Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Securing rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

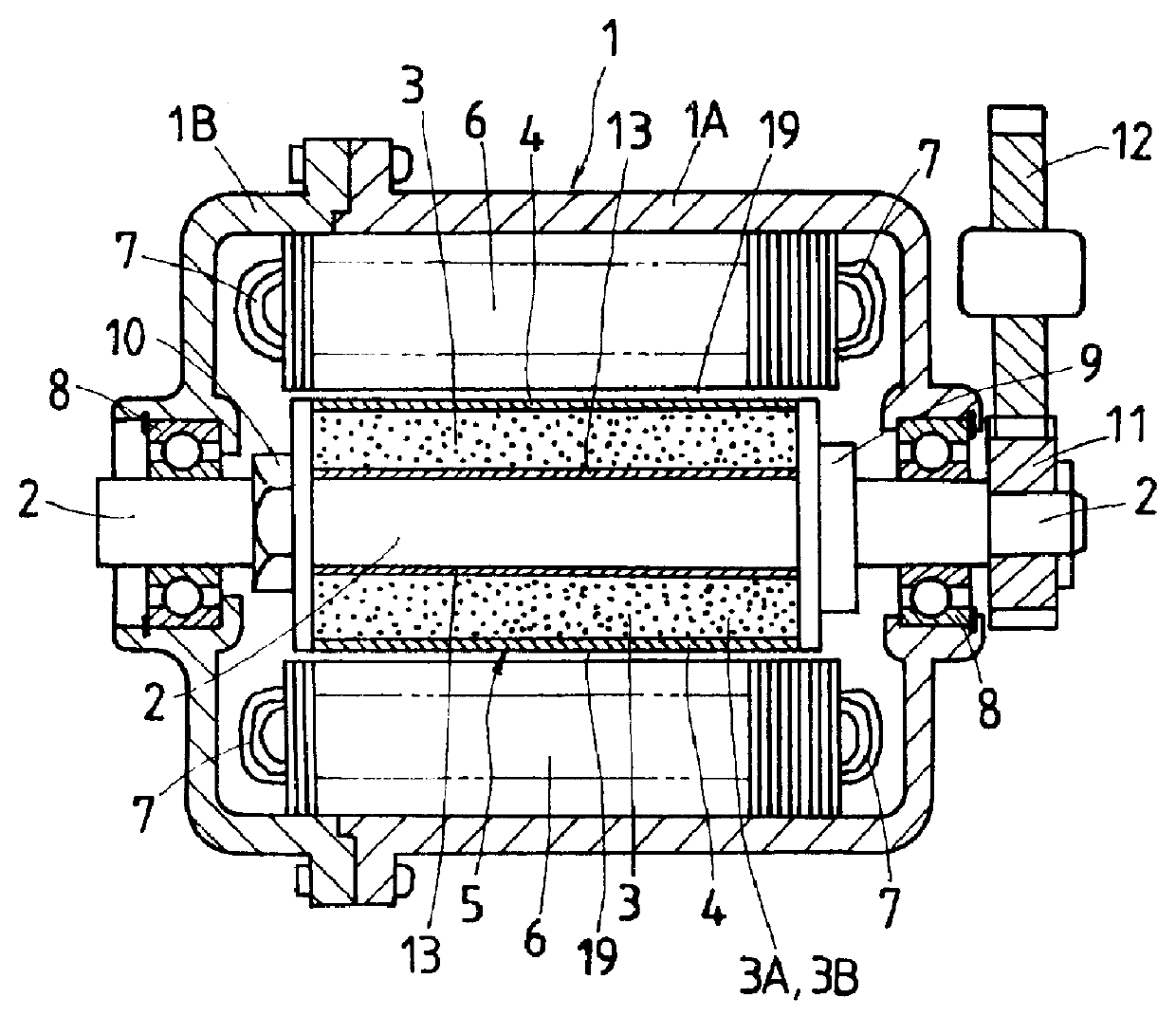

Structure of rotor for generators and method of manufacturing the same rotor

InactiveUS6144130AReduce manufacturing costImprove permeabilityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsFiberEngineering

Owner:ISUZU MOTORS LTD

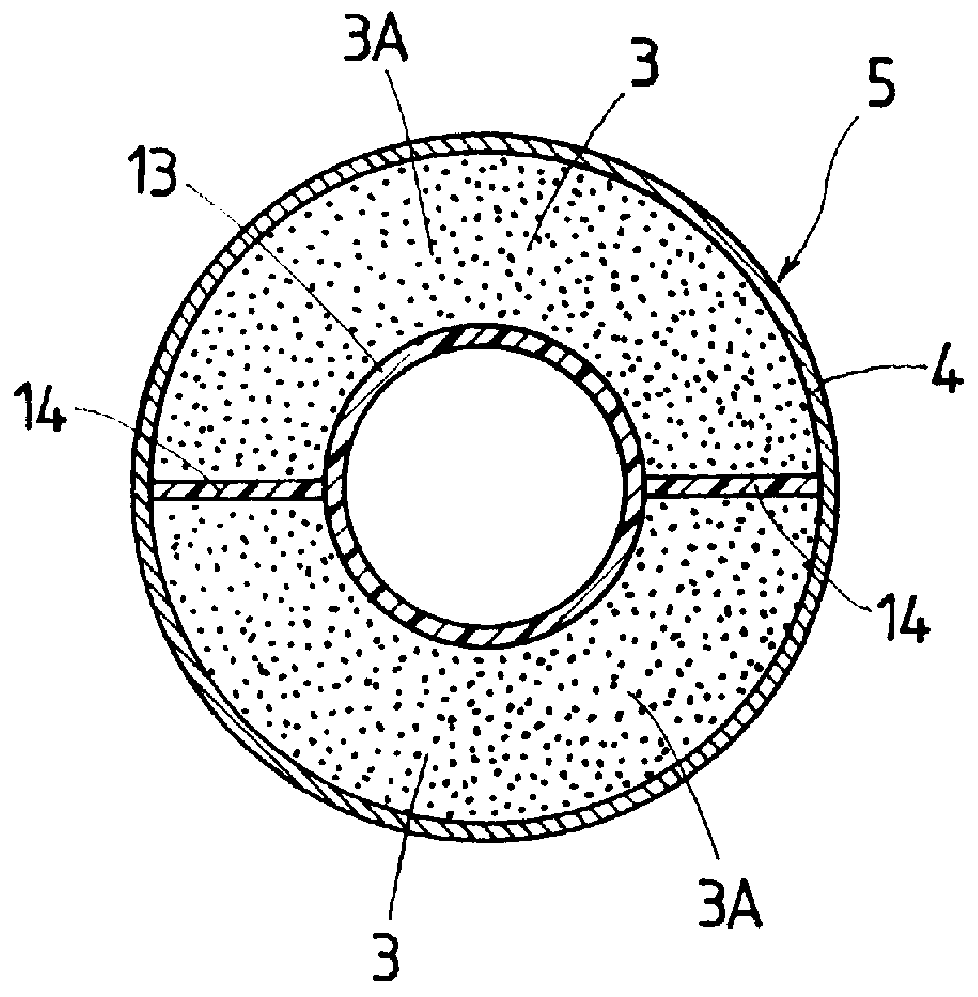

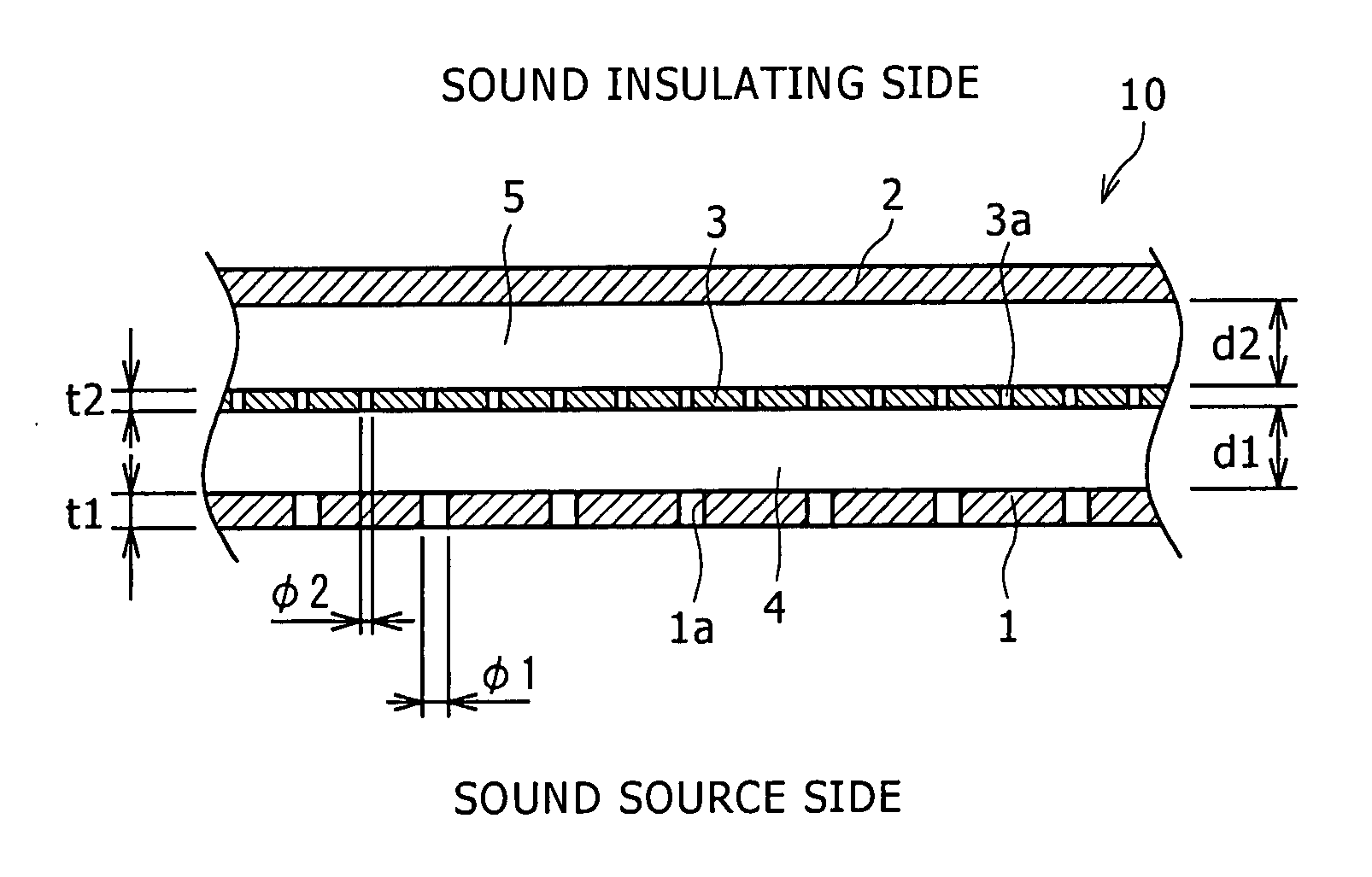

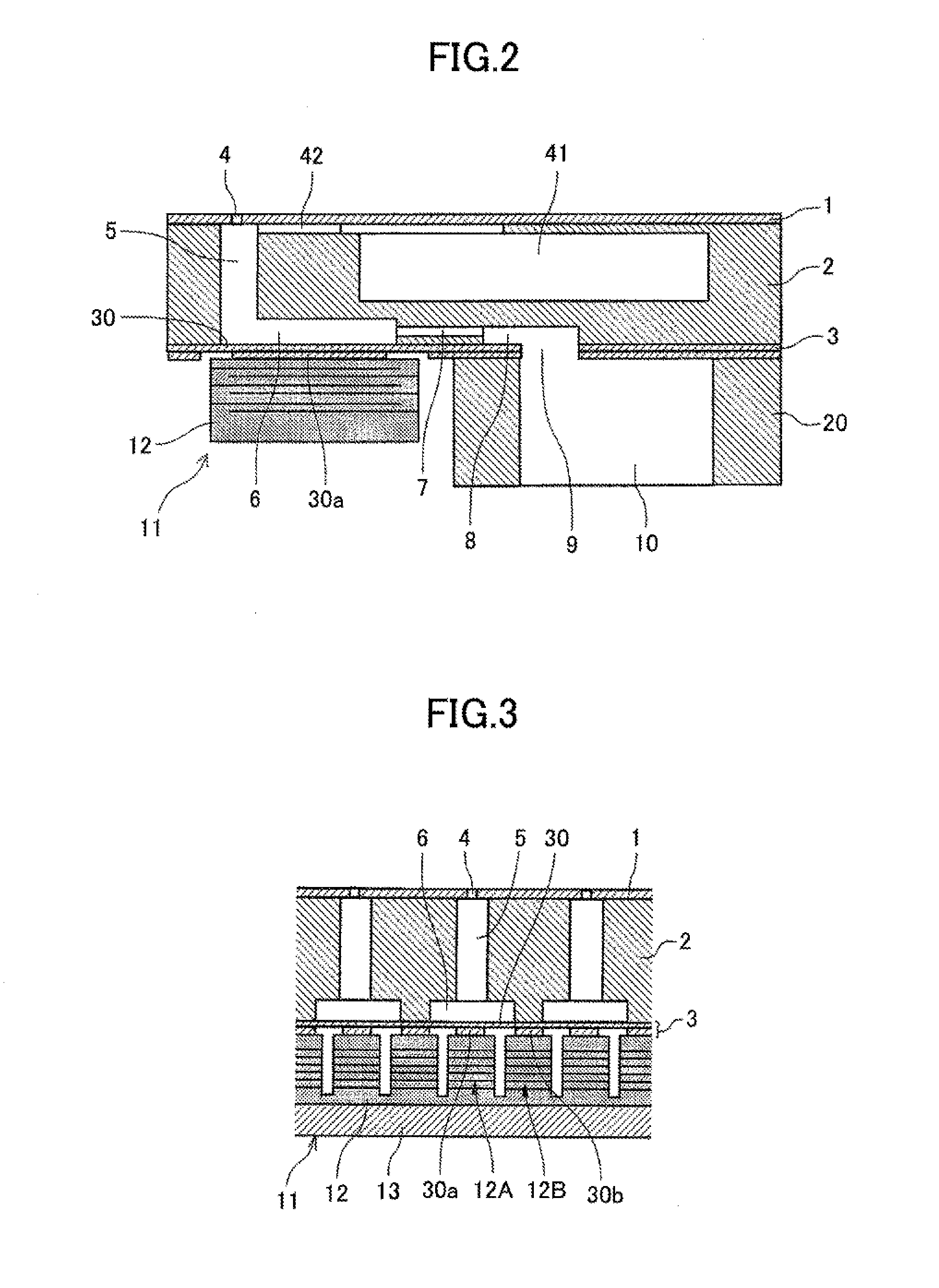

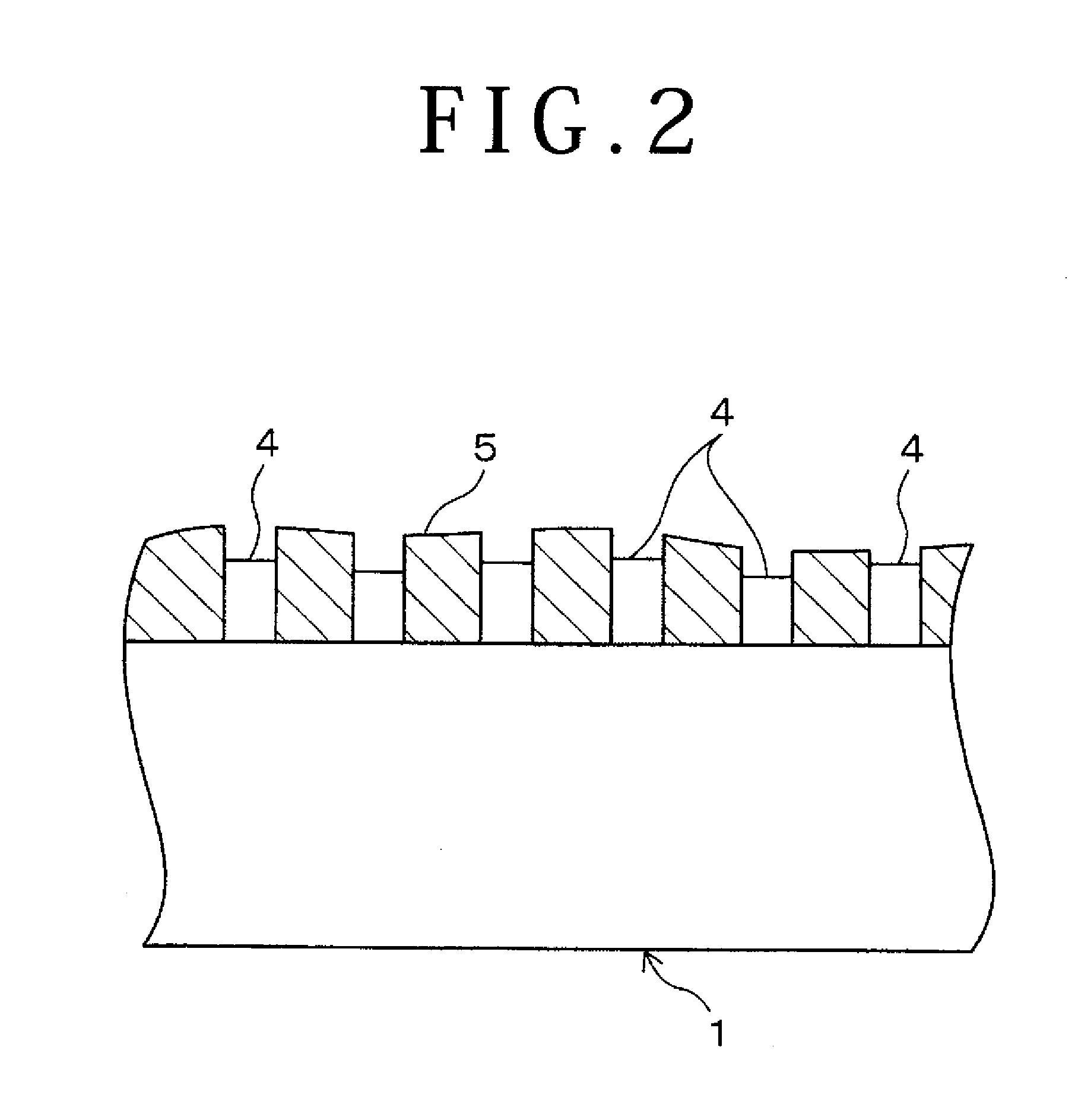

Porous Sound Absorbing Structure

InactiveUS20070272482A1Sufficient sound absorbing performancePromote conversionWallsLayered productsEngineeringAperture ratio

