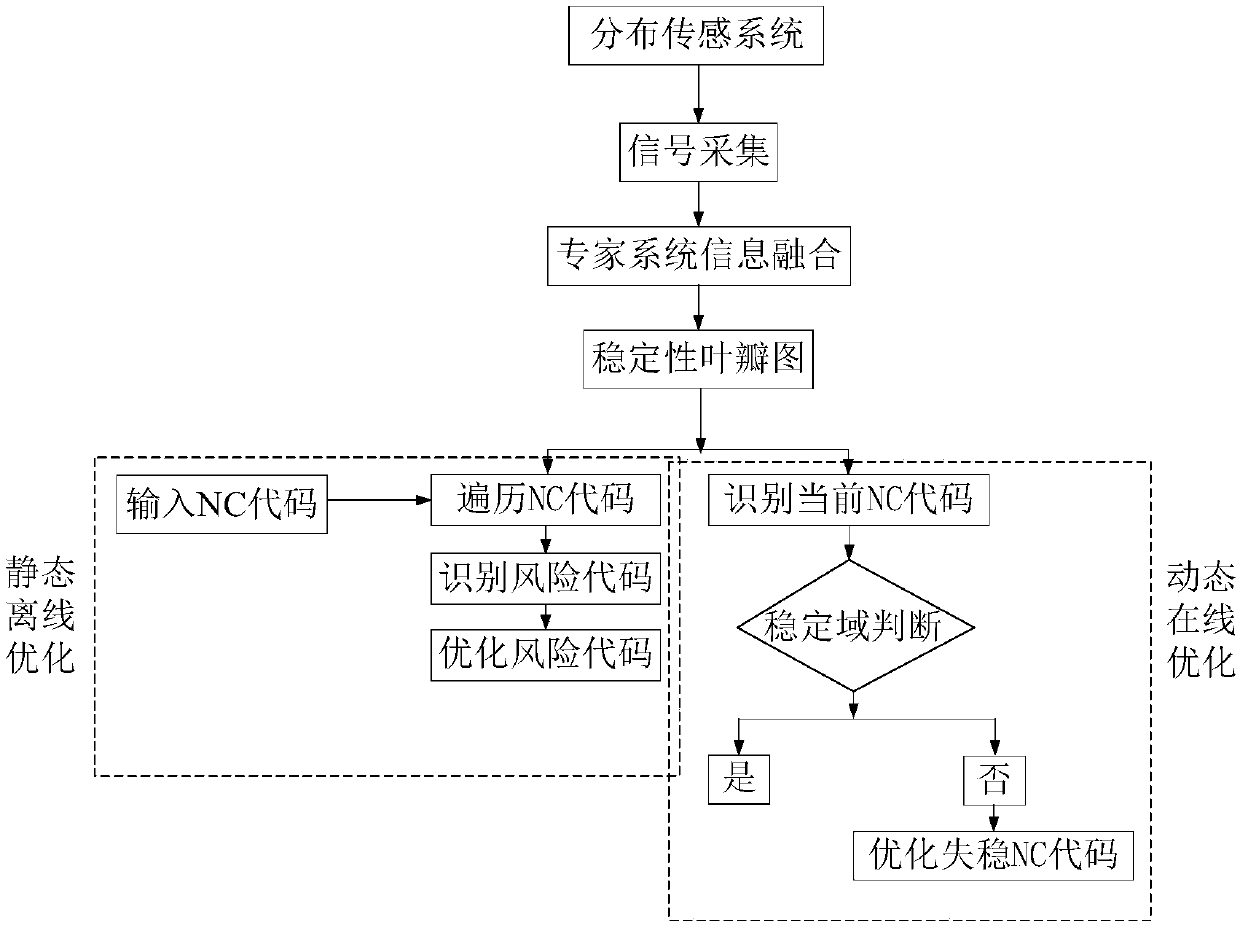

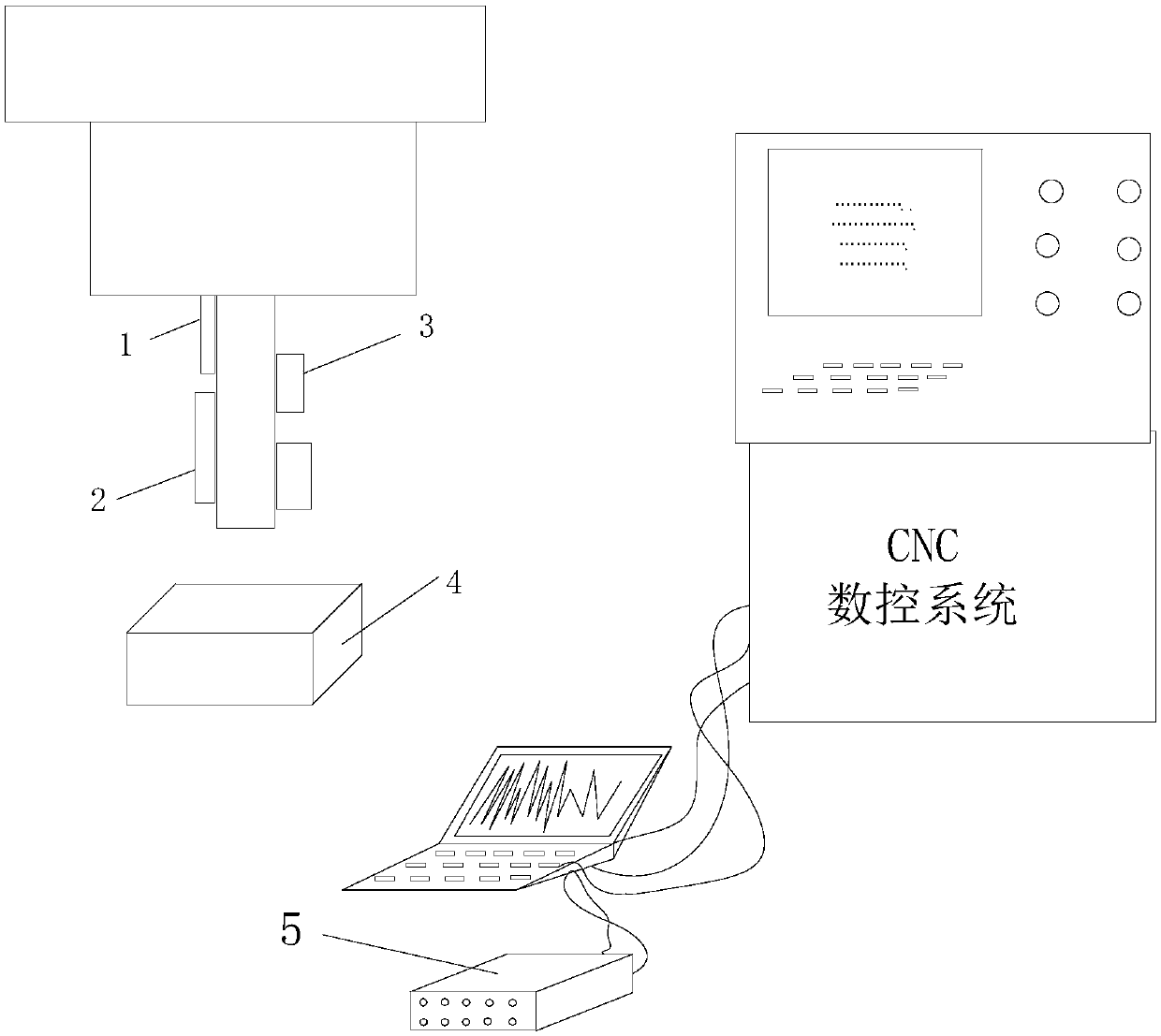

Dynamic-static optimization method of milling stability of numerical control machine tool

ActiveCN107589723AImprove processing efficiencyEasy to processProgramme controlComputer controlNumerical controlData information

The invention discloses a dynamic-static optimization method of the milling stability of a numerical control machine tool. According to the method, static and dynamic optimization of a milling processNC code can be realized based on a machine tool state self-decision expert system and a stability lobe diagram. The method includes following specific steps: operation parameters of the machine toolare acquired in real time by employing a distributed wireless sensing system, and the obtained parameters are input into a database; the machine tool state self-decision expert system learns and fusesreal-time data information, updates state parameters of the machine tool, and establishes the stability lobe diagram for the NC code; and static and dynamic optimization of the milling process of themachine tool can be developed on the basis. According to the method, the milling process of the NC code is optimized, the method is more rapid and convenient compared with the conventional optimization method, the machining efficiency can be effectively guaranteed, and good universality is achieved for multi-axis linkage numerical control machine tools of various different control systems.

