Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329results about How to "Prevent fluttering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

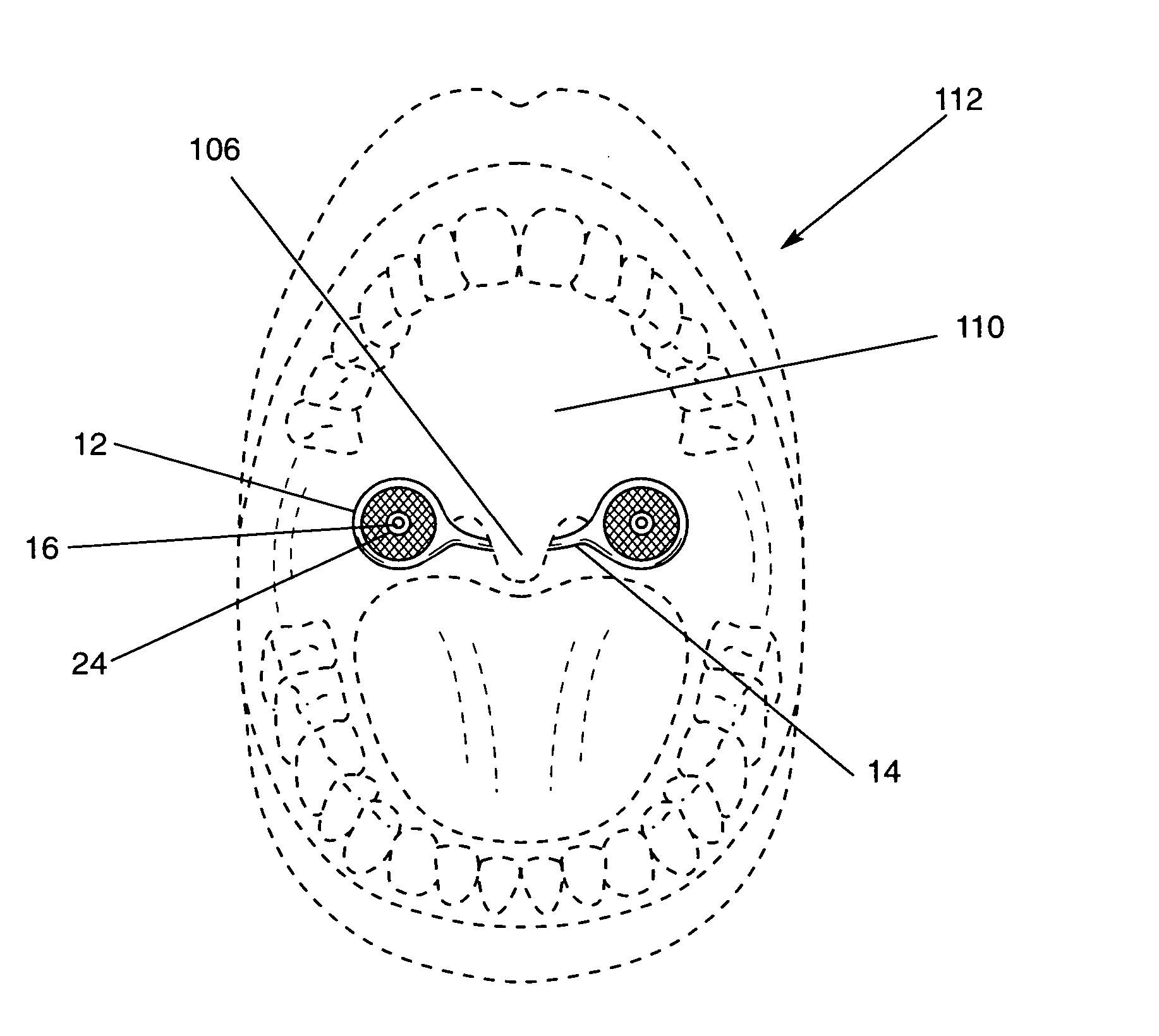

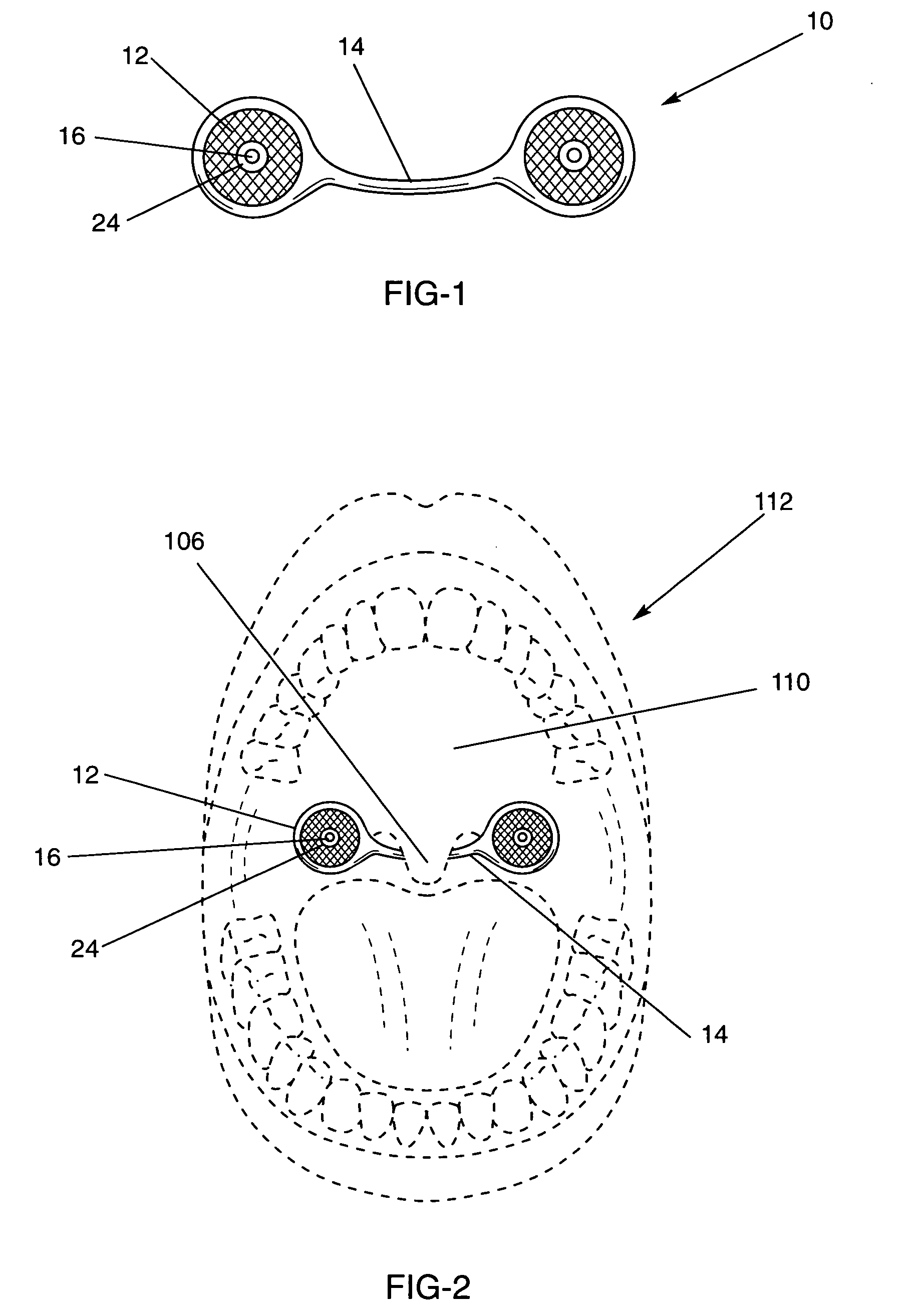

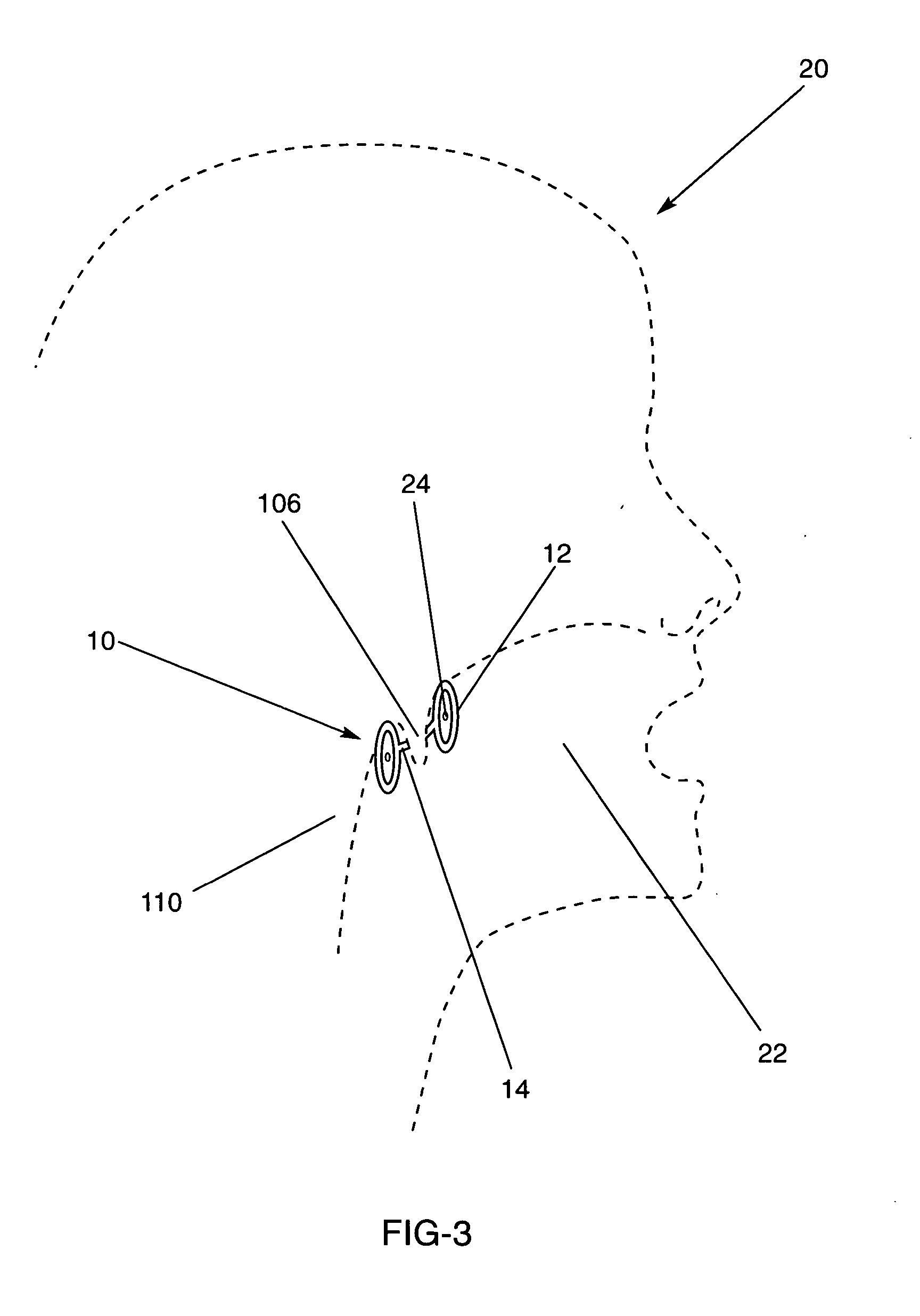

Anti-snoring apparatus and method

InactiveUS20050279365A1Prevent flutteringConstrict movementBreathing masksSnoring preventionAdhesivePalate muscle

An anti-snoring piercing in the form of specially designed thin mesh-like symmetric structure resembling a pair of wings connected symmetrically by means of a middle bar-like bridge. A middle bar-like bridge is mounted under the uvula while the two symmetric wing parts are placed over the soft palate and pierced on the soft palate in the mouth to provide stiffness to uvula-soft palate assembly and thus prevent snoring. A stiffening member is attached to the uvula by means of at least one piercing post with a backing or with an adhesive. Each of these embodiments stiffens the uvula and prevents snoring.