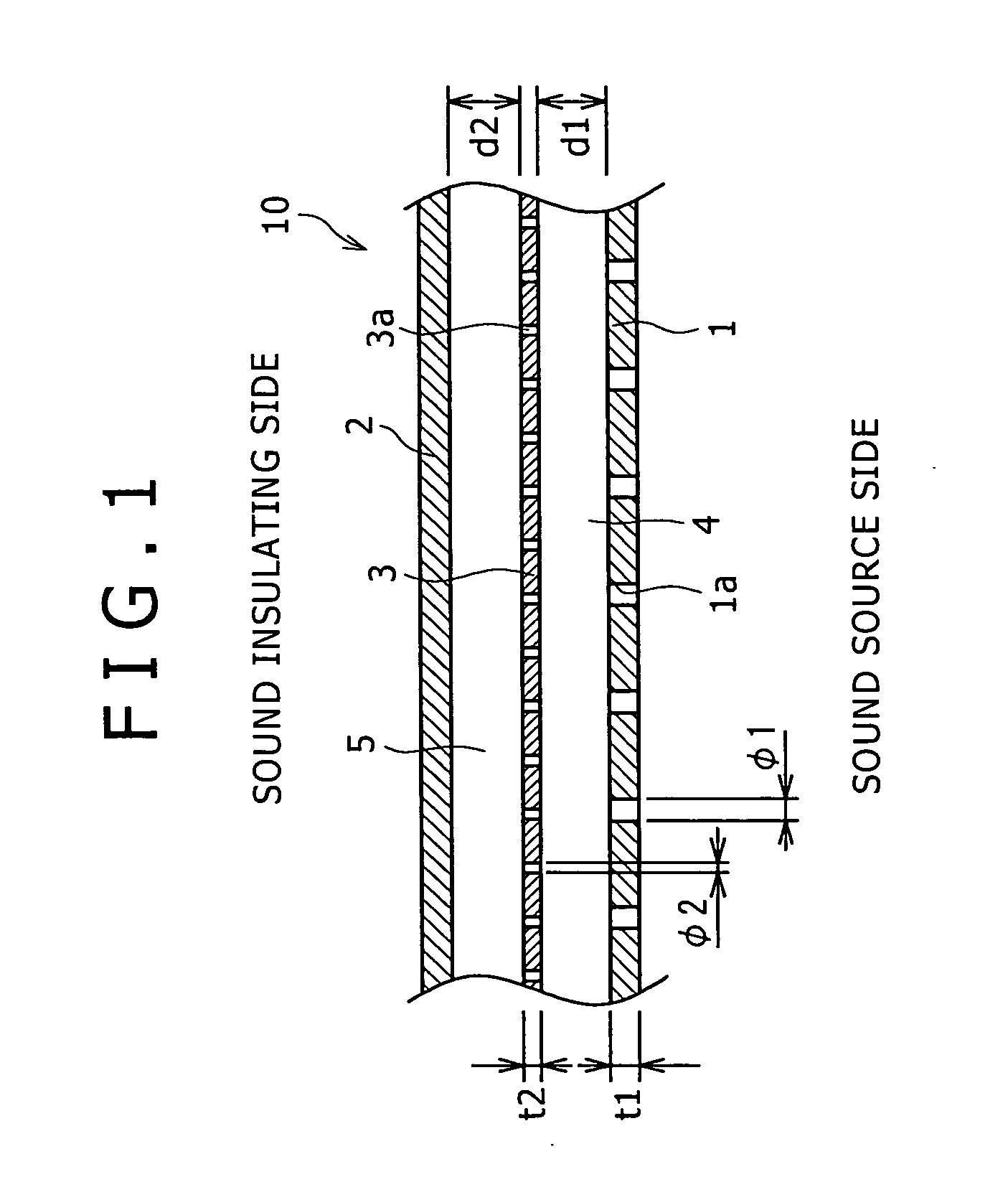

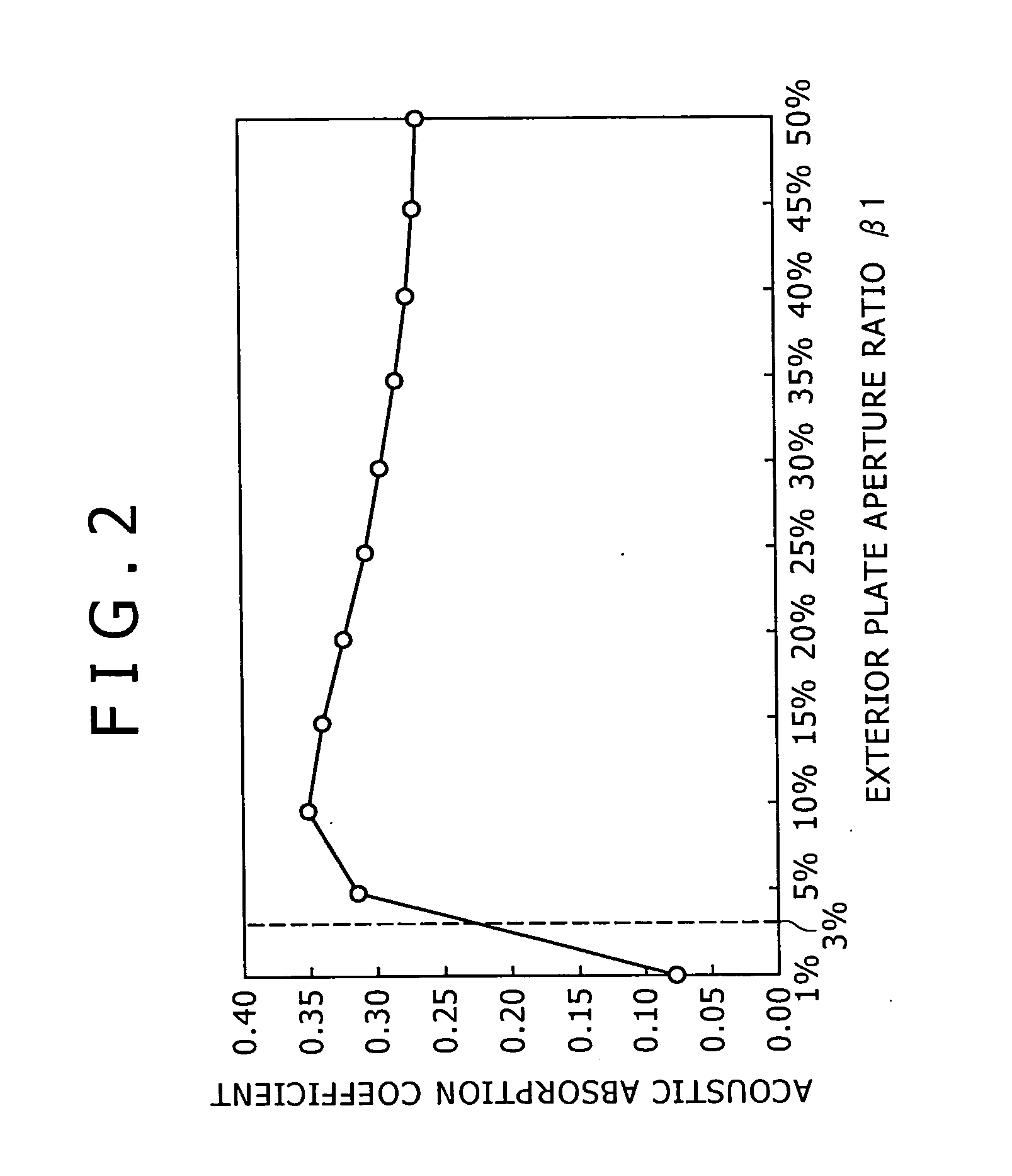

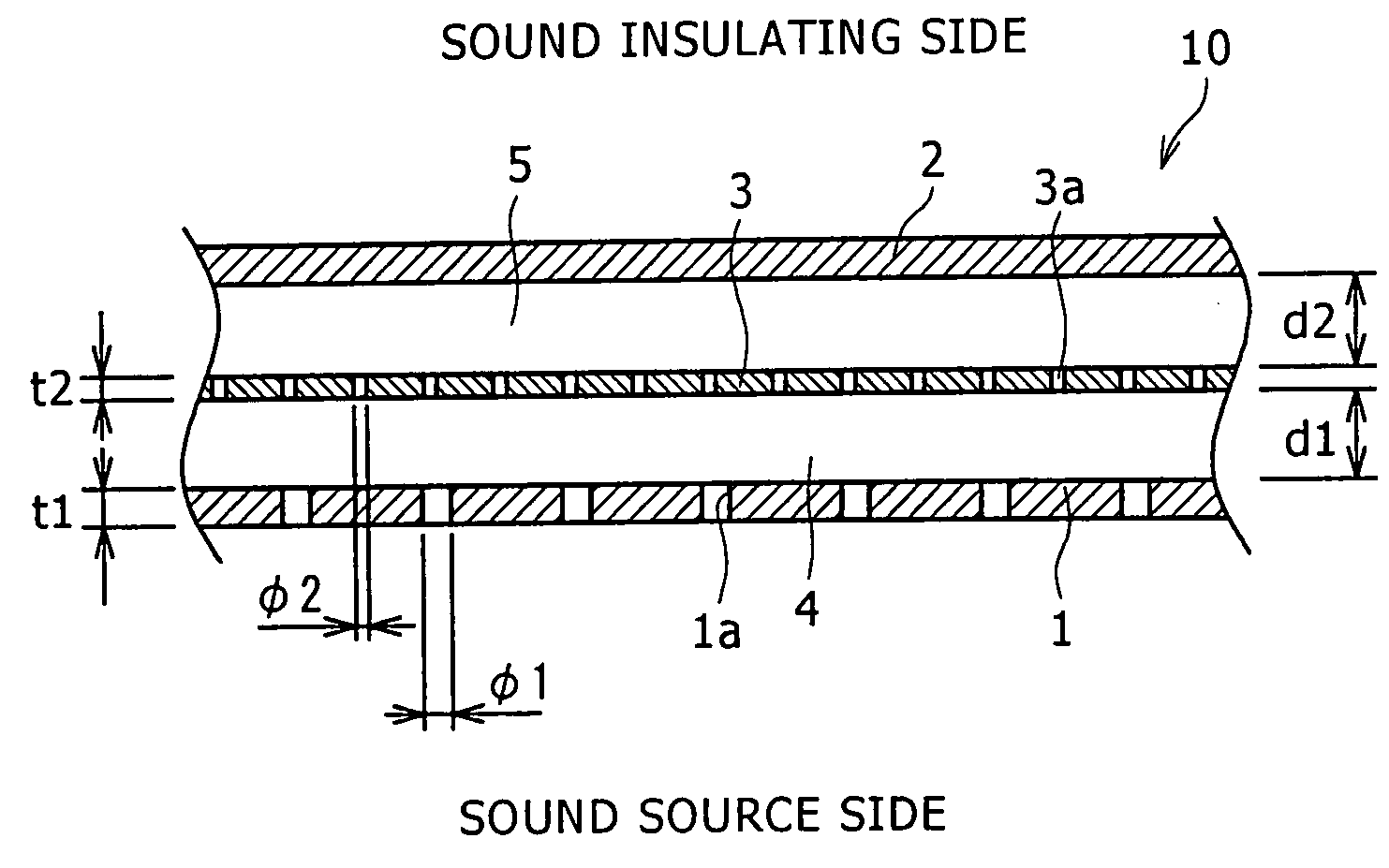

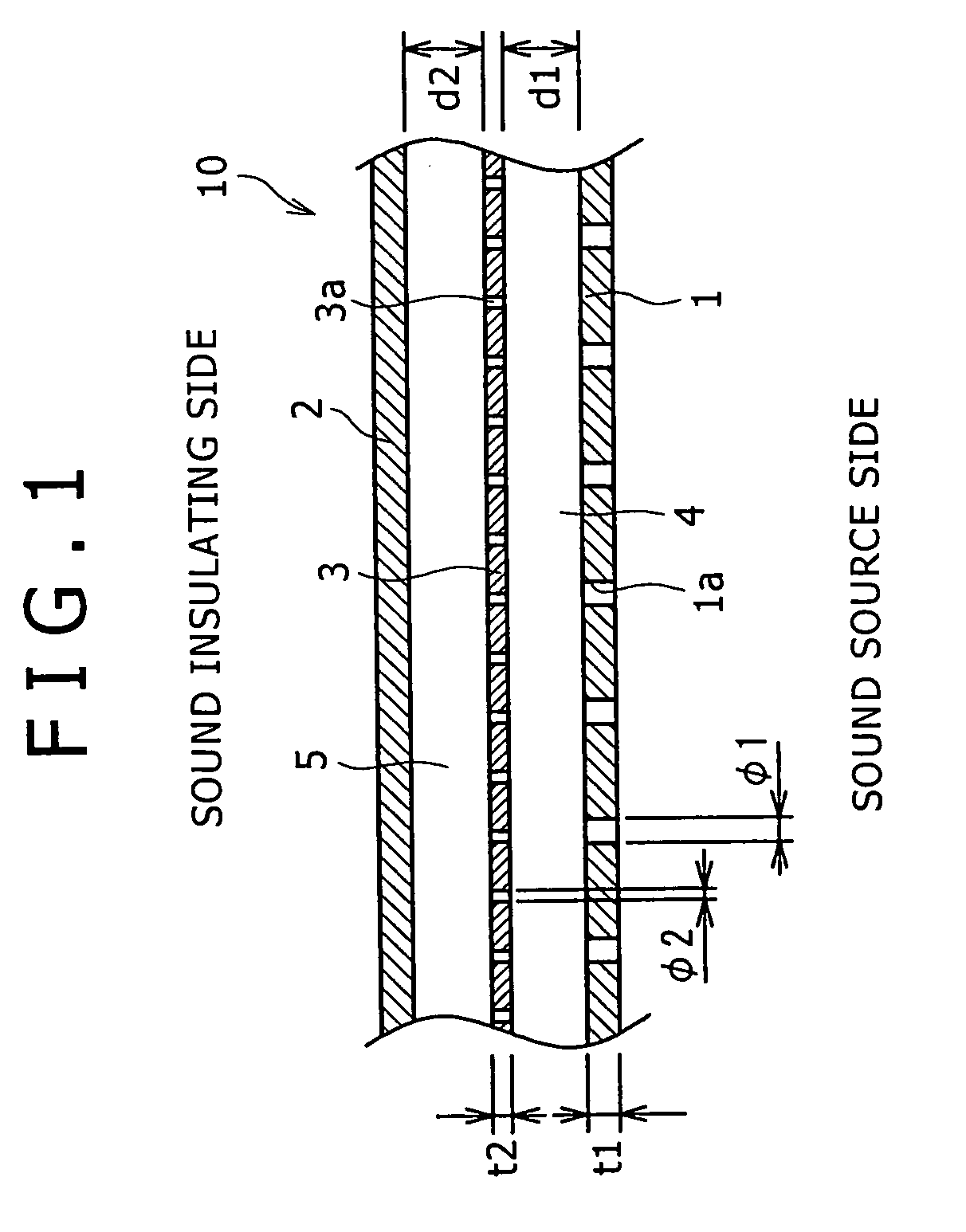

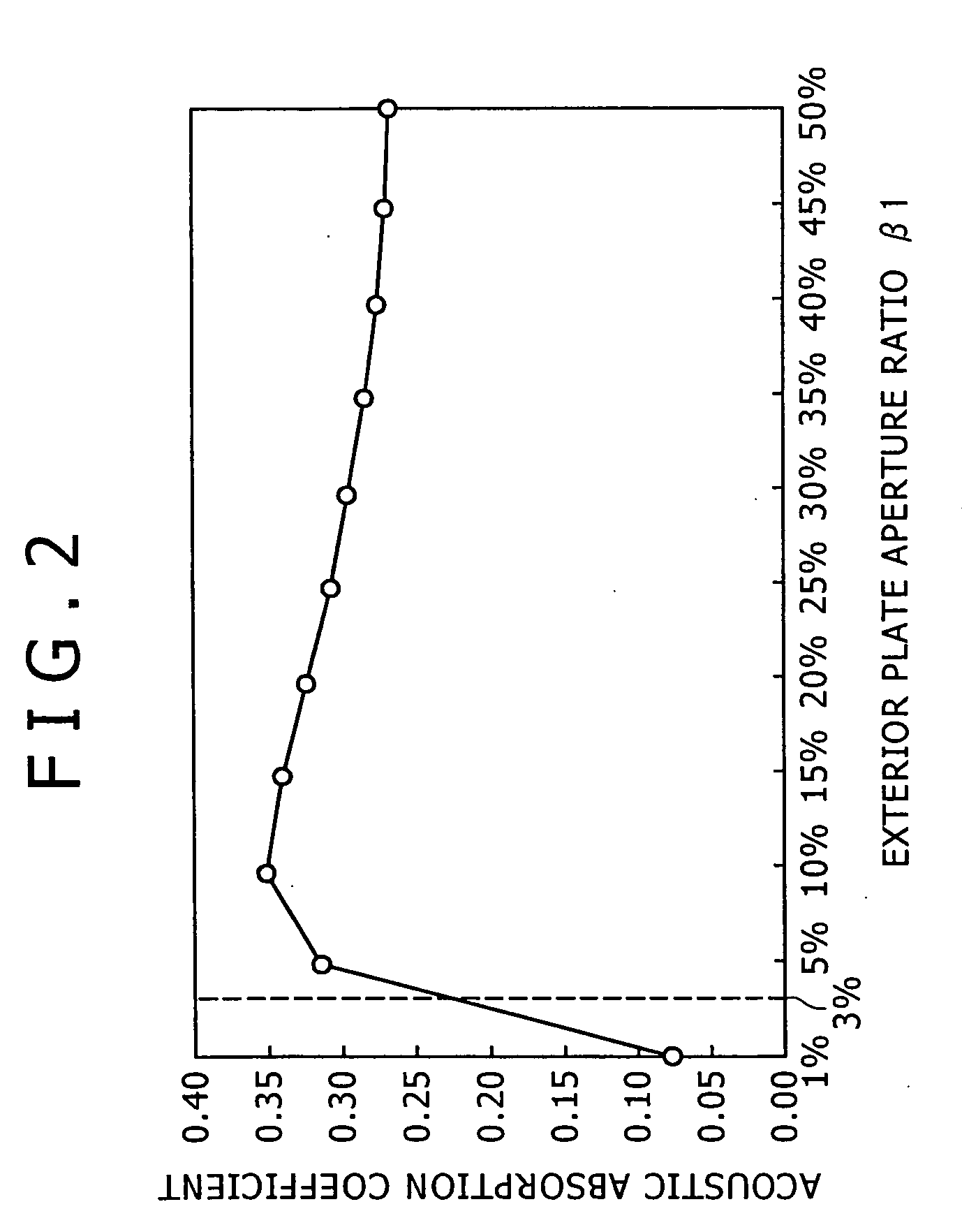

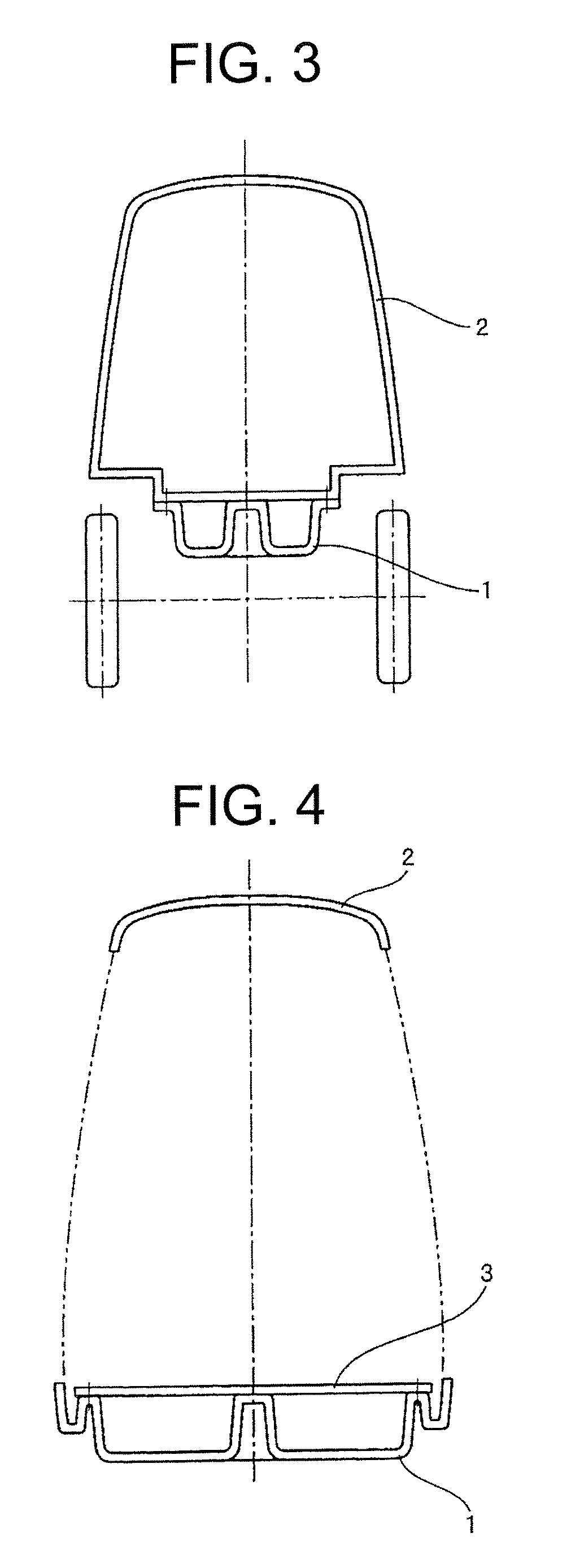

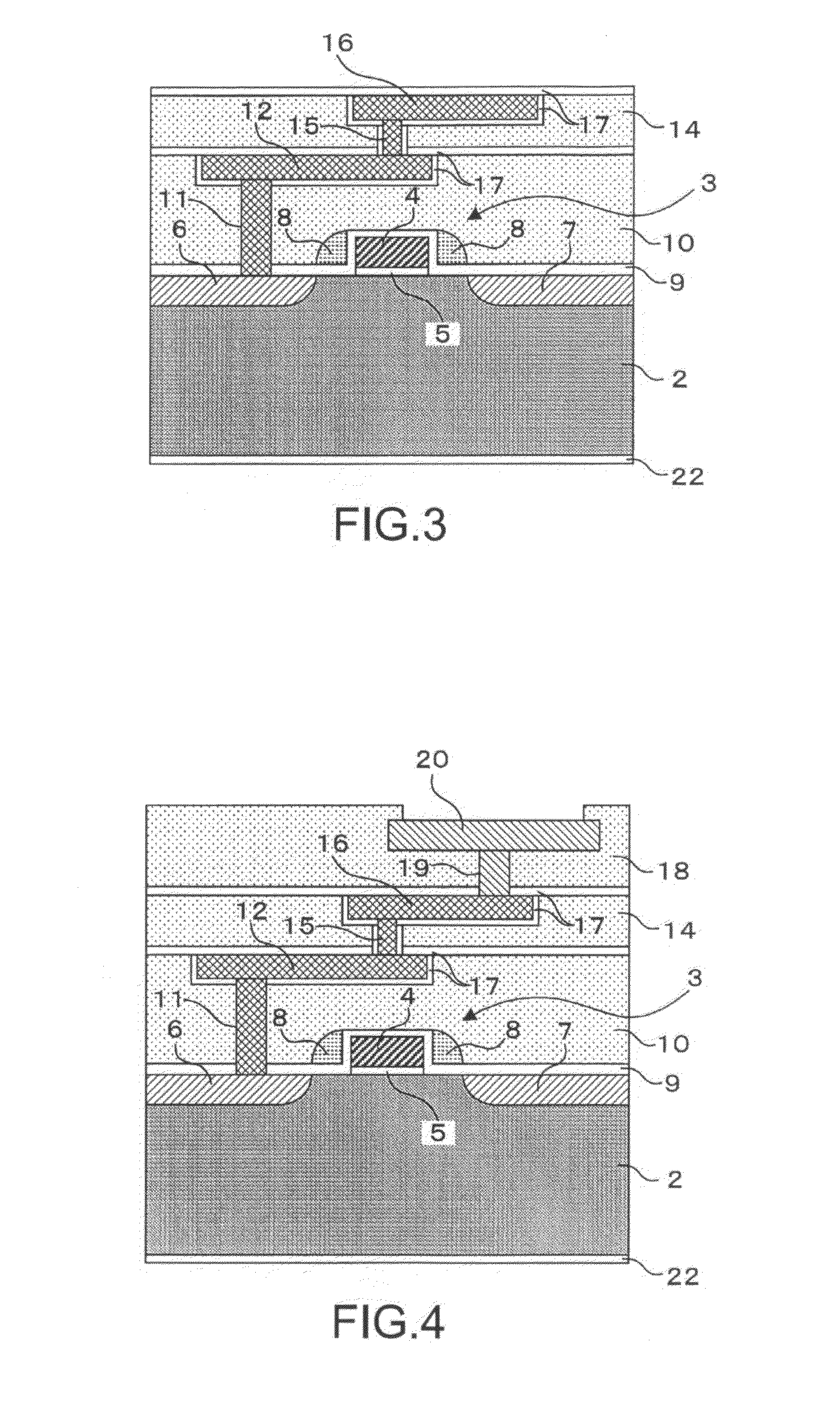

A porous sound absorbing structure 10 includes an exterior plate 1 and a closing plate 2 in order to suppress a decrease in sound absorbing performance in a wide frequency band. An interior plate 3 is arranged between the exterior plate 1 and the closing plate 2, and air layers 4 and 5 are located between the exterior plate 1 and the interior plate 3 and between the interior plate 3 and the closing plate 2 respectively. The exterior plate 1, the interior plate 3, and the closing plate 2 are arranged while opposed to each other. Many through holes 1a and 3a are made in the exterior plate 1 and the closing plate 2 respectively. In the interior plate 3, a plate thickness t2 and a diameter φ2 and an aperture ratio β2 are set so as to generate an viscous effect in air passing through the through hole 3a. The aperture ratio β1 of the through hole 1a in the exterior plate 1 is set more than 3% and not more than 50%.