Owner:SICHUAN UNIV +2

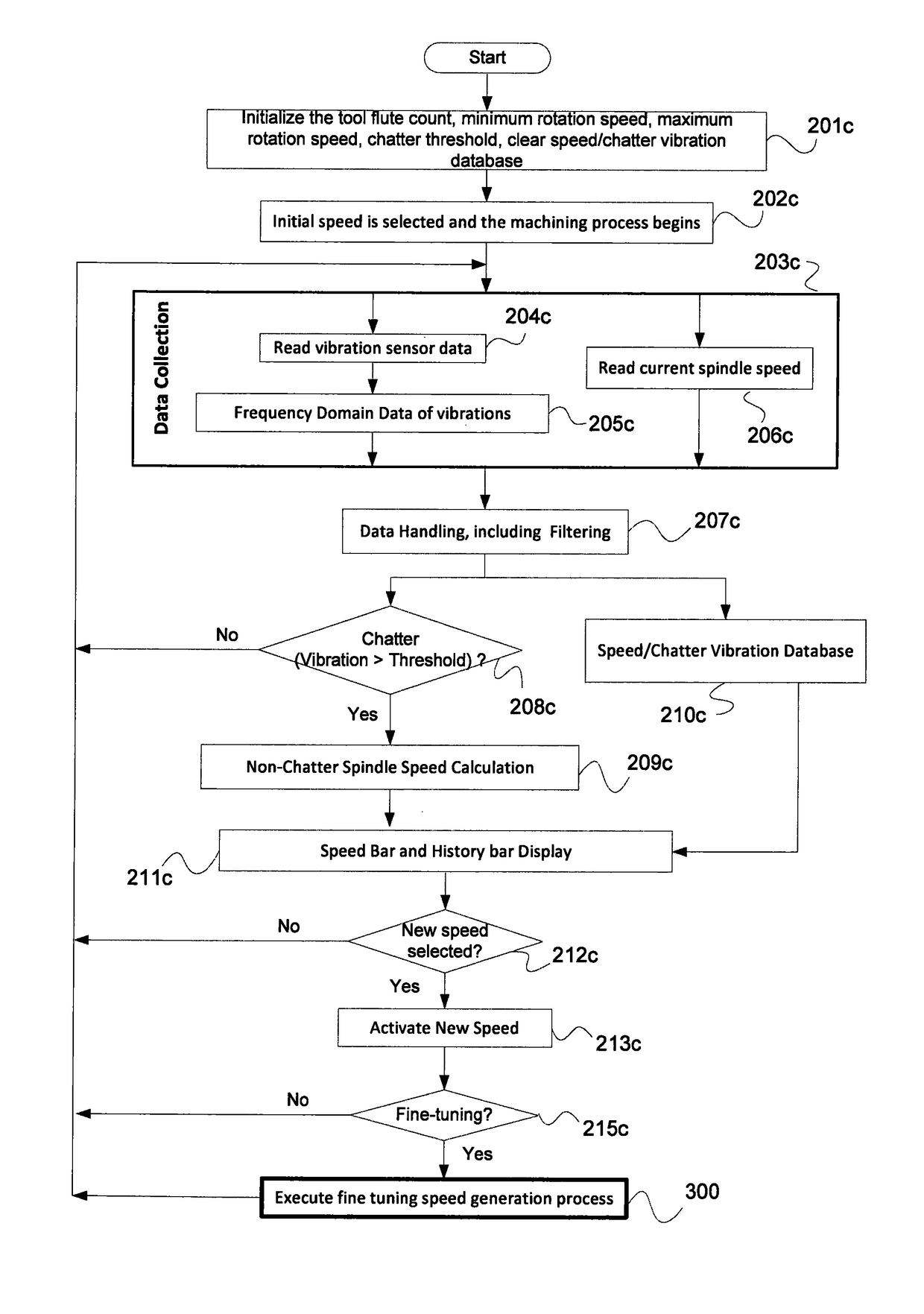

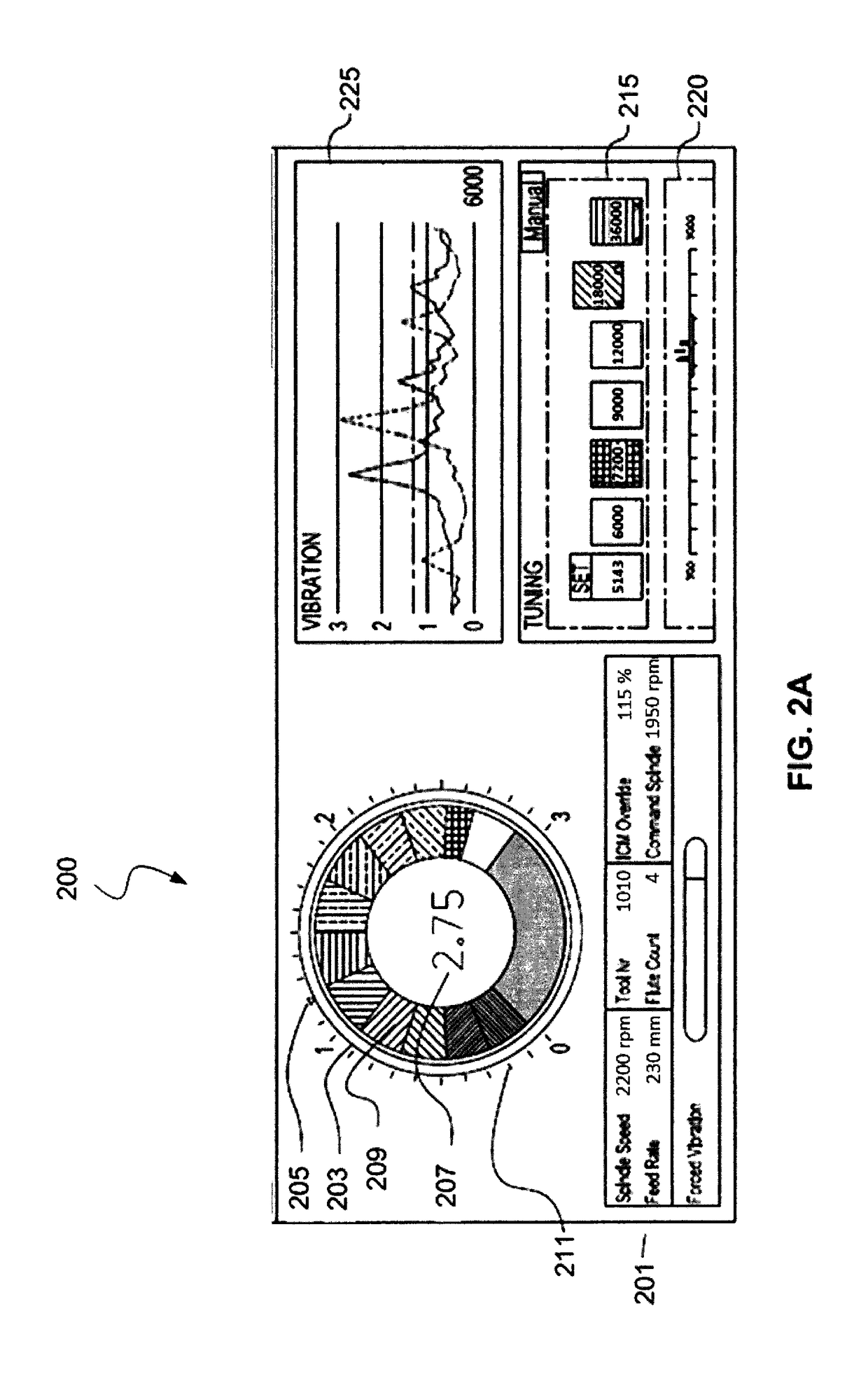

Fine-tuning speed application interface

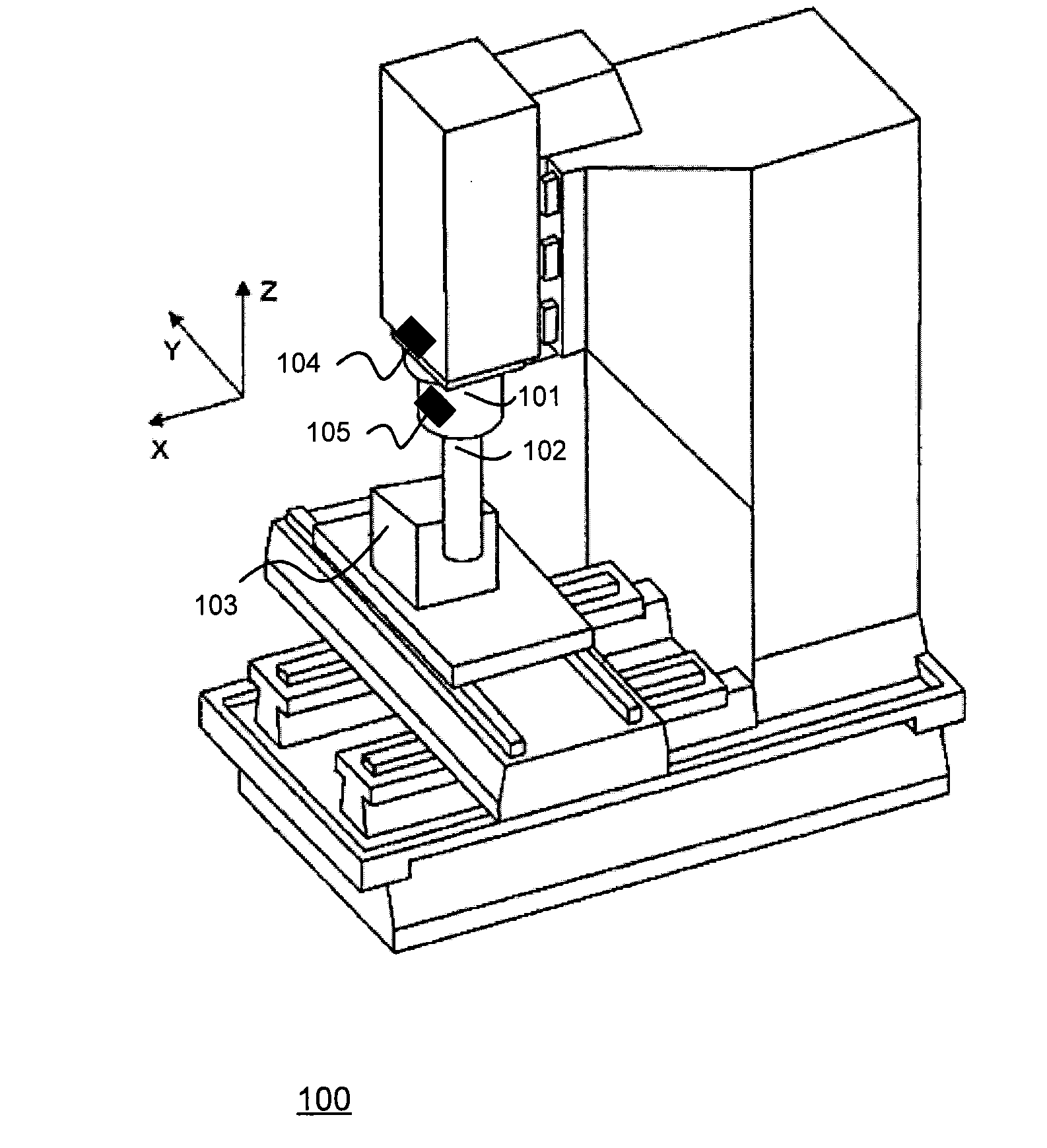

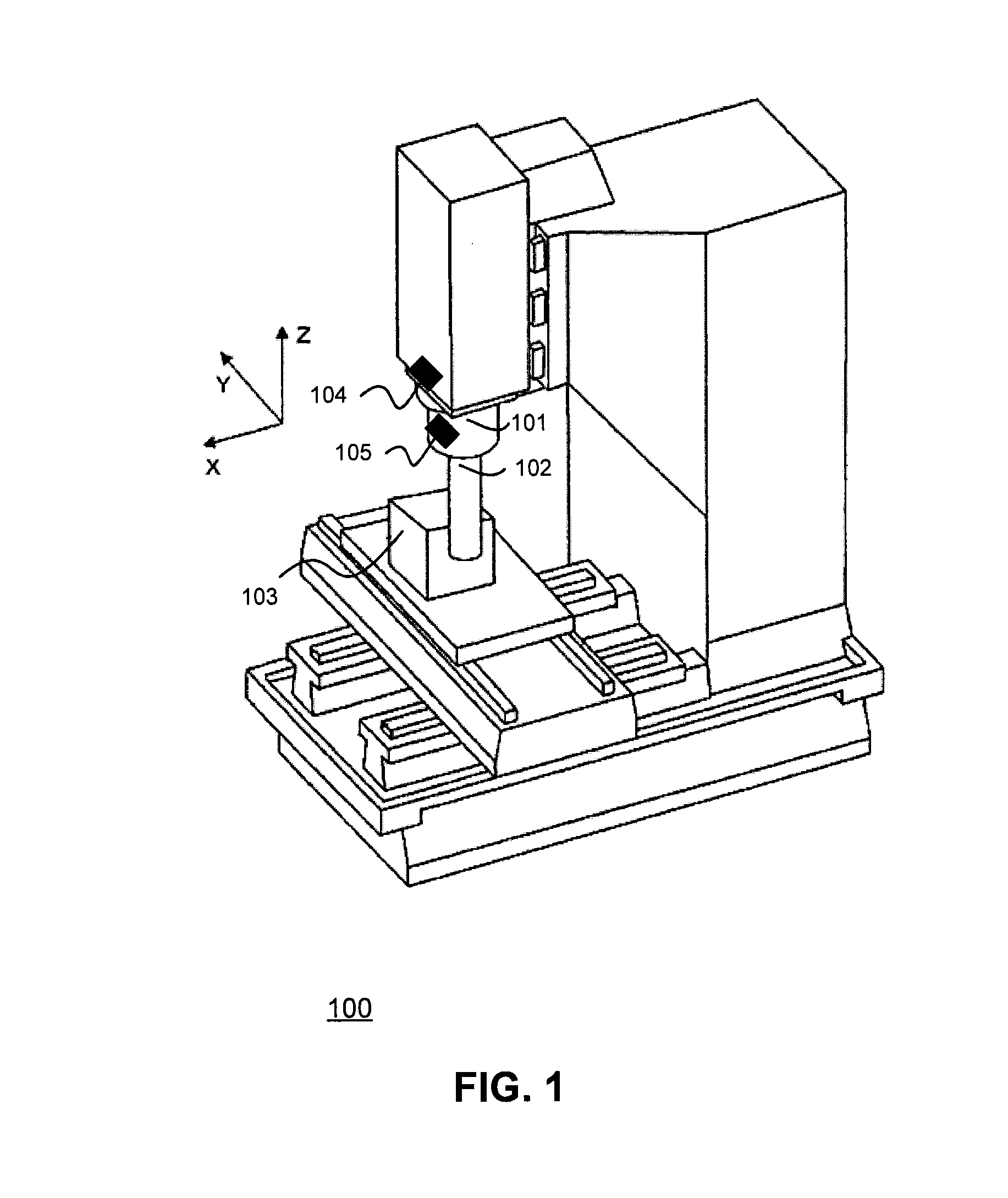

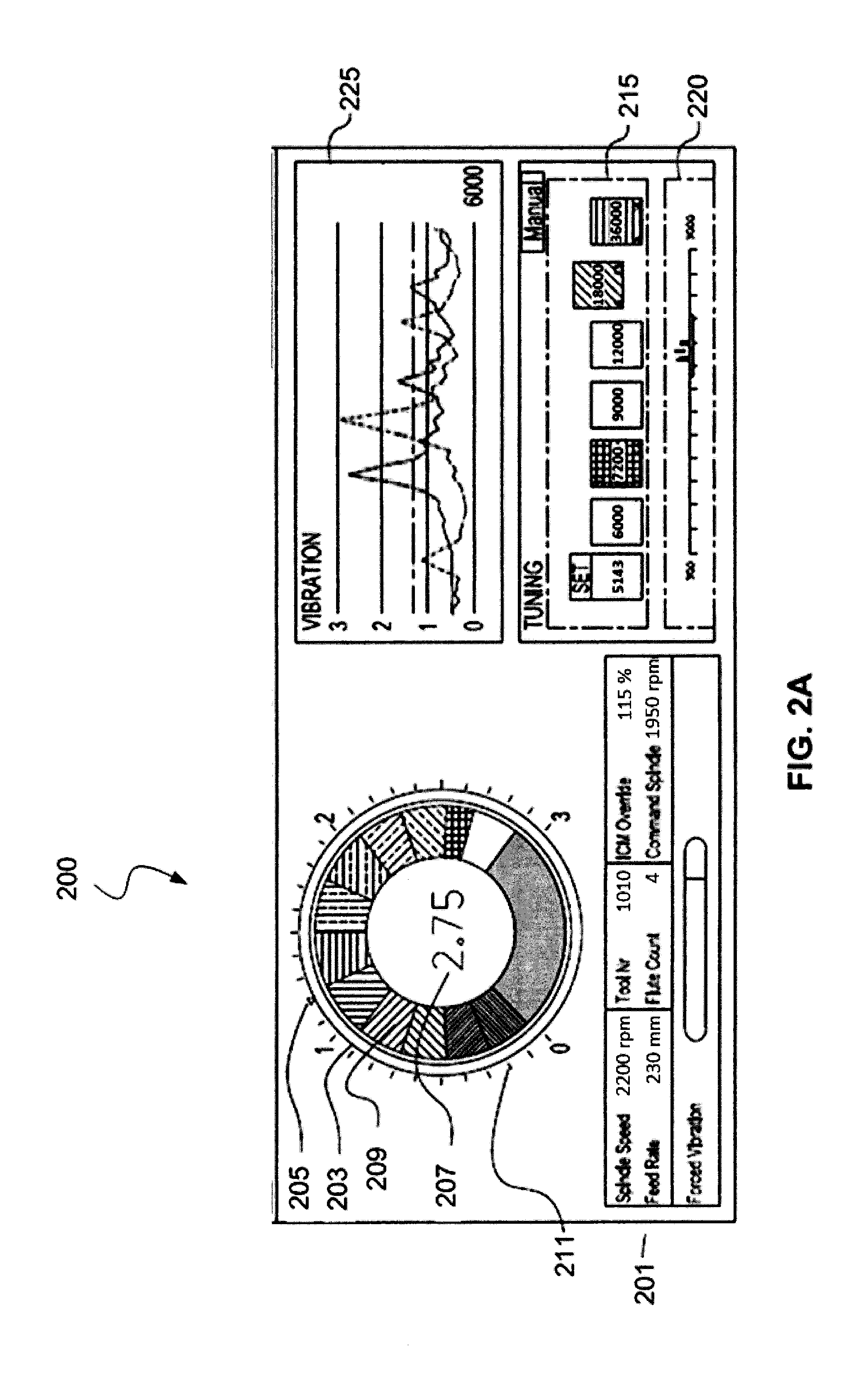

ActiveUS20160288285A1Reducing machine chatterAutomatic control devicesComputer controlComputer scienceFine-tuning

A system, method and computer-readable medium for fine-tuning speed selection for reducing machine chatter. The system includes circuitry configured to determine a predetermined speed of the machine. The circuitry identifies a stability lobe based on the predetermined speed of the machine and selects a first set of fine-tuning speeds from a range of machine speeds corresponding to the determined stability lobe. Further, the circuitry causes the machine to operate at one or more of the first set of fine-tuning speeds.

Owner:DMG MORI CO LTD

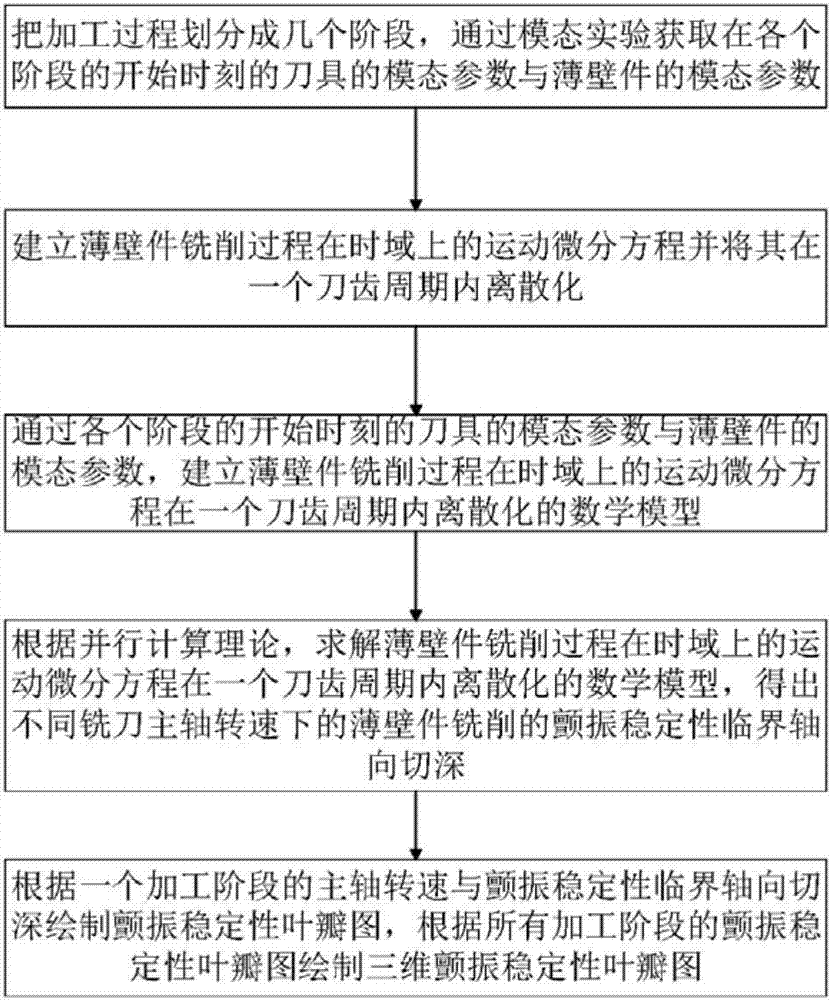

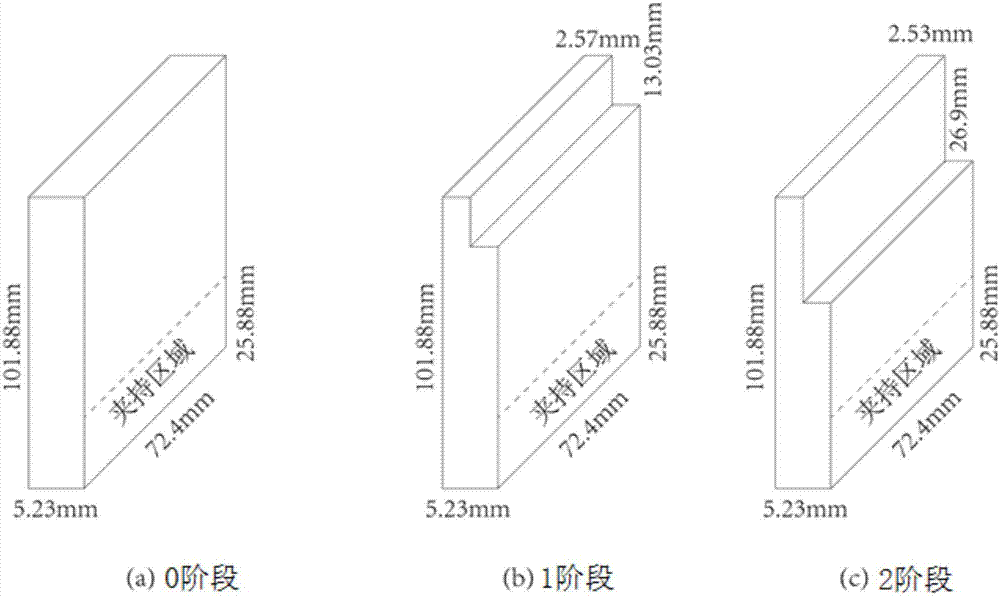

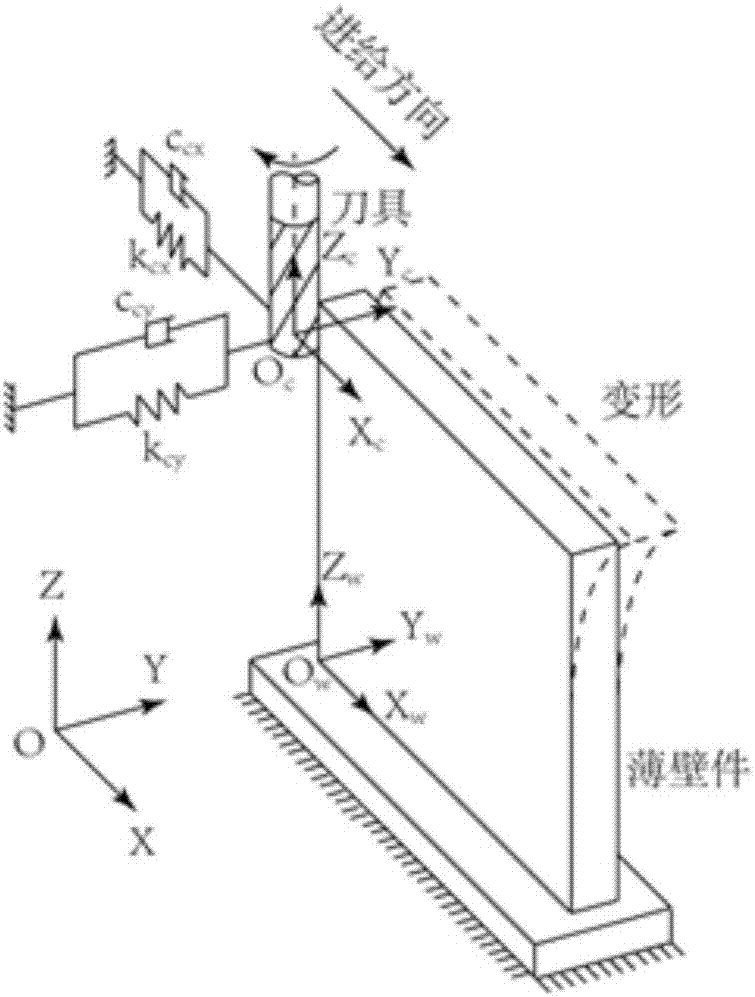

Parallel time domain method for predicating milling chatter stability based on thin-wall part

InactiveCN106940746AFlutter realReduce computing timeDesign optimisation/simulationSpecial data processing applicationsTime domainMathematical model

The invention discloses a parallel time domain method for predicating milling chatter stability based on a thin-wall part. The parallel time domain method comprises the following steps: obtaining modal parameters of a cutter and the thin-wall part; establishing a motion differential equation of a thin-wall part milling process on a time domain and discretizing the motion differential equation in one cutter tooth period; establishing a mathematical model which is obtained by discretizing the motion differential equation in one cutter tooth period, so as to obtain milling chatter stability critical axial cutting depths of the thin-wall part under different rotary speeds of a milling cutter main shaft; drawing a chatter stability lobe graph and a three-dimensional chatter stability lobe graph. According to the parallel time domain method disclosed by the invention, the time-varying property of the milling process in one cutter tooth period is considered; in a whole machining process, the time-varying property of all orders of inherent frequency, rigidity and damping ratio of the thin-wall part, and modal states of the cutter and the thin-wall part are considered, so that the milling chatter of the thin-wall part can be more accurately and really predicted; a parallel computing theory is combined, so that the computing time is double shortened along with the increase of a thread count, so that the parallel time domain method has high efficiency.

Owner:NORTHEASTERN UNIV LIAONING

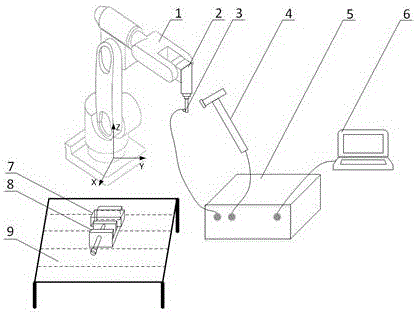

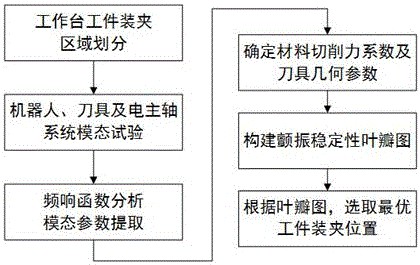

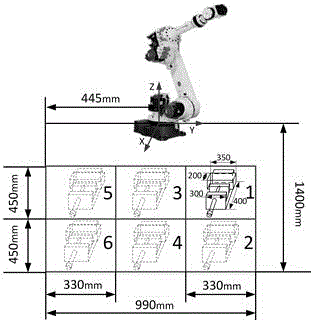

Method for optimizing workpiece clamping positions during milling machining by robot

ActiveCN106294977AReduce flutterGuaranteed quality and accuracyDesign optimisation/simulationSpecial data processing applicationsMachine partsMachining

The invention belongs to the technical field of optimization of robot milling processes and particularly relates to a method for optimizing workpiece clamping positions during milling machining by a robot. On the basis of a six-axis industrial robot provided with an electric spindle at the tail end and a fixed working platform, the working platform is properly divided into multiple rectangular areas with equal areas to serve as alternative clamping positions according to the sizes of to-be-machined workpieces and clamps for the workpieces, and the clamps are placed in the centers of the alternative areas respectively; in each area, a robot milling system is subjected to a modal experiment, corresponding modal parameters are acquired, a regenerated and coupling crossed flutter stability analysis model is used for analysis, and a flutter stability lobe graph is obtained through calculation. The position corresponding to a curve having the highest vertical coordinate in the stability lobe graph is selected as the best mounting position for the workpieces on the working platform. By means of the method, the flutter degree in the robot milling process is effectively reduced, the machining stability is improved, and the quality of machining parts and the size accuracy are guaranteed.