Owner:ARMIJO DENNIS F +1

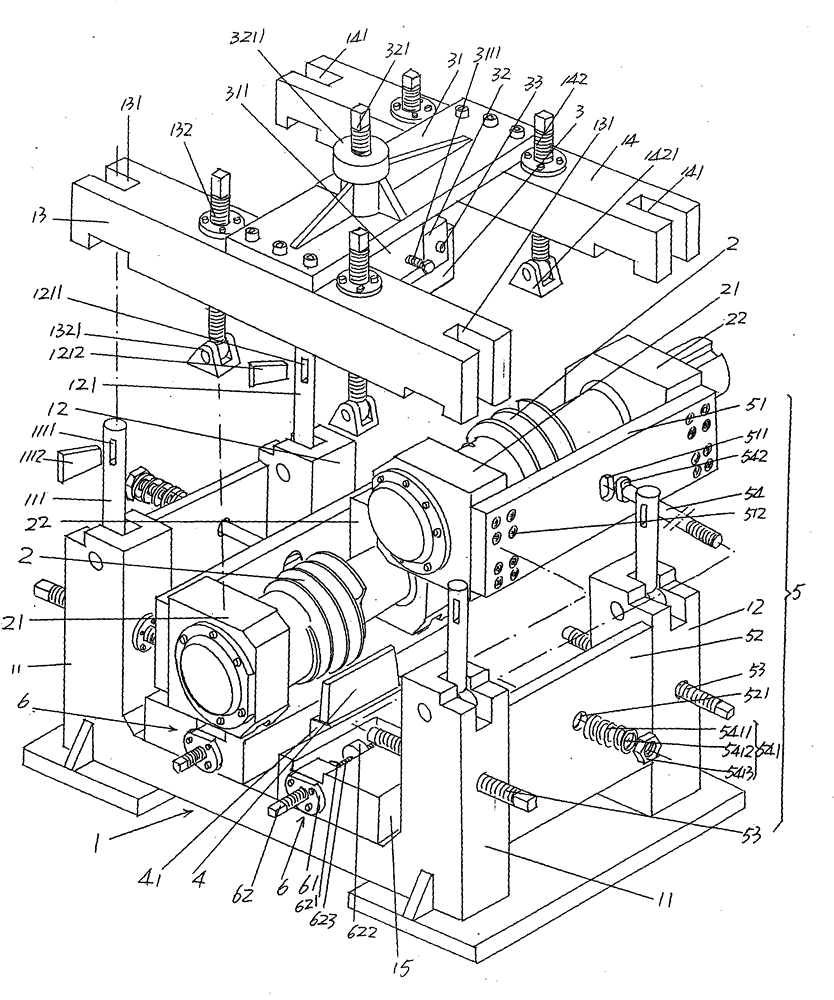

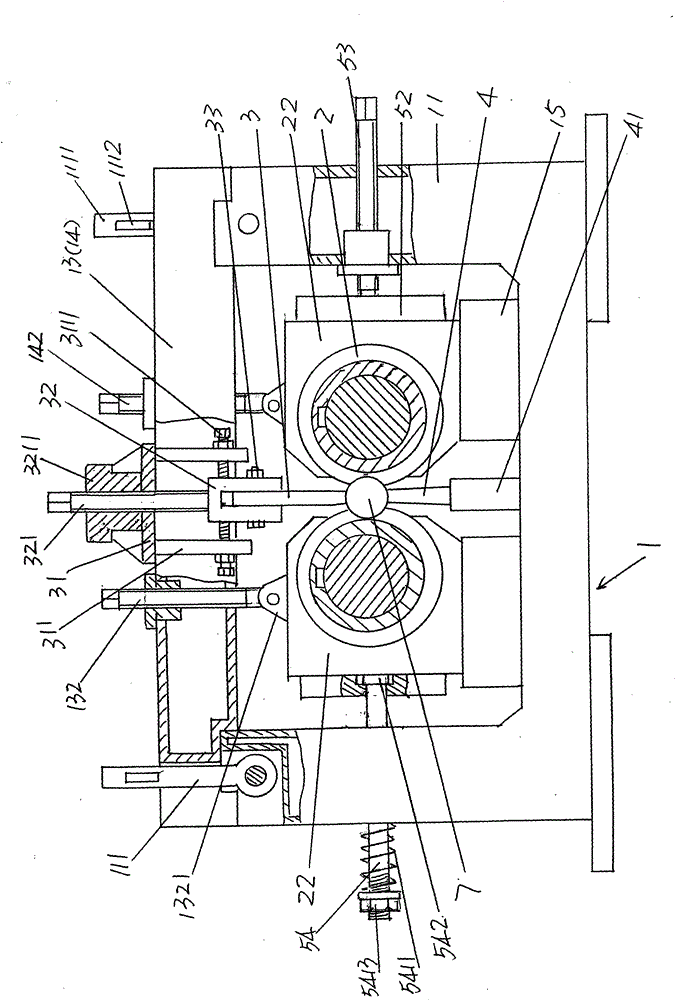

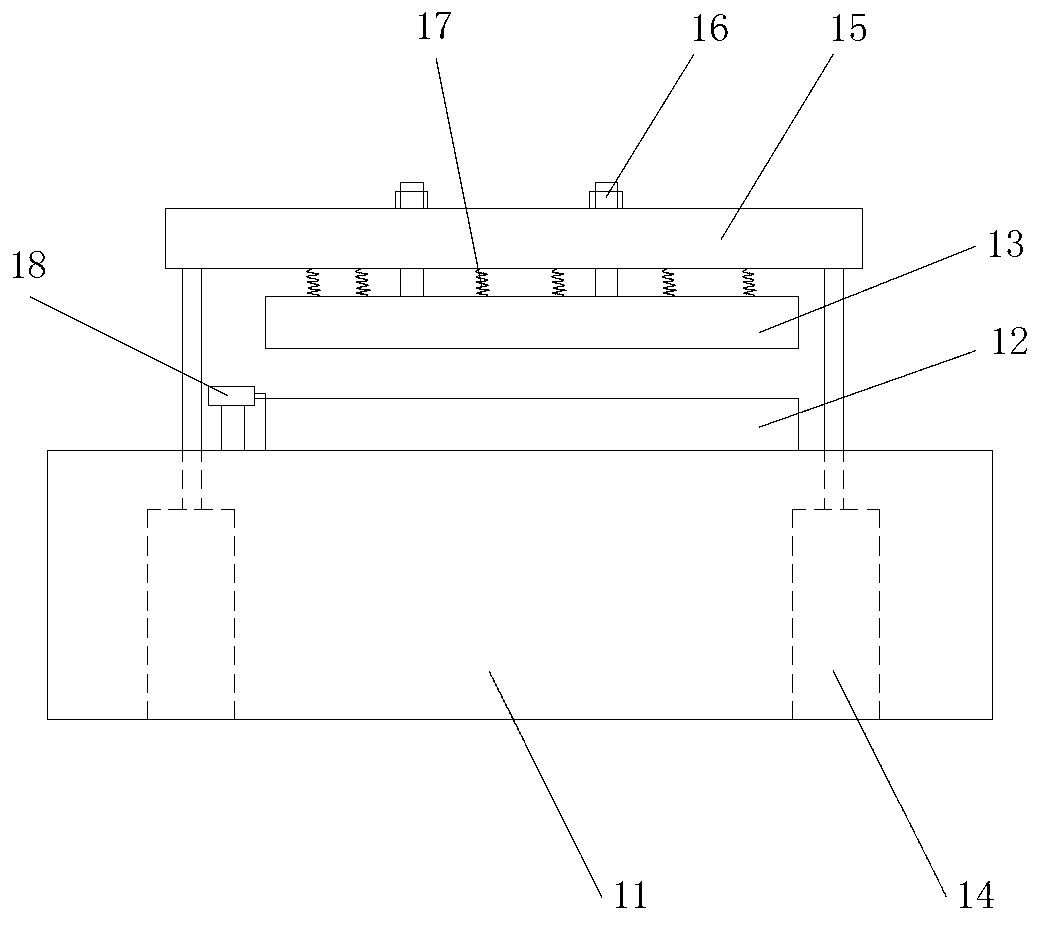

Ball forming mechanism of steel ball rolling mill with quickly assembled ball rolling rollers

The invention discloses a ball forming mechanism of a steel ball rolling mill with quickly assembled ball rolling rollers, and belongs to a steel ball processing machine. The ball forming mechanism comprises a bracket, a pair of ball forming rollers, upper and lower ball stop plates and a pair of ball forming roller parallel distance adjusting device. The ball forming mechanism is characterized in that: two ends of a first upper cross beam are provided with first locking rod grooves, the upper ends of a pair of first bracket upright posts are hinged with first locking rods, and one end of thefirst locking rod is provided with a first mortise; two ends of a second upper cross beam are provided with second locking rod grooves, the upper ends of a pair of second bracket upright posts are hinged with second locking rods, and one end of the second locking rod is provided with a second mortise; a connecting plate is provided with a pull rod head hole, a pull rod head is formed at one end of a pull rod, and the end faces of a pair of adjusting screws are propped against the surface of a connecting block; and the first upper cross beam is provided with a first compaction screw, the lowerend of the screw is hinged with a first pressure pin, the second upper cross beam