Multi-axis numerical control machining ball-end cutter-axis vector planning method for avoiding interference and flutter

A tool axis vector and interference-avoiding technology, applied in digital control, program control, electrical program control, etc., can solve problems such as inability to guarantee machining stability, achieve the effect of improving reliability and stability, and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 1-8 shown.

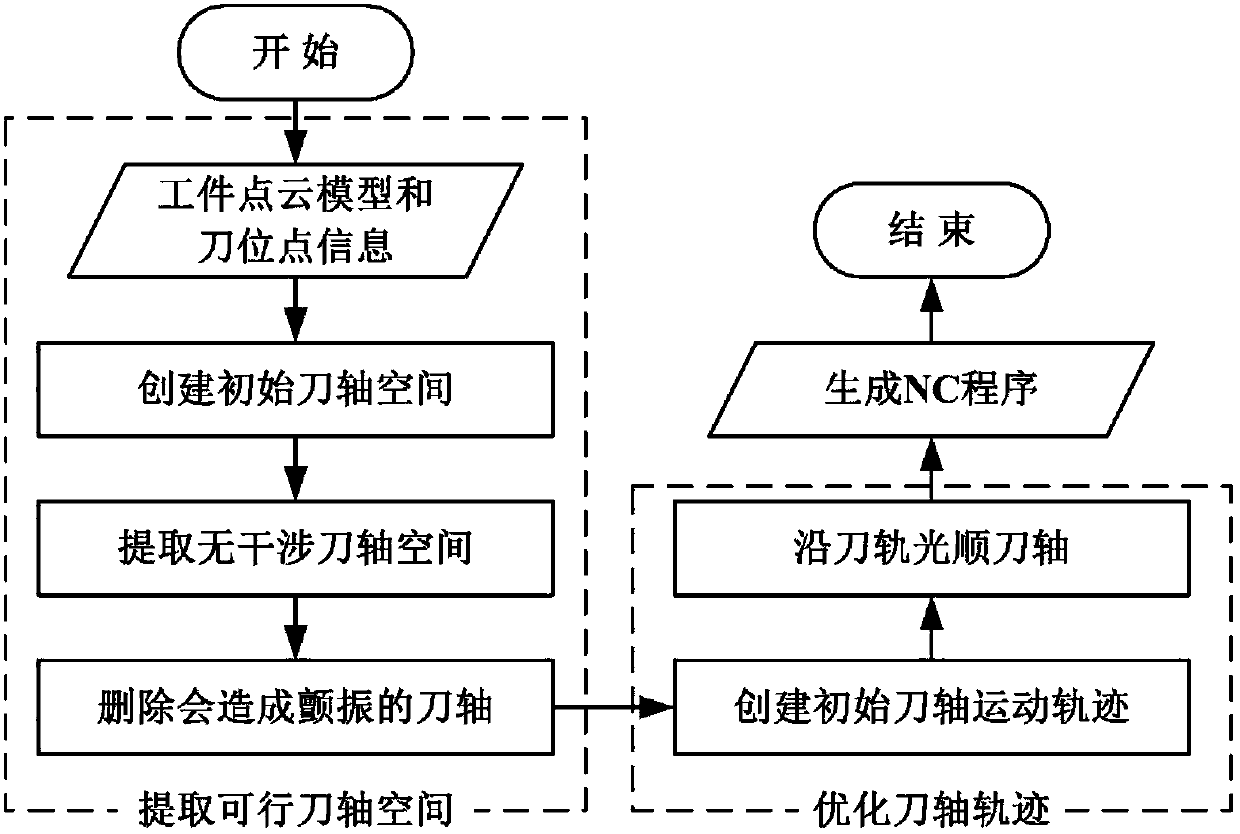

[0023] A tool axis vector planning method for multi-axis CNC machining with ball-end cutters to avoid interference and chatter, such as figure 1 As shown, it includes the following steps:

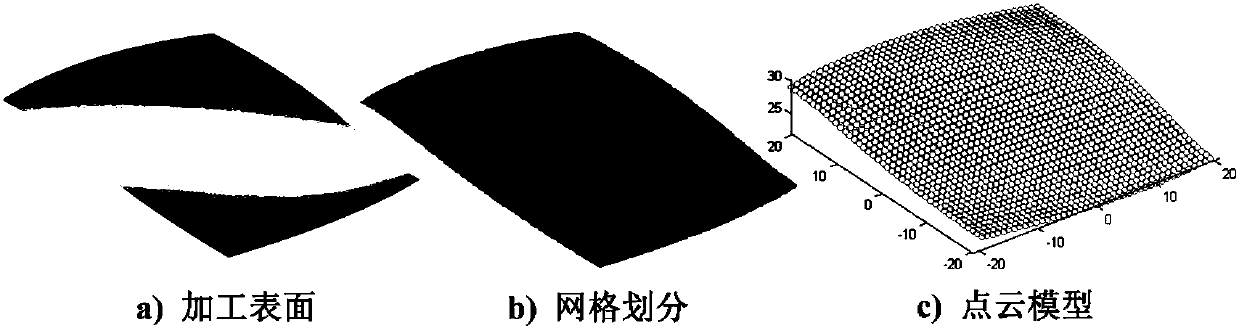

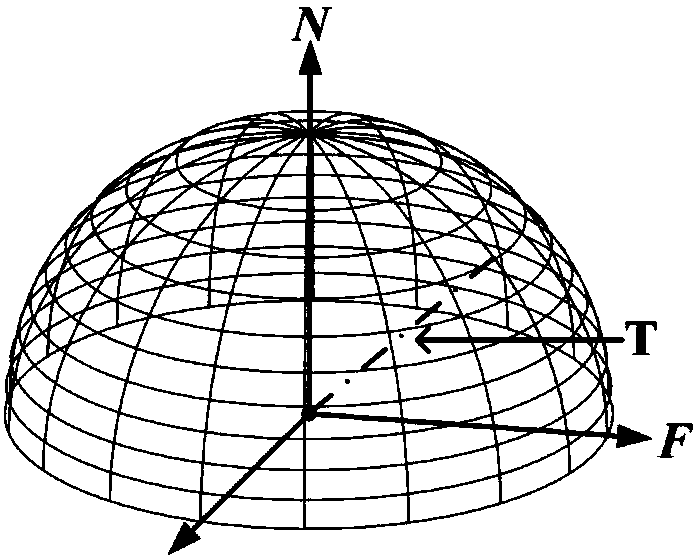

[0024] 1) Extract the surface of the workpiece model in CAD / CAM software such as UG NX, divide the surface of the workpiece into triangular meshes, extract the coordinate information of the vertices of the mesh and import them into software such as Matlab to construct the workpiece surface represented by the point set. In the above process, the surface has undergone three conversions, and the effects of each stage are as follows: figure 2 As shown, the point cloud model is finally obtained. Use methods such as equal cross-section and equal residual height to generate machining tool paths, and extract tool contact and tool posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com