Owner:SHANGHAI UNIV

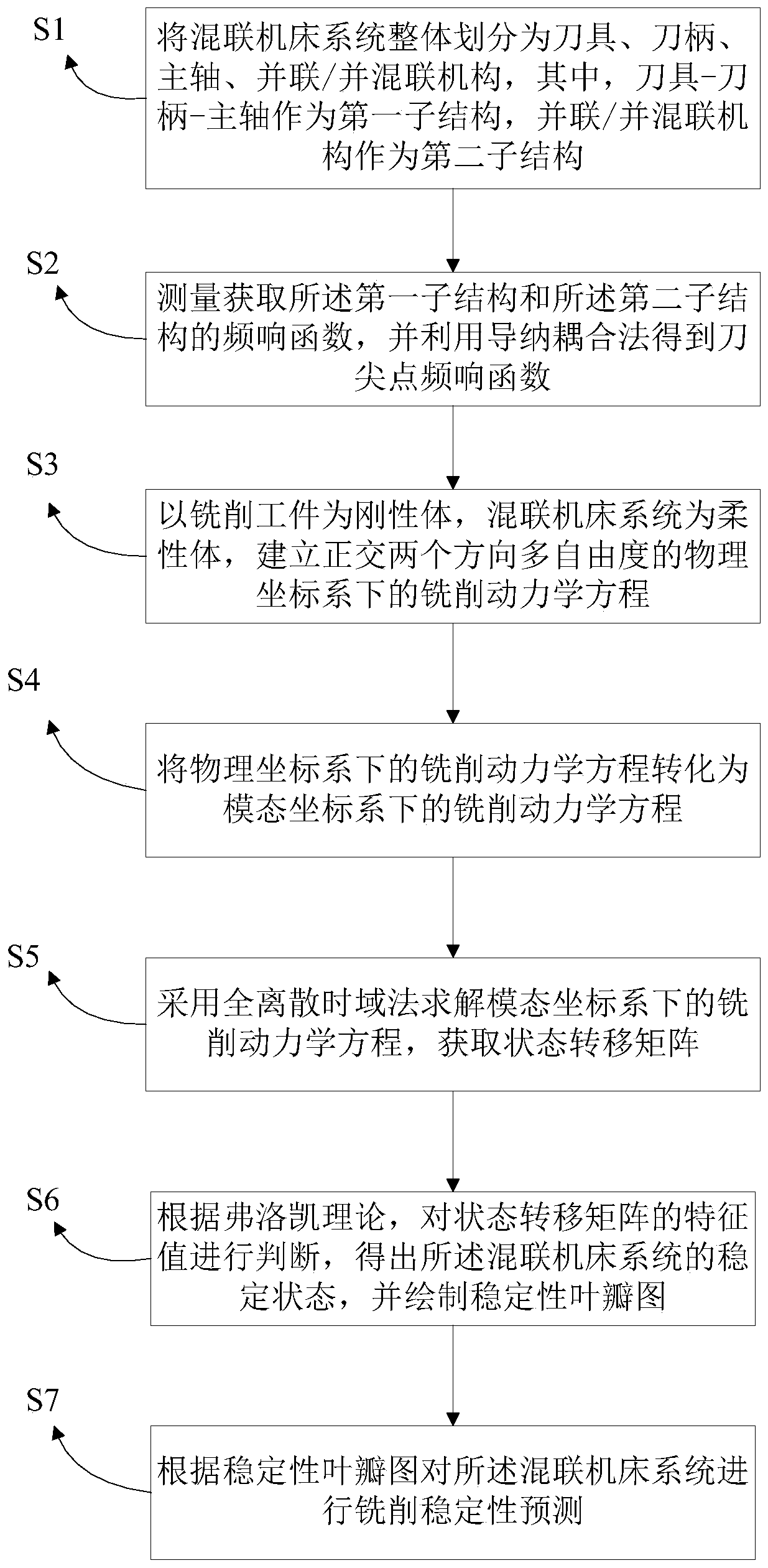

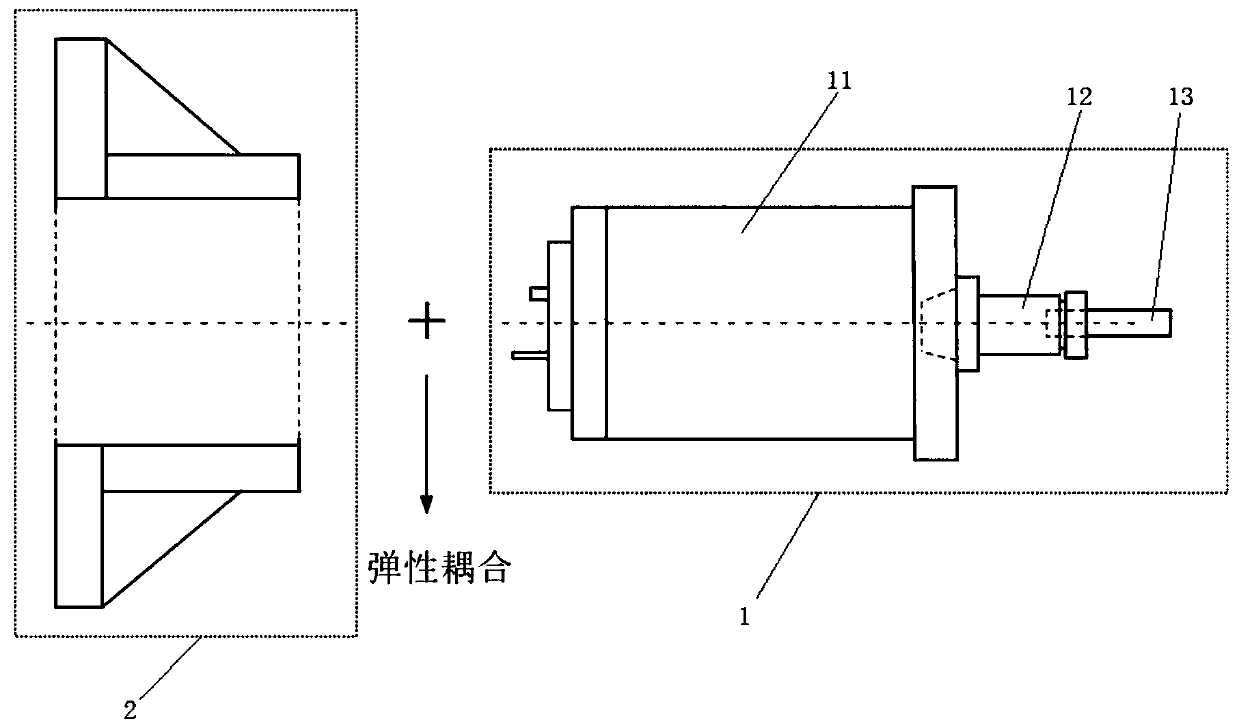

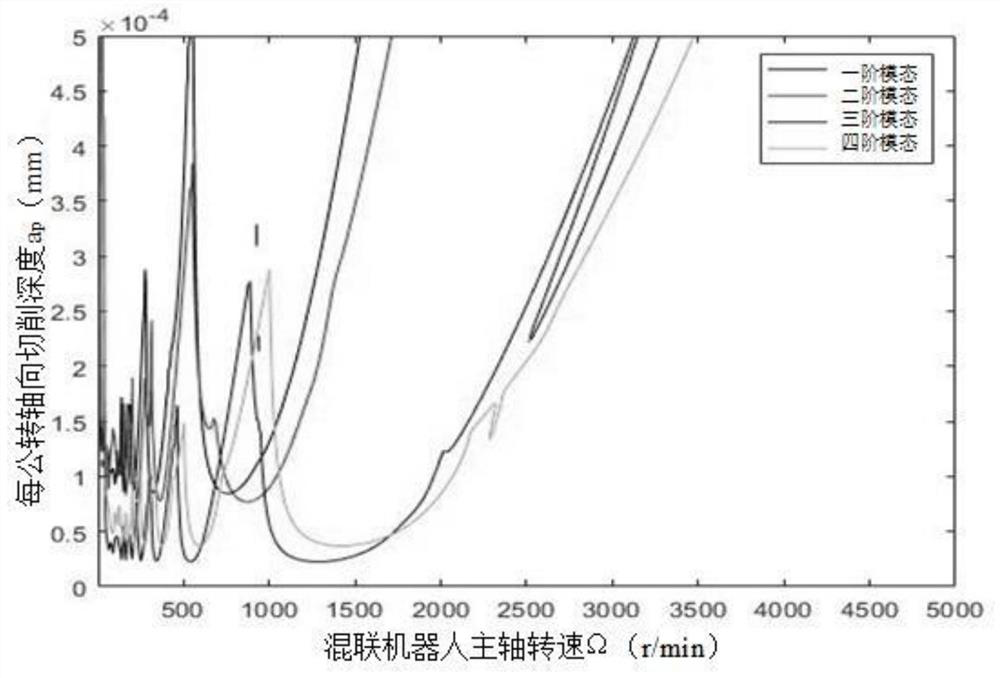

Hybrid machine tool milling stability prediction method

PendingCN111291479AImprove accuracyDrawing from basic elementsDesign optimisation/simulationControl engineeringKinetics equation

The invention discloses a hybrid machine tool milling stability prediction method. The method comprises the steps of integrally dividing a hybrid machine tool system into a cutter, a cutter handle, amain shaft and a parallel / parallel hybrid mechanism, the cutter-cutter handle-main shaft serving as a first sub-structure, and the parallel / parallel hybrid mechanism serving as a second sub-structure;measuring to obtain frequency response functions of the first sub-structure and the second sub-structure, and obtaining a tool nose point frequency response function; establishing a milling kinetic equation under a physical coordinate system; converting the milling kinetic equation under the physical coordinate system into a milling kinetic equation under a modal coordinate system; solving a milling kinetic equation under the modal coordinate system to obtain a state transition matrix; judging the characteristic value of the state transition matrix, and drawing a stable lobe graph; and carrying out milling stability prediction on the parallel hybrid machine tool system according to the stability lobe graph. According to the method, the influences of the low-order dynamic characteristics and the medium-high-order dynamic characteristics of the parallel mechanism are comprehensively considered, and the milling stability of the parallel hybrid machine tool can be predicted more accurately.

Owner:TSINGHUA UNIV

Method for facilitating chatter stability mapping in a simultaneous machining application

InactiveUS8011864B2Reduce controlOptimized machining utilities and applicationsLathesProgramme controlFluteMilling cutter

Owner:UNIV OF CONNECTICUT

Process damping modeling method for thin-walled part milling

ActiveCN108804749AImprove forecast accuracyGeometric CADSpecial data processing applicationsEngineeringKinetic control

The invention relates to a process damping modeling method suitable for a thin-walled part milling process, which considers vibration effects of two orthogonal directions at the same time. The processdamping modeling method suitable for the thin-walled part milling process comprises the following steps: firstly, calculating a dynamic cutting force matrix and a process damping matrix correspondingto each edge element considering the vibration effects of the two directions at the same time; then combining the dynamic cutting force matrix and the process damping matrix of each edge element to calculate the dynamic cutting force matrix and the process damping matrix applied on the whole tool-workpiece system; and then using the obtained dynamic cutting force matrix and process damping matrixto establish a milling dynamic control equation of the tool-workpiece system, so that a stability lobe diagram considering the damping effect of the milling process of the thin-walled part can be drawn by performing stabilized solving on the equation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

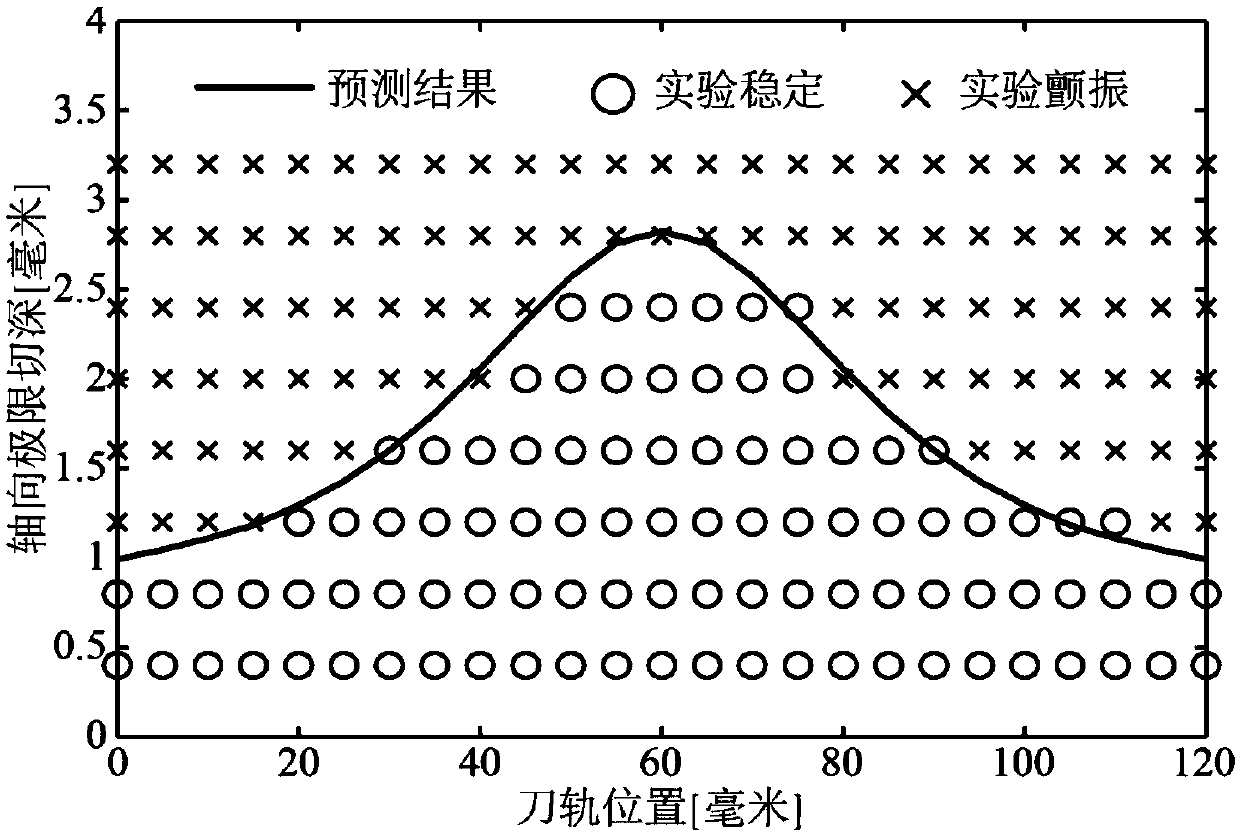

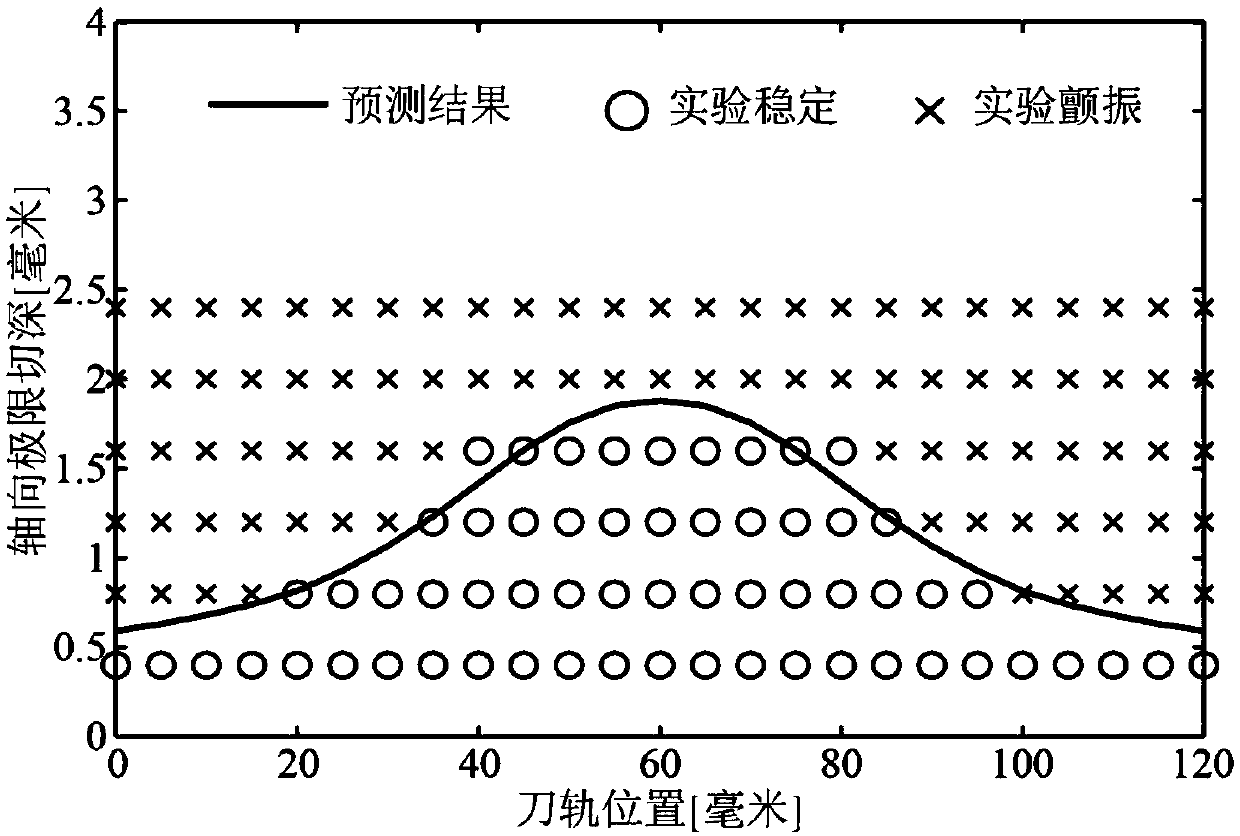

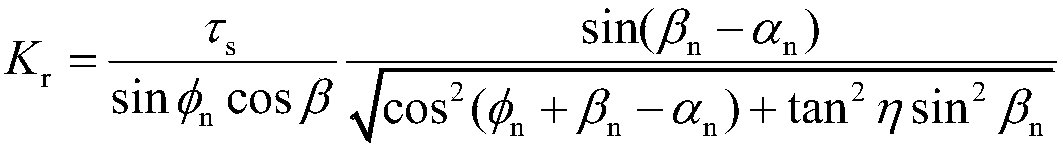

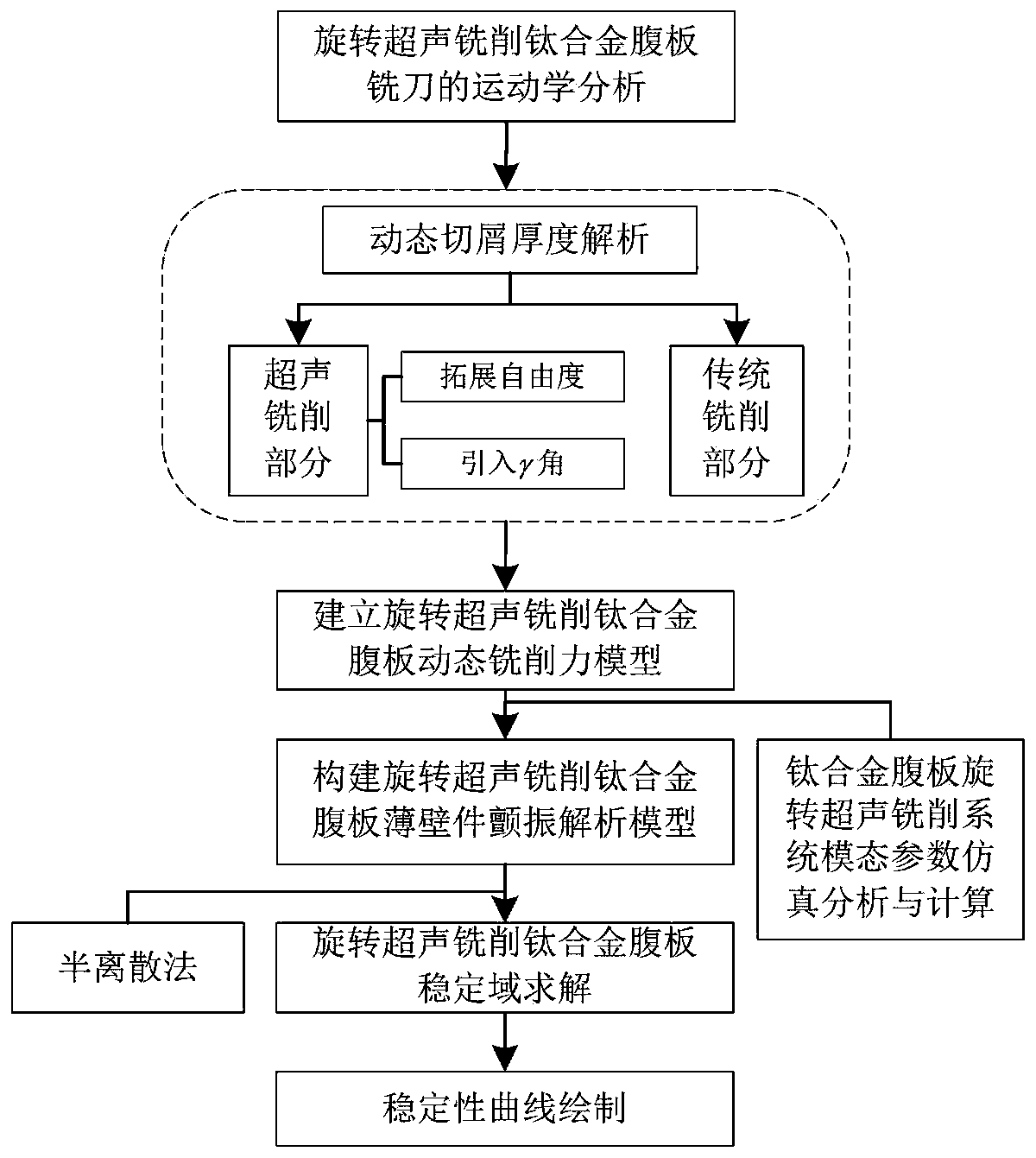

Method for improving milling stability domain of titanium alloy thin-walled workpiece

InactiveCN111177860AIncrease stability domainMilling Chatter SuppressionGeometric CADDesign optimisation/simulationMetallurgyTitanium alloy

The invention discloses a method for improving a milling stability domain of a titanium alloy thin-walled workpiece. The method comprises the following steps: step 1, establishing a kinetic equivalentmodel of a rotary ultrasonic milling system of the titanium alloy web thin-walled workpiece; step 2, determining modal characteristics of the milling system for the weak-rigidity titanium alloy thin-walled workpiece; 3, establishing a rotary ultrasonic milling dynamic milling force model; step 4, constructing a rotary ultrasonic milling titanium alloy web thin-wall part stability domain analytical model; 5, solving the stability domain of the rotary ultrasonic milling titanium alloy thin-walled workpiece by using a semi-discrete method; and step 6, drawing a stability lobe diagram of the rotary ultrasonic milling titanium alloy thin-walled workpiece to realize accurate prediction of the stability domain of the titanium alloy thin-walled workpiece. According to the method, the titanium alloy thin-wall part is milled through the rotary ultrasonic technology, the stability range of milling of the titanium alloy web is greatly improved, milling flutter is obviously restrained, and the milling quality of the titanium alloy web is effectively improved.

Owner:NANJING UNIV OF SCI & TECH

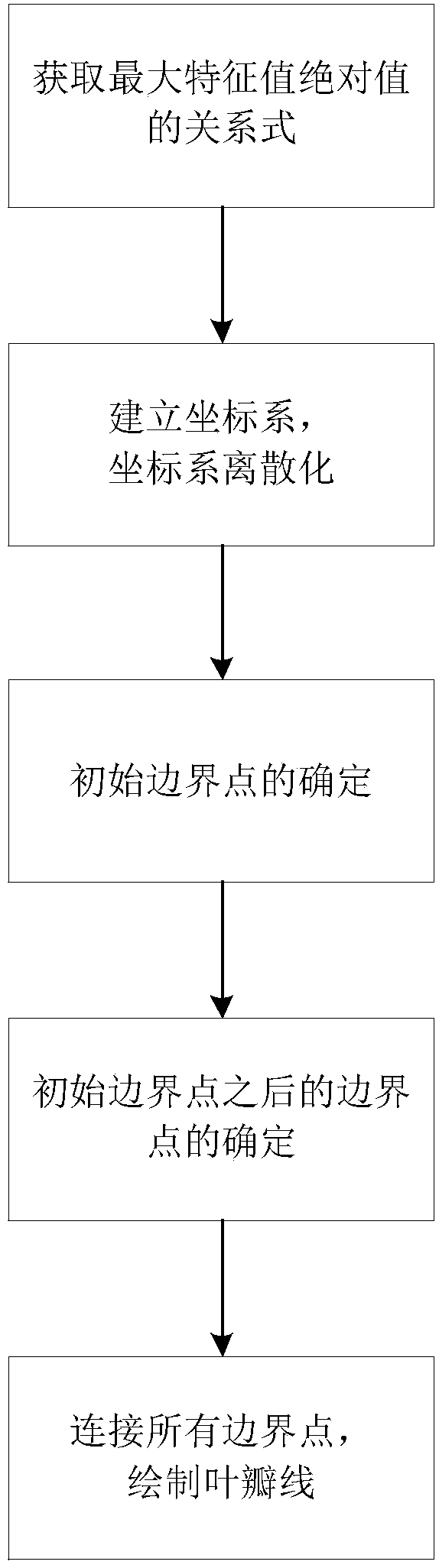

Method for acquiring stability lobe graph by utilizing full-discrete method

ActiveCN108520117AGood prediction accuracyAvoid calculationGeometric CADDesign optimisation/simulationMaximum eigenvalueTransfer matrix

The invention belongs to the field of stability prediction of a milling system, and discloses a method for acquiring a stability lobe graph by utilizing a full-discrete method. The method comprises the following steps that a, a maximum characteristic value absolute value relational expression of a state transfer matrix is acquired; b, a coordinate system of the rotating speed of a main shaft and the cutting depth is established, and the coordinate system is rasterized; c, an initial boundary point is searched for by means of dichotomy; d, a previous boundary point is translated into a grid toobtain a new point, a searching direction and a searching area are determined according to the size of the maximum characteristic value absolute value of the point until a boundary point is found; e,step d is repeated until boundary points of all the areas are obtained, and the boundary points are sequentially connected in the horizontal coordinate direction to form a lobe curve. By means of themethod, drawing of the lobe graph only relates to stability calculation of a few points near the lobe curve, which is similar to the situation that calculation is carried out along with the boundary of the stability, and then the stability lobe graph is quickly drawn in a two-dimensional coordinate system formed by the rotating speed and the cutting depth.