is provided with a second compaction screw, and the lower end of the screw is hinged with a second pressure pin. The ball forming mechanism is convenient and quick to assemble or disassemble, and can ensure the parallel distance of a pair of ball forming rollers and prevent a shaft seat from carrying the ball forming rollers to cause shake and jump.

Owner:CHANGSHU FEIFAN METALWORK

Head suspension for disk drive and method of manufacturing head suspension

InactiveUS20020181155A1Reduce weightReduce the amplitudeRecord information storageInsulating layers/substrates workingStructural engineeringEngineering

A head suspension for a disk drive has a base (19) to be attached to a carriage, a load beam (21) having a rigid part (27) and a resilient part (29) supported by the base, to apply load on a data read / write head (13) arranged at a front end (27a) of the rigid part, and a flexure (49) attached to the load beam and supporting the head. The rigid part has a multilayer structure consisting of at least three layers including metal layers (28a, 28b) and a resin layer (28c) interposed between the metal layers. The number of layers of the resilient part is smaller than that of the rigid part.

Owner:NHK SPRING CO LTD

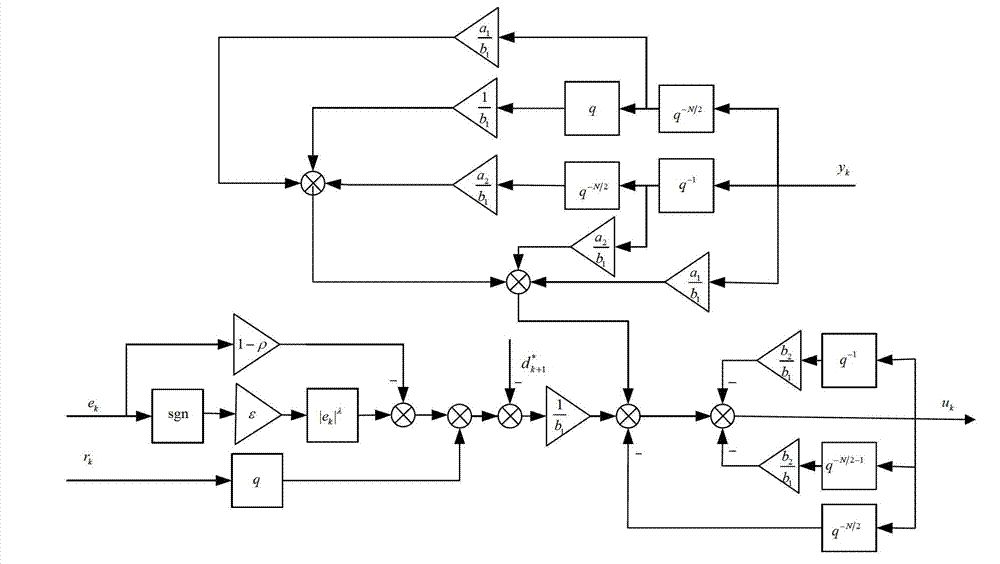

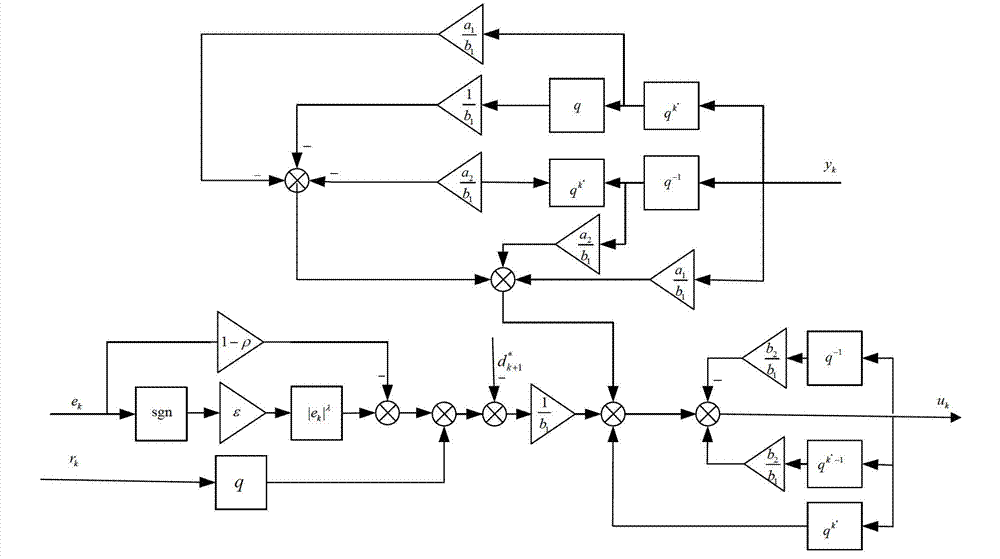

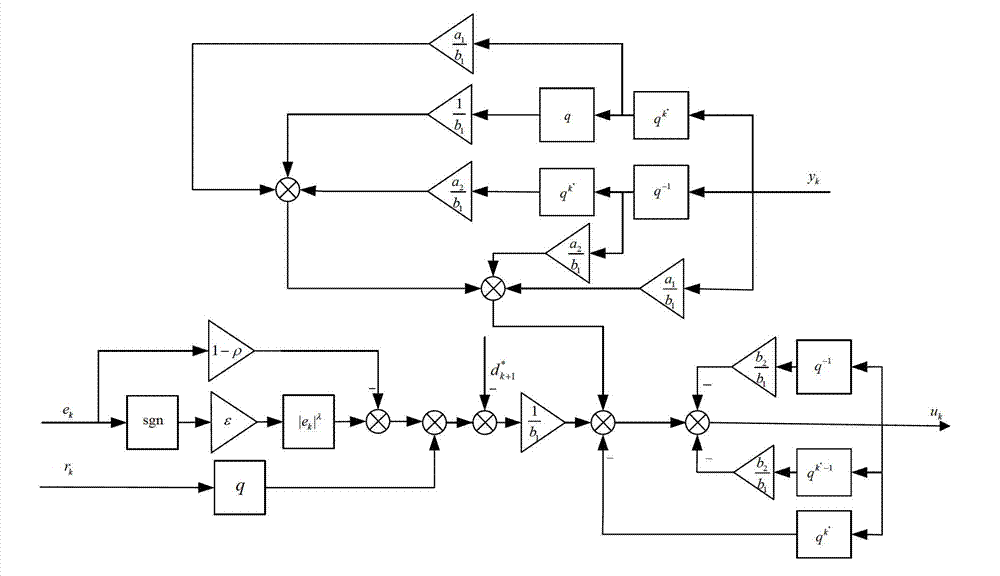

Half-cycle repetitive controller for position servo system

ActiveCN103048921AImplement trackingAchieve inhibitionElectric controllersInternal memoryDynamic equation