Owner:KOBE STEEL LTD

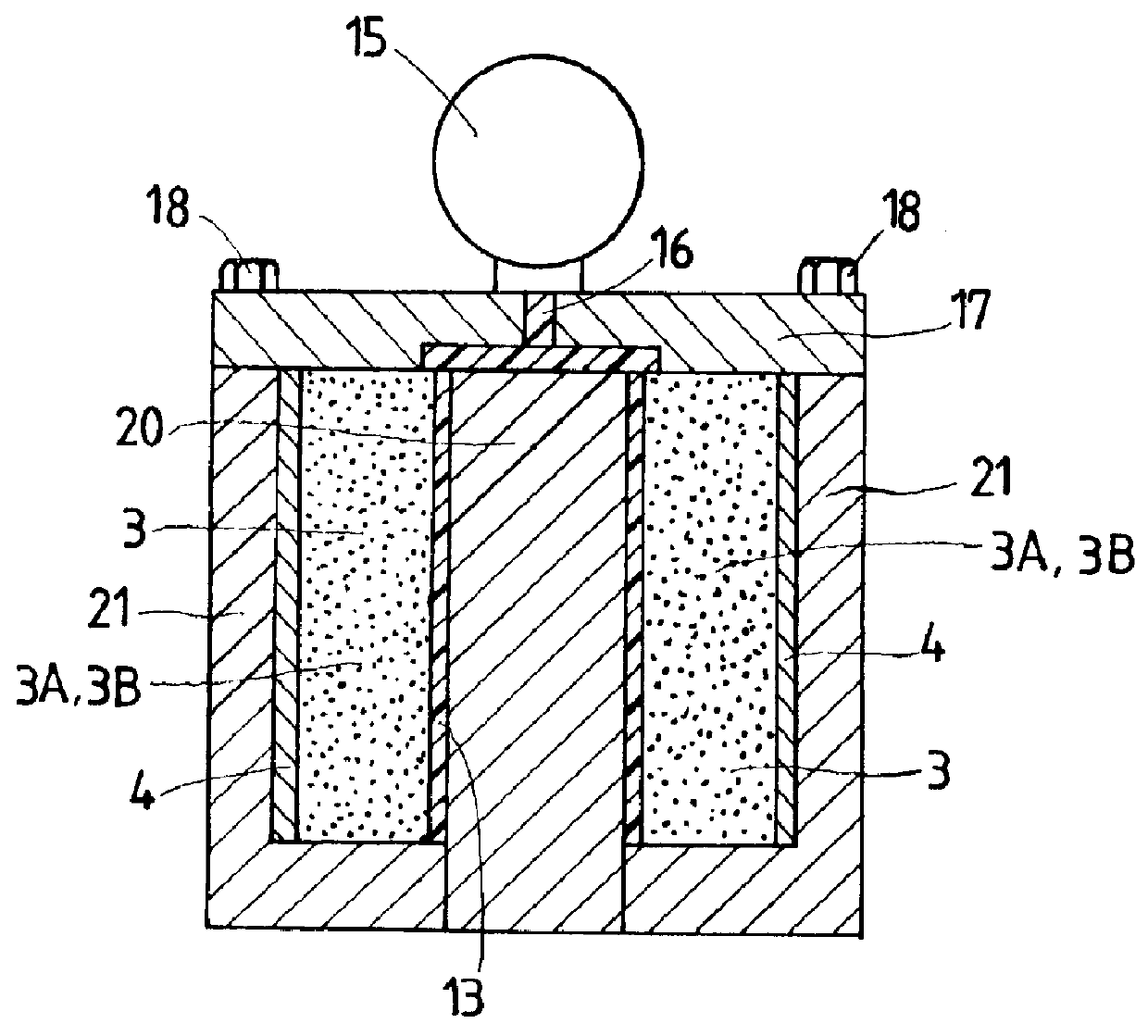

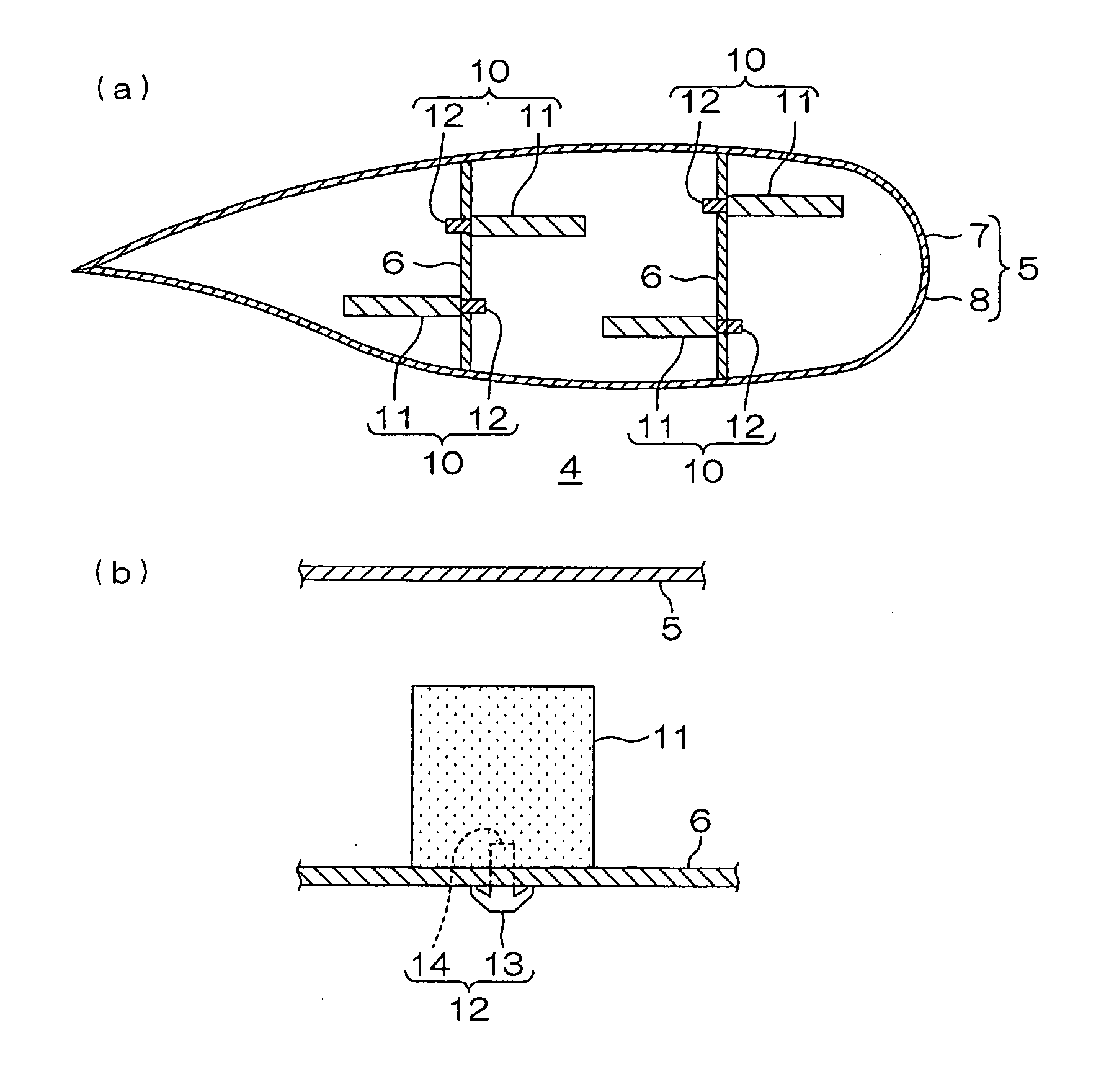

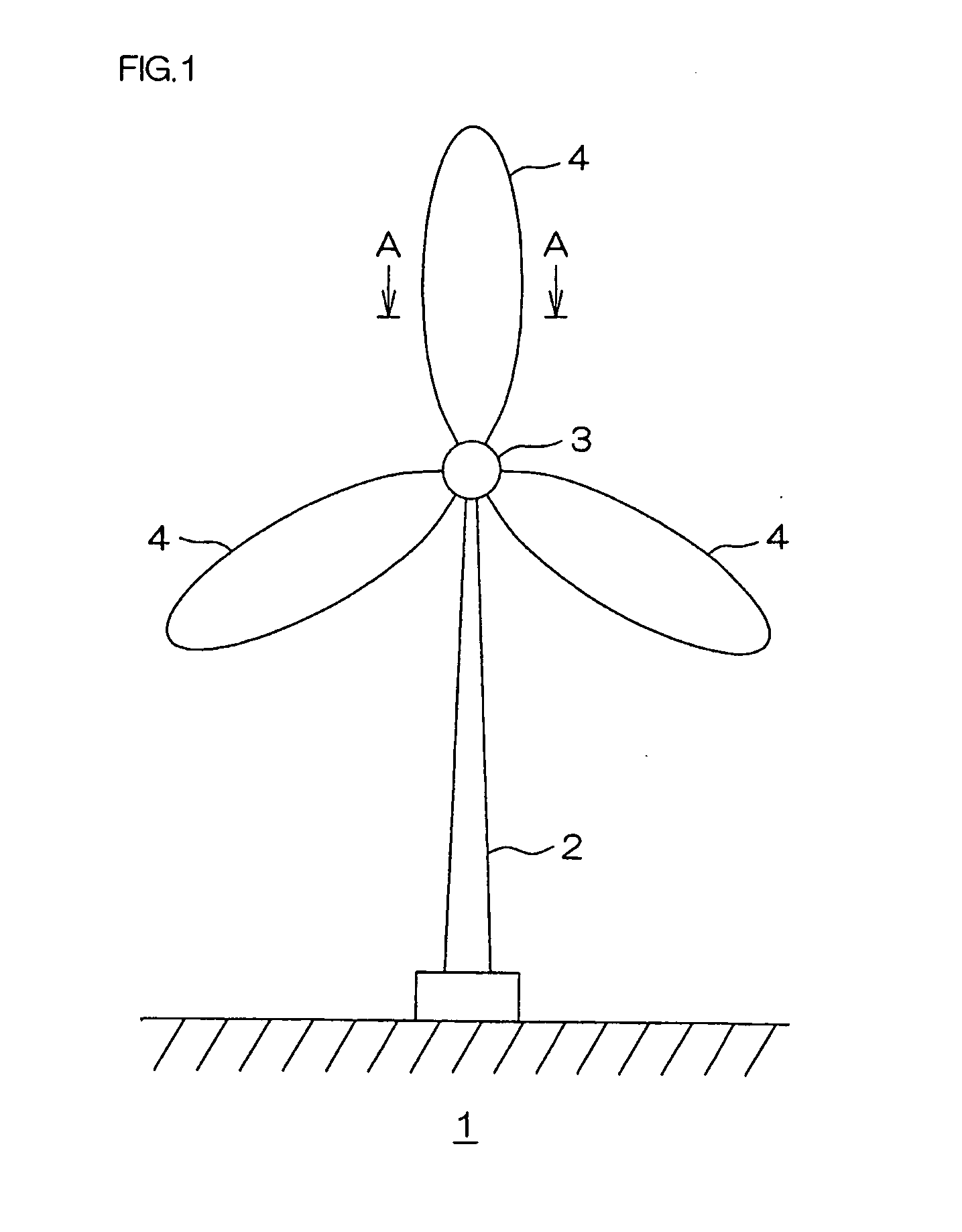

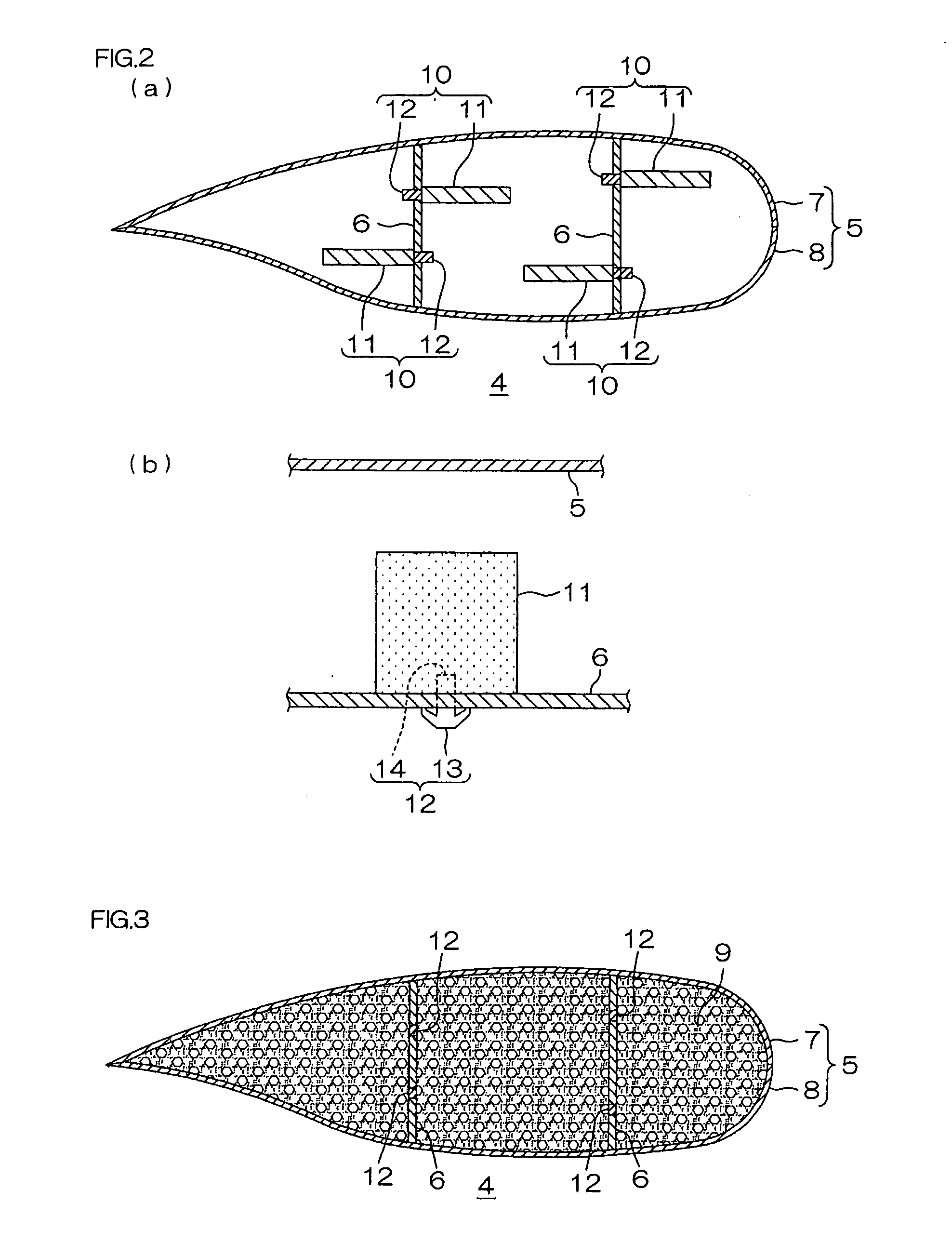

Foam filling material for wind power generator blades, foam filling member for wind power generator blades, wind power generator blade, wind power generator, and method for producing the wind power generator blade

InactiveUS20110031759A1Reduce vibrationBlocking may occurPropellersPump componentsInterior spaceFoaming agent

A foam filling material for wind power generator blades is obtained by forming a foam filling composition containing a polymer and a foaming agent into a given shape so as to be positioned in an interior space of a wind power generator blade, and is capable of filling the interior space of the wind power generator blade by foaming.

Owner:NITTO DENKO CORP

Head suspension for disk drive and method of manufacturing head suspension

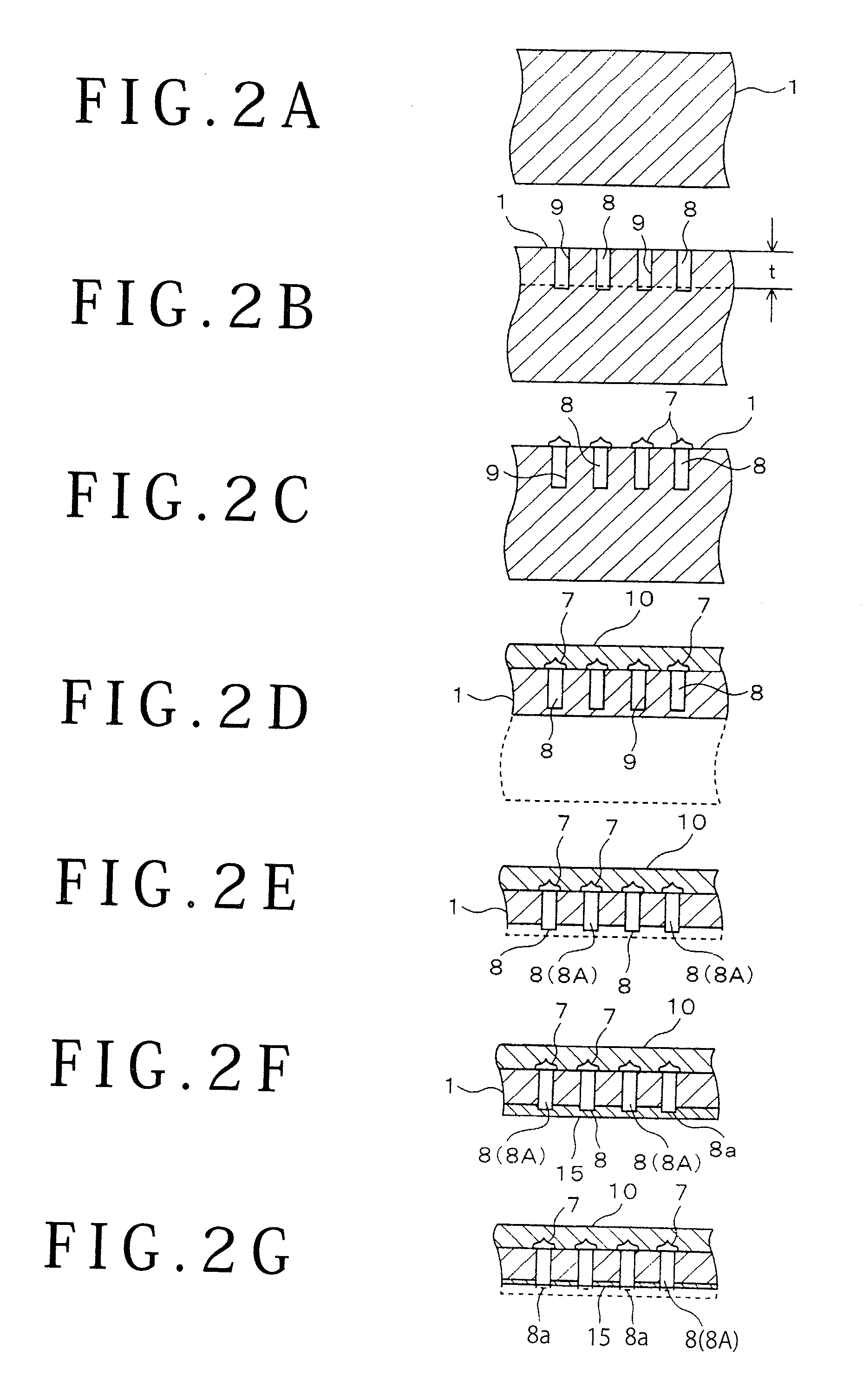

InactiveUS20020181155A1Reduce weightReduce the amplitudeRecord information storageInsulating layers/substrates workingStructural engineeringEngineering

A head suspension for a disk drive has a base (19) to be attached to a carriage, a load beam (21) having a rigid part (27) and a resilient part (29) supported by the base, to apply load on a data read / write head (13) arranged at a front end (27a) of the rigid part, and a flexure (49) attached to the load beam and supporting the head. The rigid part has a multilayer structure consisting of at least three layers including metal layers (28a, 28b) and a resin layer (28c) interposed between the metal layers. The number of layers of the resilient part is smaller than that of the rigid part.

Owner:NHK SPRING CO LTD

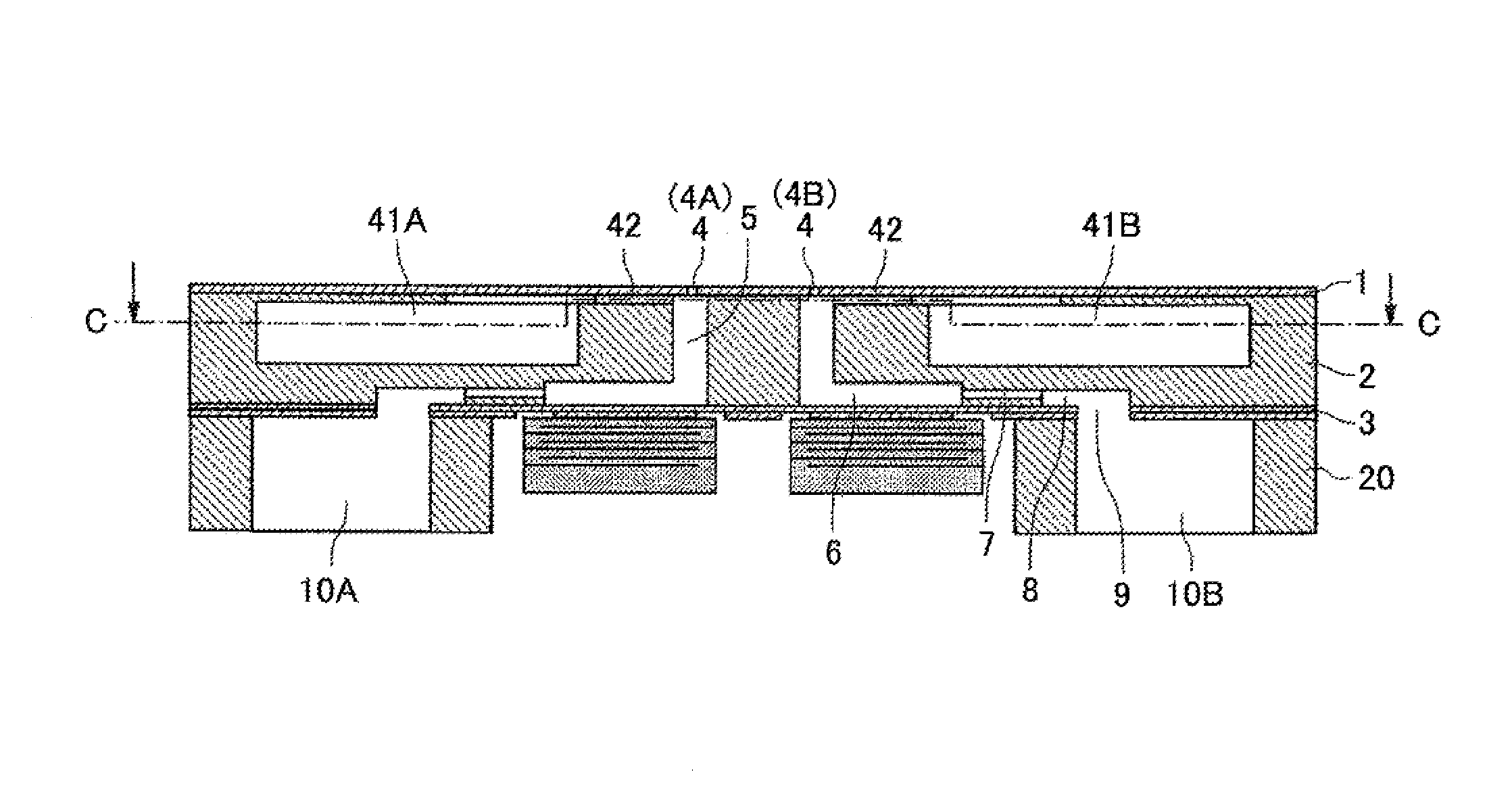

Liquid ejection head, liquid ejection unit, and apparatus for ejecting liquid

A liquid ejection head is provided. The liquid ejection head includes at least two nozzle lines configured to have a plurality of nozzles for ejecting liquid disposed in respective lines, a plurality of individual liquid chambers configured to be in communication with corresponding nozzles of the nozzle lines, and at least two circulation channels corresponding to the nozzle lines, configured to be in communication with the individual liquid chambers. The at least two circulation channels are in communication with each other through a bridging channel disposed in a direction intersecting with the nozzle line direction, and the bridging channel and the circulation channels are disposed at different positions in a thickness direction of a member which forms the bridging channel and the circulation channels.

Owner:RICOH KK

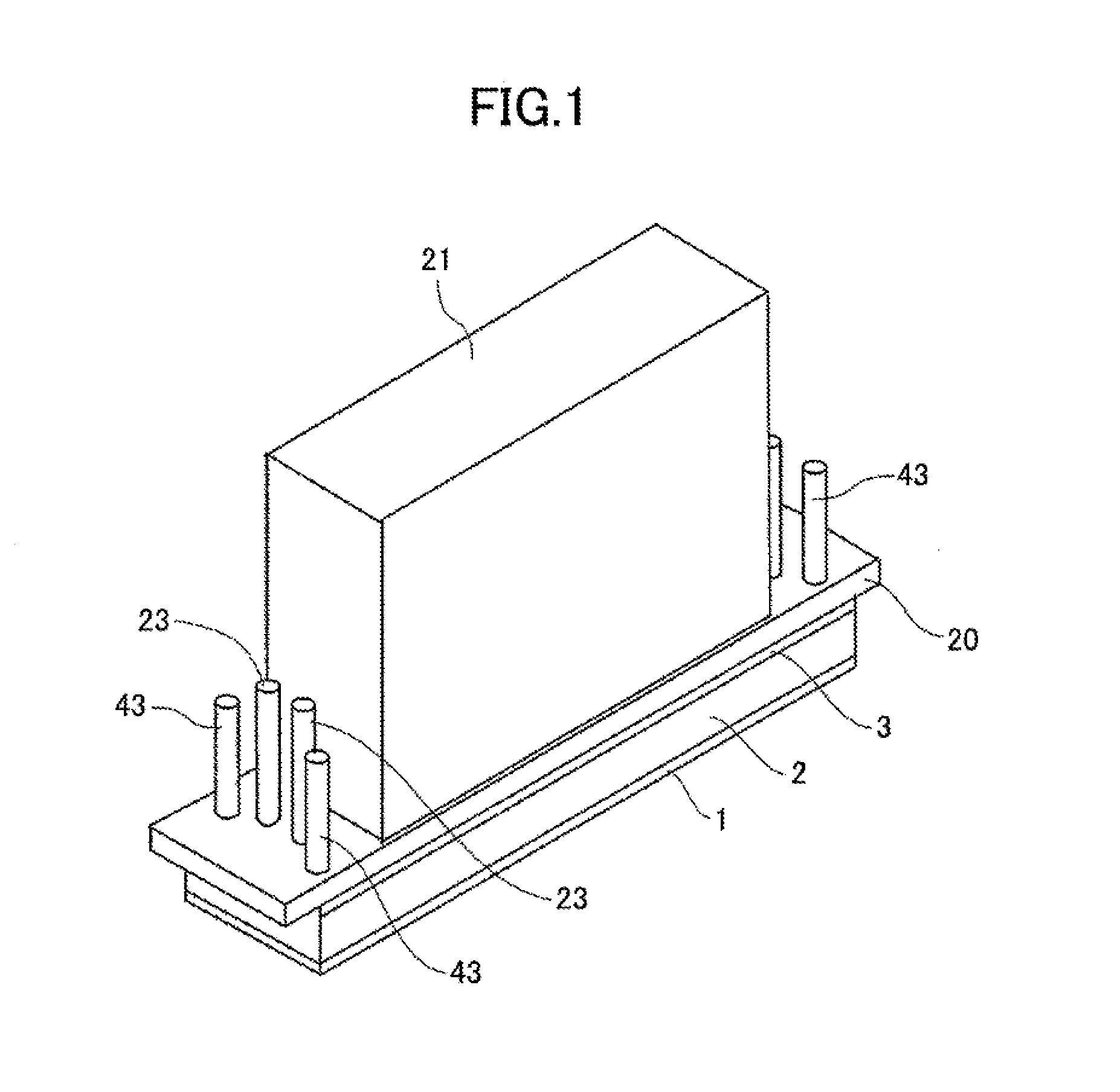

Porous sound absorbing structure

InactiveUS20100175949A1Promote conversionSufficient absorbing performanceLayered productsSound proofingViscous effectEngineering

A porous sound absorbing structure 10 includes an exterior plate 1 and a closing plate 2 in order to suppress a decrease in sound absorbing performance in a wide frequency band. An interior plate 3 is arranged between the exterior plate 1 and the closing plate 2, and air layers 4 and 5 are located between the exterior plate 1 and the interior plate 3 and between the interior plate 3 and the closing plate 2 respectively. The exterior plate 1, the interior plate 3, and the closing plate 2 are arranged while opposed to each other. Many through holes 1a and 3a are made in the exterior plate 1 and the closing plate 2 respectively. In the interior plate 3, a plate thickness t2 and a diameter φ2 and an aperture ratio β2 are set so as to generate an viscous effect in air passing through the through hole 3a. The aperture ratio β1 of the through hole 1a in the exterior plate 1 is set more than 3% and not more than 50%.