Owner:HUAZHONG UNIV OF SCI & TECH

Multi-axis numerical control machining ball-end cutter-axis vector planning method for avoiding interference and flutter

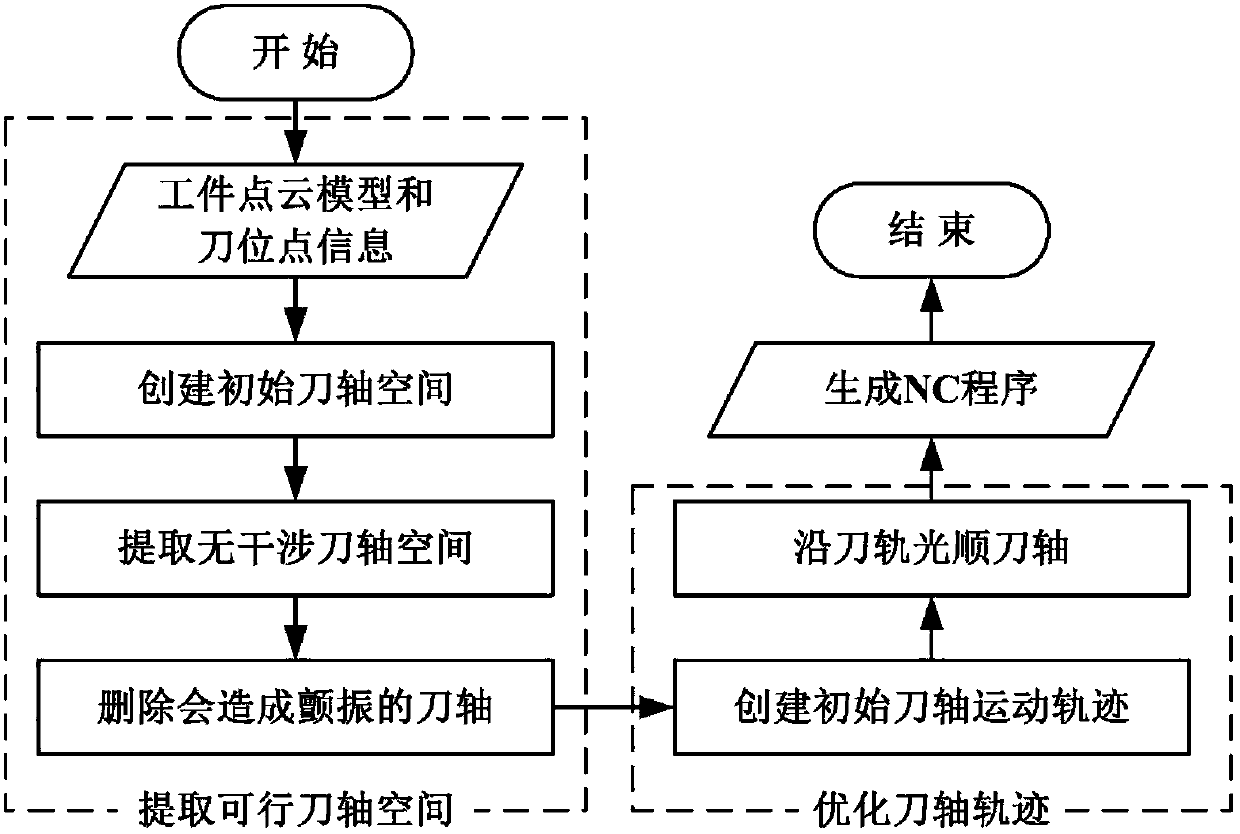

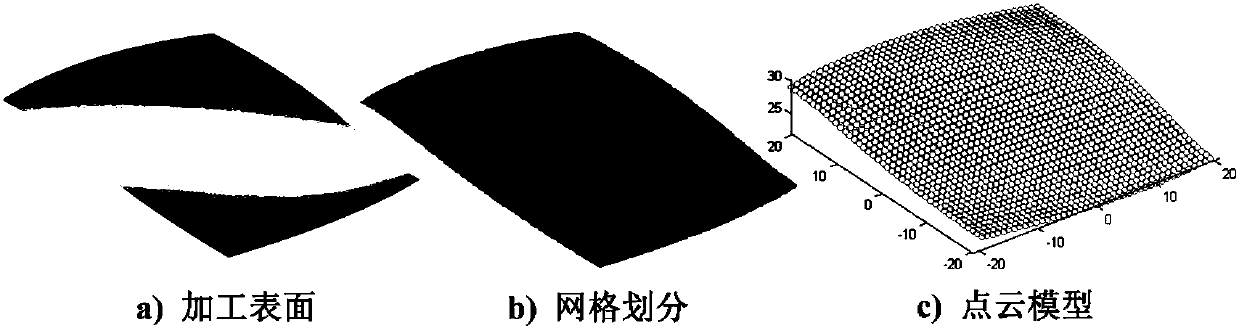

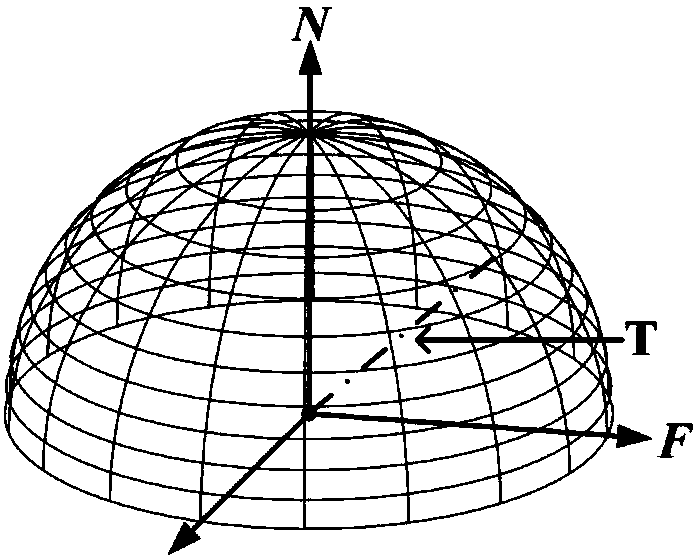

ActiveCN108519758AImprove calculation accuracyImprove reliabilityNumerical controlNumerical controlAngular velocity

A multi-axis numerical control machining cutter-axis vector planning method for avoiding interference and flutter is characterized in that an interference-free cutter axis space at each cutter contactis established according to a spatial positional relationship between a cutter and surface discrete points on a workpiece. Then, a ball-end cutting edge is dispersed along the direction of each interference-free cutter axis, and a cutting stability lobe diagram is constructed. According to the cutting stability lobe diagram, it is judged whether the current interference-free cutter axis causes flutter according to the rotational speed and the cutting depth, and then the flutter cutter axis is removed from the interference-free cutter axis space, and an interference-and flutter-free cutter axis space at each cutter contact is obtained. Finally, the minimum sweeping surface of tool motion and the minimum variance of the angular velocity between adjacent cutter contacts are searched in the cutter axis space to generate a smoothing cutter axis. The method has strong versatility, can avoid interference and flutter at the same time in multi-axis machining, ensures the reliability and stability of the processing process, and improves the surface quality of the processing.

Owner:NANJING UNIV OF TECH

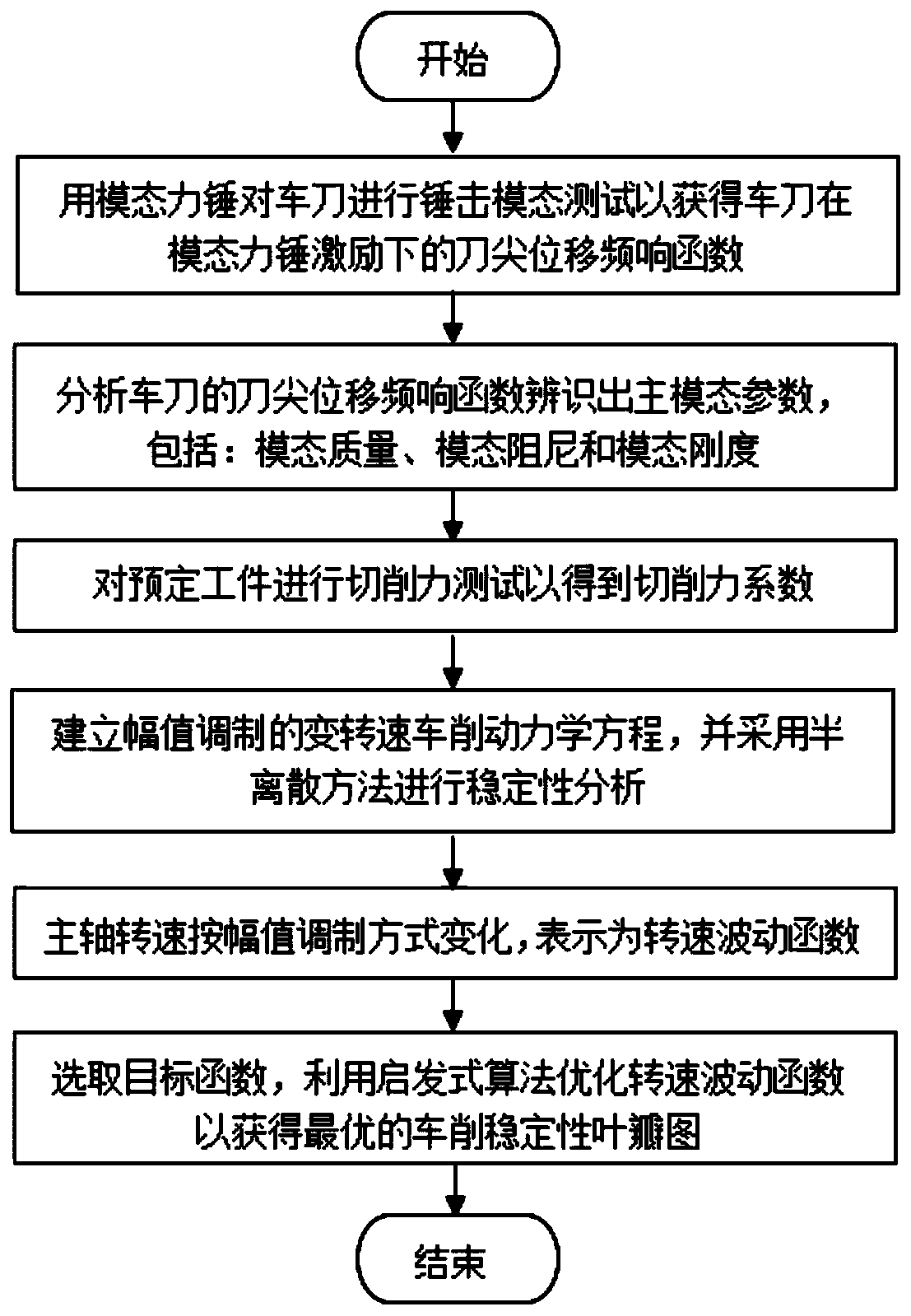

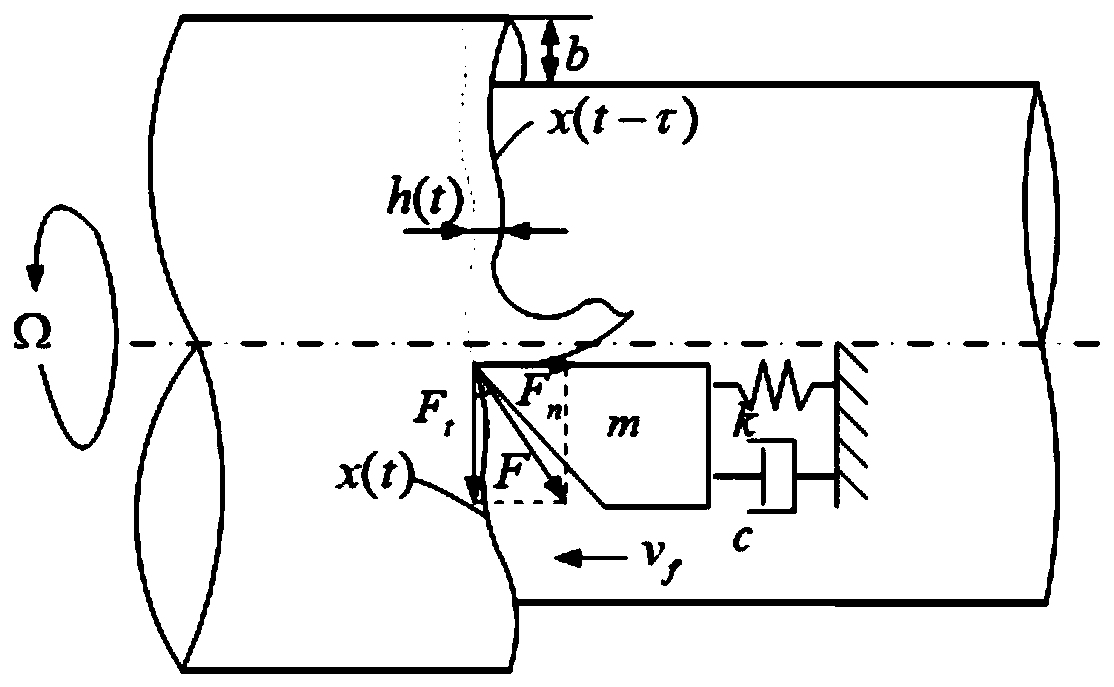

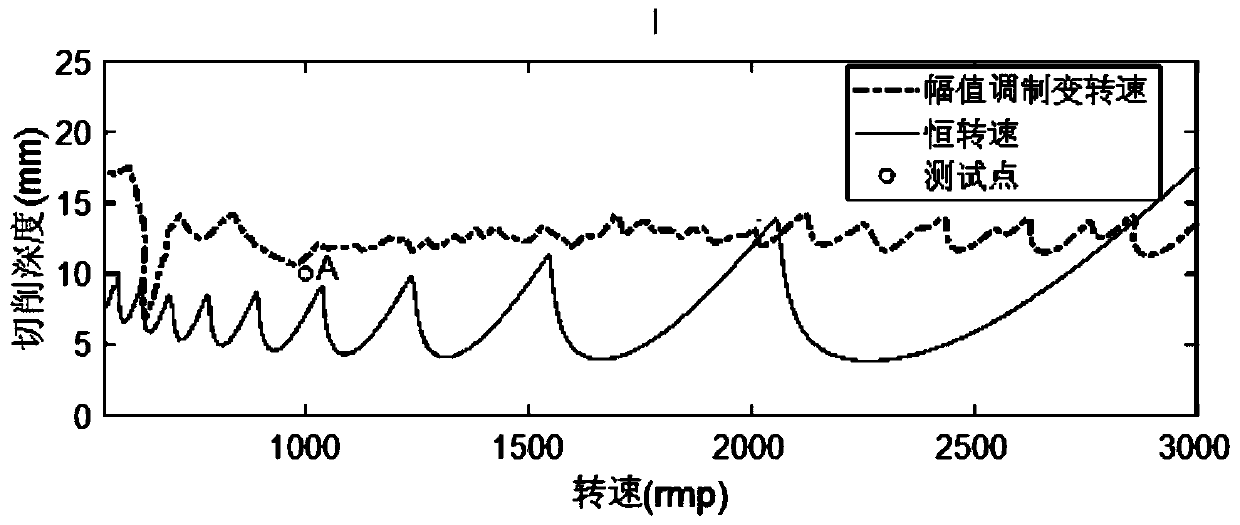

Variable-mainshaft-speed turning chatter suppression method based on amplitude modulation

ActiveCN110102787ATurning Chatter SuppressionAvoid selectivityAuxillary equipmentMaintainance and safety accessoriesModal testingEngineering

Owner:SHANGHAI JIAO TONG UNIV

Fine-tuning speed application interface

ActiveUS10022832B2Reducing machine chatterAutomatic control devicesComputer controlComputer scienceFine-tuning