The invention discloses a half-cycle repetitive controller for a position servo system. Reference signals with half-cycle symmetry are set, a half-cycle feedback link is constructed, and an ideal error dynamic is formed according to a power attraction law; and according to an ideal error dynamic equation, an e / v signal conversion module is constructed, a signal obtained by calculating through the controller is used as control input of a controlled servo object, and the position servo system changes together with the reference signals by completely eliminating half-cycle symmetrical interference signals. By the half-cycle repetitive controller, the internal memory of the controller can be obviously reduced and the periodic interference is quickly and completely suppressed under the half-cycle symmetrical reference signals, and the half-cycle repetitive controller has high cost performance.

Owner:辽宁吉尔电子有限责任公司 +1

Milling process parameter optimization method

ActiveCN104076733AExcellent milling process parametersImprove productivityNumerical controlProduction rateProcess engineering

The invention provides a milling process parameter optimization method and belongs to the field of cutting machining processes. The coupling effect of a machining device dynamic behavior and the high-speed milling process is considered in the method, the maximum milling extreme cutting depth changing with the rotating speed of a machine tool spindle and shortest machining time of single part are regarded as optimization targets, a milling process parameter optimization model based on cutting stability and productivity is established, and optimal milling process parameters of a milling process parameter combining scheme under the condition that a cutting state is stable when the productivity is maximum are calculated. The milling process parameter optimization method can improve the cutting depth to the most extent during milling, decrease feed times, obtains maximum productivity, meanwhile ensures the cutting stability and avoids flutter. In addition, the milling process parameter optimization method can be applied to the high-speed milling process, the defect that the interactive effect of the machining device dynamic behavior and the milling process parameters is not considered in the high-speed milling process at present is overcome, and optimal high-speed milling process parameters can be obtained.

Owner:TONGJI UNIV

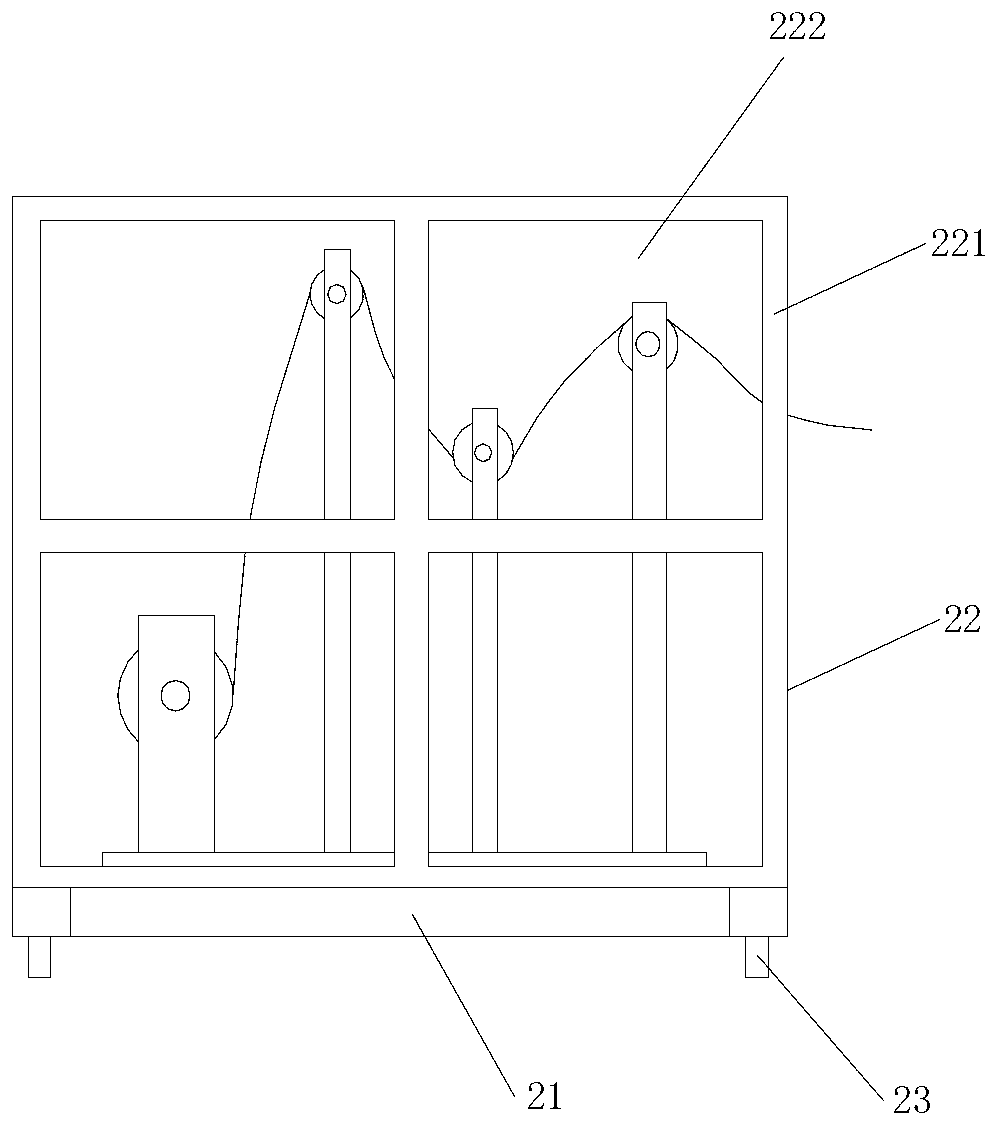

Double-point coating production line for hot-melt adhesive padding cloth

InactiveCN102697213APrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Turbine nozzle airfoil

ActiveUS20050008485A1Easily be redesignedPrevent flutteringPropellersReaction enginesSuction stressTurbine

An easily producible turbine nozzle for a gas turbine engine is provided, which is capable of preventing flutter of the turbine nozzle during operation of the gas turbine engine. The turbine nozzle comprises airfoils stacked along the stacking axis. The high curvature portions on suction surface in airfoil section successively formed along the stacking axis of the airfoil describe a parabola line that curves toward the pressure side of the airfoil when seen from the front or rear of the turbine nozzle. The high curvature portions on suction surface in airfoil section curve most at the center along the stacking axis of the airfoil from a straight line that connects with a first intersection between the parabola line and an inner band in the turbine nozzle and with a second intersection between the parabola line and an outer band in the turbine nozzle. The maximum curvature falls within a range from 0.02 to 0.03-fold of the stacking axis of the airfoil.