Owner:KOBE STEEL LTD

Rubber composition for tread used for studless tire and studless tire having tread using thereof

InactiveUS20100184908A1Improve wear resistanceReduce hardnessSpecial tyresTyre tread bands/patternsPolymer sciencePolybutadiene

It is an object of the present invention to lessen strain dependency of hardness of a tread rubber used for a studless tire, have good performance on snow and ice while securing rigidity on non-snow roads, and improve abrasion resistance. The present invention provides a rubber composition for tread used for a studless tire comprising 30 to 150 parts by weight as a total of (1) silica with a nitrogen absorption specific surface area of at most 100 m2 / g and (2) silica with a nitrogen absorption specific surface area of at least 180 m2 / g based on 100 parts by weight of a rubber component in which a content of a natural rubber and / or a polybutadiene rubber is at least 80% by weight, wherein contents of silica (1) and silica (2) satisfy the formula below:[Content of silica (1)]×0.2≦[Content of silica (2)]≦[Content of silica (1)]×6.5,tan δ peak temperature Tg is at most −50° C., and rubber hardness at 0° C. is at most 64.

Owner:SUMITOMO RUBBER IND LTD

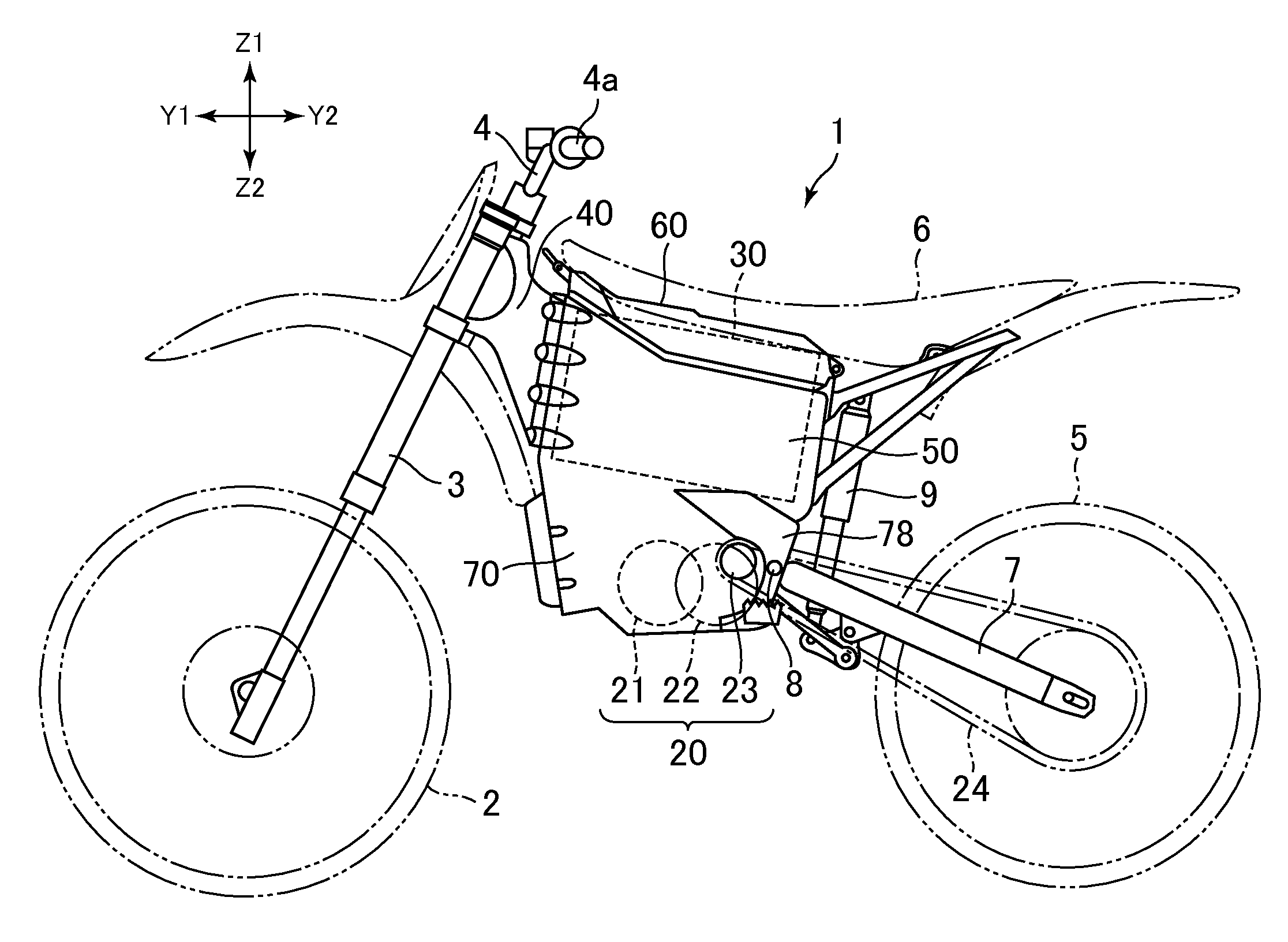

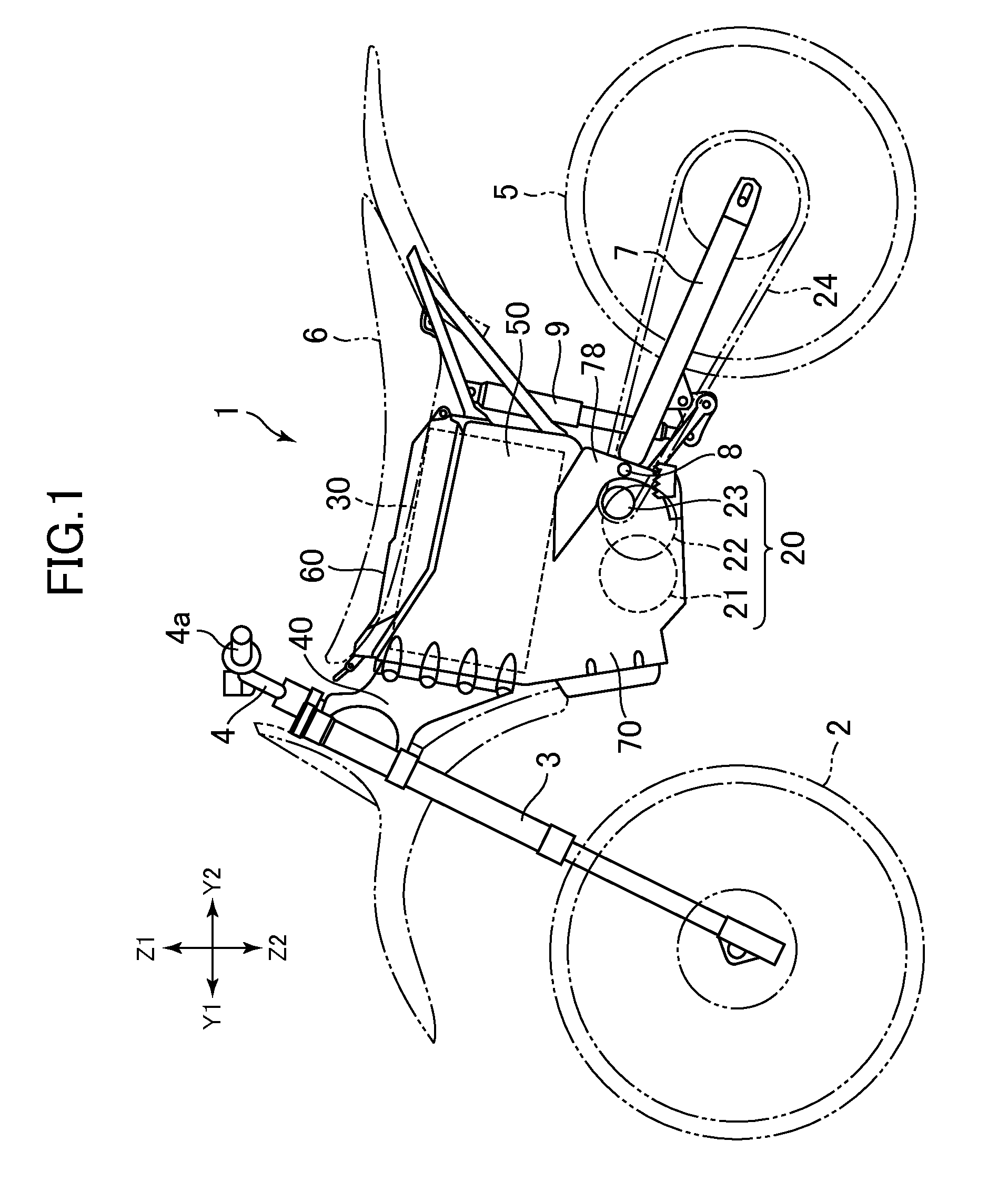

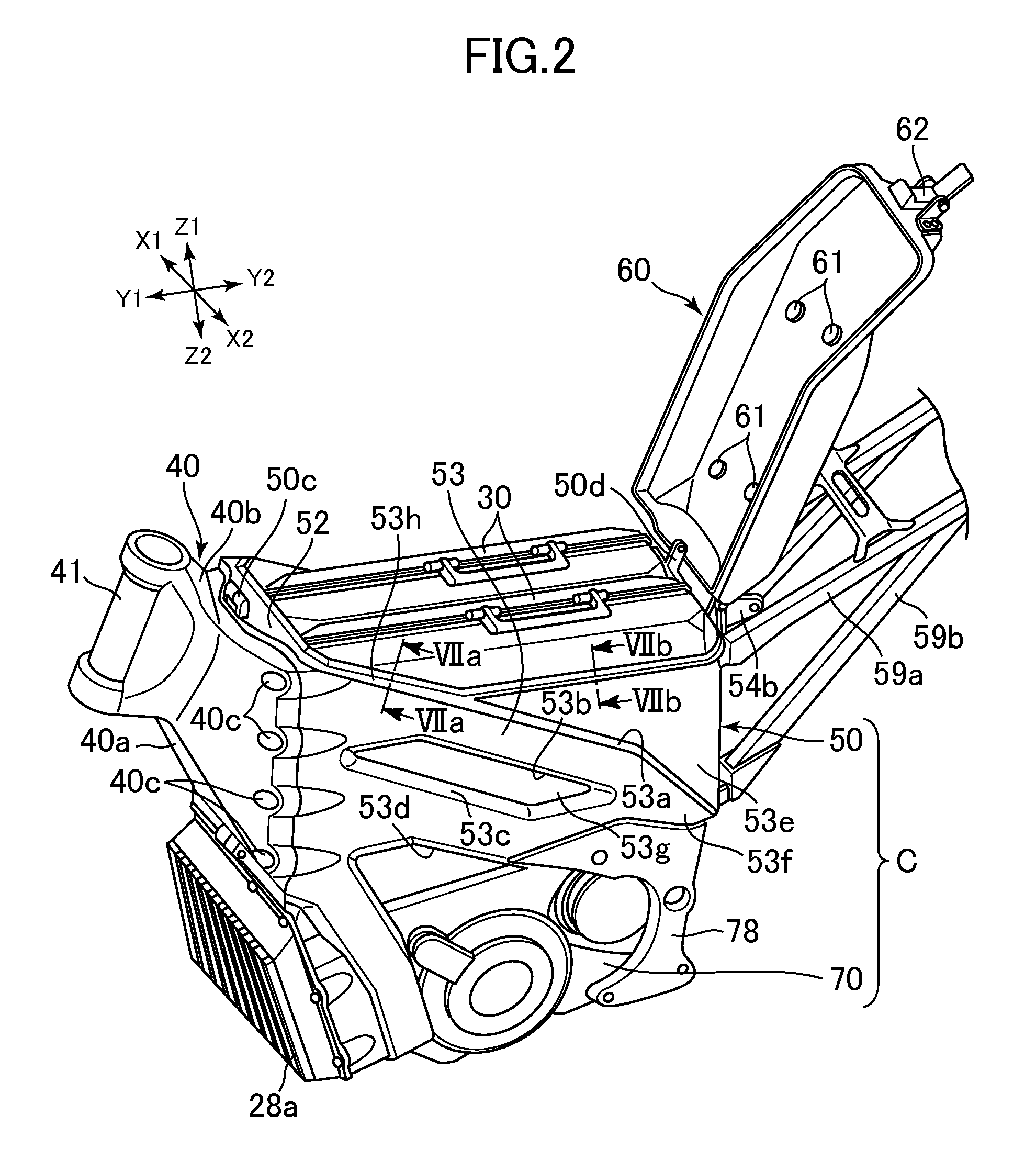

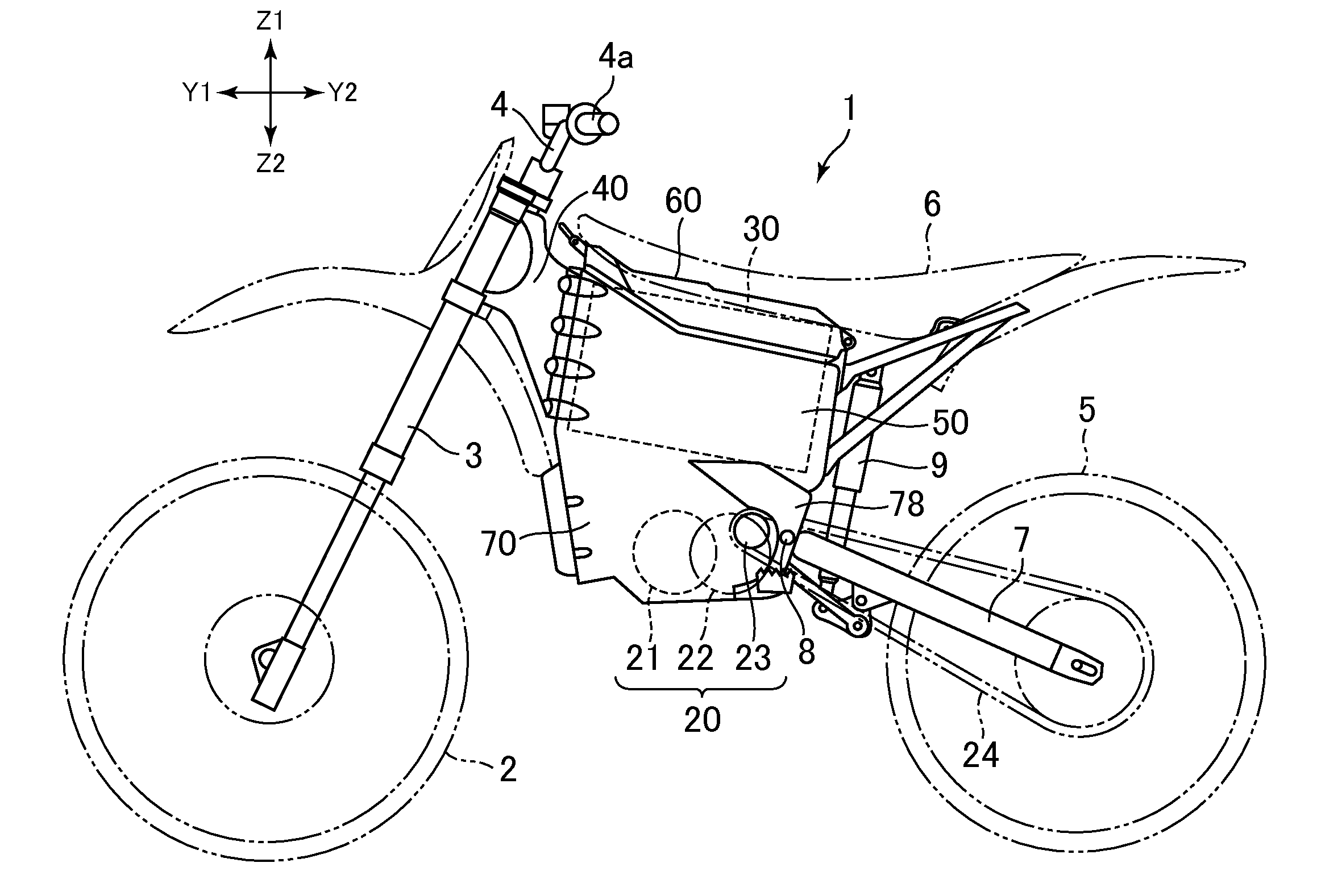

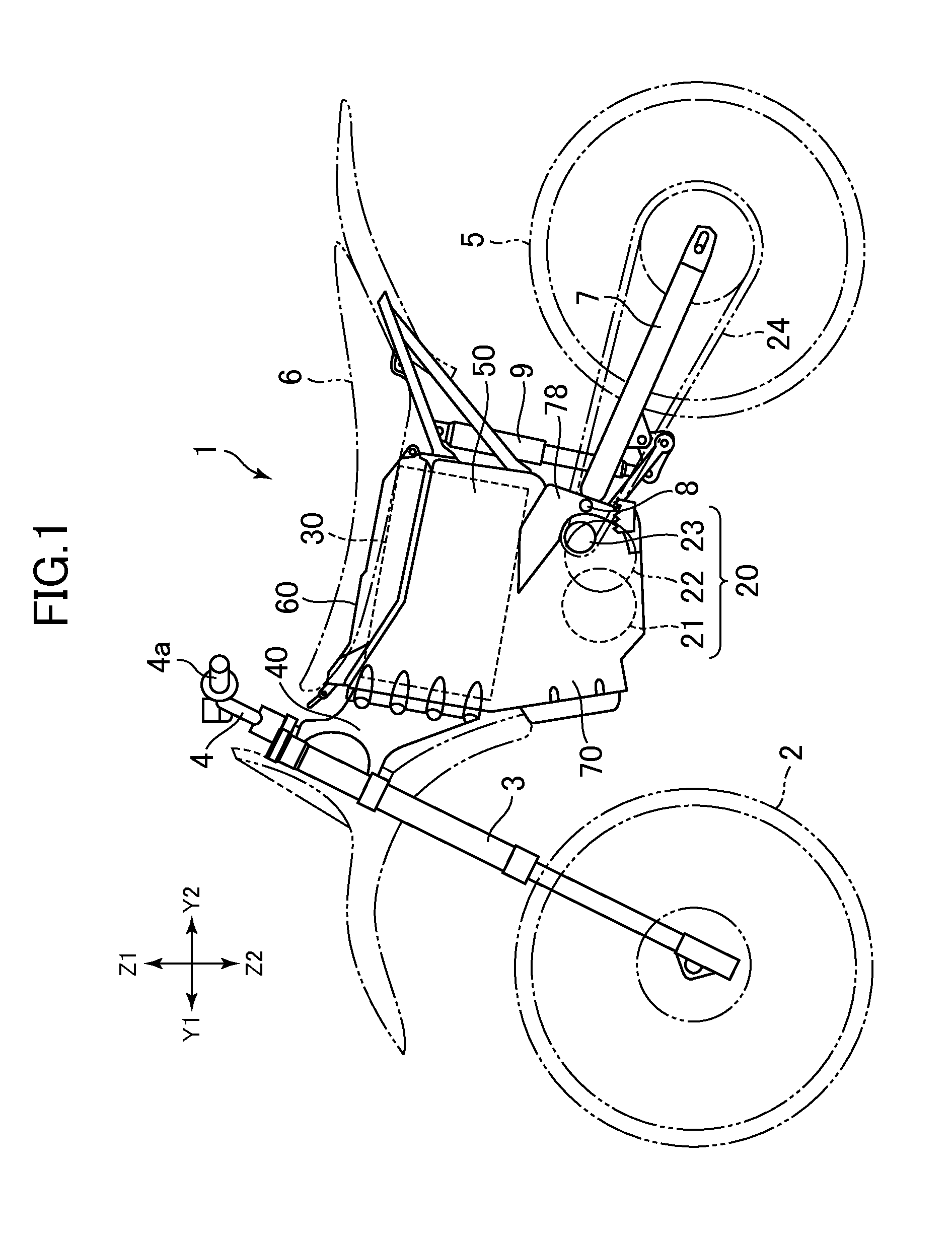

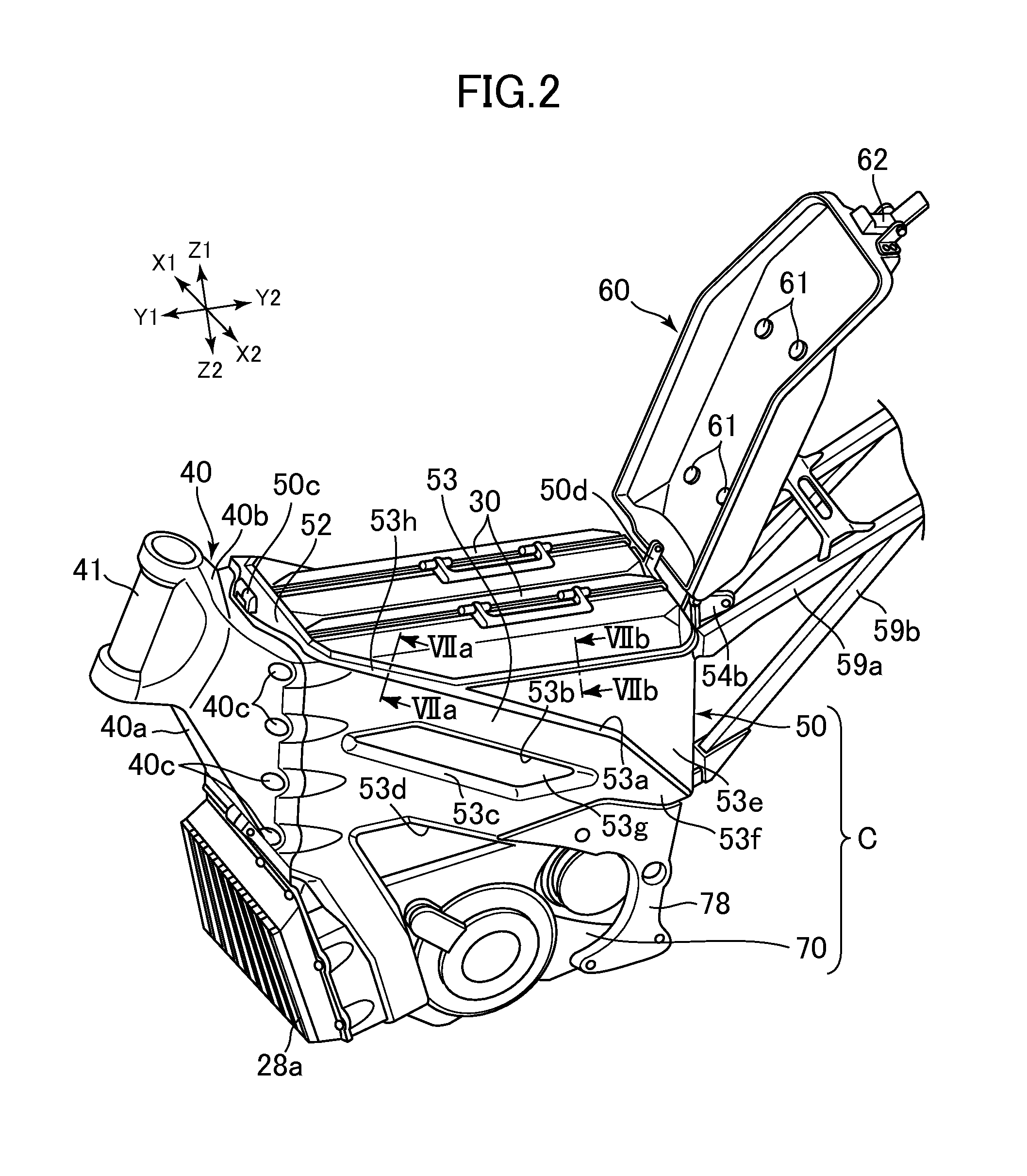

Saddle-type electric vehicle

ActiveUS9545968B2Good adhesionEasy detachmentCharging stationsElectric propulsion mountingEngineeringElectric vehicle

An electric two-wheel vehicle includes a battery case that accommodates two batteries. The battery case is open in an upward direction. A head pipe supports a steering shaft and is connected to a front portion of the battery case. The battery case includes a beam portion that is disposed between the two batteries and extends rearward from a front wall portion of the battery case. Accordingly, it is possible to easily attach and detach the batteries with respect to a vehicle body for charging, protect the batteries, and secure the rigidity of a vehicle body frame.