Owner:DMG MORI CO LTD

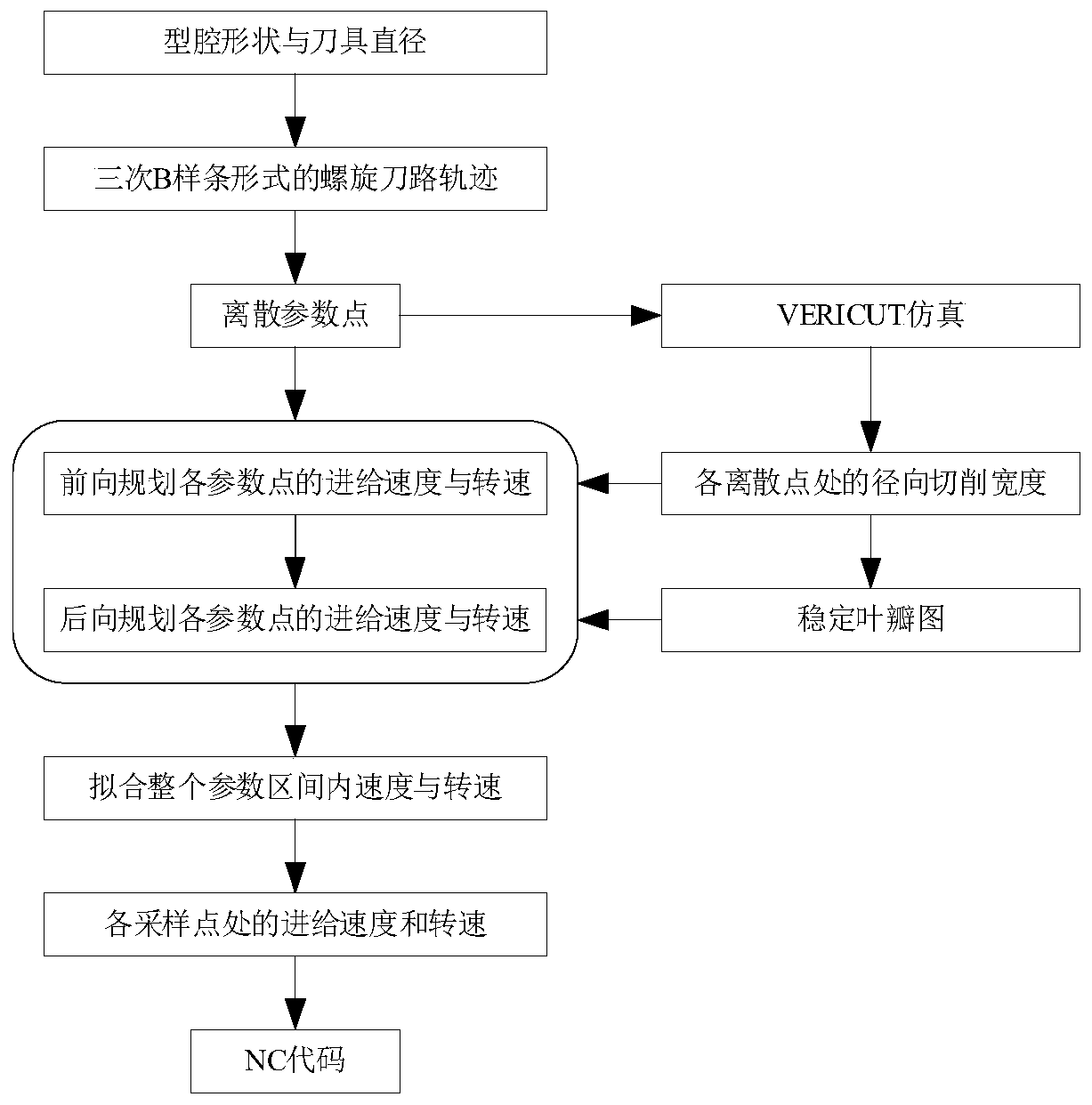

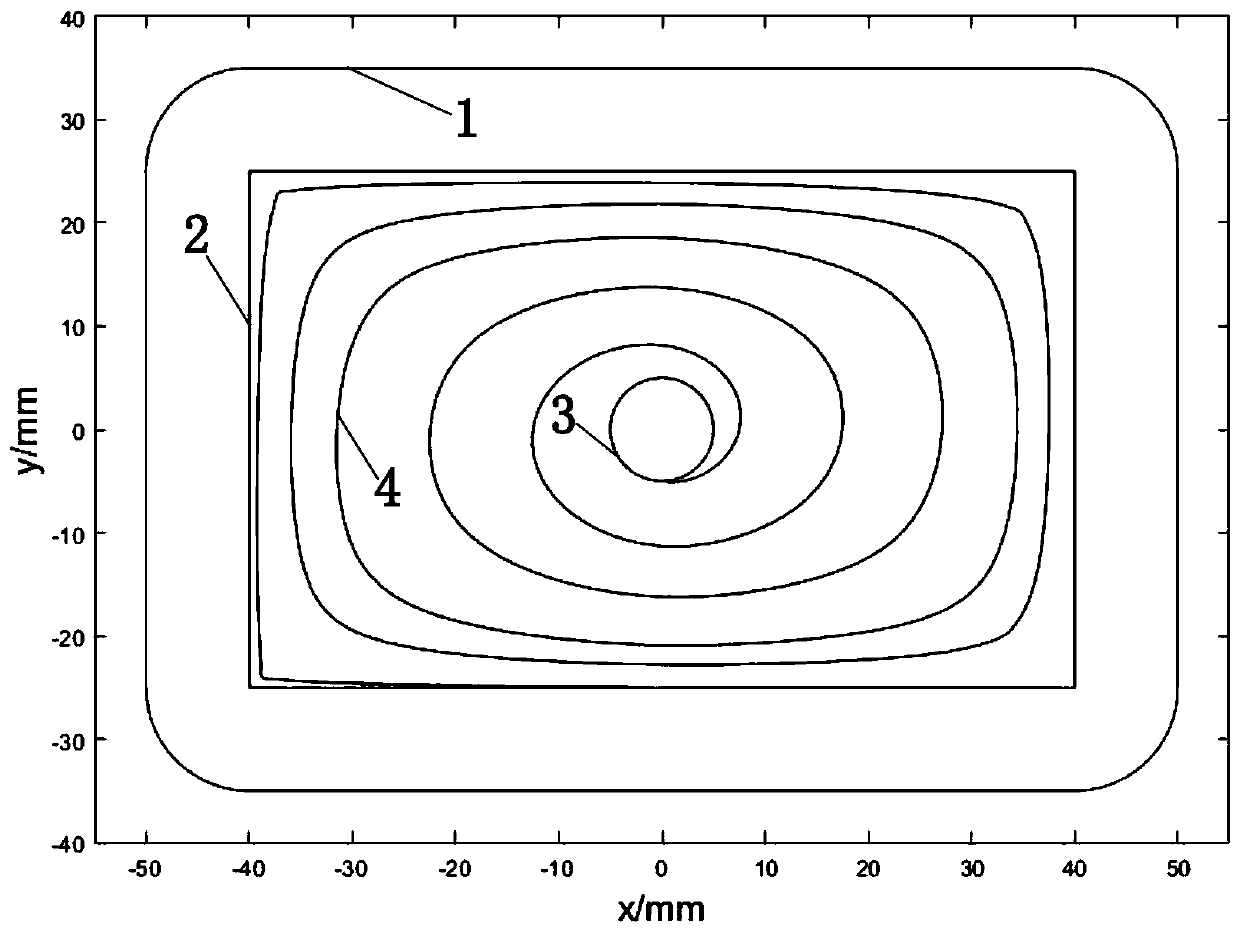

Cavity spiral milling machining feed rate and rotating speed offline planning method

ActiveCN111176209AConstrained high errorMotion velocity constraintNumerical controlCutter locationControl engineering

The invention provides a cavity spiral milling machining feed rate and rotating speed offline planning method. Firstly, a cubic spline curve smooth spiral line is obtained, the spline curve track is equally divided and discretized according to parameters to obtain each discrete parameter point; a tool path formed by the discrete points is simulated to obtain radial cutting widths at the discrete points; a stable lobe graph is calculated and a corresponding relation between the rotating speed and the critical cutting depth is established; the corresponding relationship between the radial cutting width and the rotating speed at each parameter point and the critical cutting depth is utilized to establish a feeding speed and rotating speed planning model with optimal time at each parameter point, and a feeding speed and rotating speed plan with optimal time at each parameter point is obtained through forward planning and backward planning; the speed and the rotating speed in the whole parameter interval are obtained through fitting; and finally, the position, the maximum feeding speed and the rotating speed of each cutter location point are obtained, and corresponding NC codes are outputted for a specific machine tool numerical control system to be used for actual machining. The method is suitable for high-speed milling of the cavity.

Owner:SHANGHAI JIAO TONG UNIV

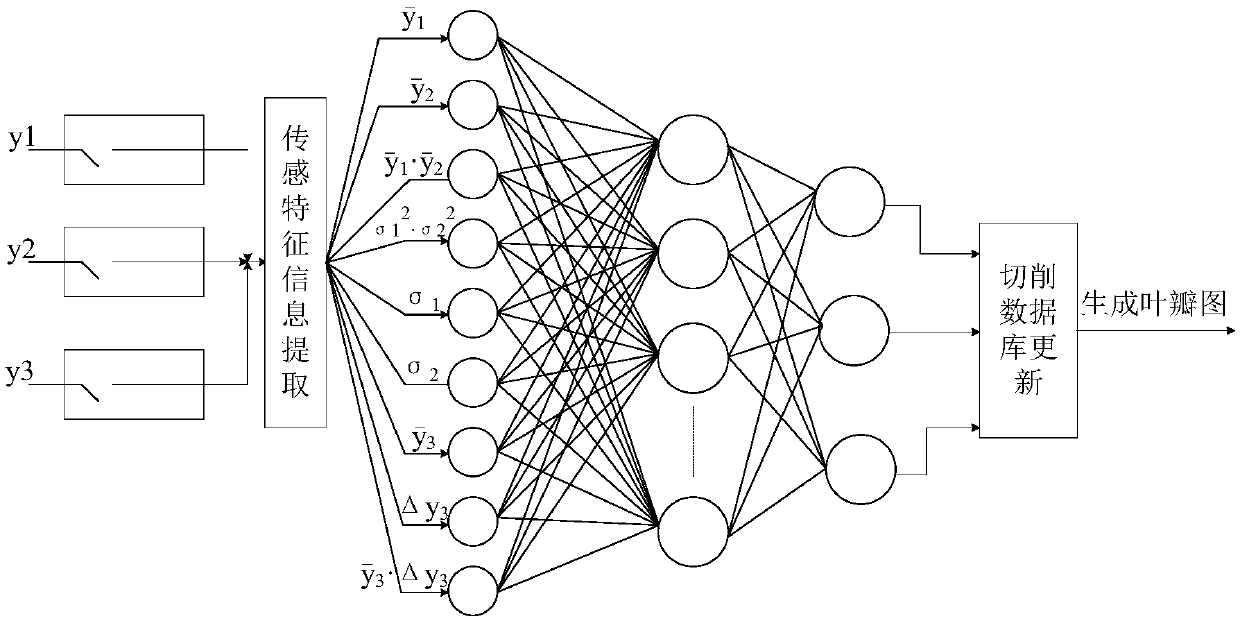

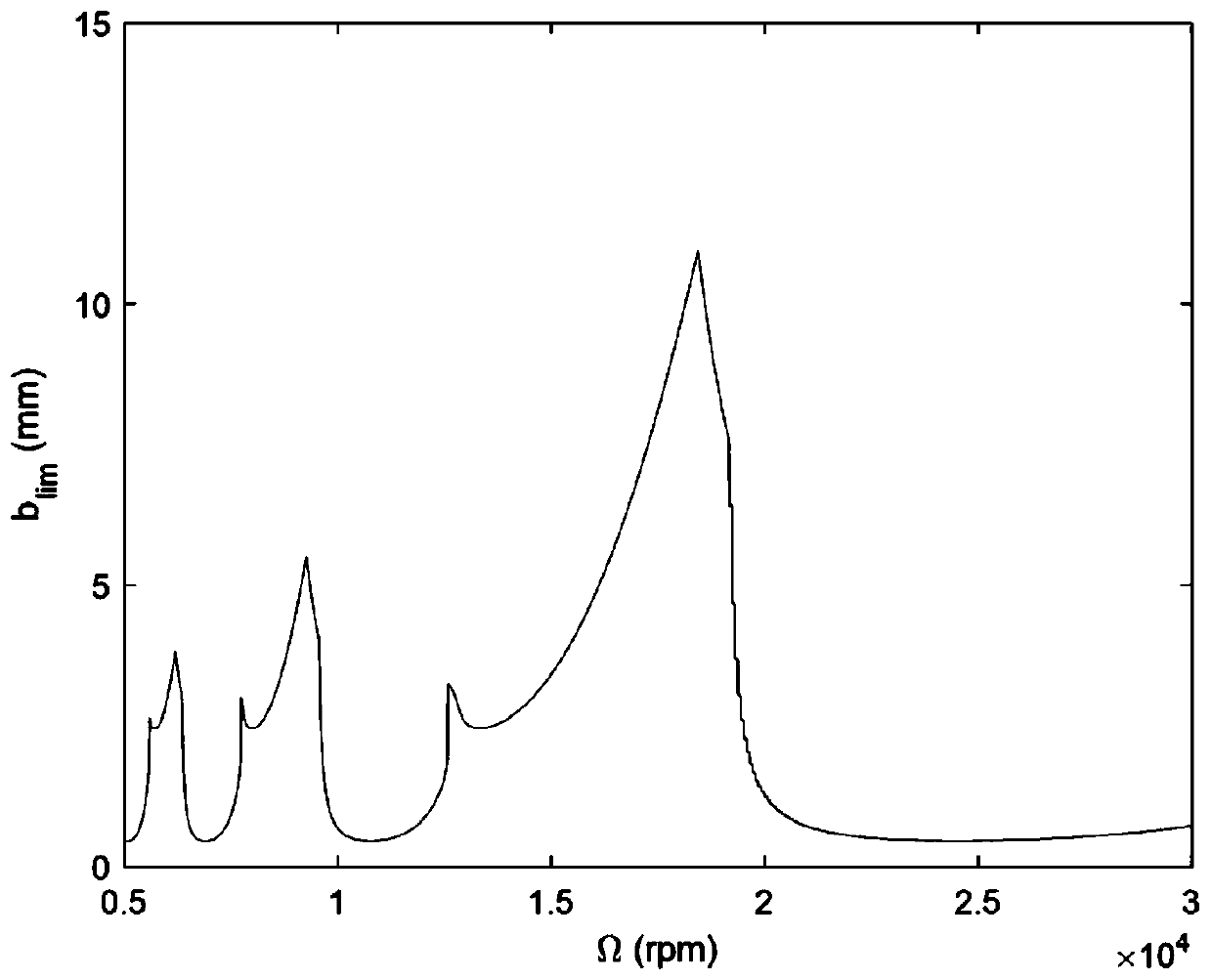

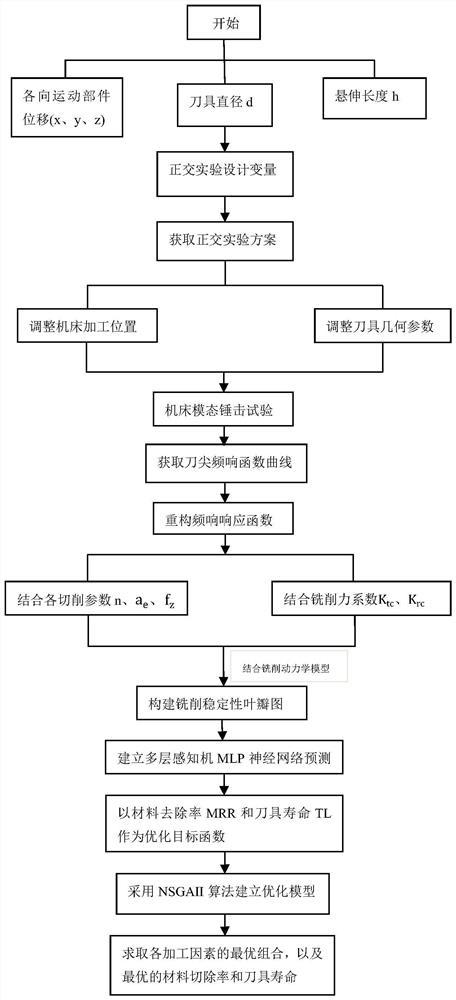

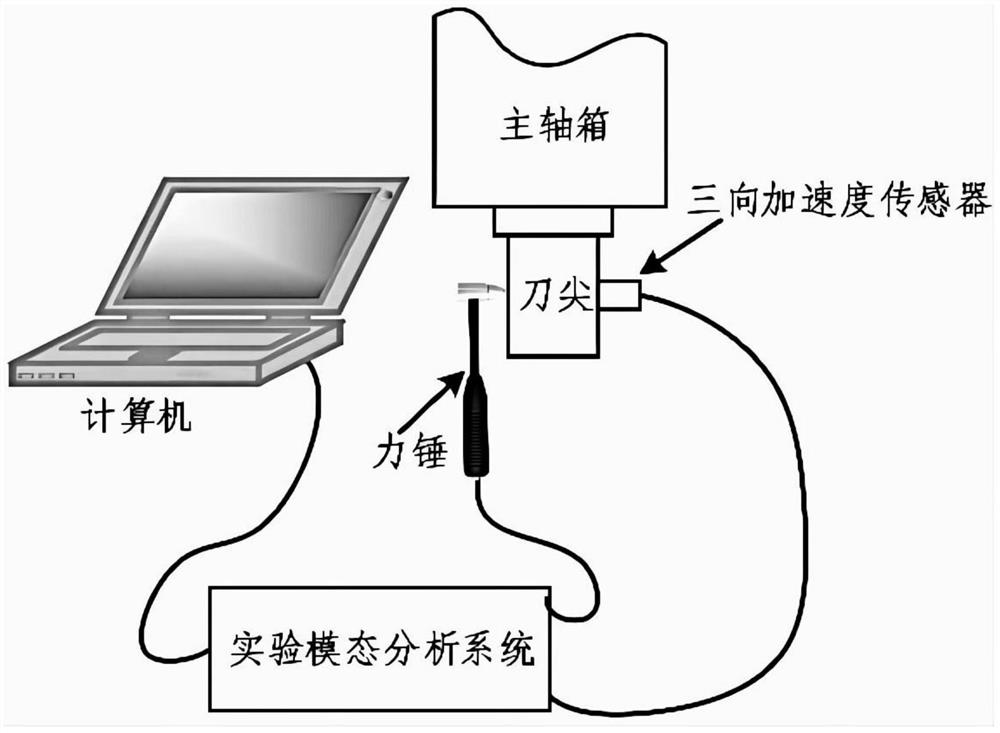

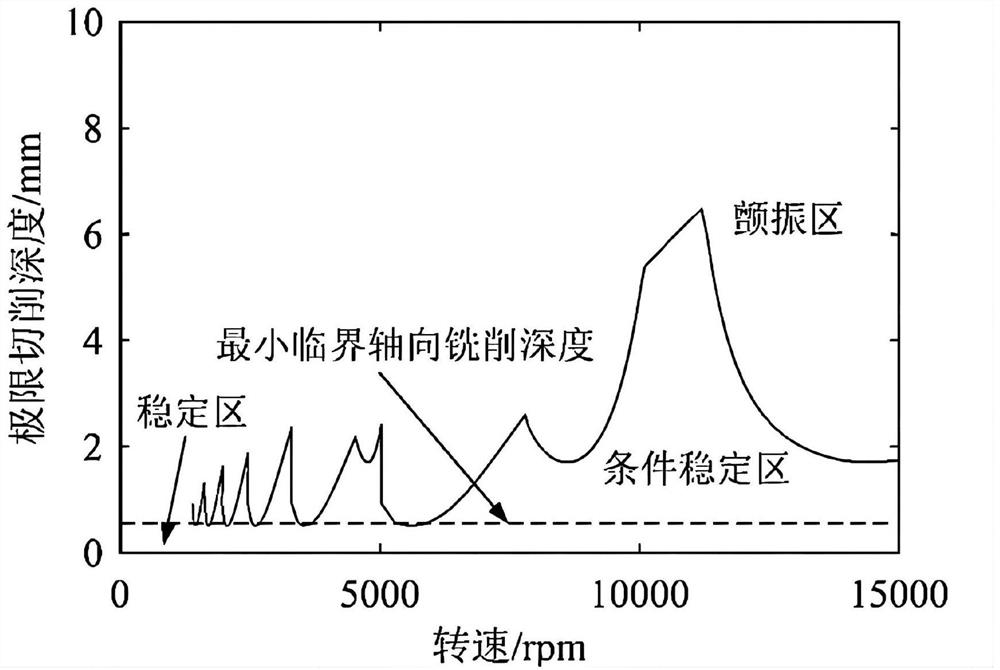

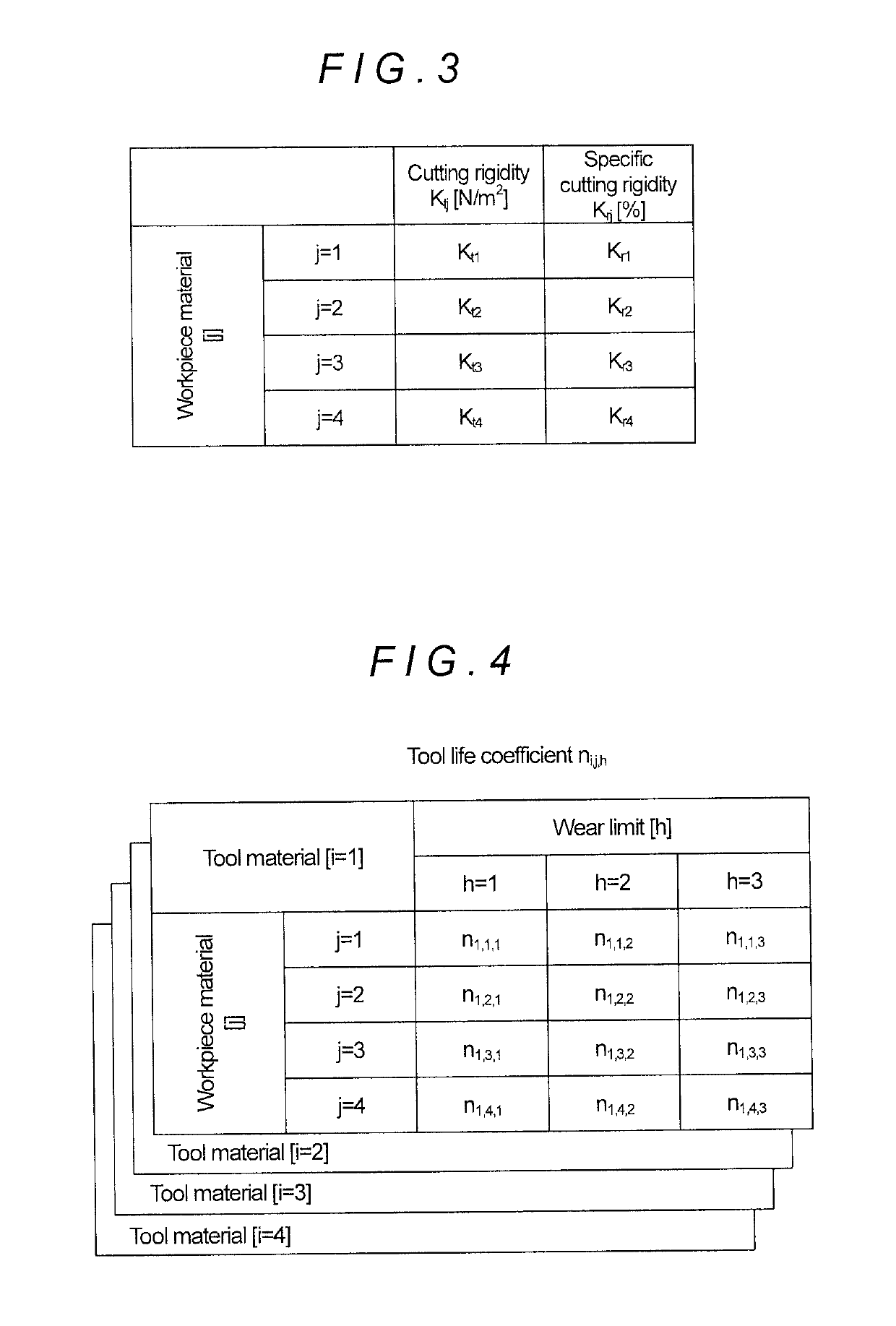

Numerical control machine tool multi-working-condition cutting parameter optimization method based on multilayer perceptron

The invention relates to a numerical control machine tool multi-working-condition cutting parameter optimization method based on a multilayer perceptron, and belongs to the field of numerical control machine tool intelligent manufacturing equipment. The invention provides a multi-working-condition cutting parameter optimization method of a numerical control machine tool based on a multi-layer perceptron, aiming at solving the problem of uncertainty of machine tool coordinates and cutter parameters of the numerical control machine tool, which can cause strong flutter of the numerical control machine tool in a cutting process. The method comprises the steps that firstly, a tool nose frequency response function curve based on different main shaft coordinates, tool diameters and overhanging lengths needs to be obtained under a hammering modal experiment, and a milling stability lobe graph is drawn by combining a modal theoretical formula and milling chatter stability mathematical model analysis; according to a cutting chatter stability prediction method, constructing a limit cutting depth MLP prediction model taking the displacement of a moving part in each direction, the diameter of a cutter, the overhanging length, the rotating speed of a main shaft, the cutting width and the feeding amount of each tooth as input; the regression prediction model is adopted as a cutting stability constraint to establish a multi-objective optimization model of the material removal rate and the cutter life, and optimal machining parameter configuration is solved through a non-dominated sorting NSGAII algorithm with an elitist strategy. And example research and analysis are carried out by one machining center, so that the obtained optimal configuration can meet stable cutting of the machine tool, and the reliability and the effectiveness of the method are verified.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