Owner:IHI CORP

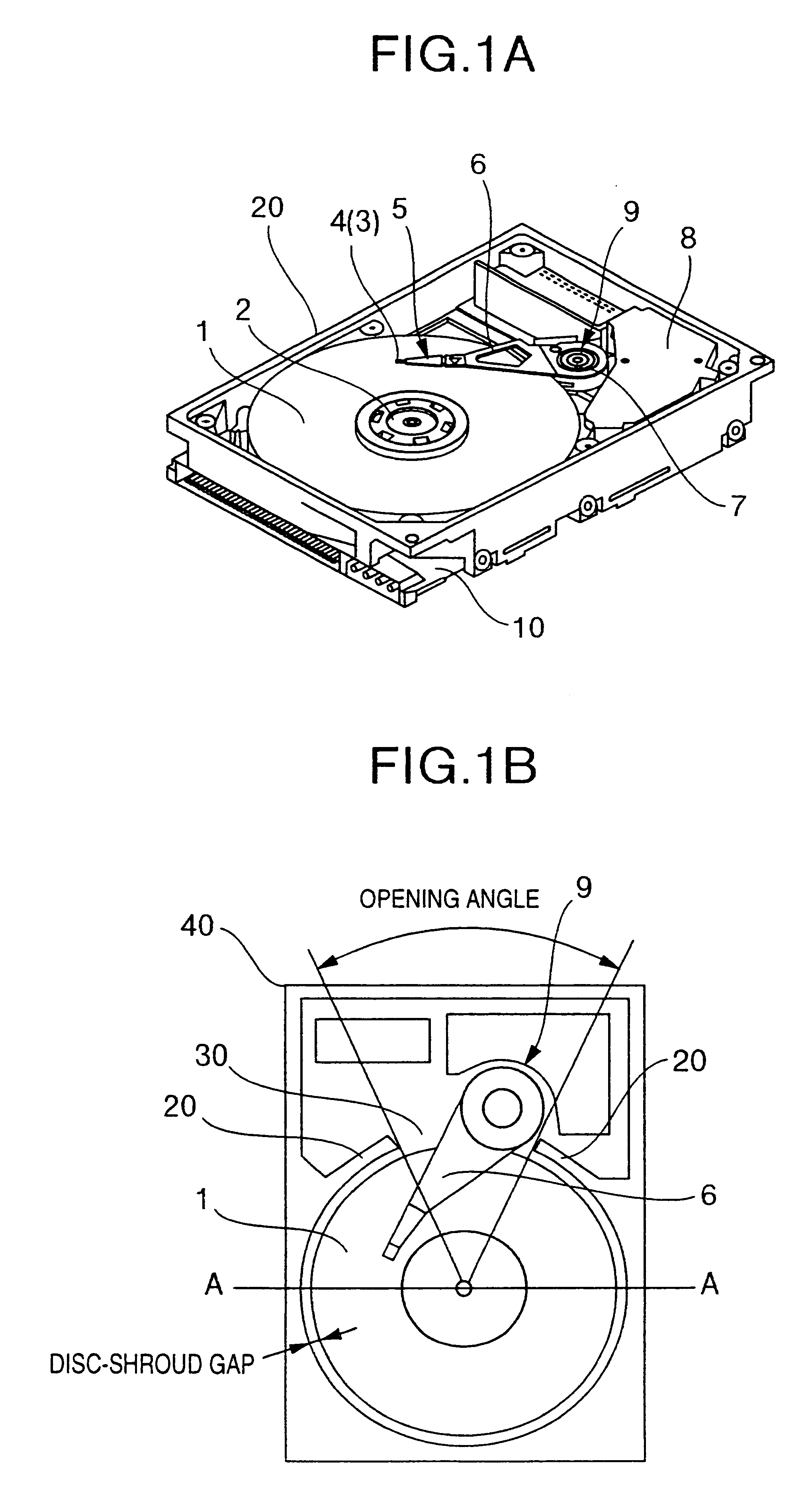

Magnetic-disc unit with gap between disc and shroud

InactiveUS6665139B2Prevent flutteringHigh positioning accuracyApparatus for flat record carriersUndesired vibrations/sounds insulation/absorptionArcuate shapeEngineering

In a magnetic disc apparatus including a plurality of magnetic discs mounted on a spindle, arms supporting magnetic heads, a rotary actuator for the arms, and a housing having an arcuate-shaped shroud, the improvement wherein gaps between the shroud and the sides of outer peripheries of the magnetic discs are larger than 0.1 mm and less than 0.6 mm. An open space is located, downstream of the arms with respect to the air flow on surfaces of the magnetic discs, the open space being devoid of the shroud. An opening is provided in the shroud, upstream of the arms with respect to the air flow and having a greater width than a width of the gaps defined between the magnetic discs and the shroud, and a bypass channel is provided which communicates between the opening and open space.

Owner:WESTERN DIGITAL TECH INC +1

Five-axis linkage simulation machining method of dental prosthesis

InactiveCN101829801AConsistent shapeHigh precisionMilling equipment detailsProcessing accuracyOral Prosthesis

The invention discloses a five-axis linkage simulation machining method of a dental prosthesis, which comprises the following steps: firstly, carrying out automatic identification and extraction on the characteristic surfaces of the tips, iliac crests, nests and grooves of the dental prosthesis; then, determining the machining tool path of five-axis linkage high-speed milling according to the original appearance of the occlusal surface of an offending tooth and the changing rule of the normal vectors of all points on each characteristic surface; and finally moving a micro-diameter ball-head cutter under the command of spline interpolation machining numerical control codes along the machining tool path to obtain the dental prosthesis by milling. The simulation machining method of the invention solves the problems of low machining accuracy, poor machining pattern, long manufacturing period, poor occlusion function and easy detention of meal residue of the existing dental prosthesis, improves the machining speed and accuracy of the dental prosthesis, and effectively reduces the manufacturing cost.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Working robot system and method for live line maintaining of transformer substation

ActiveCN108673467AReduce weightStable center of gravityManipulatorApparatus for overhead lines/cablesRobotic systemsForeign matter

The invention discloses a working robot system and method for live line maintaining of a transformer substation. The system comprises a robot body, a live line working tool, a remote control terminal,and a moving and carrying vehicle for conveying the robot body, wherein the robot body comprises a moving chassis, and an insulating lifting arm which is arranged on the moving chassis; a small fly jib is connected to the front end of the insulating lifting arm; a hotline working platform for positioning the hotline working tool is arranged at the front end of the small fly jib; the small fly jibis connected to the hotline working tool through a rapid connecting device; the electric working tool comprises a foreign matter cleaning tool, a conductor repairing tool, an insulator sweeping tooland / or a dry ice washing tool. The system has the beneficial effects that a multi-sensor information fusion technology is adopted; various types of sensors are mounted on the robot and used for sensing the robot body and the information of surrounding environment, so that the operation safety and reliability of the robot can be improved.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Magnetic disc unit

InactiveUS6751050B1Prevent flutteringHigh positioning accuracyCarrier constructional parts dispositionApparatus for flat record carriersEngineeringPressure difference

A magnetic disc unit which can restrain occurrence of flutter so as to countermeasure such a problem that the larger the rotational speed of discs, the higher the flutter, causing heat positioning errors, in order that the high rotational speed and high positioning accuracy are consistent with each other. Discs are surrounded along their outer peripheries by a shroud (outer wall) while a gap between end faces of the discs and the shroud is decreased to a predetermined distance, thereby to eliminate air pressure differential between opposite surfaces of each of the discs in order to reduce flutter.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

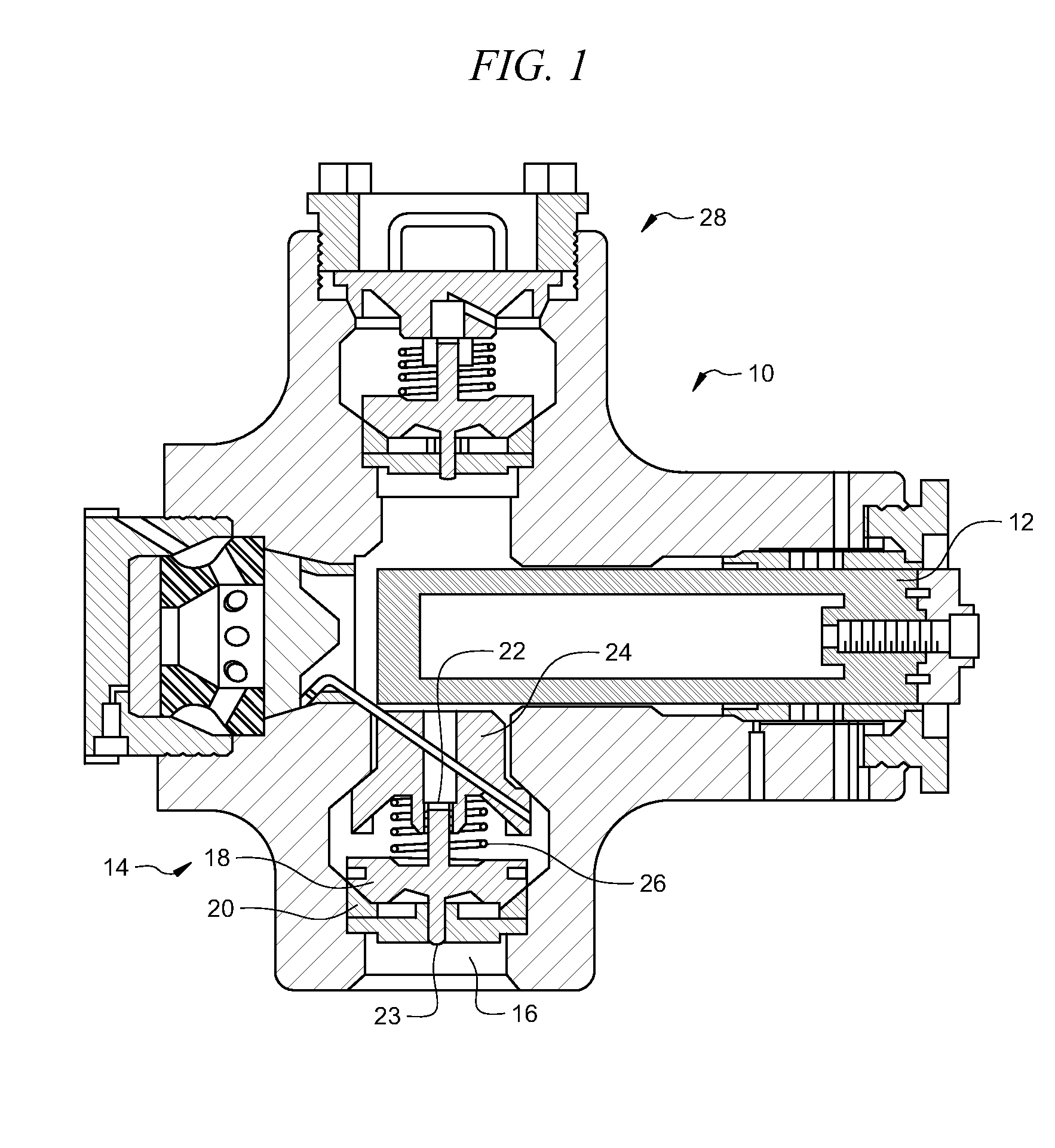

Quick lift zero flutter oil service pump valve

InactiveUS20090142199A1Open fastPrevent flutteringFlexible member pumpsCheck valvesCavitationEngineering

A suction valve for a positive displacement pump. Two springs are used to actuate a valve plug. A first spring has an uncompressed length greater than a distance between a spring retainer and the valve plug, providing a preload force closing the valve. A second spring has an uncompressed length less than the distance between the retainer and the plug, providing closing force to the plug only after a preselected valve lift. The first spring is relatively light and permits rapid opening of the valve to avoid cavitation. The second spring increases the effective spring constant when the valve is open to prevent flutter and to assist in closing of the valve upon commencement of a discharge pump stroke.