Owner:YAMAHA MOTOR CO LTD

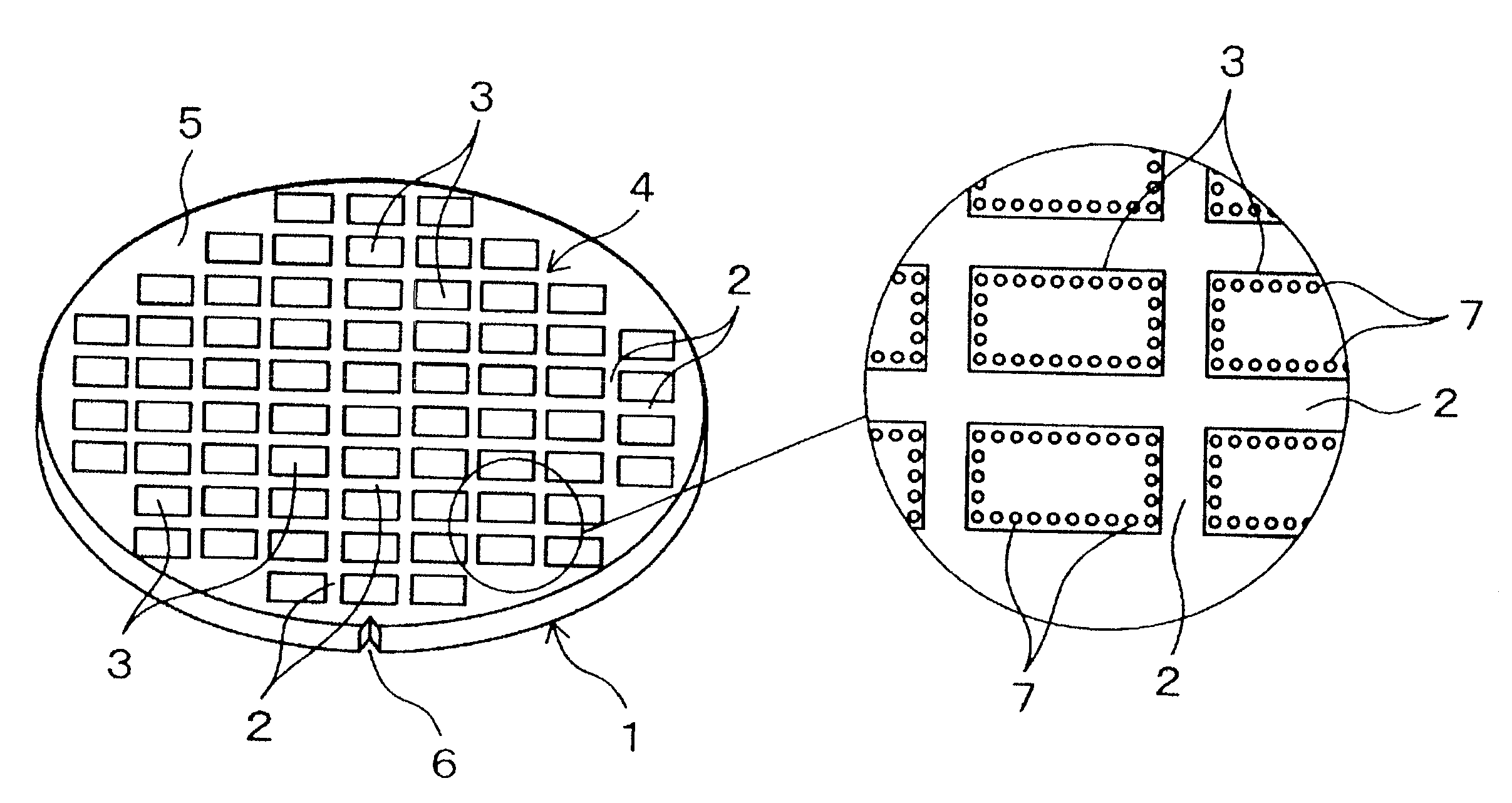

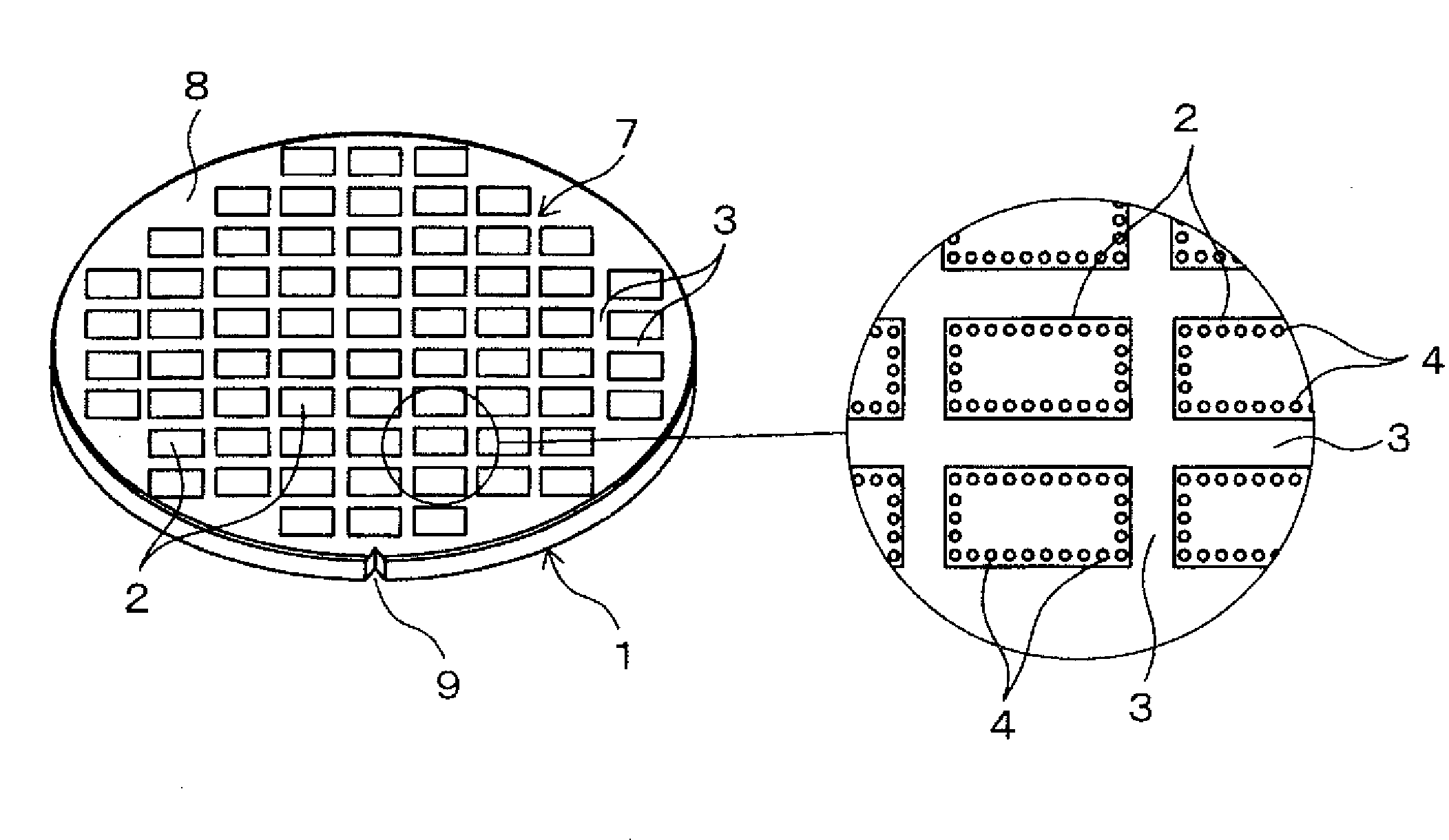

Method of machining wafer

ActiveUS20090004859A1Facilitate handlingSmoothly transferDecorative surface effectsSemiconductor/solid-state device detailsMetallic electrodeMetal

A method of machining a wafer in which, at the time of grinding the back-side surface of the wafer, only a back-side surface region corresponding to a device formation region where semiconductor chips are formed is thinned by grinding, to form a recessed part on the back side of the wafer. An annular projected part surrounding the recessed part is utilized to secure rigidity of the wafer. Next, the recessed part is etched to cause metallic electrodes to project from the bottom surface of the recessed part, thereby forming a back-side electrode parts, then an insulating film is formed in the recessed part, and the insulating film and end surfaces of the back-side electrode parts are cut.

Owner:DISCO CORP

Saddle-type electric vehicle

ActiveUS20150122569A1High strengthImprove rigidityCharging stationsElectric propulsion mountingElectric vehiclePipe support

An electric two-wheel vehicle includes a battery case that accommodates two batteries. The battery case is open in an upward direction. A head pipe supports a steering shaft and is connected to a front portion of the battery case. The battery case includes a beam portion that is disposed between the two batteries and extends rearward from a front wall portion of the battery case. Accordingly, it is possible to easily attach and detach the batteries with respect to a vehicle body for charging, protect the batteries, and secure the rigidity of a vehicle body frame.