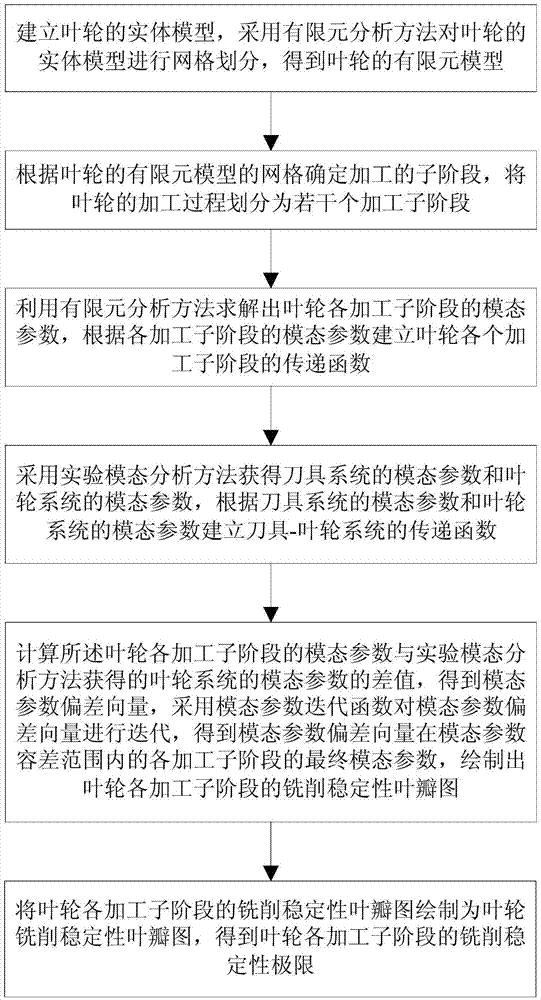

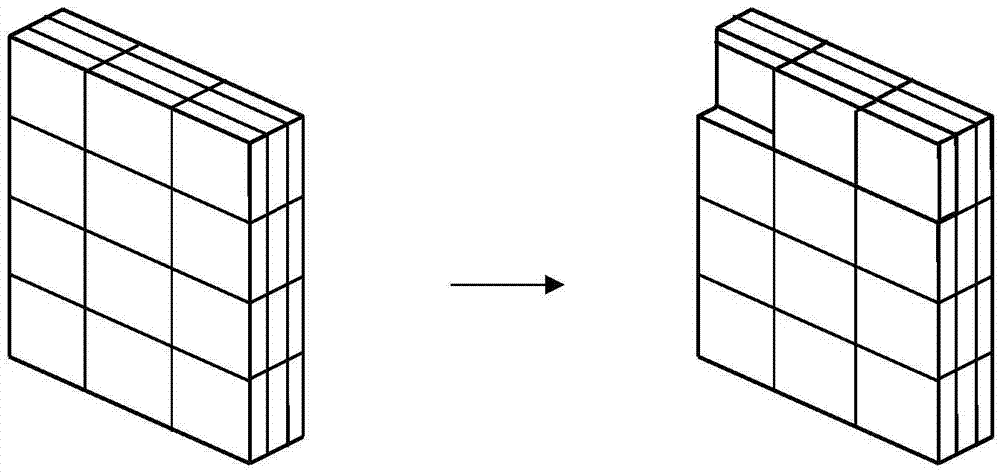

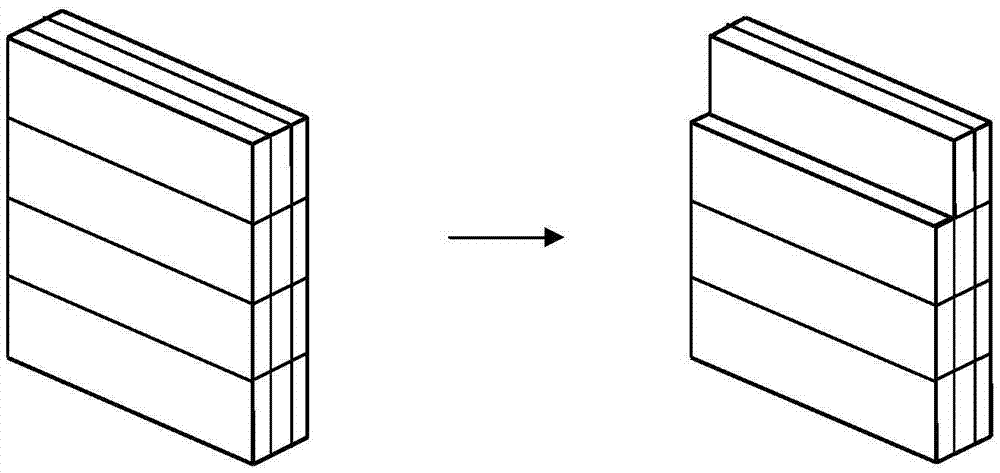

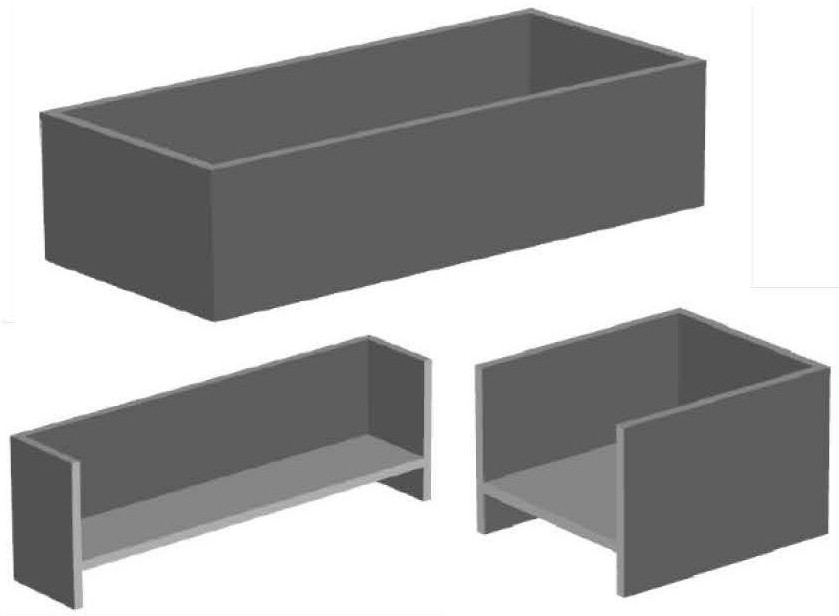

Method for predicting shaking of impeller

ActiveCN105447286AAnalysis is intuitive and accurateImprove accuracyDesign optimisation/simulationSpecial data processing applicationsImpellerDeviation vector

The invention provides a method for predicting the shaking of an impeller. The method includes the steps of conducting grid division on an entity model of the impeller through a finite element analysis method, dividing the machining process of the impeller into a plurality of machining sub-stages, obtaining modulus parameters of all the machining sub-stages of the impeller through the finite element analysis method, establishing a transfer function of each machining sub-stage of the impeller, obtaining the modulus parameters of a tool system and the modulus parameters of an impeller system through an experiment modulus analysis method, establishing a transfer function of a tool-impeller system, calculating the difference between the modulus parameters of each machining sub-stage of the impeller and the modulus parameters, obtained through the experiment modulus analysis method, of the impeller system, obtaining the modulus parameter deviation vector, conducting iteration on the modulus parameter deviation vector through a modulus parameter iteration function, obtaining the final modulus parameters of the modulus parameter deviation vector within the modulus parameter tolerance range of all the machining sub-stages, and drawing the milling stability lobe graph of all the machining sub-stages of the impeller.

Owner:NORTHEASTERN UNIV LIAONING

Milling chatter prediction method for thin bottom plate

ActiveCN113326586AA function to implement flutter stability predictionBroaden your optionsGeometric CADDesign optimisation/simulationAlgorithmStructural engineering

The invention relates to a thin bottom plate milling chatter prediction method which is suitable for predicting a stability domain of a thin bottom plate component in a milling process. According to the method, stability analysis of the thin bottom plate milling process is carried out by establishing a dynamic cutting force model of the thin bottom plate milling process considering cutter deformation, a stability lobe graph of the thin bottom plate milling process is obtained, a parameter selection range is widened for stable milling of the thin bottom plate, and the function of predicting the flutter stability of the whole thin bottom plate milling process is achieved. The method can improve the prediction precision.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

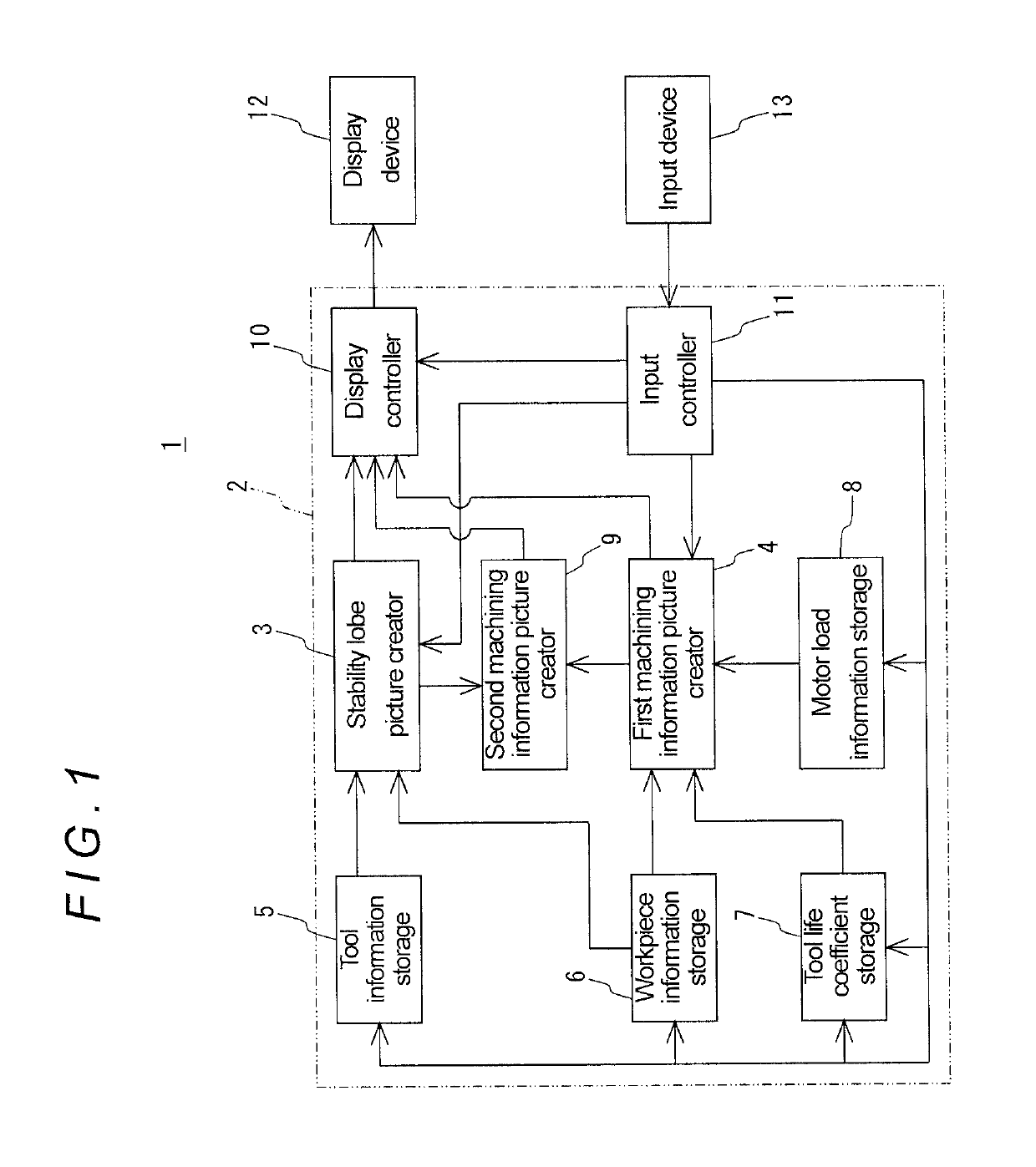

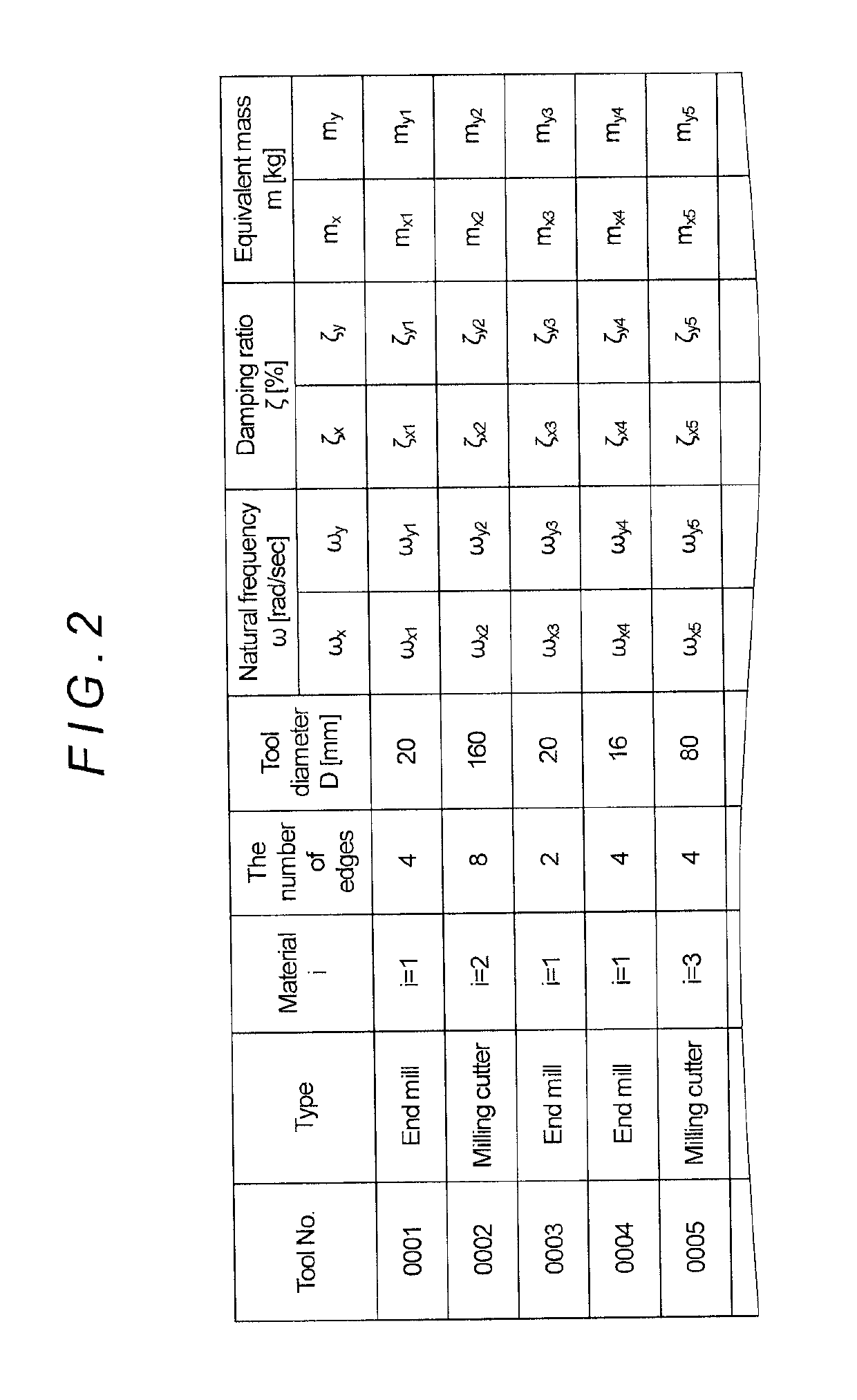

Machining status display apparatus

ActiveUS10386831B2Quickly recognize appropriate machining conditionQuick identificationProgramme controlSafety arrangmentsComputer graphics (images)Display device

A machining status display apparatus includes a display device having a display screen, a stability lobe picture creator creating, based on specifications of a tool to be used, display picture data for displaying a stability lobe as a correlation diagram between a spindle rotation speed and a limit depth of cut of the tool above which regenerative chatter occurs, a first machining information picture creator creating display picture data for displaying machining related information other than regenerative chatter corresponding to set machining conditions, and a display controller displaying the stability lobe and the machining related information with the stability lobe and the machining related information superimposed one on another on the display screen of the display device based on the display picture data created by the stability lobe picture creator and the display picture data created by the first machining information picture creator.