Owner:HALLIBURTON ENERGY SERVICES INC

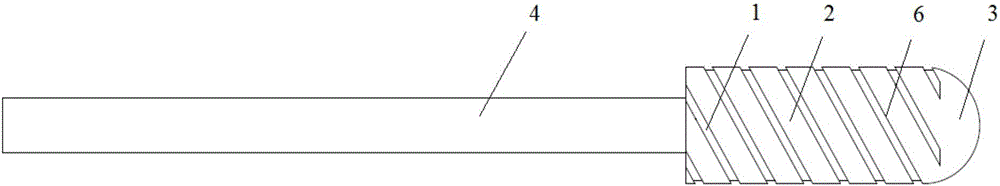

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

Rotationally symmetrical tool for cutting material surfaces and method for the production of such a tool

ActiveUS20130025429A1Prevent flutteringCost-effectiveSupport wheelsFlexible-parts wheelsCircular discEngineering

A tool has disks or ring disks arranged for metal-cutting, which are stacked on top of each other in an overlapping fashion and engage into each other at their incisions which reach from the outer circumference up to the center point of the disks or the inner circumference of the ring disks. The incisions of the directly adjacent disks or ring disks are respectively angularly offset by 360° / n, with n being the number of the disks or ring disks. A production method is also provided for such a tool, in which the disks or ring disks are incised up to the center point or inner circumference, are completely slid into each other at the incisions, folded towards one another and displaced until an angular offset of the incisions of 360° / n is produced.

Owner:GERD EISENBLATTER GMBH

Predicating method for wind turbine blade airfoil fluttering

InactiveCN103810341AAvoid Blade FlutterAvoid hazards and consequencesSpecial data processing applicationsTip-speed ratioWind force

The invention relates to a predicating method for wind turbine blade airfoil fluttering. Fluttering intervals are firstly predicated through a characteristic value method, according to the fluttering intervals which are obtained according to the characteristic value method, detailed solving is performed at the critical tip speed ratio or nearby the position where changes are violent, other tip speed ratios can be selected according to needs and do not need to be selected according to step lengths, the blindness of a time domain analysis method can be obviously reduced, in this way, through adjusting the tip speed ratios, divergence and convergence conditions of various pneumatic responses can be observed, the fluttering intervals which can be obtained are adjusted, and meanwhile the violent degree of fluttering is judged. Fluttering section results obtained through the two methods can be mutually verified and supported, wind turbine blades are promoted to operate safely and stably, blade fluttering is prevented from occurring, and therefore all kinds of risks and results are avoided.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

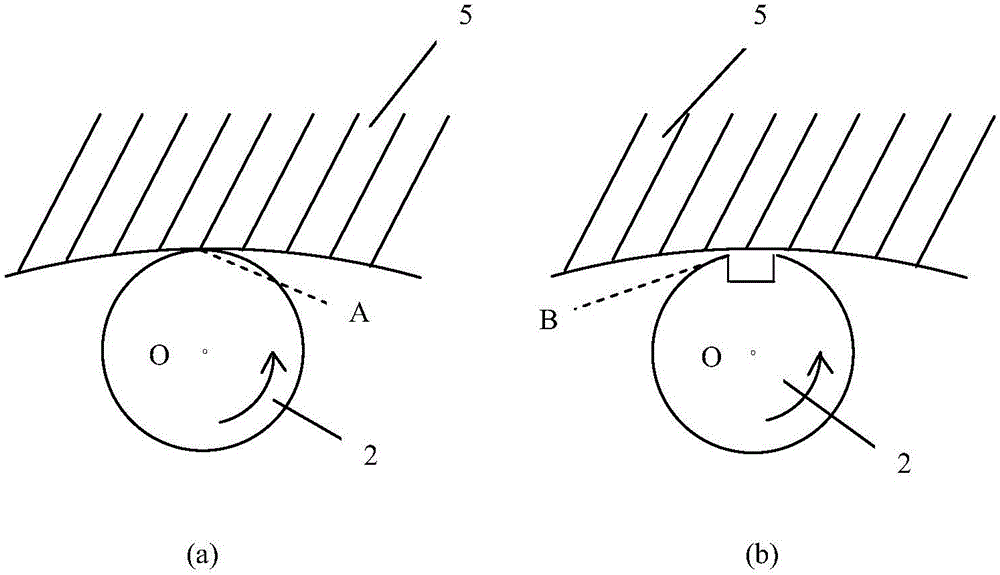

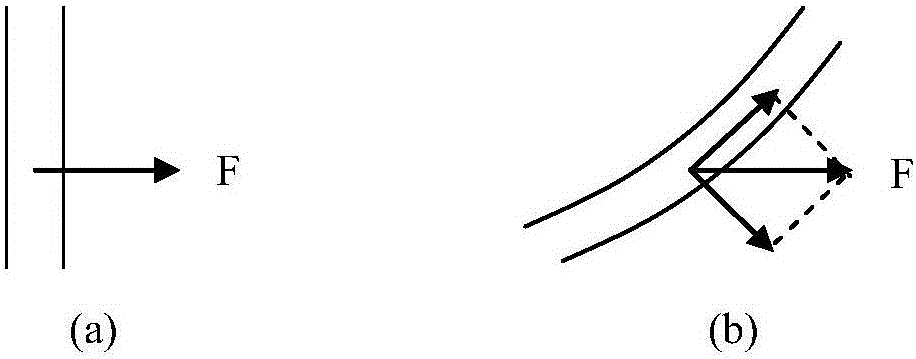

Speed change control method for cam non-circular grinding based on constant contact arc length

InactiveCN101323099AImprove machining accuracyAvoid shockBelt grinding machinesControl mannerChange control

The invention relates to a variable speed control method based on invariable contact arc length in cam non-circle grinding. The method provides a non-circle grinding control method which controls variable speed rotation of a work piece according to the principle of invariable contact arc length in regard to the problem how to ensure variable grinding amount in the cam non-circle grinding. The method better overcomes the problem of constantly changing of grinding arc length and the grinding amount at the position of each grinding point caused by obvious change of the curvature radius of the cam profile. Compared with the existing method of controlling constant angle speed and constant line speed, the method is more beneficial to avoiding impact and vibration caused by violent change of grinding force, thus obtaining higher processing precision and better surface quality of the work piece.

Owner:SHANGHAI UNIV

VTOL/STOL ducted propeller aircraft

InactiveUS7281680B2Avoid vibrationPrevent flutteringAircraft navigation controlVertical landing/take-off aircraftsLouverDucted propeller

The aircraft incorporates a single ducted propeller. The fuselage Bridges over the ducted propeller assembly, and is shaped in a way that the incoming air can smoothly flow into the propeller area. The duct has an aerodynamically shaped frontal area, and an aft extension, which forms the tail section. The wings are attached to the side of the duct. The ducted propeller assembly also contains louvers, which run span wise, to redirect the outgoing air in horizontal direction. During vertical take-off or landing, the propeller has a horizontal plane of rotation, after take-off the whole craft entirely tilts forward approximately 26 degrees to transition into horizontal wing born flight. During vertical flight, the aircraft is controlled by control louvers installed inside the ducted propeller assembly in the propeller slipstream.

Owner:MELKUTI ATTILA

Image reading apparatus

ActiveUS20080297857A1Avoid it happening againQuality improvementPictoral communicationLeading edgeTrailing edge

An image reading apparatus capable of preventing the occurrence of a streak and reading a quality image from the leading edge to the trailing edge of a original. An original is conveyed along a convey pass. The original being conveyed is guided by a guide member, at least part of the guide member being transparent. An image of the original being conveyed is read by an image sensor through the guide member. Airflow is generated, the airflow being blown into the convey pass from a location upstream in a conveying direction compared to a location of the image sensor. The guide member has a convex portion disposed at a location upstream in the conveying direction compared to the location of the image sensor.