Owner:YAMAHA MOTOR CO LTD

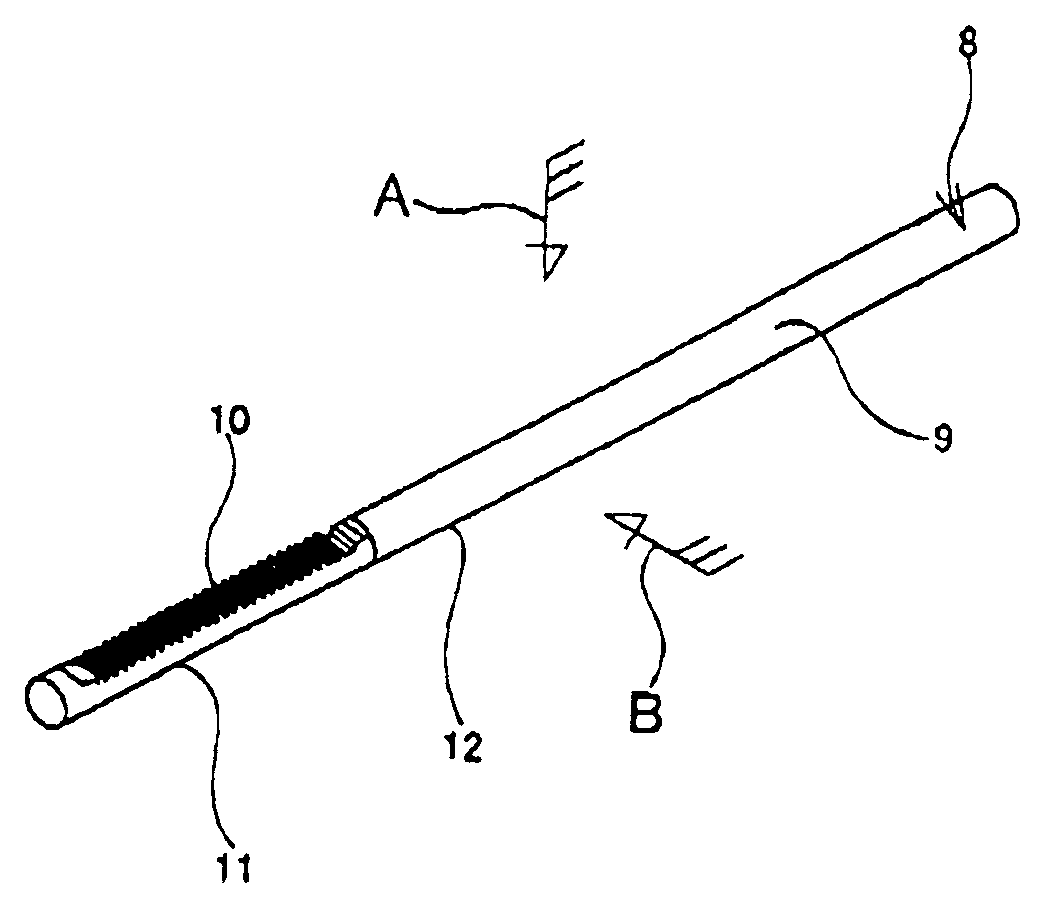

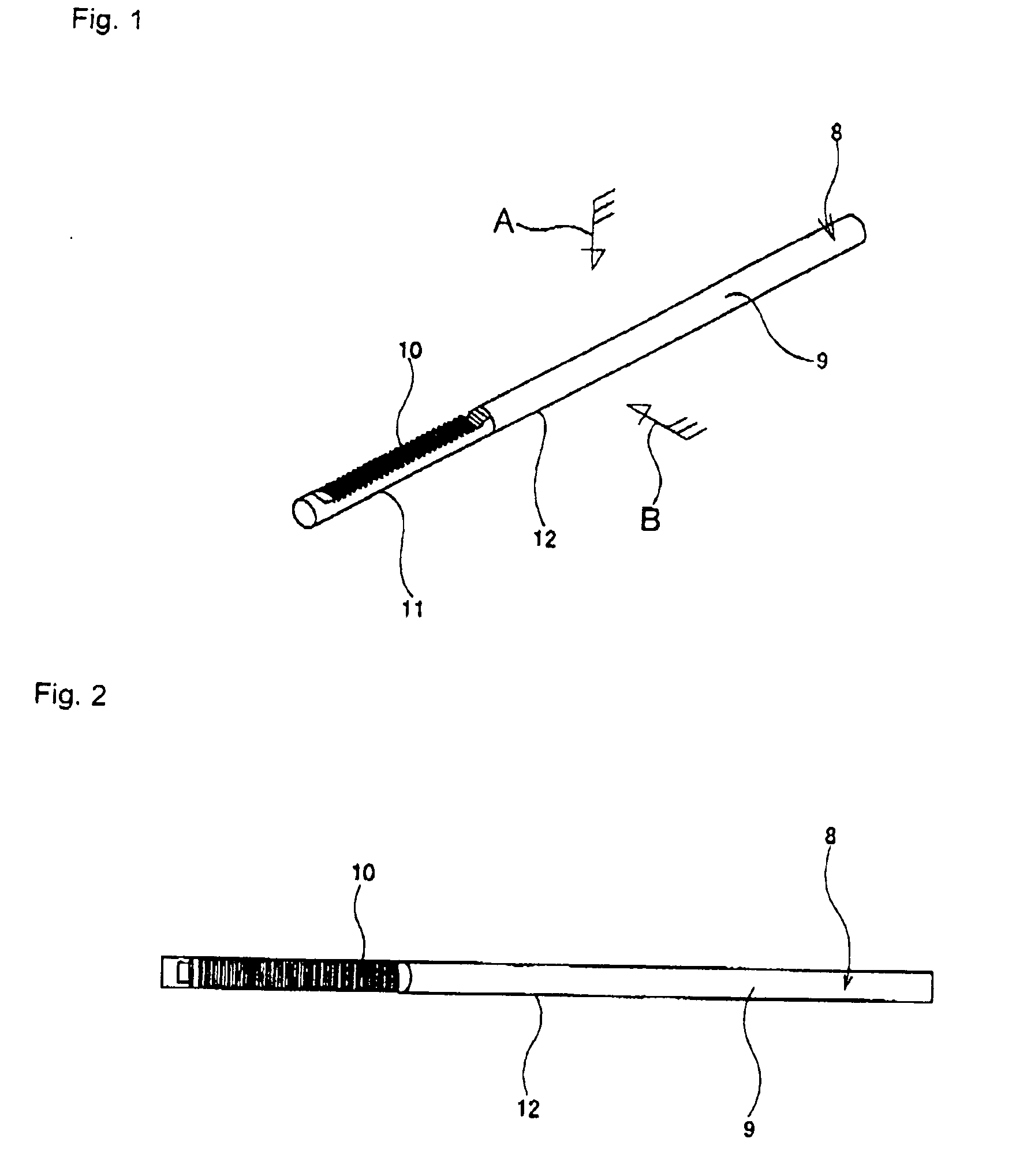

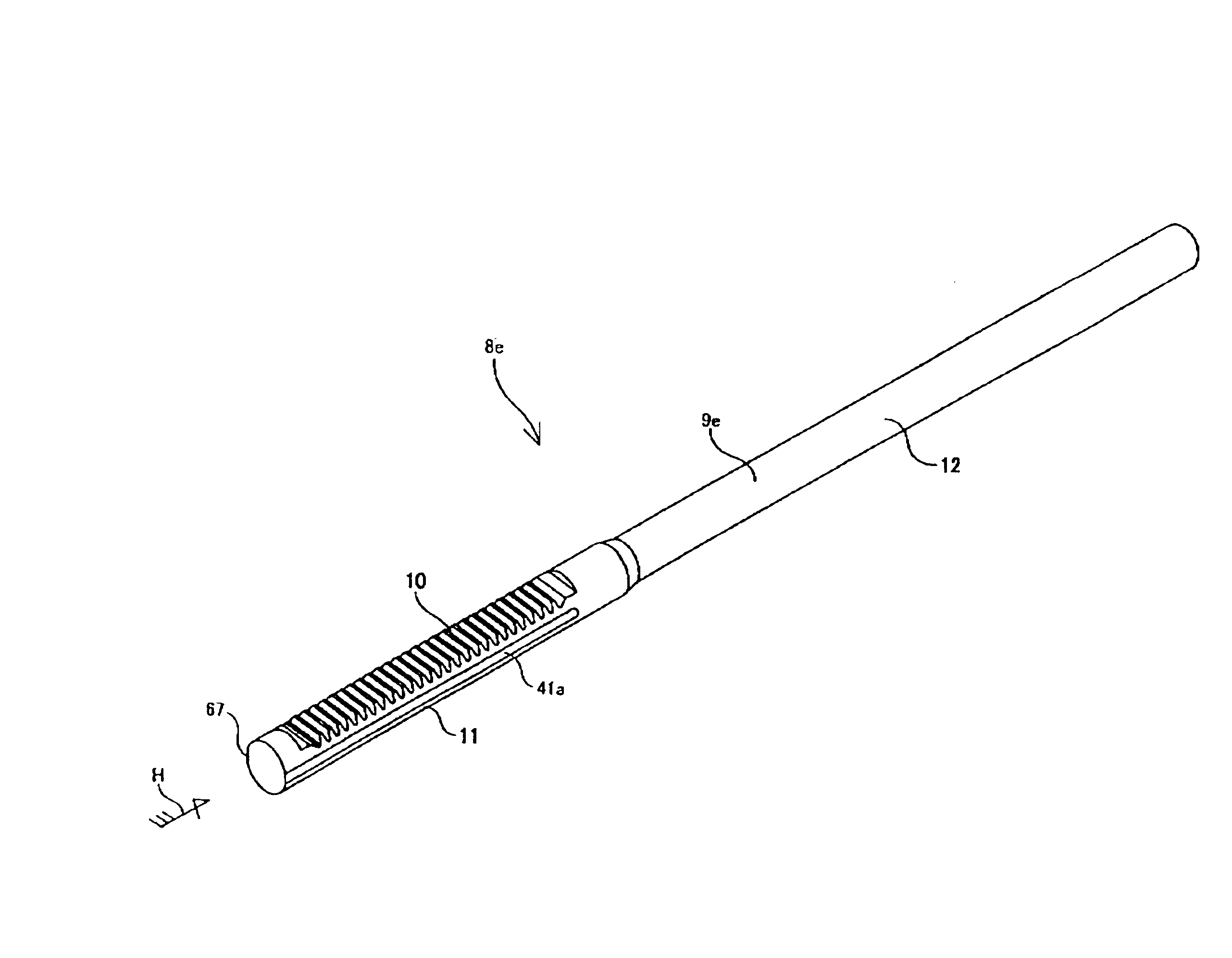

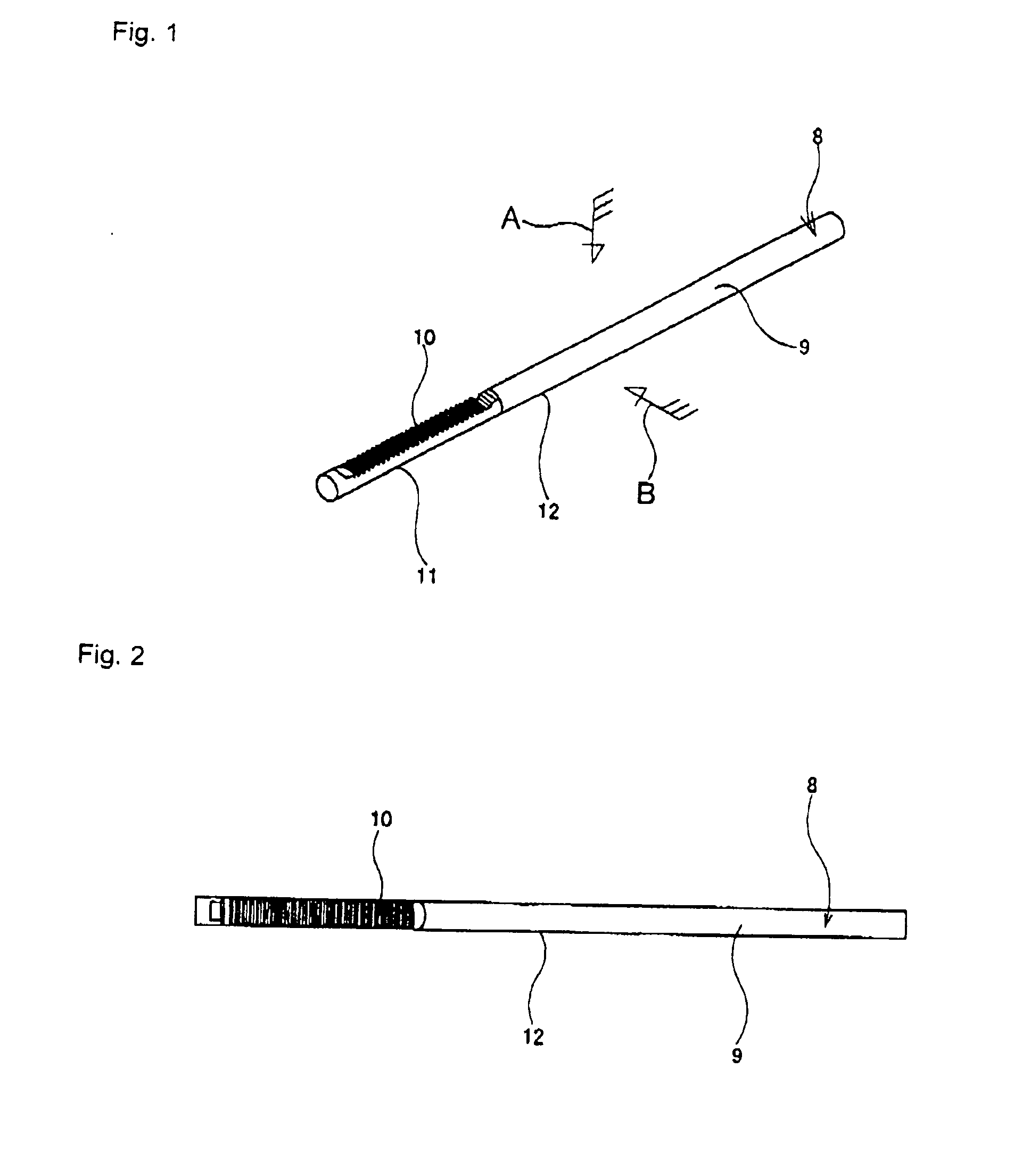

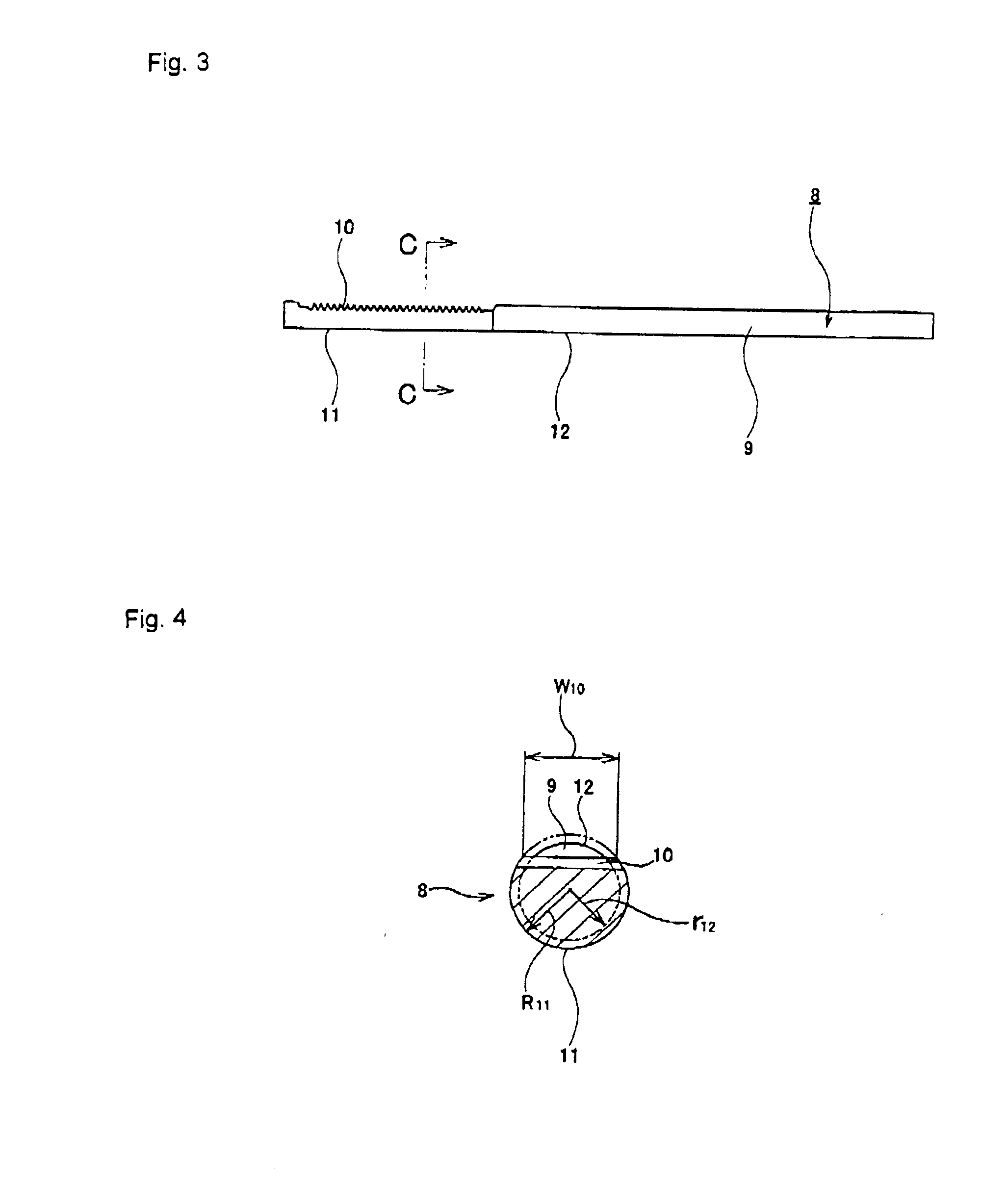

Rack and manufacturing method thereof

InactiveUS20100162843A1Low costSecure strength and rigidityMetal-working apparatusToothed gearingsSizingEngineering

To sufficiently secure the width dimension, strength and rigidity of the rack teeth 10, and to realize the light weight construction and the manufacturing method of the rack 8, the rack teeth 10 is formed by plastic working on one side surface in the radial direction of part in the axial direction of a rod unit 9 having a circular cross-sectional shape, and the curvature radius of the portion which is separated in the radial direction from the portion where the rack teeth 10 is formed, is made greater than that of the cross sectional shape of the outer surface of the axial remaining portion of the rod unit 9. For this purpose, as shown in (A) to (B), while a portion in the circumferential direction of part in the axial direction of a material 13 is compressed, the remaining portion in the circumferential direction of this part in the axial direction is formed into a partial cylindrical surface 17 whose curvature radius is larger than that of the outer surface of the material 13, to form an intermediate material 20. Then, as shown in (C) to (D), the rack teeth 10 are formed on the circumferential portion of the axial part of the intermediate material 20. At last, as shown in (E) to (F), sizing is performed to obtain the rack 8.

Owner:NSK LTD

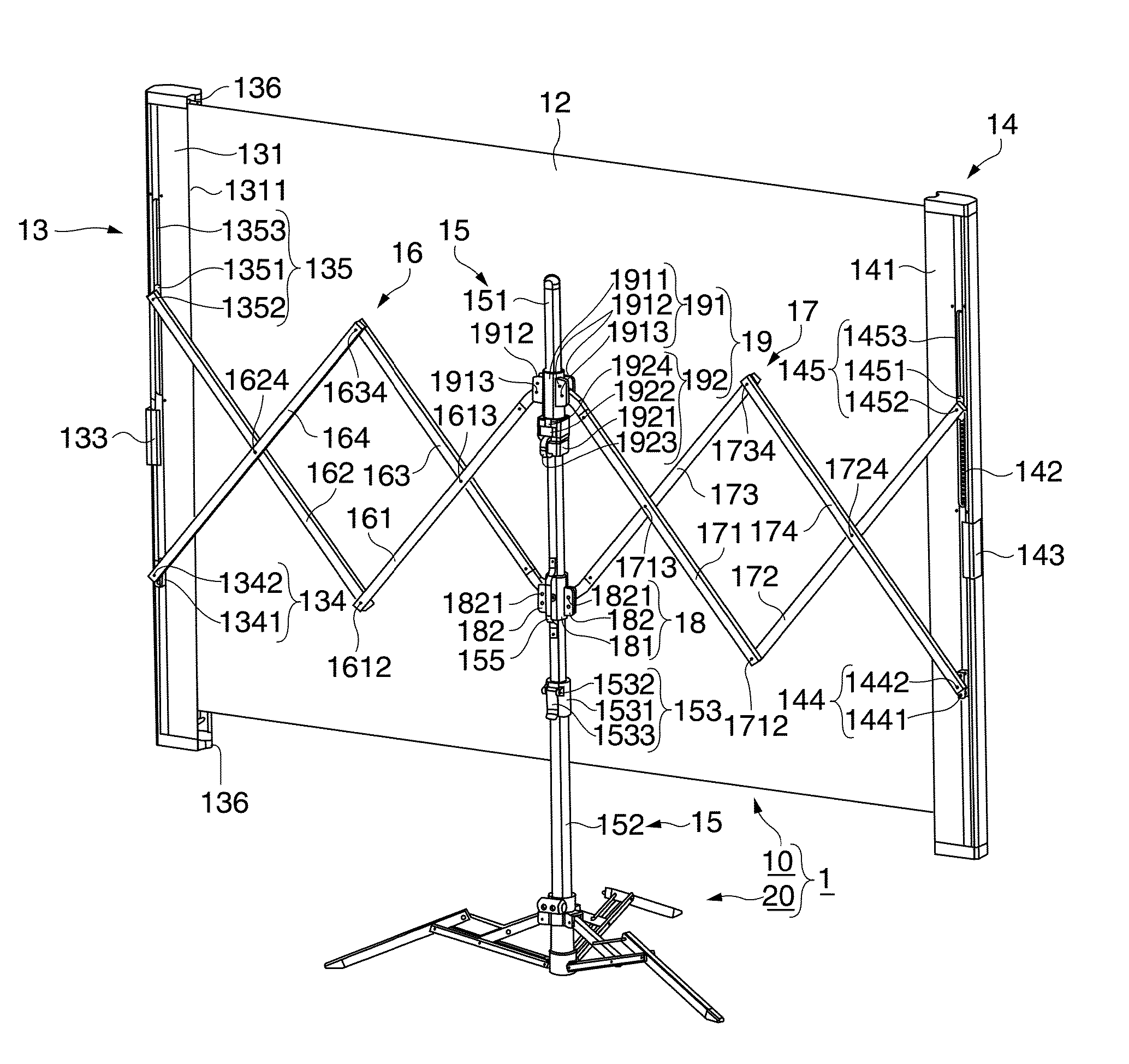

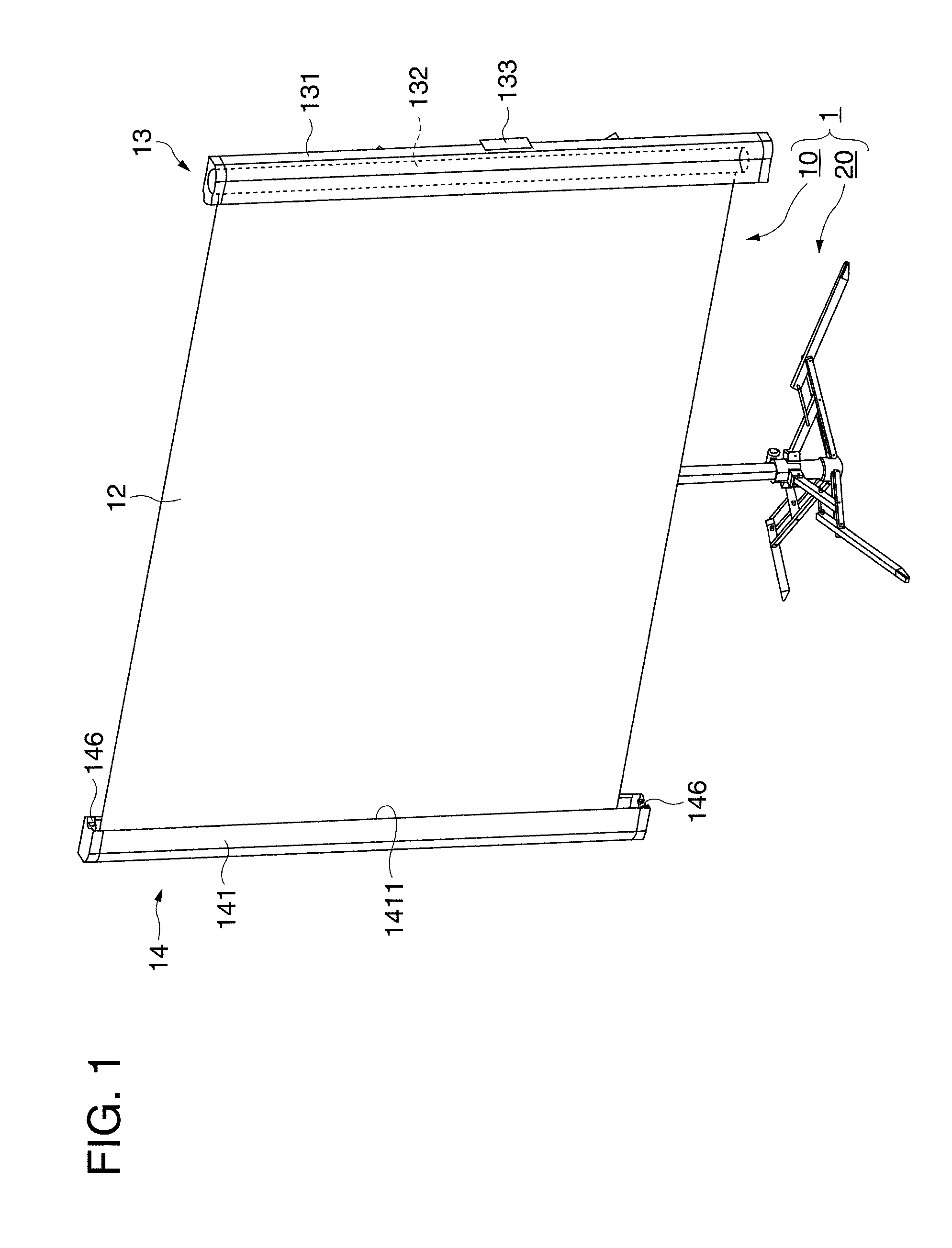

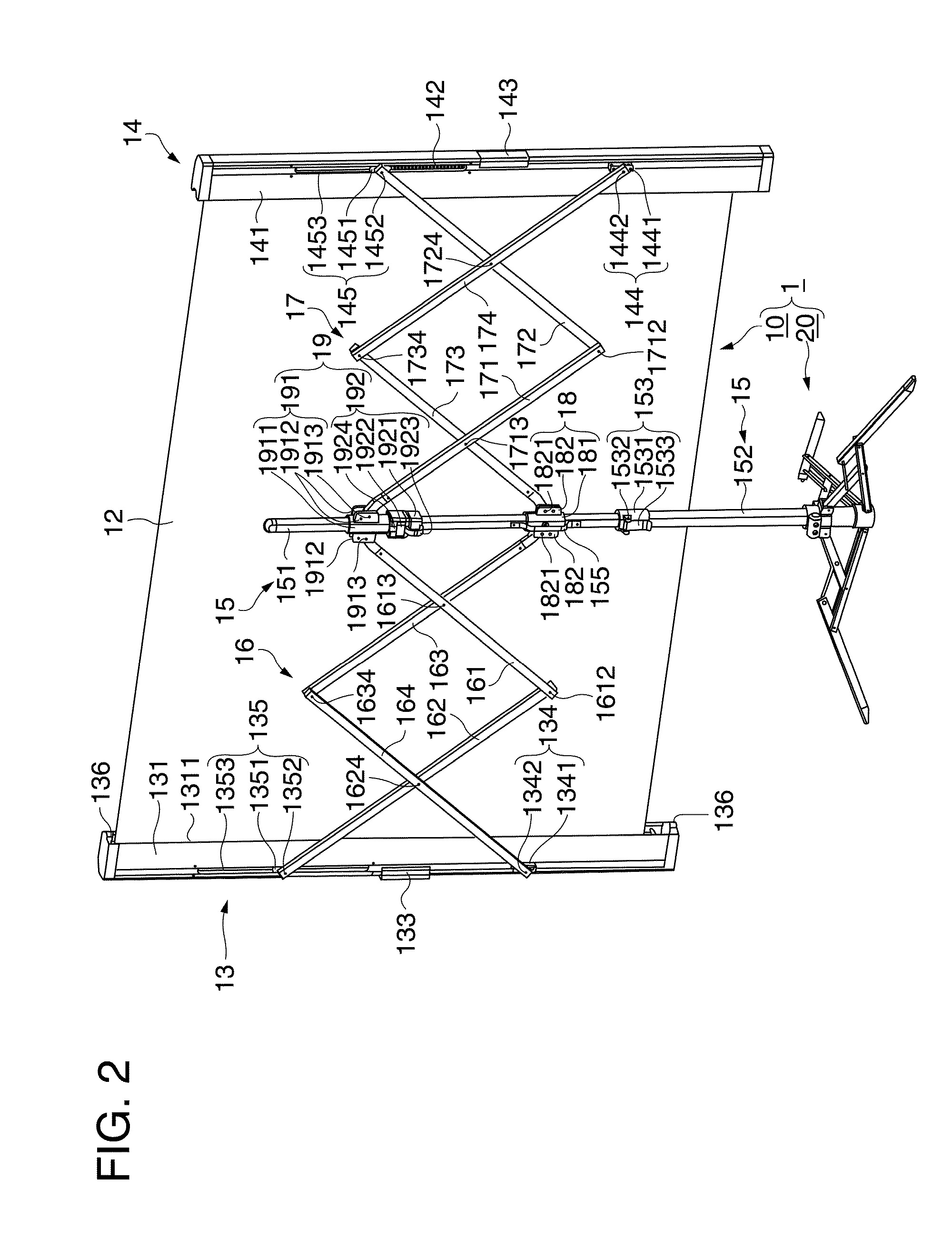

Screen

ActiveUS20100007950A1Flexibility of the position of arrangementFixed column is increasedProjectorsEngineering

A screen includes: a flexible screen body on which image light is projected; a fixed column arranged in a central portion; an arm sliding unit configured to pivotably support the second arm member of the first pantograph mechanism and the second arm member of the second pantograph mechanism with respect to the fixed column so as to be slidable in the vertical direction, in which the first pantograph mechanism and the second pantograph mechanism are expanded and contracted to move the first supporting unit and the second supporting unit toward and away from each other by a sliding movement of the arm sliding unit, and an urging member configured to urge the first supporting unit and the second supporting unit to move away from each other is provided.