Owner:DMG MORI CO LTD

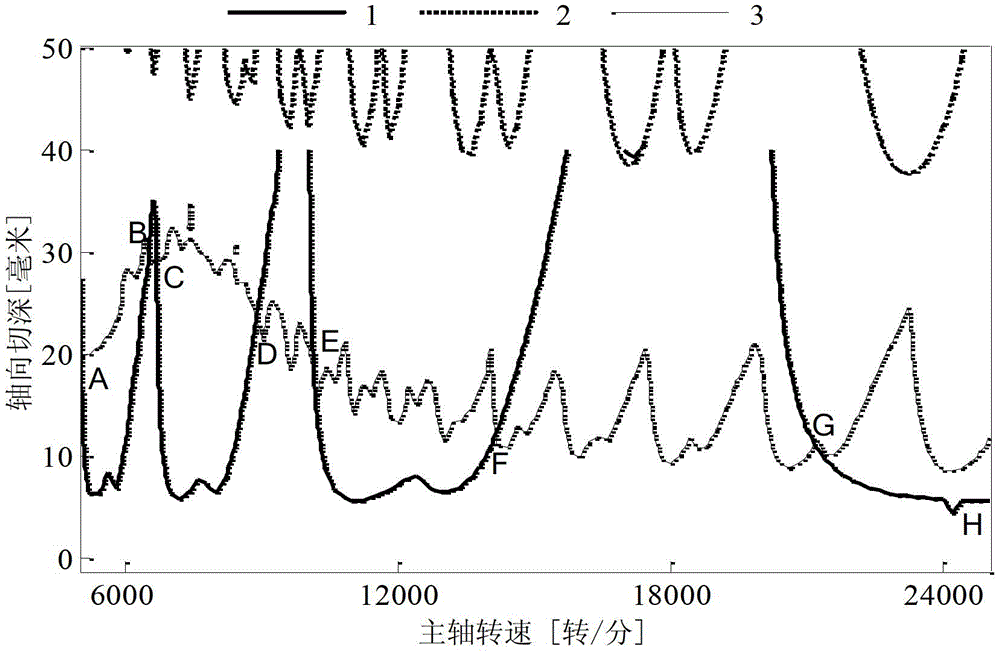

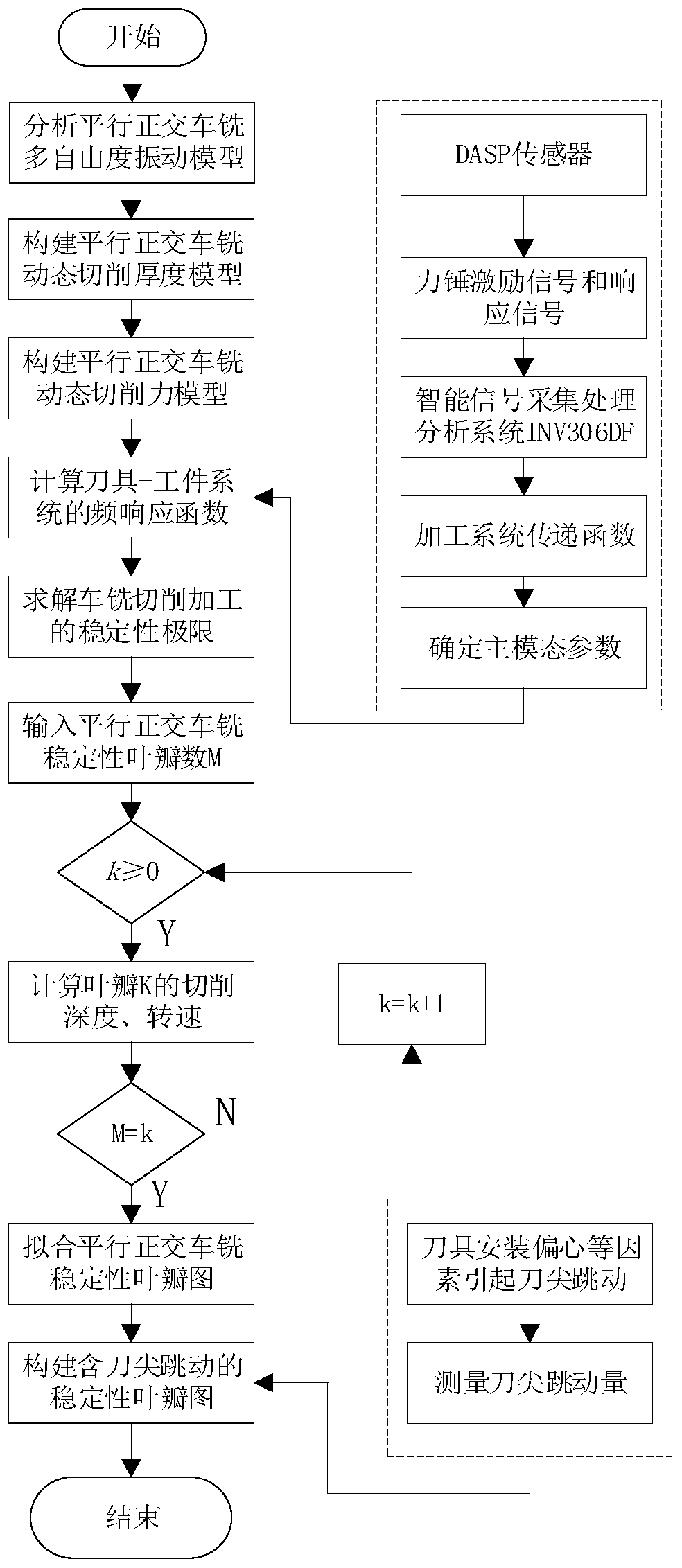

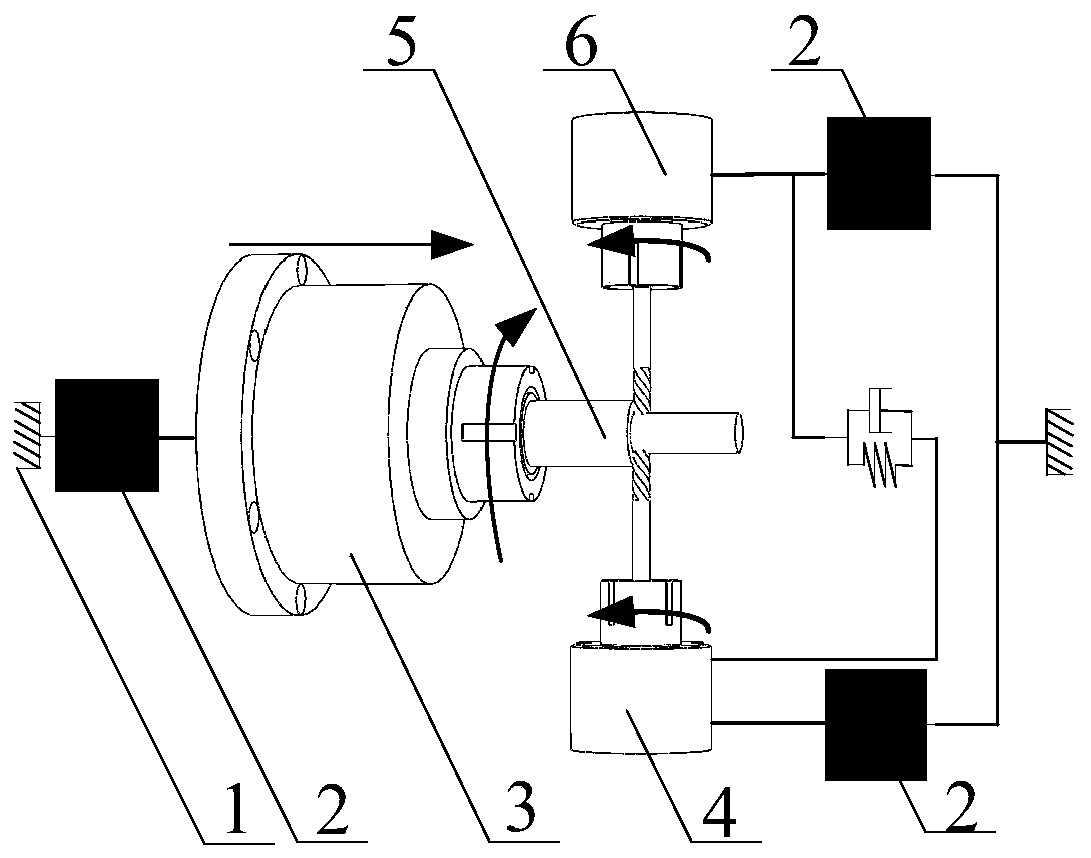

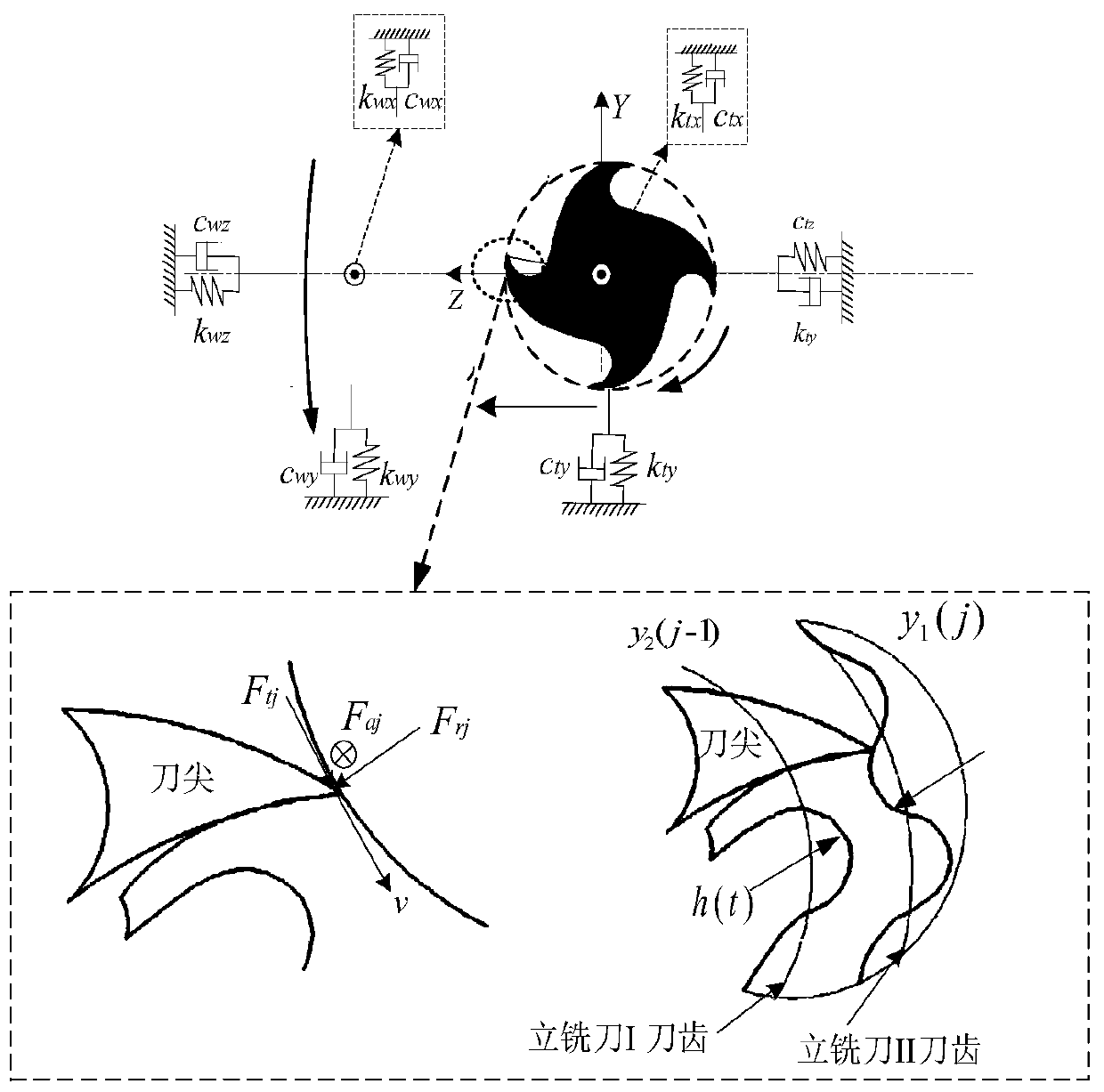

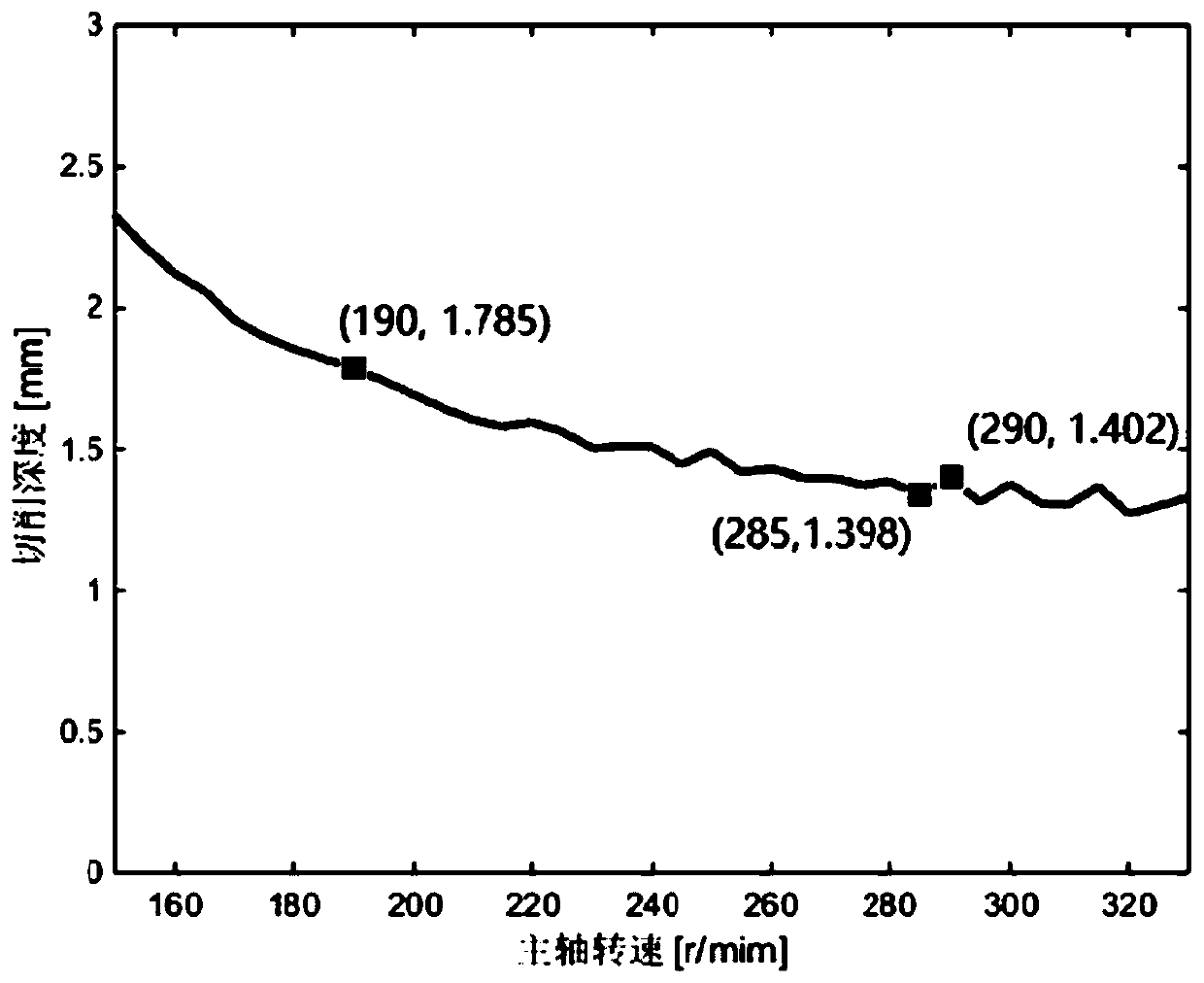

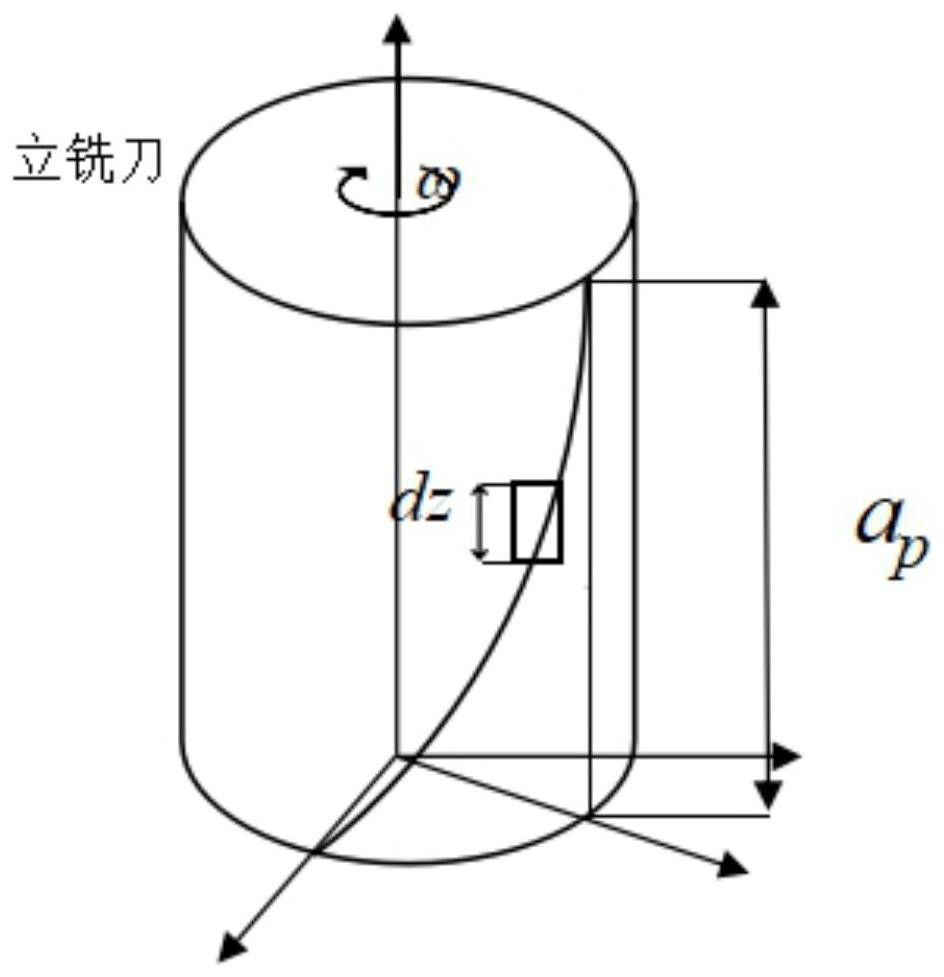

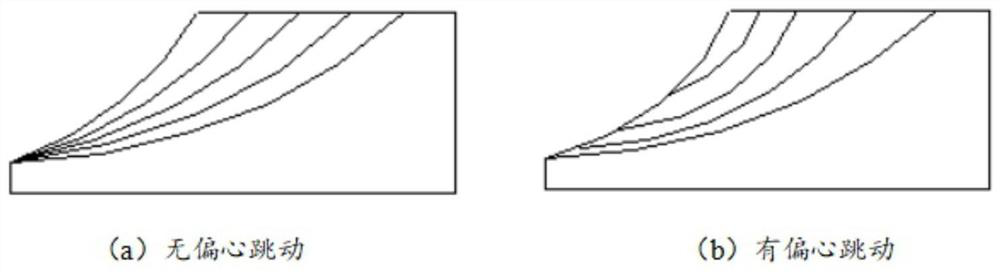

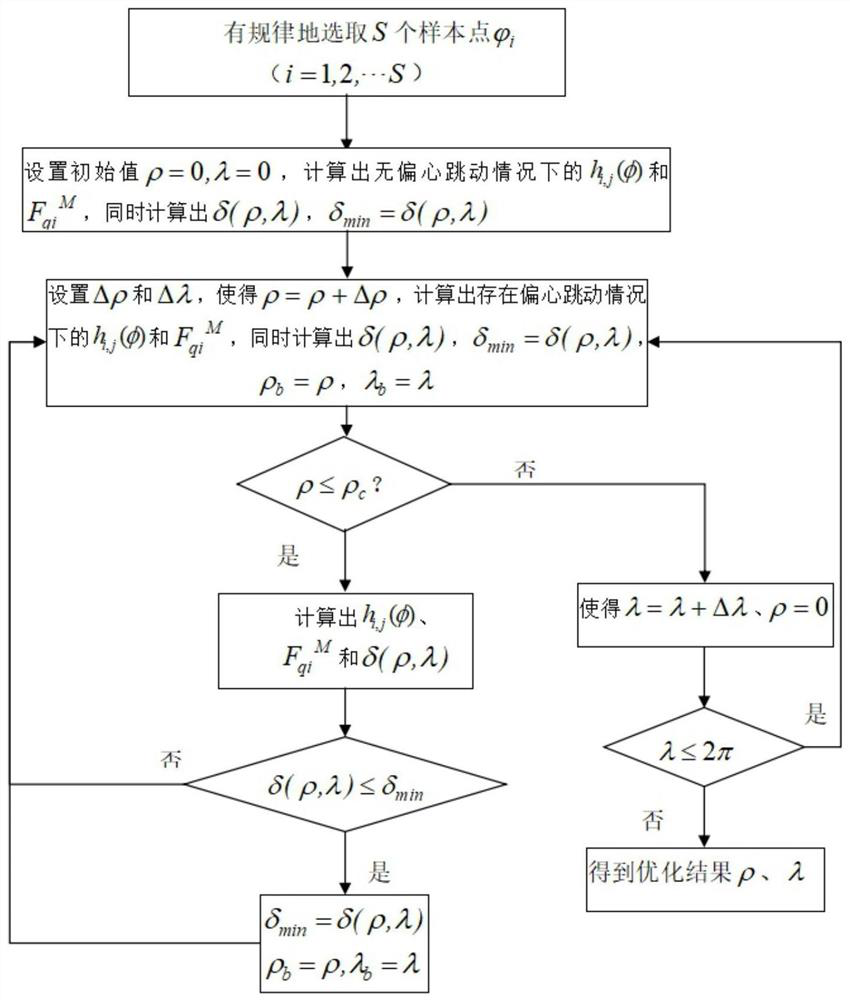

Parallel synchronous orthogonal turn-milling flutter stability lobe graph prediction method

The invention discloses a parallel synchronous orthogonal turn-milling flutter stability lobe graph prediction method, and belongs to the technical field of machining and manufacturing. The method isimplemented by the following steps of: sequentially performing steps; analyzing a parallel synchronous orthogonal turn-milling multi-degree-of-freedom vibration model; constructing a dynamic cutting thickness model for parallel synchronous orthogonal turn-milling cutting; constructing a dynamic cutting force model for parallel synchronous orthogonal turn-milling cutting; and calculating a frequency response function of the tool-workpiece system, solving a stability limit of parallel synchronous orthogonal turn-milling cutting machining, constructing a stability lobe graph of parallel synchronous orthogonal turn-milling cutting machining, and constructing a stability lobe graph of parallel synchronous orthogonal turn-milling cutting machining considering tool nose bounce. The parallel synchronous orthogonal turn-milling flutter area and the stable area can be accurately predicted, and the flutter problem in the parallel synchronous orthogonal turn-milling process can be effectively solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