Owner:CANON DENSHI KK

Construction method of time-varying dynamic model for high-feed turning of external thread members

ActiveCN107368665AAids in analytical researchAdjust and optimize processing parametersGeometric CADSpecial data processing applicationsVirtual workStrain energy

The invention relates to a construction method of a time-varying dynamic model for high-feed turning of external thread members; the method comprises the steps of I, using, based on the Rayleigh beam vibration theory, a nose track spiral line equation as an integration object to solve a workpiece strain energy and kinetic energy equation for a tool that performs cutting along the nose spiral track; II, considering, based on an established tool instant cutting force model, the impact of 'quasi-regeneration effect' upon instant cutting force for turning a large-pitch thread member so as to correct the existing instant cutting force model and perform numerical solution; III, describing boundary conditions of thread member turning through a vibration mode function, and performing solving; IV, establishing and solving a workpiece vibration model according to the virtual work principle and the method of separation of variables. The large-pitch external thread member vibration equation established herein is capable of predicting a sharply varying position of a workpiece upon vibration and displacement, and can assist in adjusting and optimizing parameters of a machining process for large-pitch thread members.

Owner:HARBIN UNIV OF SCI & TECH

Turbine nozzle airfoil

ActiveUS7118330B2Easily be redesignedPrevent flutteringPropellersReaction enginesSuction stressTurbine

An easily producible turbine nozzle for a gas turbine engine is provided, which is capable of preventing flutter of the turbine nozzle during operation of the gas turbine engine. The turbine nozzle comprises airfoils stacked along the stacking axis. The high curvature portions on suction surface in airfoil section successively formed along the stacking axis of the airfoil describe a parabola line that curves toward the pressure side of the airfoil when seen from the front or rear of the turbine nozzle. The high curvature portions on suction surface in airfoil section curve most at the center along the stacking axis of the airfoil from a straight line that connects with a first intersection between the parabola line and an inner band in the turbine nozzle and with a second intersection between the parabola line and an outer band in the turbine nozzle. The maximum curvature falls within a range from 0.02 to 0.03-fold of the stacking axis of the airfoil.

Owner:IHI CORP

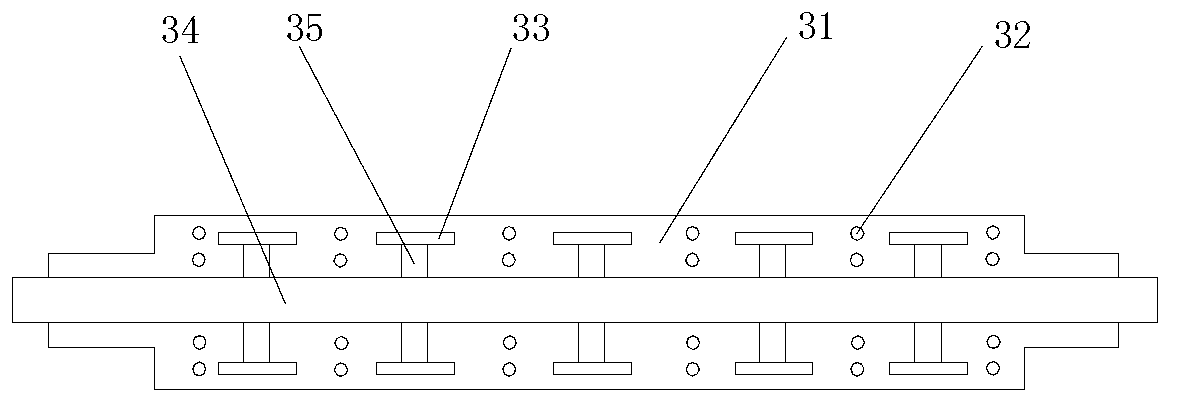

Head suspension for disk drive

InactiveUS6967820B2Suppress tremorPrevent flutteringDisposition/mounting of recording headsRecord information storageMechanical engineering

A head suspension for a disk drive has a flexure extended from a load beam toward a plate. The flexure is structured to prevent fluttering. The head suspension has the plate attached to a carriage and turned around a spindle, the load beam having a rigid part and a resilient part and supported by the plate with the resilient part adjoining an end of the plate, to apply load on a slider arranged at a front end of the load beam, the flexure having a head to write and read data to and from a hard disk and a conductive path to transmit write and read signals to and from the head, the flexure being attached to the load beam and extended toward the plate, and a fixing piece formed on the flexure. The fixing piece is fixed to a resilient material at the end of the plate.

Owner:NHK SPRING CO LTD

Charged maintenance operation robot for transformer substation equipment

ActiveCN108748073AReduce weightStable center of gravityProgramme-controlled manipulatorGripping headsSimulationForeign body

The invention discloses a charged maintenance operation robot for transformer substation equipment. The charged maintenance operation robot includes a robot body; the robot body comprises a moving chassis and an insulating lifting arm arranged on the moving chassis; a small flying arm is connected to the front end of the insulating lifting arm, a charged operating platform used for storing a charged operating tool is arranged at the front end of the small flying arm, and the small flying arm is connected with the charged operating tool through a fast connecting device; and the charged operating tool includes a foreign body cleaning tool, a wire repairing tool, and an insulator cleaning tool. The charged maintenance operation robot has the beneficial effects that a multi-sensor informationfusion technology is adopted, various sensors installed on the robot are used to sense the information of the robot body and the surrounding environment, and the safety and reliability of the robot operation are improved.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Three-wheel pedal-style wheelchair

A three-wheel pedal-style wheelchair which includes a roller at a side, close to the ground, of the wheelchair, wherein the roller prevents the wheelchair from turning over, a steering wheel arranged at a side of the wheelchair, and two front wheels respectively arranged at two opposite sides of the wheelchair, wherein the two front wheels comprises a driving wheel led to rotate forward or backward by a user stepping and a loose wheel, wherein when the wheelchair turns to a direction in a small radius, the steering wheel is considerably rotated to a direction and the driving wheel is rotated forward, wherein when the wheelchair turns to another direction, the steering wheel is considerably rotated to a direction and the driving wheel is rotated backward. Accordingly, the wheelchair is easily controlled to have a small turn, like whirling in one spot, to move and to turn safely.

Owner:TOHOKU TECHNO ARCH CO LTD +1

Rotating disk storage device with charging filter

InactiveUS20050195523A1Improve rigidityLarge in charging quantityApparatus for flat record carriersDispersed particle filtrationFilter mediaPleat

A rotating disk storage device is provided with a charging filter capable of efficiently removing dust staying in the interior of the device. In one embodiment, a charging filter is disposed below a magnetic disk and on a bottom of a base. The charging filter has plural through holes by forming a fibrous electret filter medium in a pleat shape. The through holes are formed so as to face a flowing direction of air. Dust, which is moving together with the air flow, is polarized and is attracted to the charging filter. The charging filter can collect even very fine particles without causing such problems as clogging and pressure loss. The pleat portion, which forms the through holes, further exhibits an air flow uniforming effect.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Cotton seed separating device

InactiveCN109652862AEasy to separatePrevent flutteringVegetable fibre separation from seedsFiberWood splinter

The invention relates to the field of textile, and discloses a cotton seed separating device which comprises a body. The inside of the body is provided with a feeding port, a feeding pipe, an operation barrel, a pressuring roller and a sliding rail, a screw rod is arranged in the feeding pipe and provided with a chamber, a through hole, a first bevel gear, a steamer and a motor, the first bevel gear is engaged with a second bevel gear, the second bevel gear is coaxially connected with an incomplete gear, a baffle plate is fixedly connected at the tail end of the feeding pipe, a conveying pipeis fixedly connected at the top of the operation barrel and connected with a treatment box, an air feeding plate, a plurality of heating pipes and a fan are arranged in the operation barrel, air outlet holes are densely formed in the air feeding plate, a separating tank is arranged on the operation barrel, a brush is arranged in a separating box, a collecting box is communicated with the bottom ofthe separating box, a rack and a spring are arranged in a guide rail, a pushing rod and a connecting rod mechanism are arranged on the rack, a needle plate is arranged on the pushing rod, iron splinters are densely distributed on the needle plate. By the aid of the technical scheme, the separating device solves the problems of low quality of cotton fibers separated by a ginning machine and more cotton dust in the prior art.

Owner:象山平悦环保科技有限公司

Solid liquid mixing device for preparing superfine slurry

PendingCN108355569APrevent flutteringEasy to flyTransportation and packagingMixer accessoriesSlurrySolid particle

The invention discloses a solid liquid mixing device for preparing superfine slurry. The solid liquid mixing device comprises a liquid mixing feeding device, a solid pulverizing feeding device, a primary solid liquid mixing device, a conveying pump, a secondary solid liquid mixing device, a material return pipe and the like, wherein a pulverizing device performs primary pulverizing on solid particles, so that the mixing speed is accelerated; through the arrangement of a baffle plate and a blast blower, the solid particles are prevented from flying into air; a stirring paddle is arranged into aspiral paddle shape, so that mixed materials can be easily driven to rotate in an advancing way; a screen mesh type framework is arranged at the periphery of a tube body, so that the solid particlescan conveniently go in or out; the mixing speed is accelerated; an included angle of a stirring blade and a stirring shaft forms a certain angle, so that the pulverizing and mixing effects are reinforced. The solid liquid mixing device disclosed by the invention has the advantages that the air dust pollution cannot be caused; the mixing efficiency is high; the mixing speed is high; the continuousoperation can be realized; the goal of preparing the superfine slurry through solid liquid mixing can be fast and efficiently achieved.