Owner:SEIKO EPSON CORP

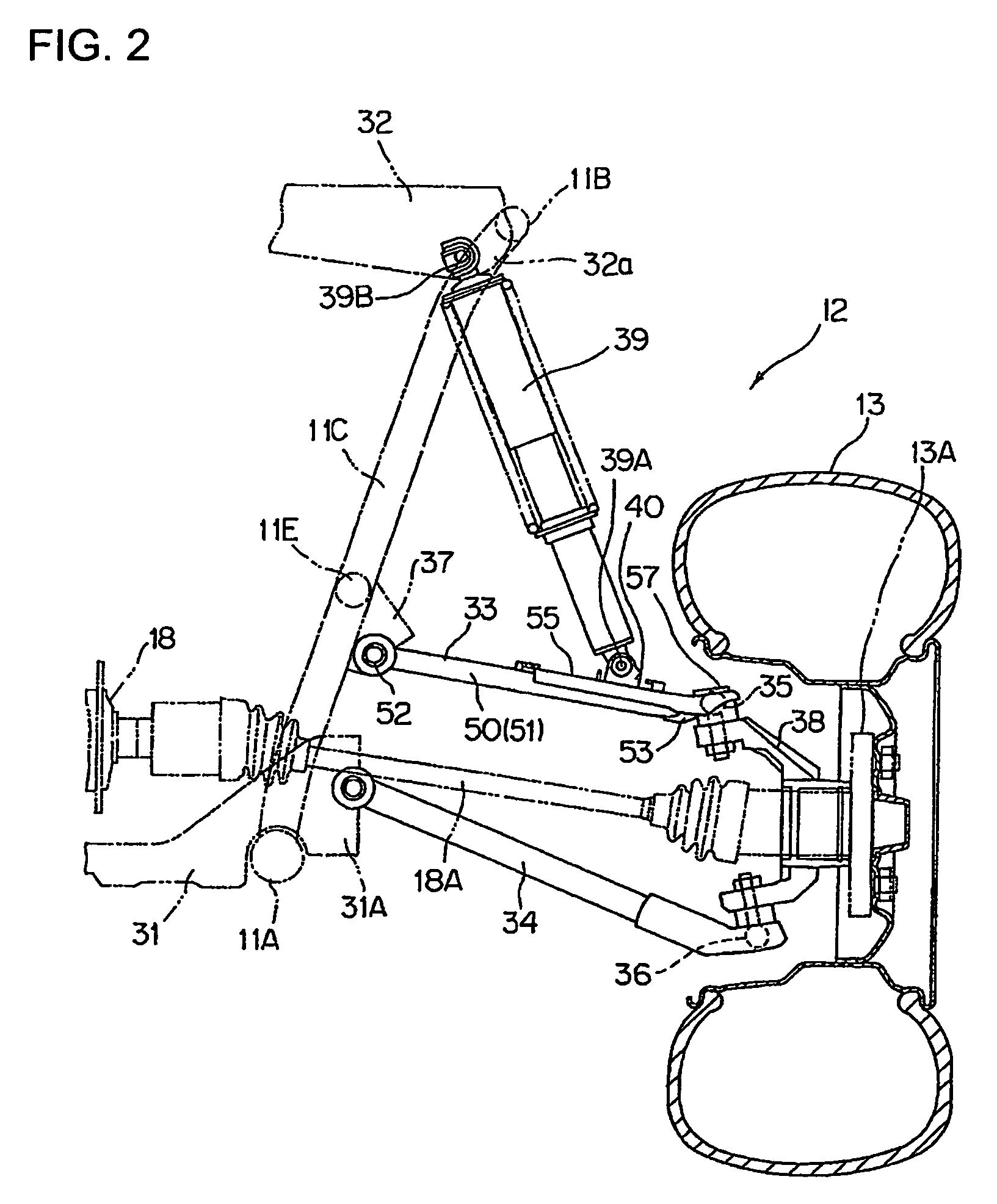

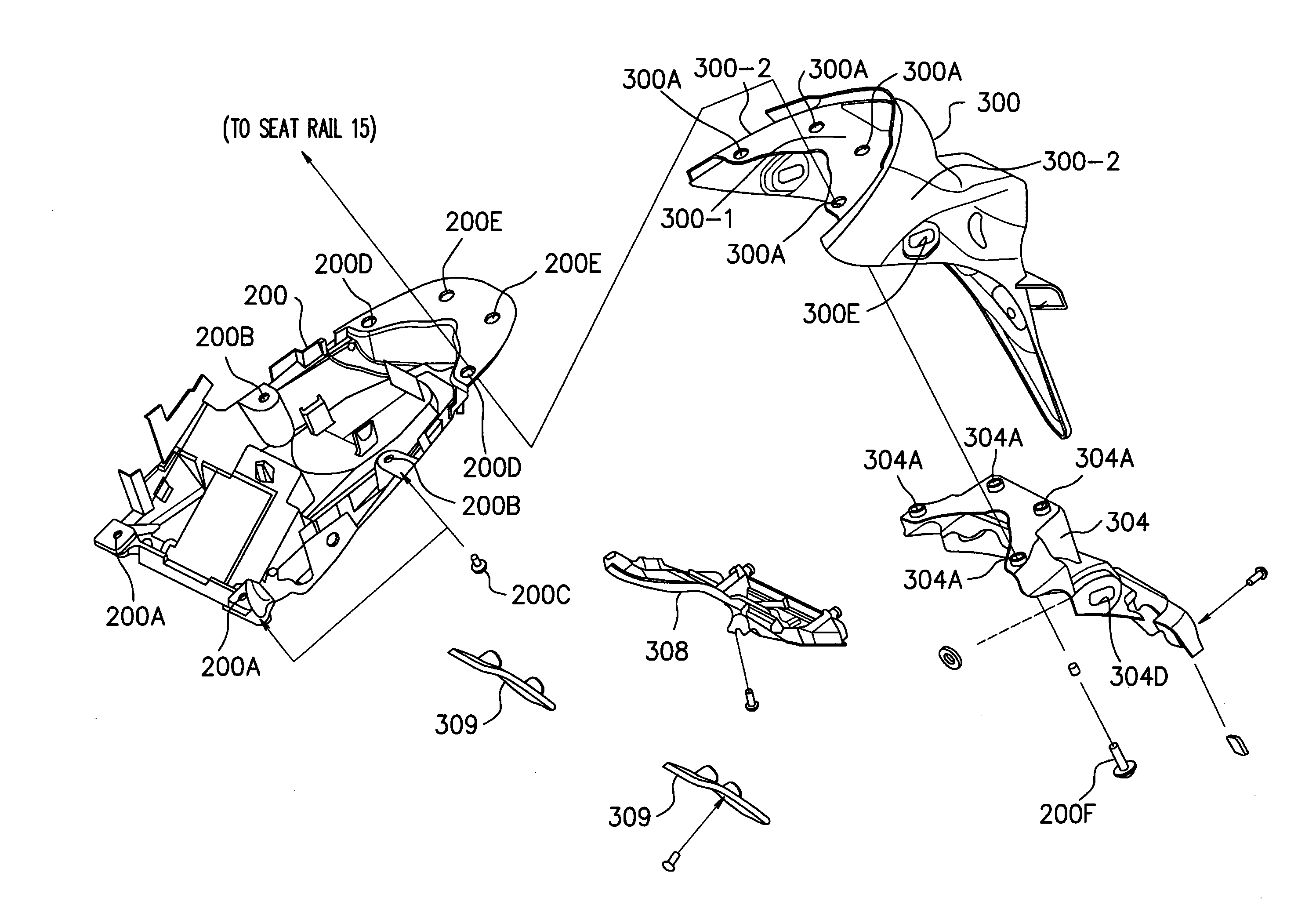

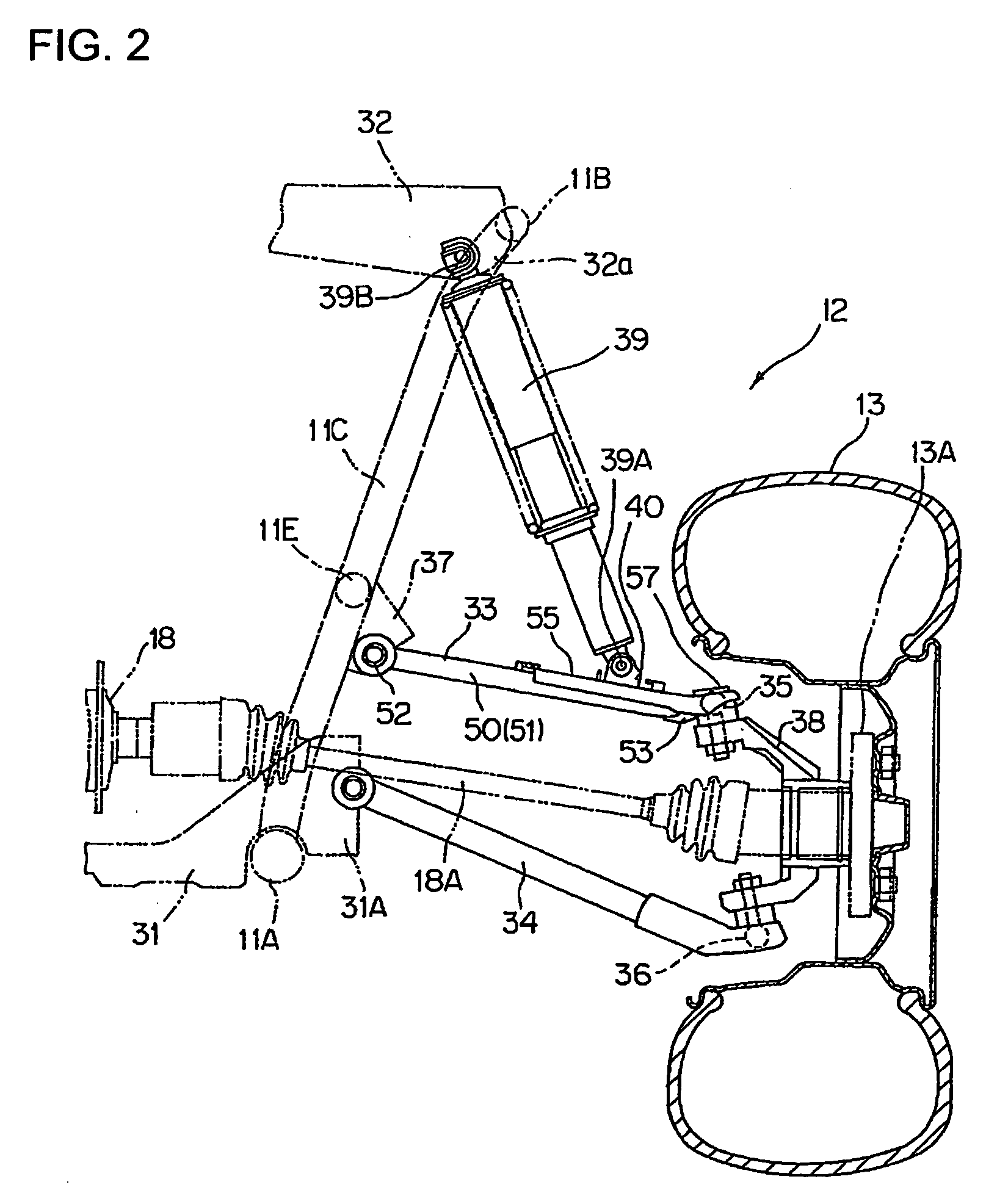

Suspension arm assembly for a vehicle, and vehicle incorporating same

ActiveUS7934735B2Improve connection strengthIncrease the areaVehicle seatsResilient suspensionsJoint componentEngineering

A suspension arm assembly for a vehicle includes a pivot pipe pivotally attached to a vehicle body frame, a pair of pipes extending in a lateral direction of a vehicle body, a joint member attached to distal end portions of the pipes, and a substantially U-shaped band. Proximal end portions of the pipes are connected to the pivot pipe and spaced apart from each other in a front-rear direction, and distal end portions thereof are arranged close to each other, thereby forming a substantially triangular profile. The joint member includes a plate portion and a boss portion having a knuckle attached thereto. The distal end portions of the pipes are operatively connected to a convex surface of the U-shaped band, and the plate portion of the joint member is attached to the pipes for covering the U-shaped band.

Owner:HONDA MOTOR CO LTD

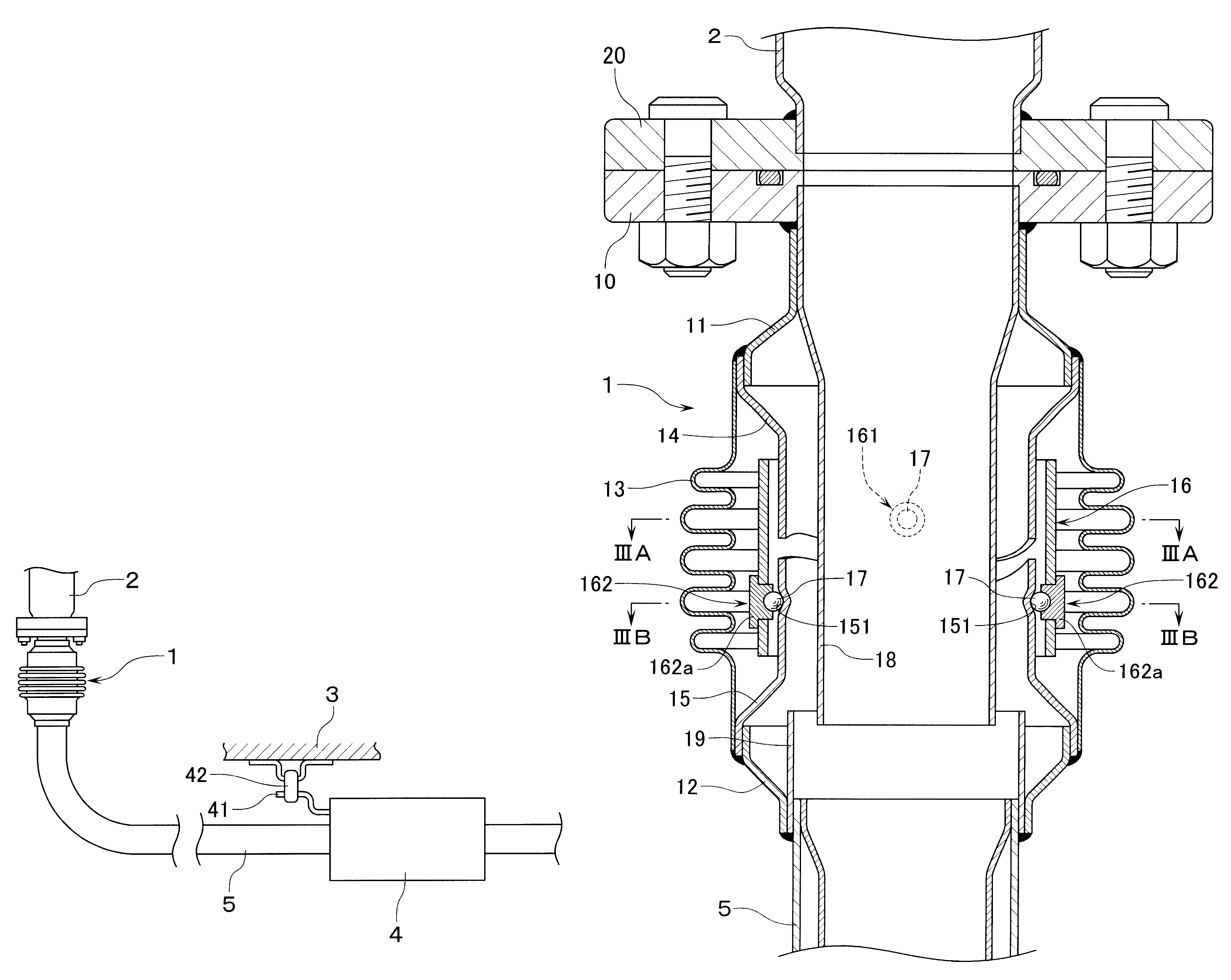

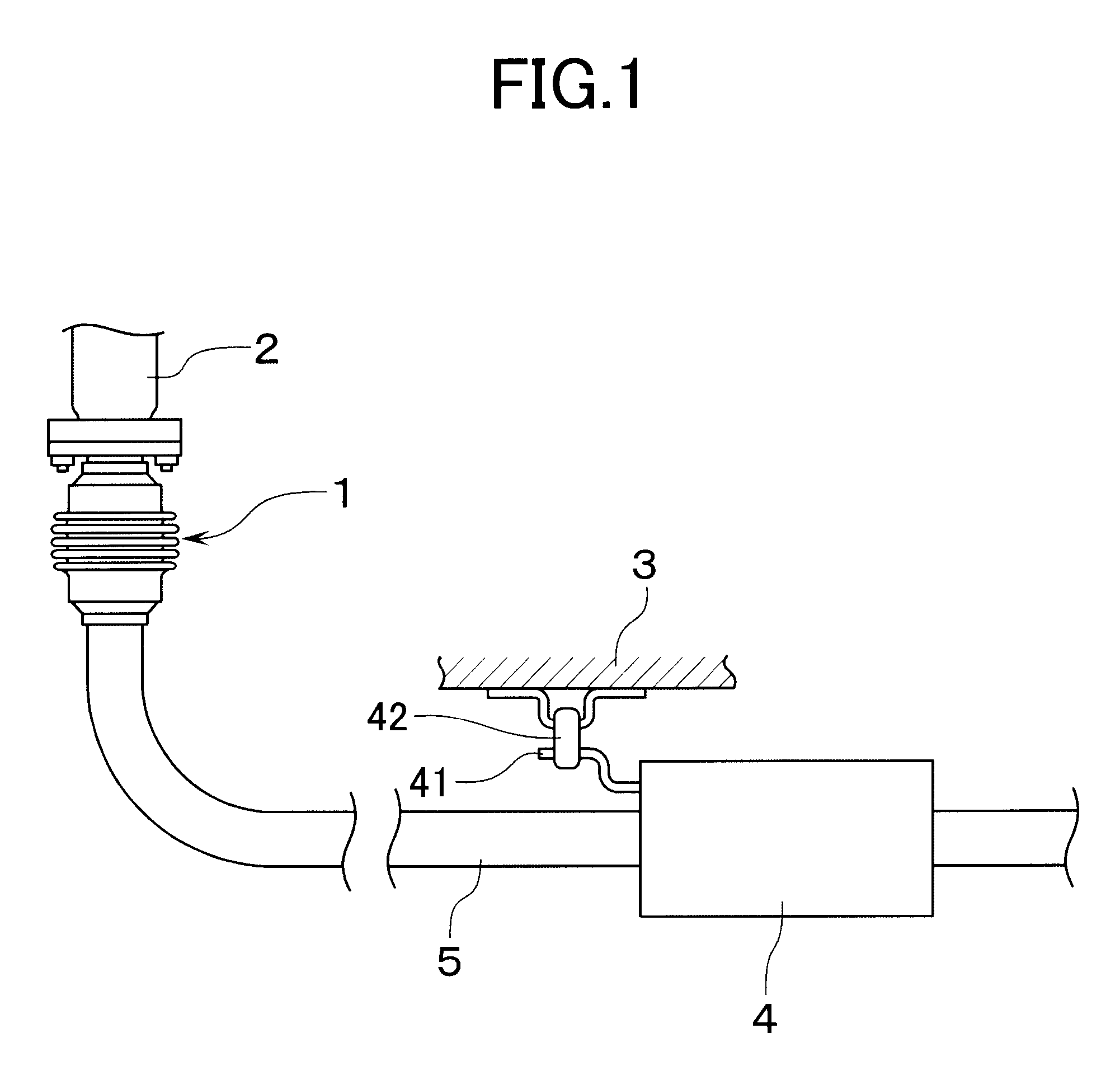

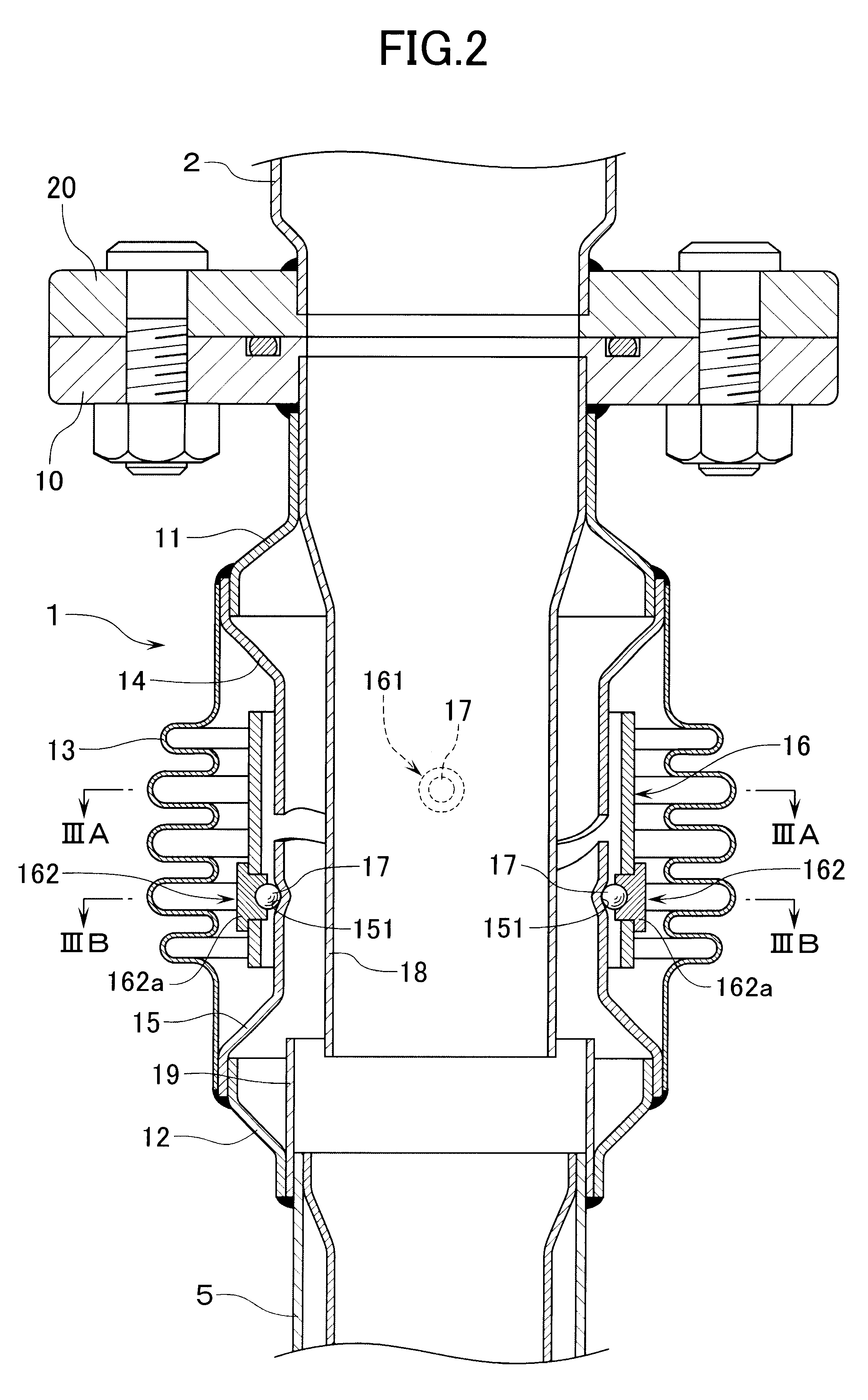

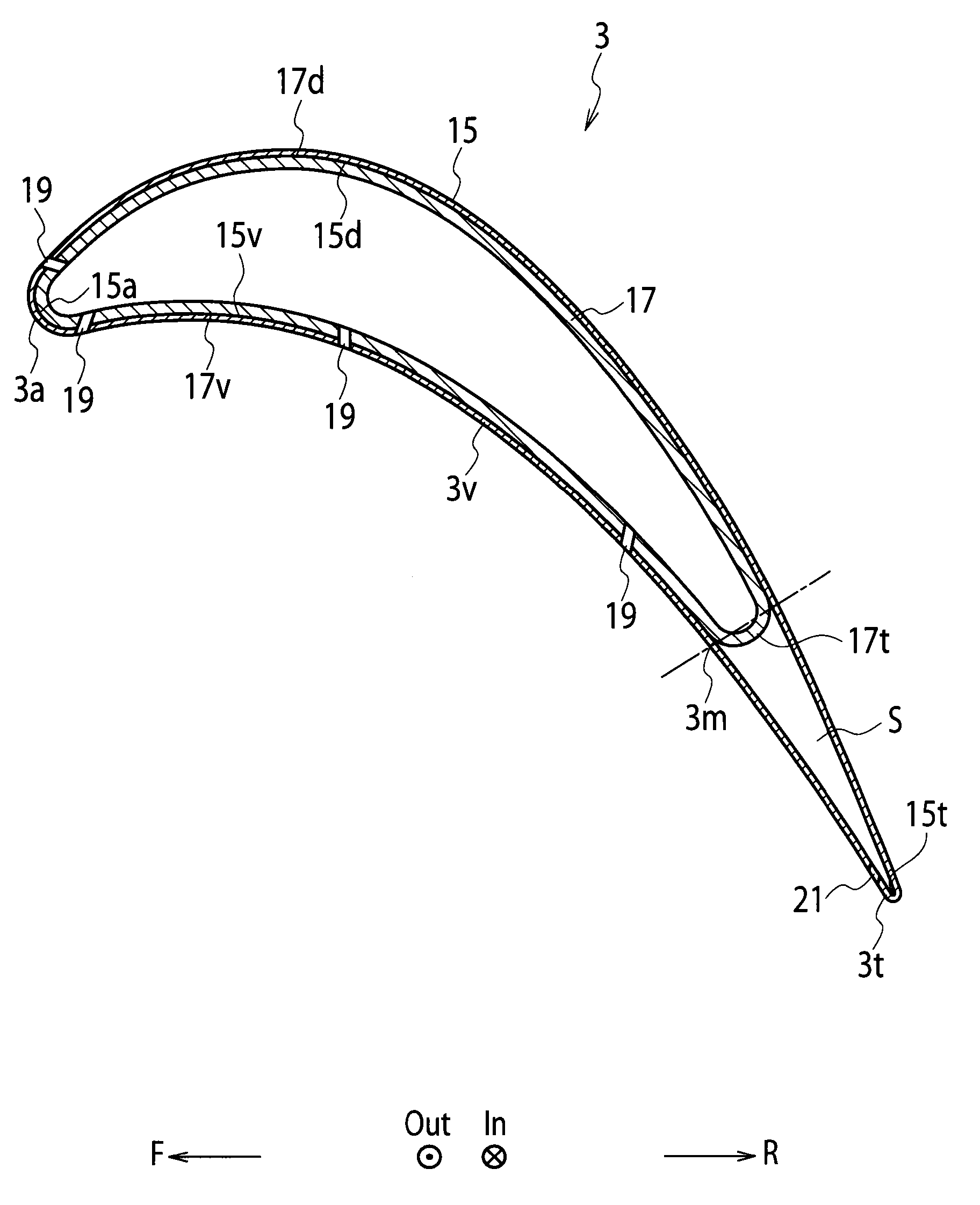

Exhaust pipe joint assembly

InactiveUS6419280B2Reduce rigidityRigidity of joint can be securedThermal insulationExhaust apparatusPhase differenceEngineering

An exhaust pipe assembly provided with a bellows pipe for connecting an upstream exhaust pipe and a downstream exhaust pipe is disposed so as to form a double pipe construction with a first joint pipe which is connected to the upstream exhaust pipe and a second joint pipe which is connected to the downstream exhaust pipe. A pair of ball receiving portions are disposed on a peripheral surface of the first joint pipe at a distance from each other in a circumferential direction, and a pair of ball receiving portions are disposed on a peripheral surface of the second joint pipe at a distance from each other in a circumferential direction. The ball receiving portions are disposed at an angular phase difference with each other in the circumferential direction. There is provided a coupling piece which has a pair of first ball joint portions engaged with the pair of ball receiving portions of the first joint pipe through a ball, and a pair of second ball joint portions engaged with the pair of ball receiving portions of the second joint pipe respectively through a ball.

