Process damping modeling method for thin-walled part milling

A modeling method and technology of thin-walled parts, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of inability to model reasonably the damping of the small radial depth of cut milling process, and achieve the effect of process damping , the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

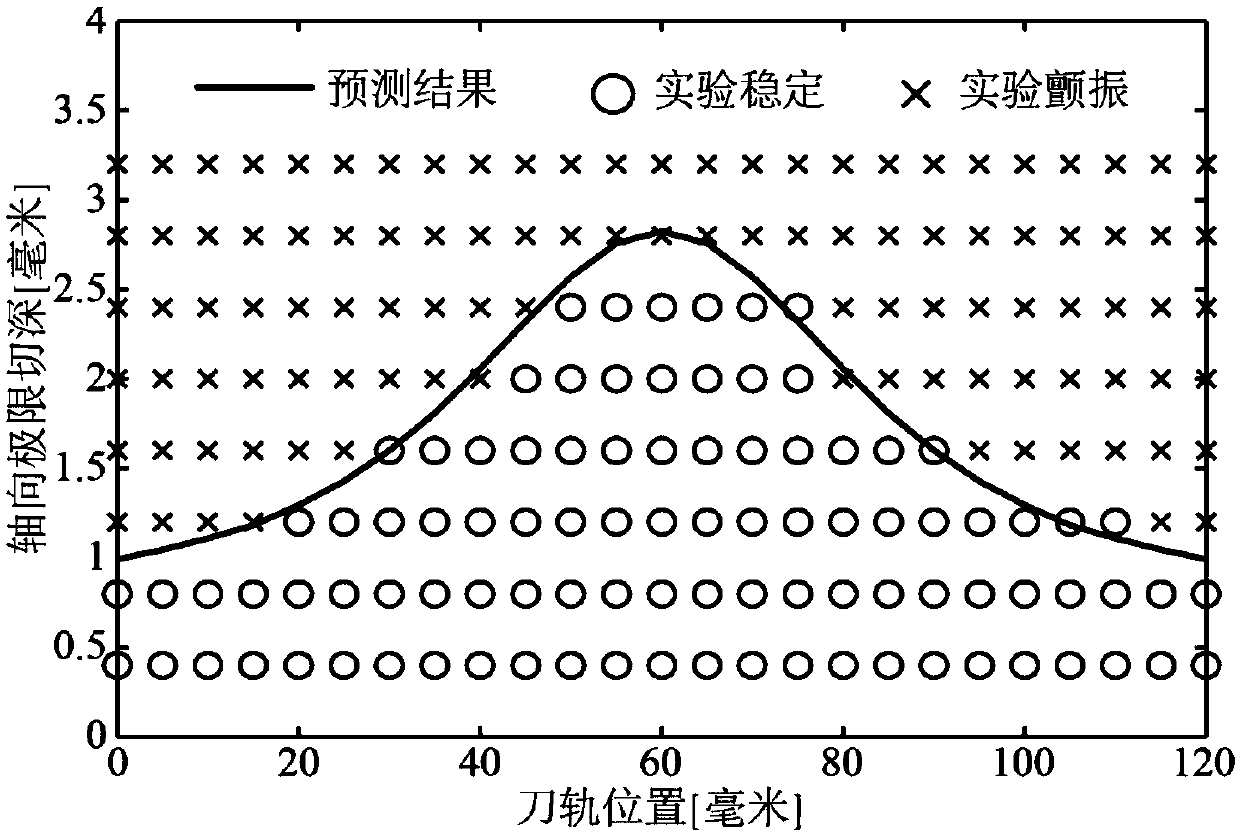

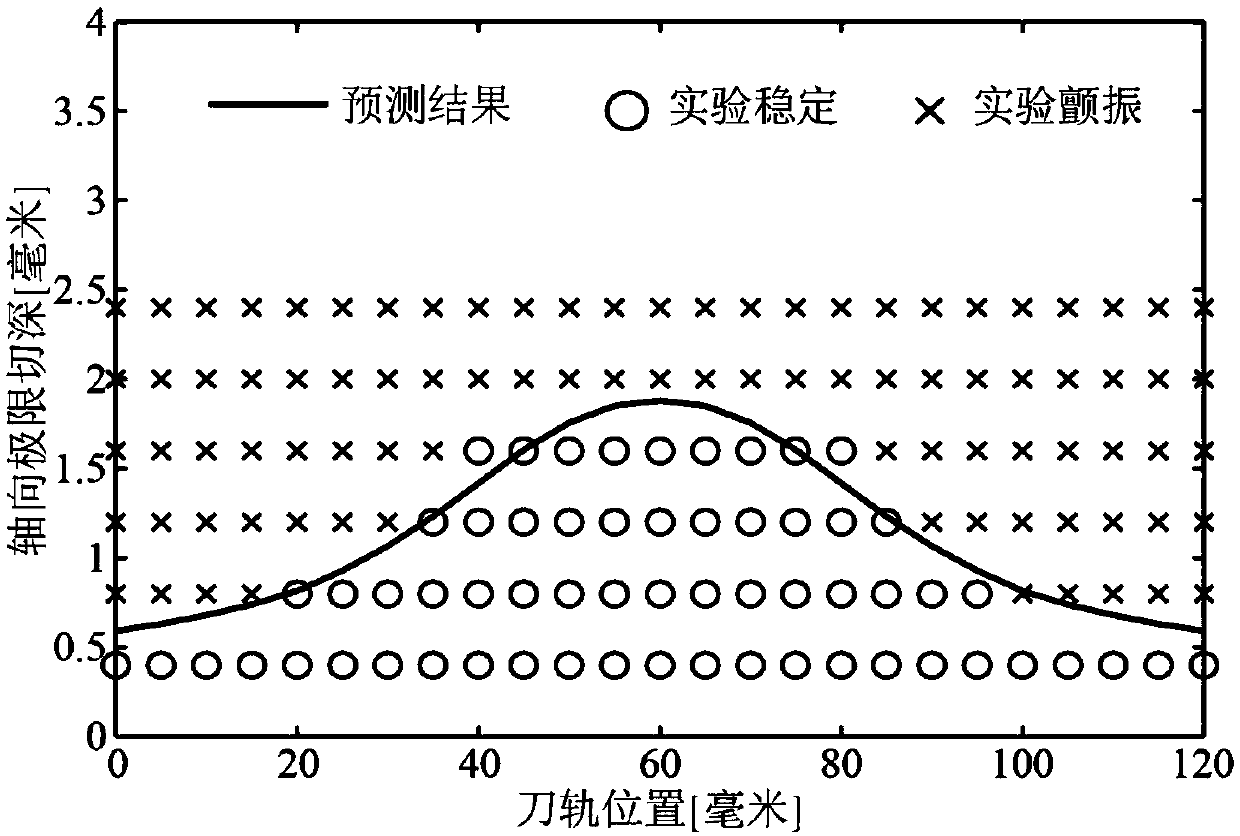

[0043] The number of teeth selected in the experiment is N=4 teeth, the radius R=6 mm, the helix angle β=30 degrees, and the normal forward angle α n = 10 degrees, the flat-bottomed carbide end mill with relief angle γ = 7 degrees adopts the down-milling cutting method in the three-coordinate vertical machining center, and the radial depth of cut is a e = 0.6 mm, the cutting parameters of feed per tooth c = 0.05 mm / tooth were used for the milling test of aluminum alloy thin-walled parts.

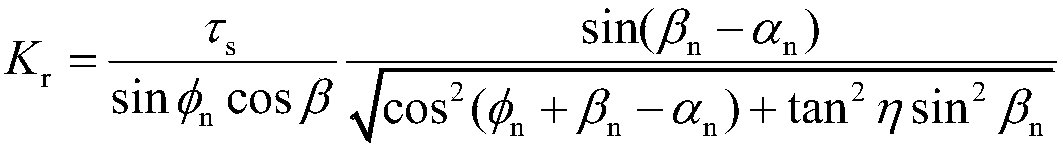

[0044] Step 1. Refer to the cutting data disclosed in the right-angle cutting parameter library to determine the material physical parameter φ n , β n and τ s(Refer to the literature "M. Kaymakci, Z.M. Kilic, Y. Altintas, Unified cutting force model forwarding, boring, drilling and milling operations, International Journal of Machine Tools and Manufacture 54-55 (2012) 34-45"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com