Owner:SUZHOU SUNMUN TECH CO LTD

Low flow resistance check valve with high sealing force

InactiveCN102563135AImprove sealingSmall flow resistanceCheck valvesValve housingsMagnetic tension forceCircular disc

The invention relates to a low flow resistance check valve with high sealing force. The low flow resistance check valve is characterized in that the low flow resistance check valve is provided with a valve body, a valve cap and a valve rod, wherein an inlet and an outlet are formed in the valve body; a central line of the inlet and a central line of the outlet of the valve body are arranged by 90 degrees; the valve cap is mounted on an outer plane of the valve body, which is opposite to the inlet; a permanent magnet is mounted in an inner hole of the valve cap; central lines of the valve cap, the valve rod and the inlet are consistent; the valve rod comprises rod parts arranged at two ends of the valve rod and disks positioned on the intermediate sections of the rod parts; the rod parts are respectively matched in holes of the valve cap and a guide plate of the inlet in a sliding way; the disks and corresponding annular blade edges of the valve body form a valve; and a spring is mounted on the valve rod between the disk and the valve cap. Due to the adoption of common action of a strong magnetic force and a spring force, the low flow resistance check valve has the characteristics of high sealing force and low flow resistance.

Owner:HANGZHOU CHUNJIANG VALVE

Three-wheel pedal-style wheelchair

ActiveUS20120267175A1Easy to controlEasy to getPassenger cyclesChildren cyclesSteering wheelDrive wheel

A three-wheel pedal-style wheelchair which includes a roller at a side, close to the ground, of the wheelchair, wherein the roller prevents the wheelchair from turning over, a steering wheel arranged at a side of the wheelchair, and two front wheels respectively arranged at two opposite sides of the wheelchair, wherein the two front wheels comprises a driving wheel led to rotate forward or backward by a user stepping and a loose wheel, wherein when the wheelchair turns to a direction in a small radius, the steering wheel is considerably rotated to a direction and the driving wheel is rotated forward, wherein when the wheelchair turns to another direction, the steering wheel is considerably rotated to a direction and the driving wheel is rotated backward. Accordingly, the wheelchair is easily controlled to have a small turn, like whirling in one spot, to move and to turn safely.

Owner:TOHOKU TECHNO ARCH CO LTD +1

Image reading apparatus

An image reading apparatus capable of preventing the occurrence of a streak and reading a quality image from the leading edge to the trailing edge of a original. An original is conveyed along a convey pass. The original being conveyed is guided by a guide member, at least part of the guide member being transparent. An image of the original being conveyed is read by an image sensor through the guide member. Airflow is generated, the airflow being blown into the convey pass from a location upstream in a conveying direction compared to a location of the image sensor. The guide member has a convex portion disposed at a location upstream in the conveying direction compared to the location of the image sensor.

Owner:CANON DENSHI KK

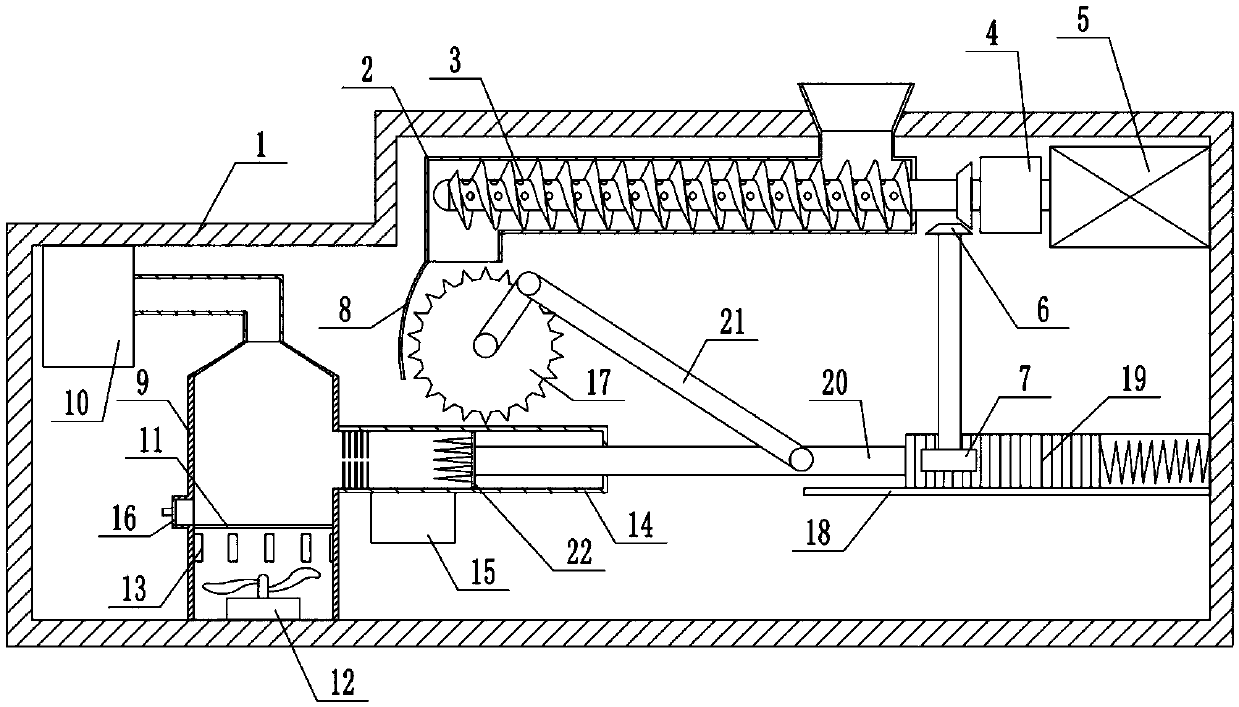

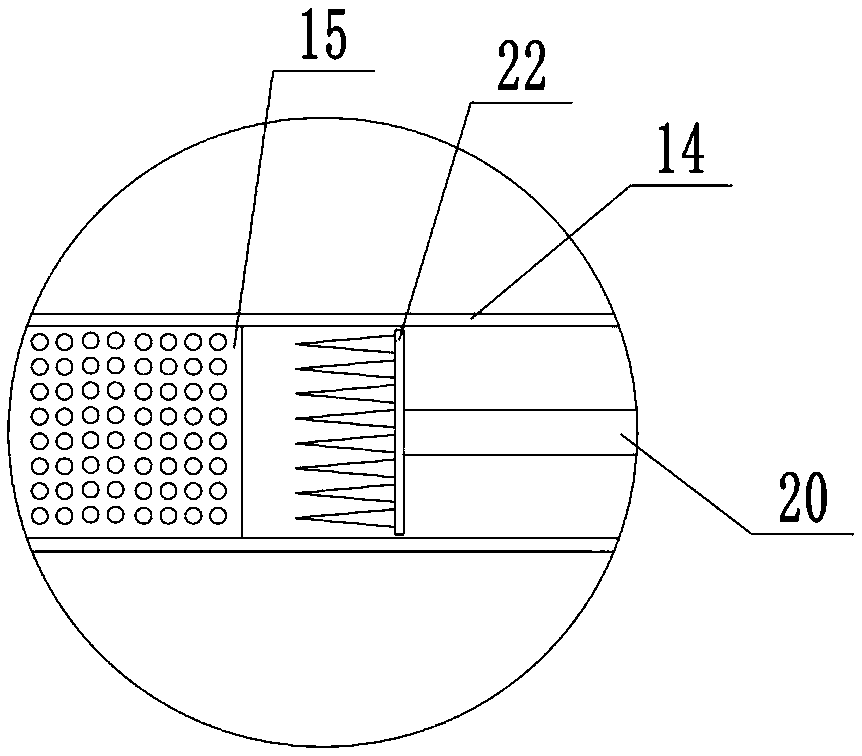

Environment-friendly horizontal feed crushing and screening device for livestock and poultry breeding

InactiveCN108144701AIncrease the output speedImprove work performanceSievingFeeding-stuffEngineeringLivestock

The invention discloses an environment-friendly horizontal feed crushing and screening device for livestock and poultry breeding. The environment-friendly horizontal feed crushing and screening devicecomprises an outer frame, wherein the two sides of the outer frame are fixedly connected with first motors respectively, one ends of the output shafts of the first motors penetrate through the outerframe and extend into the interior of the outer frame, the ends of the output shafts of the first motors, located inside the outer frame, are fixedly connected with crushing rods, and a base is rotationally connected between two opposite ends of the two crushing rods. The invention relates to the technical field of feed crushing and screening devices. According to the environment-friendly horizontal feed crushing and screening device for the livestock and poultry breeding, the purpose of conveniently crushing feed in water is achieved, the crushing effect of feed is guaranteed, the crushed feed is increased to rapidly pass through a filter screen, the waste of time is reduced, the filter screen is prevented from being blocked, the discharge speed of the feed is increased, the damage of thedevice is prevented, the use of people is facilitated, the sealing performance is good, dust is prevented from flying, the environment-friendly performance of the device is improved, and the practicability of the device is improved.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com