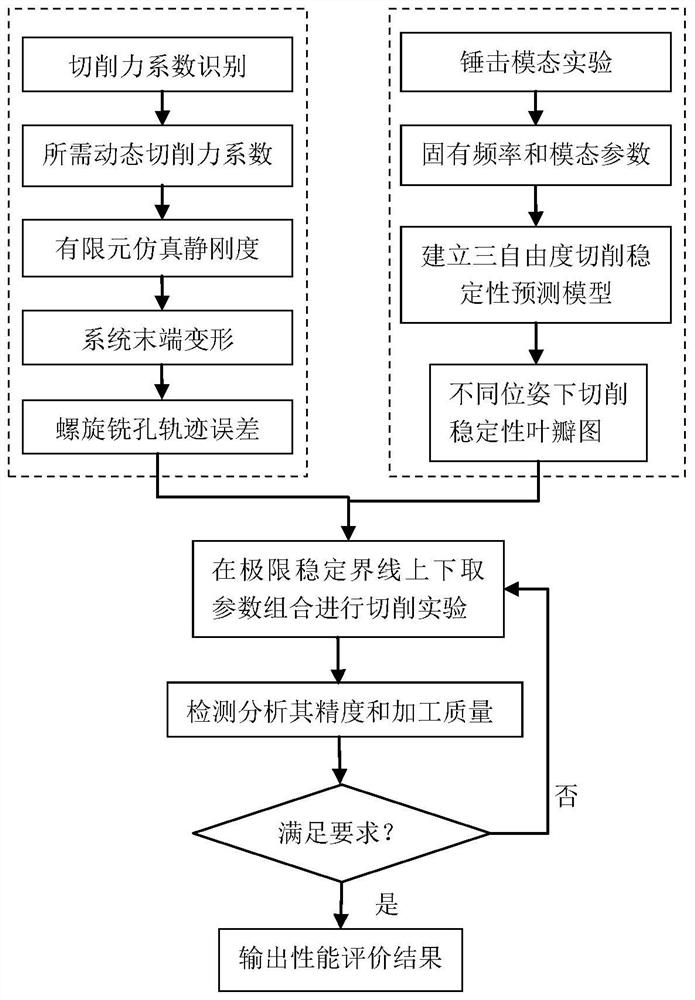

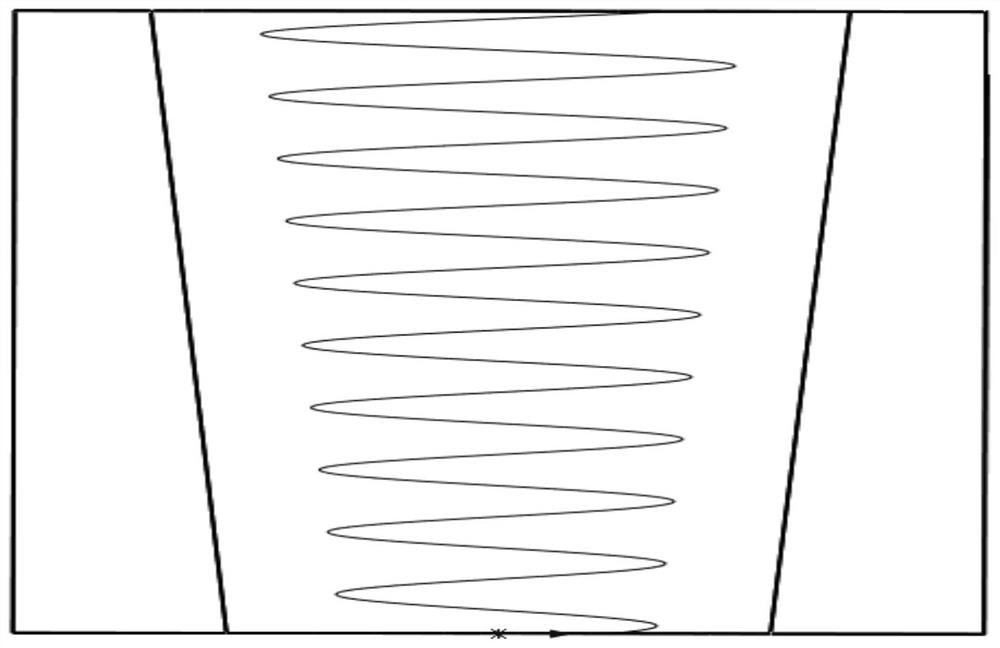

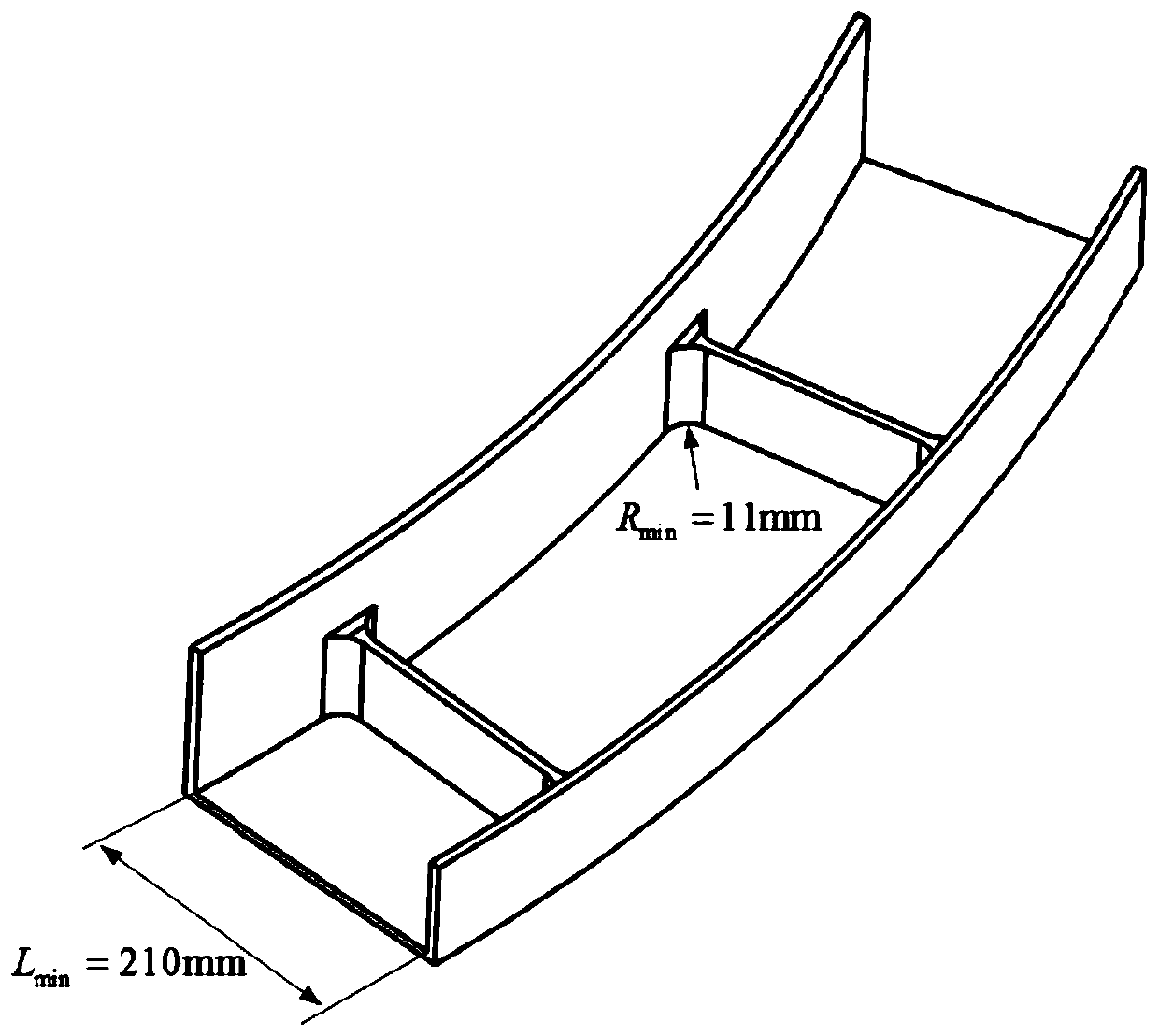

Method for evaluating machining performance of hybrid robot under different poses based on spiral hole milling

ActiveCN112733298AAccurate analysisComprehensive and accurate dynamic performanceGeometric CADDesign optimisation/simulationEvaluation resultControl engineering

The invention discloses a method for evaluating the machining performance of a series-parallel robot in different poses based on spiral hole milling. The method comprises the steps of obtaining a cutting force coefficient; obtaining modal parameters of the hybrid robot under different poses through modal experiments; predicting a spiral hole milling track error; predicting the cutting stability of the spiral milling hole; taking the rotating speed of the main shaft of the hybrid robot and the axial cutting depth of each revolution of the cutter as a parameter combination near the stability critical state of each stability lobe graph, taking the combined parameter as a cutting parameter to process a workpiece when the hybrid robot performs a spiral hole milling experiment, and then detecting the processing precision and the surface quality of the workpiece; and evaluating the processing performance of the hybrid robot under different poses according to the evaluation result. By adopting the method, the evaluation efficiency and the evaluation precision can be improved.

Owner:TIANJIN UNIV

Low-vibration titanium alloy milling process parameter optimization method

ActiveCN109901516AExtend your lifeImprove milling efficiencyProgramme controlComputer controlResonanceTitanium alloy

The invention discloses a low-vibration titanium alloy milling process parameter optimization method. According to the method, a titanium alloy cutting rotation speed range is determined on the basisof a recommended titanium alloy cutting speed, and therefore, it can be ensured that a cutter works at a reasonable speed; the cutting time of each blade and a workpiec is controlled, and a radial cutting depth is determined, and therefore, it can be ensured that the cutter has a certain service life; an axial cutting depth is determined through a milling stability lobe diagram, so that possible vibration during a milling process can be avoided; the low-order natural frequency of a machine tool spindle is measured, and a spindle rotation frequency which is far away from the natural frequency of the machine tool spindle, and a cutter tooth cutting frequency are selected, a spindle speed is determined, so that possible resonance during the milling process can be avoided; and a feed rate is determined according to chip shapes generated in actual milling.

Owner:XIAN AIRCRAFT IND GROUP

High-speed milling machining dynamic cutting force prediction system and parameter optimization method

PendingCN113158371AReduce the number of trialsReduce testing costsGeometric CADDesign optimisation/simulationControl engineeringGenetics algorithms

The invention discloses a high-speed milling machining dynamic cutting force prediction system and a parameter optimization method, the milling force can be predicted through the milling force prediction system, a cutting force coefficient predicted by the system can be applied to prediction of the milling force under the same milling condition and different process parameters, meanwhile, the test frequency is reduced, and under the condition that the test is reliable, milling force model parameters can be identified through a single test, the test cost is reduced, the reliability and the success rate of the test are improved, a flutter stability lobe graph is obtained through an analytical method, a stable interval is obtained, and on the basis of the stable interval, the milling force is brought into constraint conditions for milling parameter process optimization; and meanwhile, aiming at a part of limitation of the standard genetic algorithm, the coding mode and the crossover and mutation probability in the standard genetic algorithm are improved, and the purpose of optimally balancing the processing efficiency and the production cost is achieved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

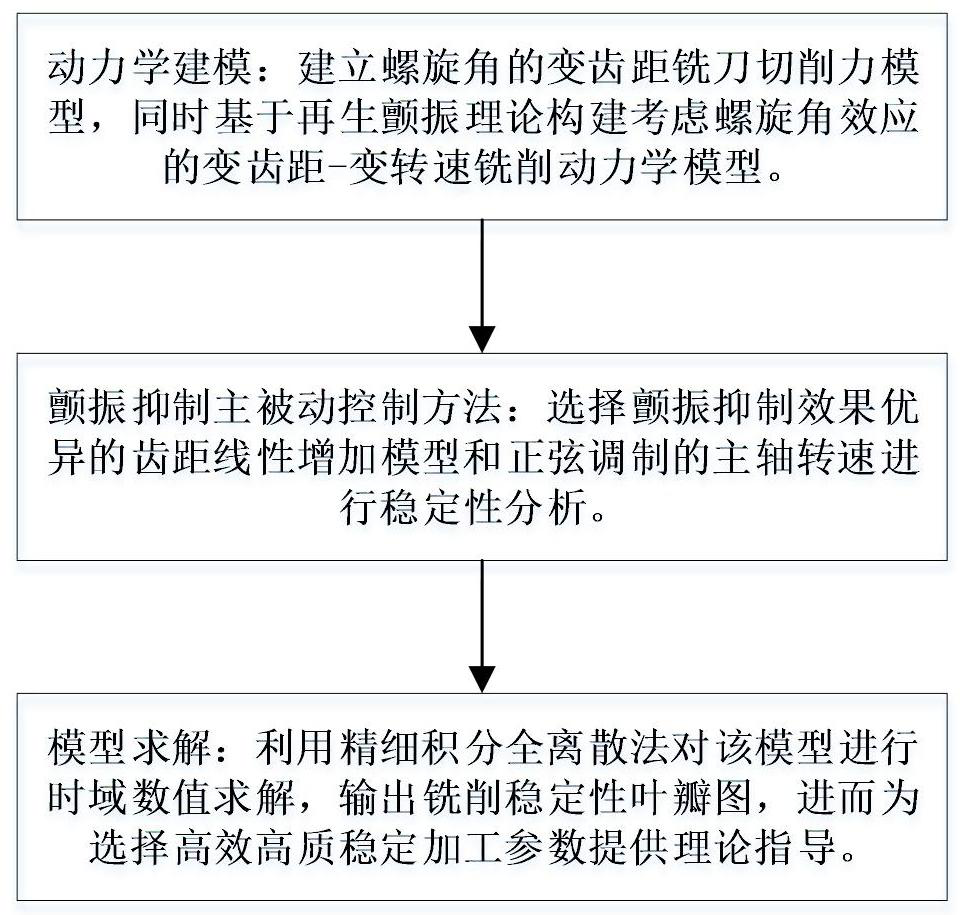

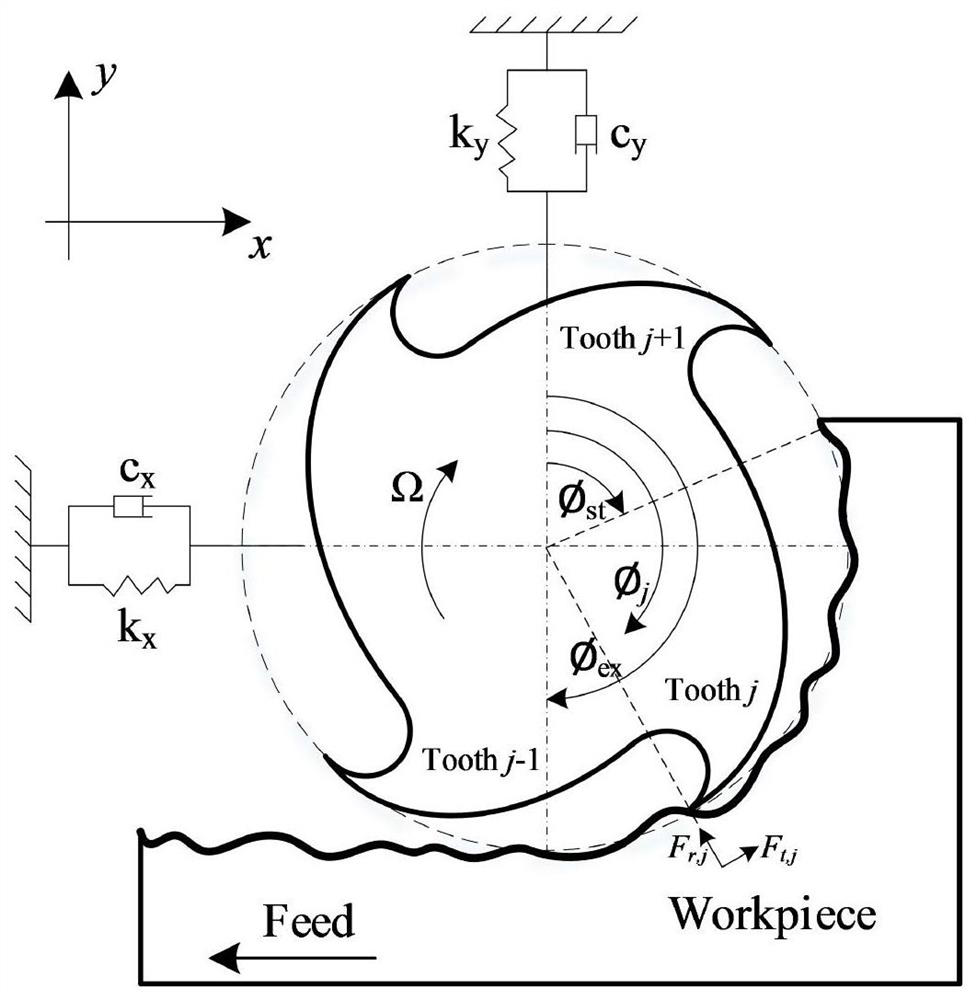

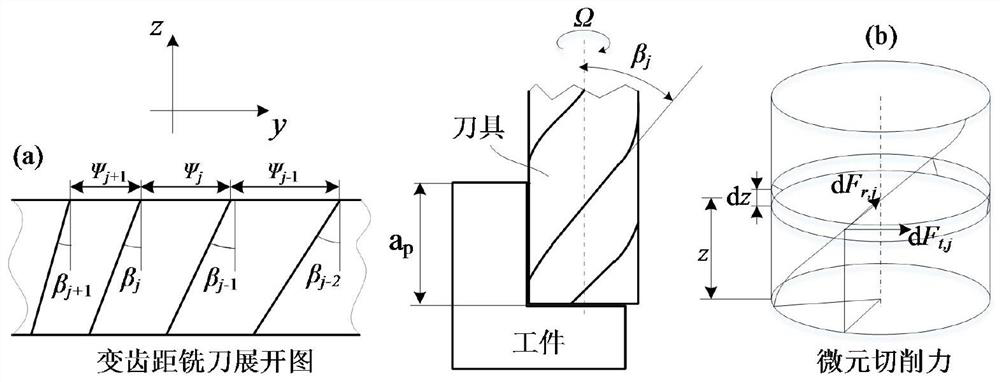

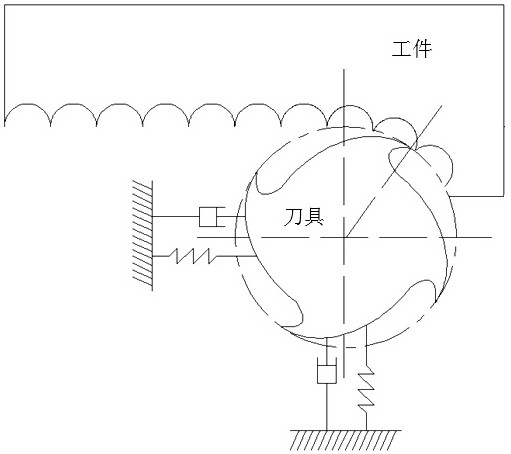

Variable-pitch variable-rotating-speed milling flutter active and passive suppression method considering helical angle effect

PendingCN111914368AIn line with actual processingExpanding the stable domain of millingGeometric CADDesign optimisation/simulationMilling cutterProcess kinetics

The invention discloses a variable-pitch variable-rotating-speed milling chatter active and passive suppression method considering a helical angle effect, which comprises the following steps: S1, establishing a variable-pitch milling cutter cutting model considering the helical angle effect, and constructing a variable-pitch variable-rotating-speed milling process kinetic equation considering thehelical angle effect based on a regeneration chatter theory; S2, based on a disturbance regeneration flutter effect mechanism, achieving an active and passive control method for realizing flutter suppression by selecting a milling cutter tooth pitch linear increasing model and a sinusoidal modulation main shaft rotating speed strategy; and S3, solving the model to obtain a stable lobe graph of themilling process, and taking the stable lobe graph as a theoretical basis for selecting efficient, high-quality and stable machining parameters. A variable-pitch variable-rotating-speed milling kinetic model is constructed by considering the helical angle effect, the fine integral full-discrete method is expanded to be suitable for multi-time-varying time-lag kinetic differential equation numerical solution, and the variable-pitch variable-rotating-speed milling stability lobe diagram considering the helical angle effect can be efficiently constructed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

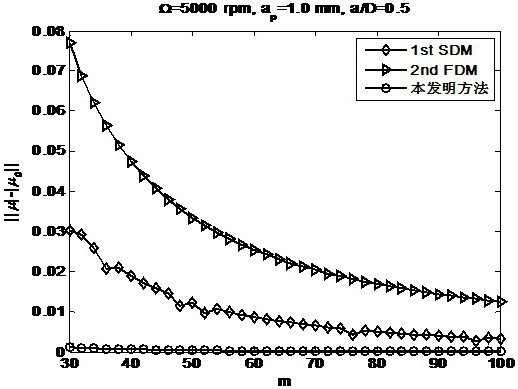

Milling stability prediction method based on implicit exponential time-history difference multi-step method

PendingCN112131713AFast convergenceImprove calculation accuracyDesign optimisation/simulationComplex mathematical operationsNumerical controlAlgorithm

A milling stability prediction method based on an implicit exponential time-history difference multistep method comprises the steps that a milling system is analyzed, a kinetic model is established, then a forced vibration stage is divided into a plurality of time intervals at equal intervals, discrete values at discrete points are solved through the implicit exponential time-history difference multistep method within each time interval, the state transfer matrix of the milling system in the adjacent periods is obtained, the characteristic value of the state transfer matrix is calculated, andthe stability of the milling system is judged according to the Floquet theory, so that the prediction precision and the calculation efficiency are improved, and therefore, proper process parameters can be optimally selected to improve the processing efficiency and reduce the production cost; specifically, in the high-speed cutting process of a numerical control precision machining center, reasonable cutting parameters are selected through a milling flutter stability lobe graph, flutter-free stable cutting machining is achieved, and better surface quality and machining precision are obtained.

Owner:HUNAN INST OF TECH

Method for predicting milling stability based on piecewise Hermite interpolation polynomial and overall discrete strategy

ActiveCN112016203AFast convergenceImprove calculation accuracyDesign optimisation/simulationComplex mathematical operationsKinetics equationMachining system

The invention relates to a method for predicting milling stability based on a piecewise Hermite interpolation polynomial and an overall discrete strategy, which comprises the following steps: firstly,constructing a high-speed milling system kinetic model considering a regeneration effect, and equally dividing a forced vibration stage into a plurality of small time periods on the basis of the high-speed milling system kinetic model; and then adopting a piecewise Hermite interpolation polynomial to integrally approach a period coefficient item, a state item and a time lag item in a kinetic equation to obtain a state transfer matrix of the milling system in an adjacent period, then calculating the spectral radius of the state transfer matrix, and judging the stability of the milling system according to the Floquet theory. Compared with an existing semi-discrete and integral discrete method, the method has the advantages that prediction precision and calculation efficiency are improved, then the high-speed milling flutter stability lobe graph is efficiently and accurately constructed, reasonable cutting parameters are selected through the milling flutter stability lobe graph, flutter-free stable cutting machining is achieved, and better surface quality and machining precision are obtained.

Owner:HUNAN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com