Owner:HONDA MOTOR CO LTD +1

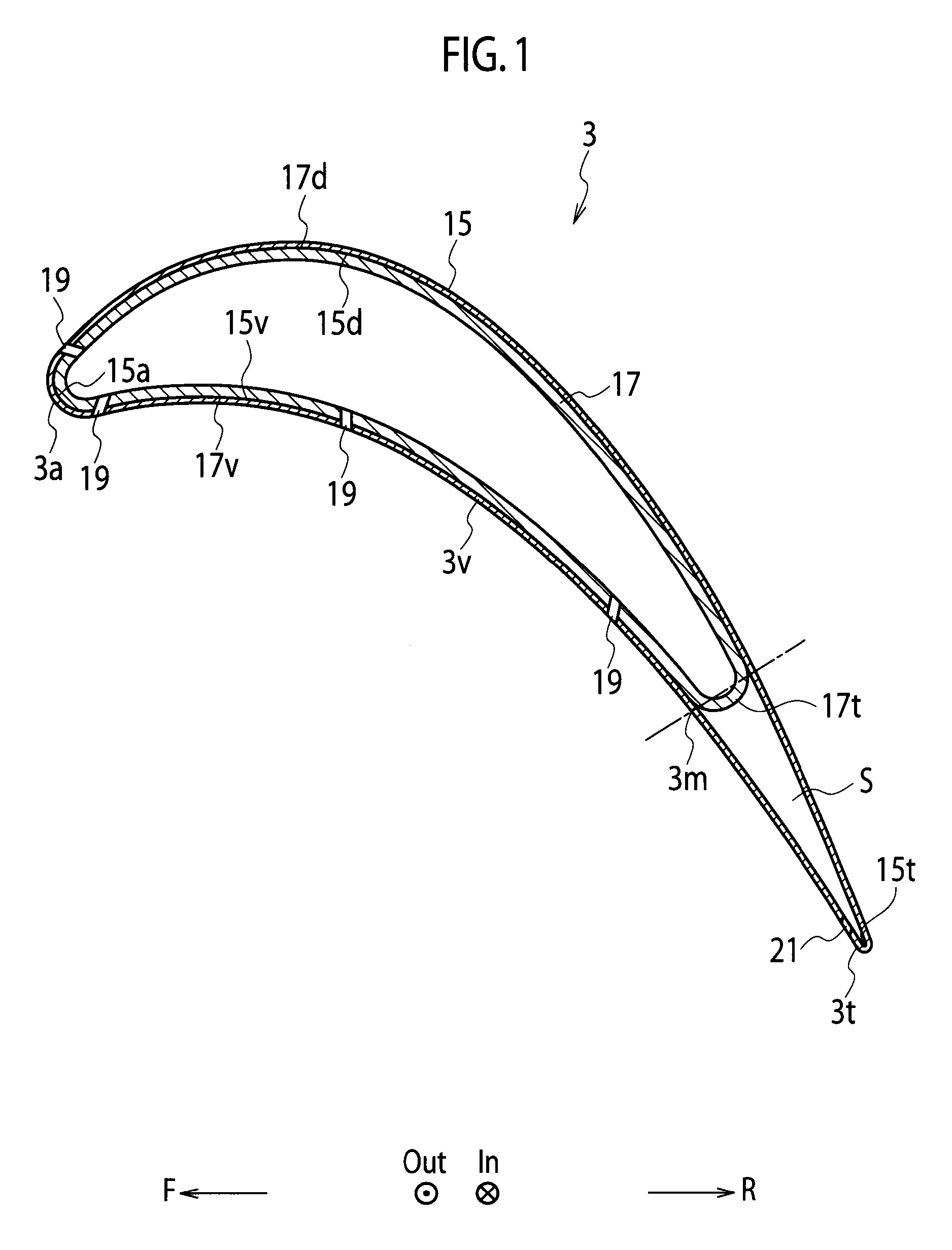

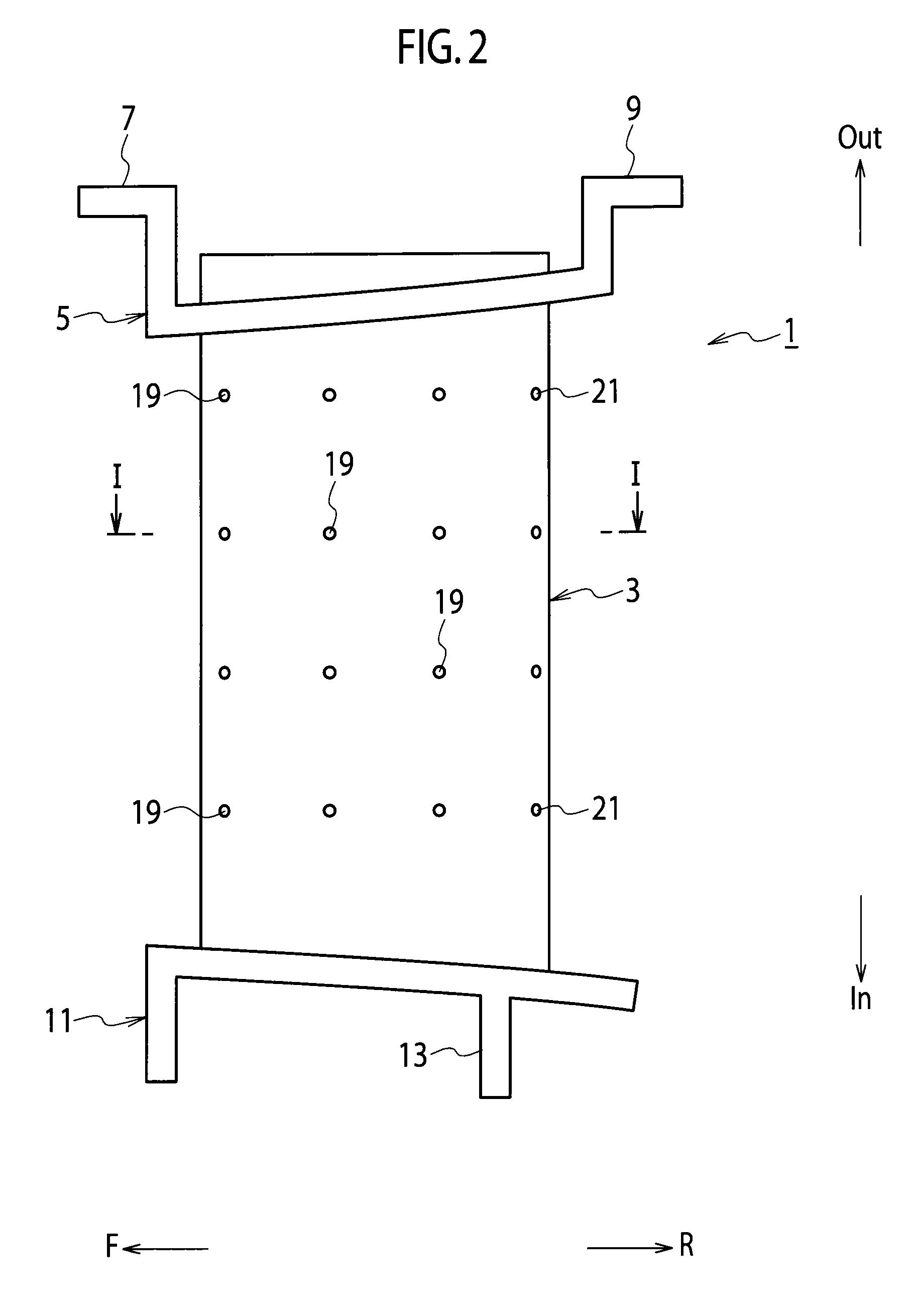

Method for manufacturing vane

InactiveUS20120279631A1Turbine efficiency and compressor efficiency be improveImprove efficiencyPump componentsBlade accessoriesTrailing edgeFiber

In a manufacturing method of a vane having an inner-ply vane within an outer-ply vane and a rear space in its inside, (a) an inner-ply vane woven-fiber formed body made of reinforcement fiber is formed on a jig corresponding to an inner surface profile of the inner-ply vane; (b) matrix is infiltrated into the inner-ply vane woven-fiber formed body to make the inner-ply vane; (c) the jig is removed; (d) a supplemental jig corresponding to the rear space and the inner-ply vane are integrated to form a integrated body; (e) an outer-ply vane woven-fiber formed body made of reinforcement fiber on a surface of the integrated body; (f) matrix is infiltrated into the outer-ply vane woven-fiber formed body to make the outer-ply vane. According to the manufacturing method, it becomes possible to manufacture a vane that can improve turbine efficiency by reducing thickness of a trailing edge of the vane.

Owner:IHI CORP

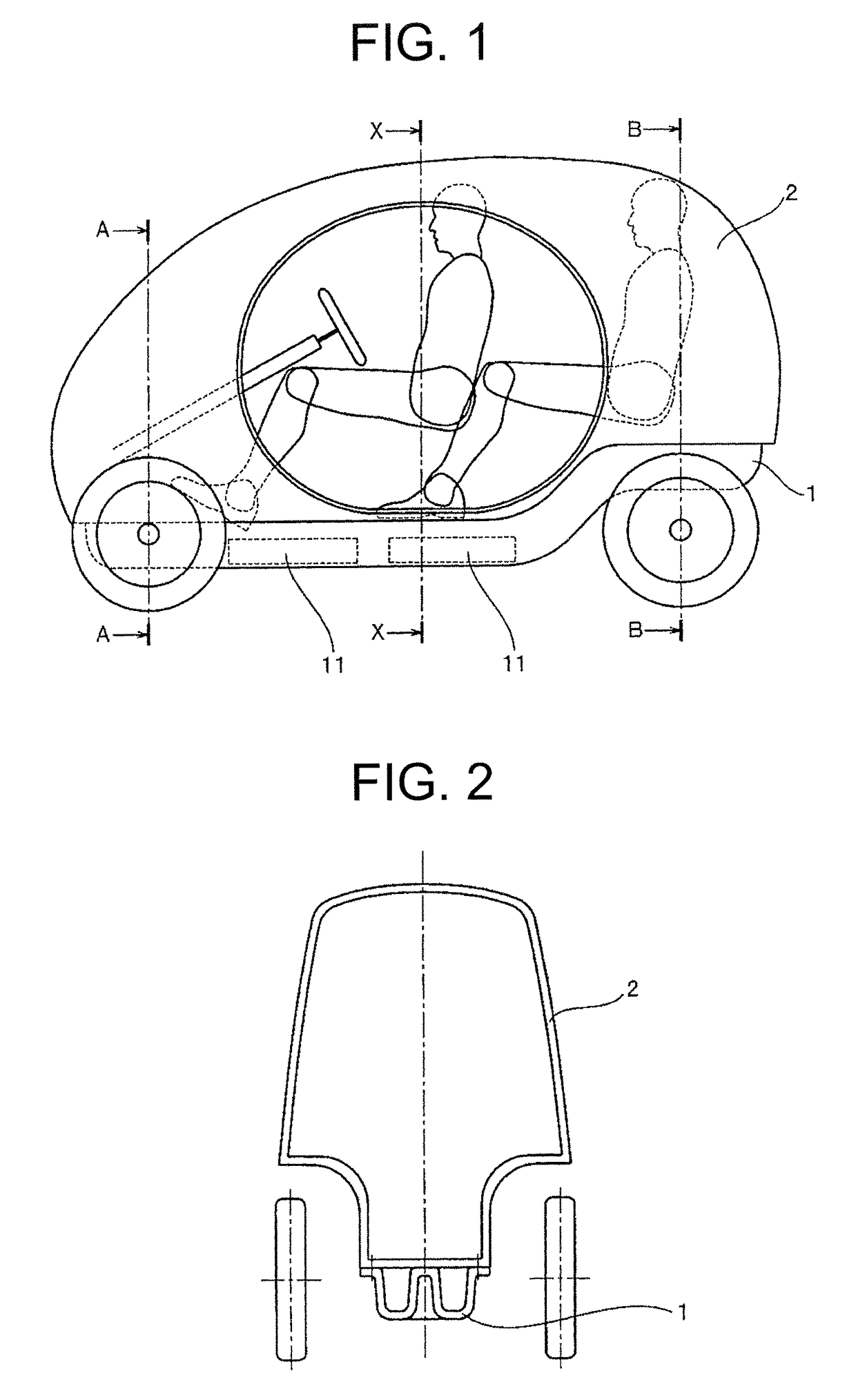

Vehicle of monocoque construction formed from thermoplastic resin members

ActiveUS9802650B2Increase awarenessImprove securityElectric propulsion mountingVehicle sub-unit featuresEngineeringField of view

Owner:TEIJIN LTD

Mounting structure of front body frame in vehicle

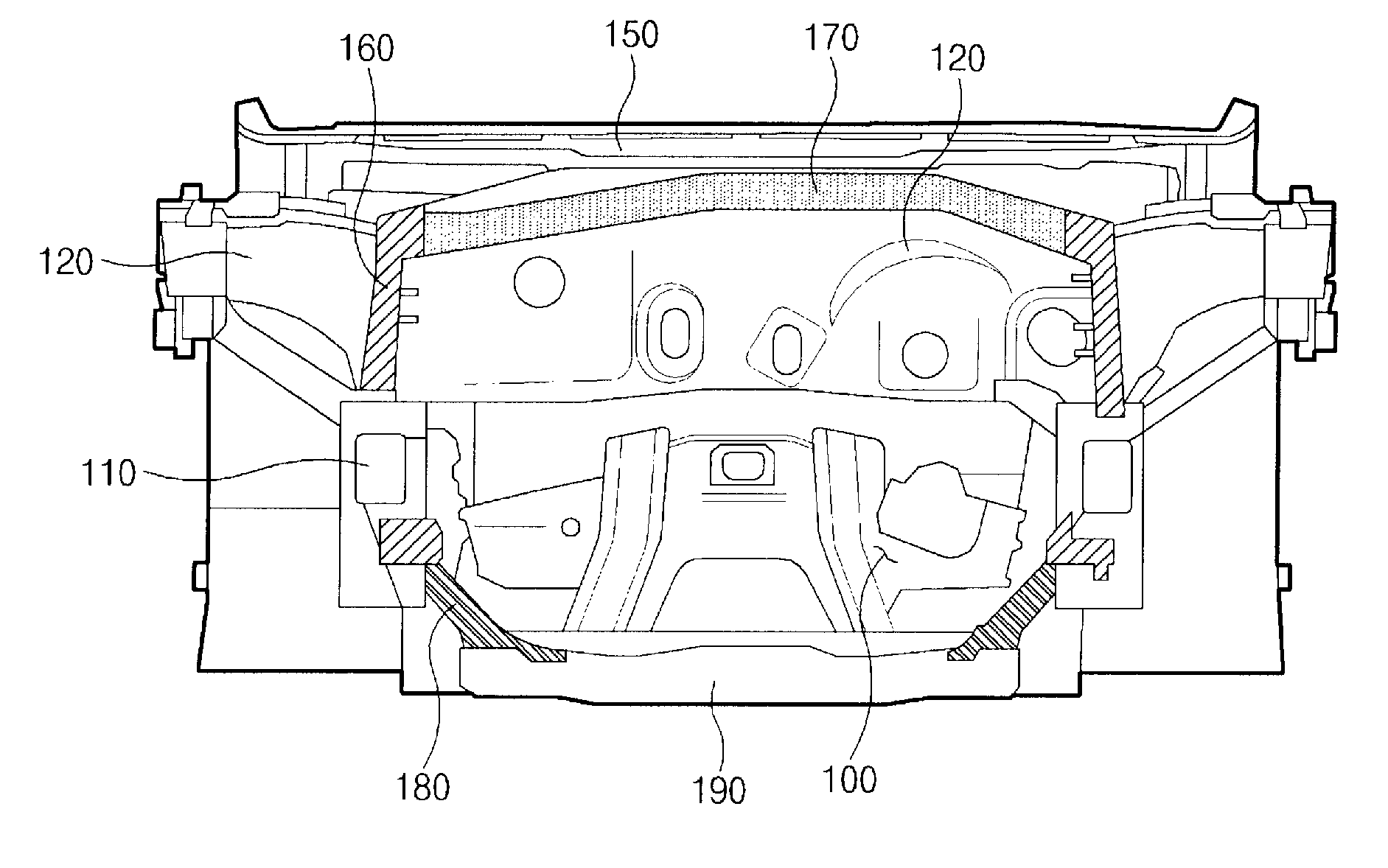

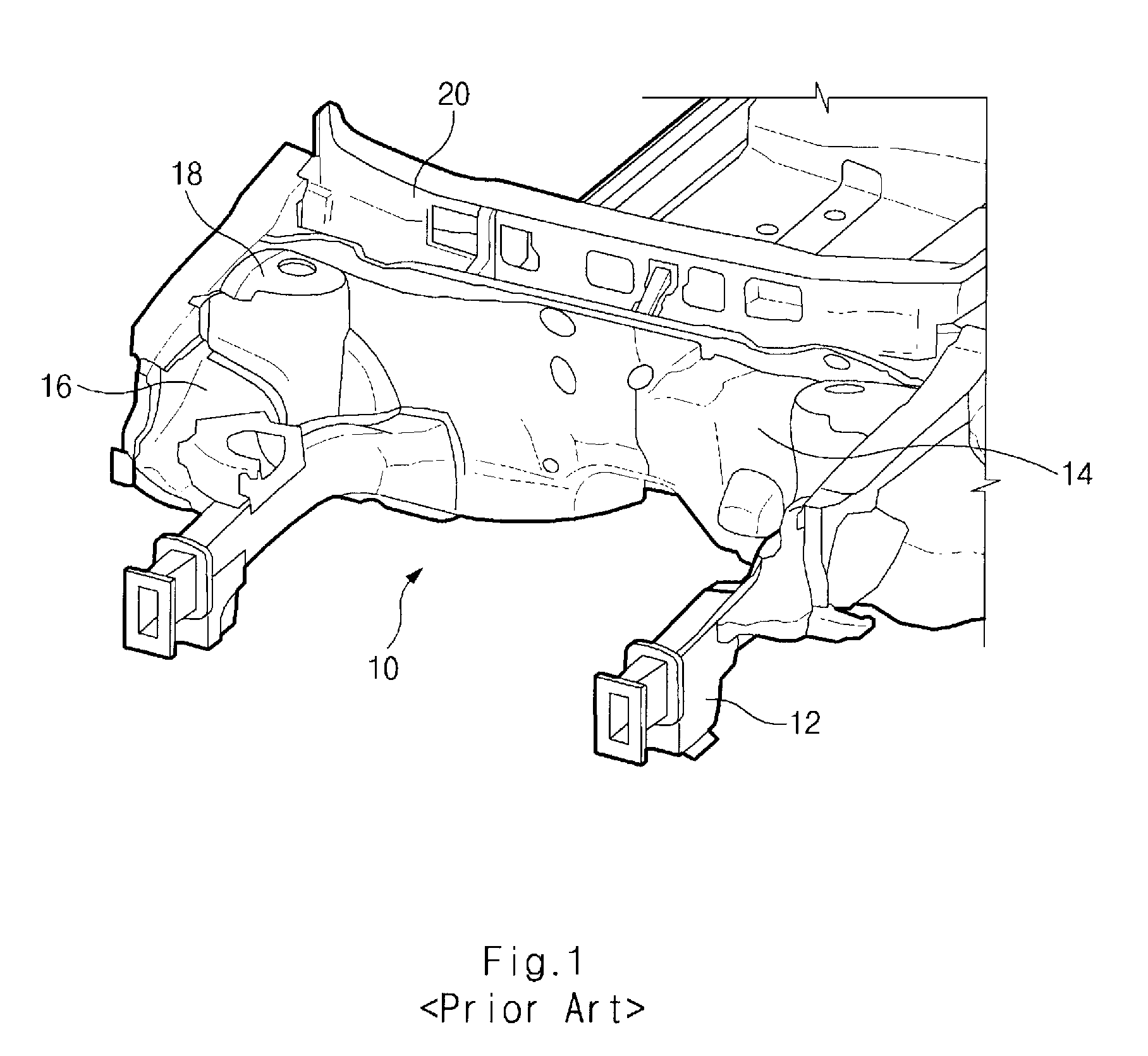

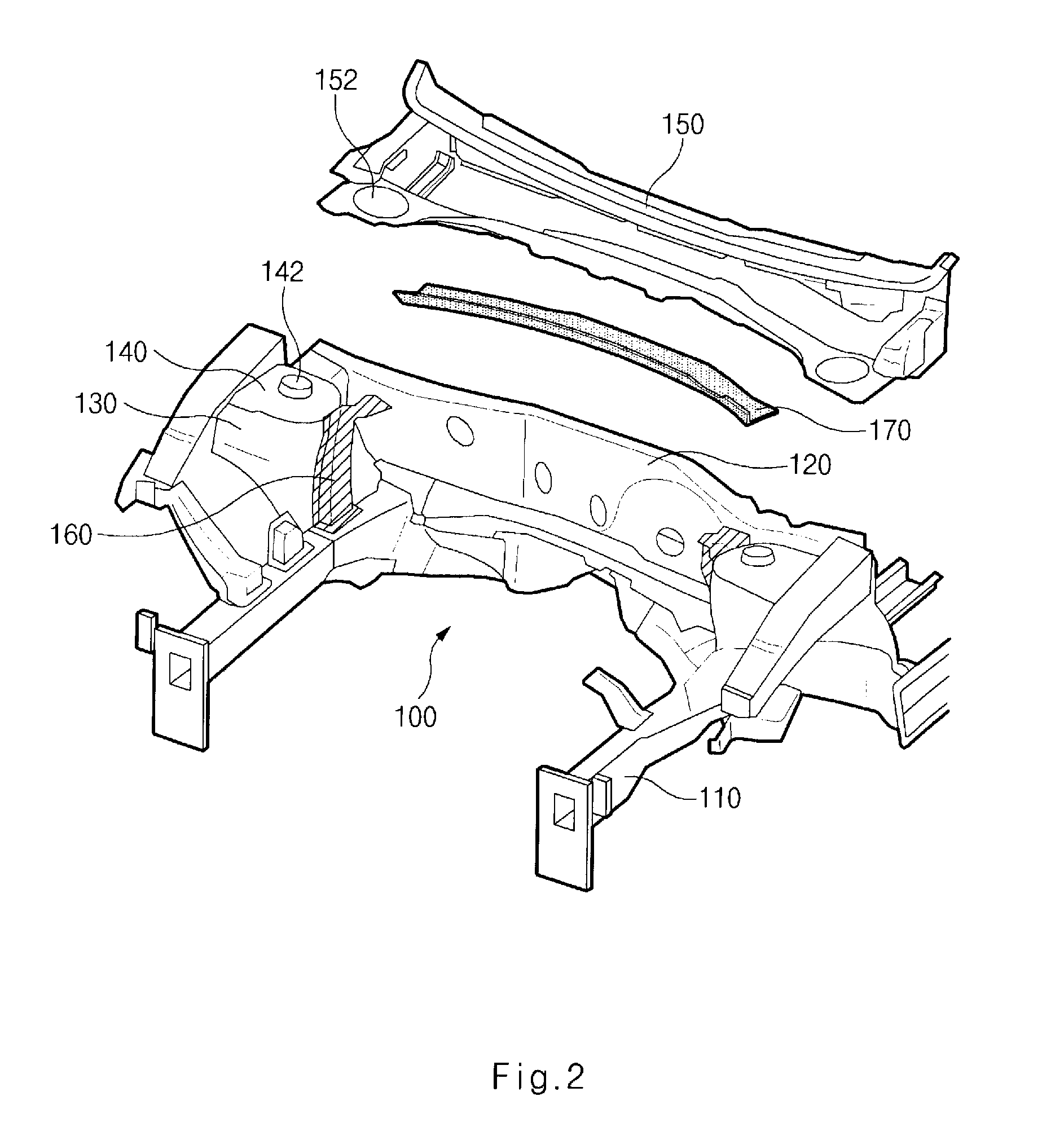

ActiveUS8240747B2Secure of rigiditySecure stabilityVehicle seatsMetal-working apparatusVehicle frameIn vehicle

A mounting structure of a front body frame in a vehicle may include: a pair of support members whose lower part is equipped to be fixed on both side members and whose upper part is equipped to be fixed on the dash panel; a cowl member whose each of two edges are connected to an upper side of the pair of support members by welding, the cowl member arranged to support a lower side of the cowl panel; a pair of side frames arranged at the lower side of the side members along an extension line where the lower part of the support members is extended; and a cross member arranged so that each of the lower parts of the side frames are mutually connected, wherein each of the cowl member, the support members, the side frames and the cross member are connected to be a ring shape.

Owner:HYUNDAI MOTOR CO LTD +1

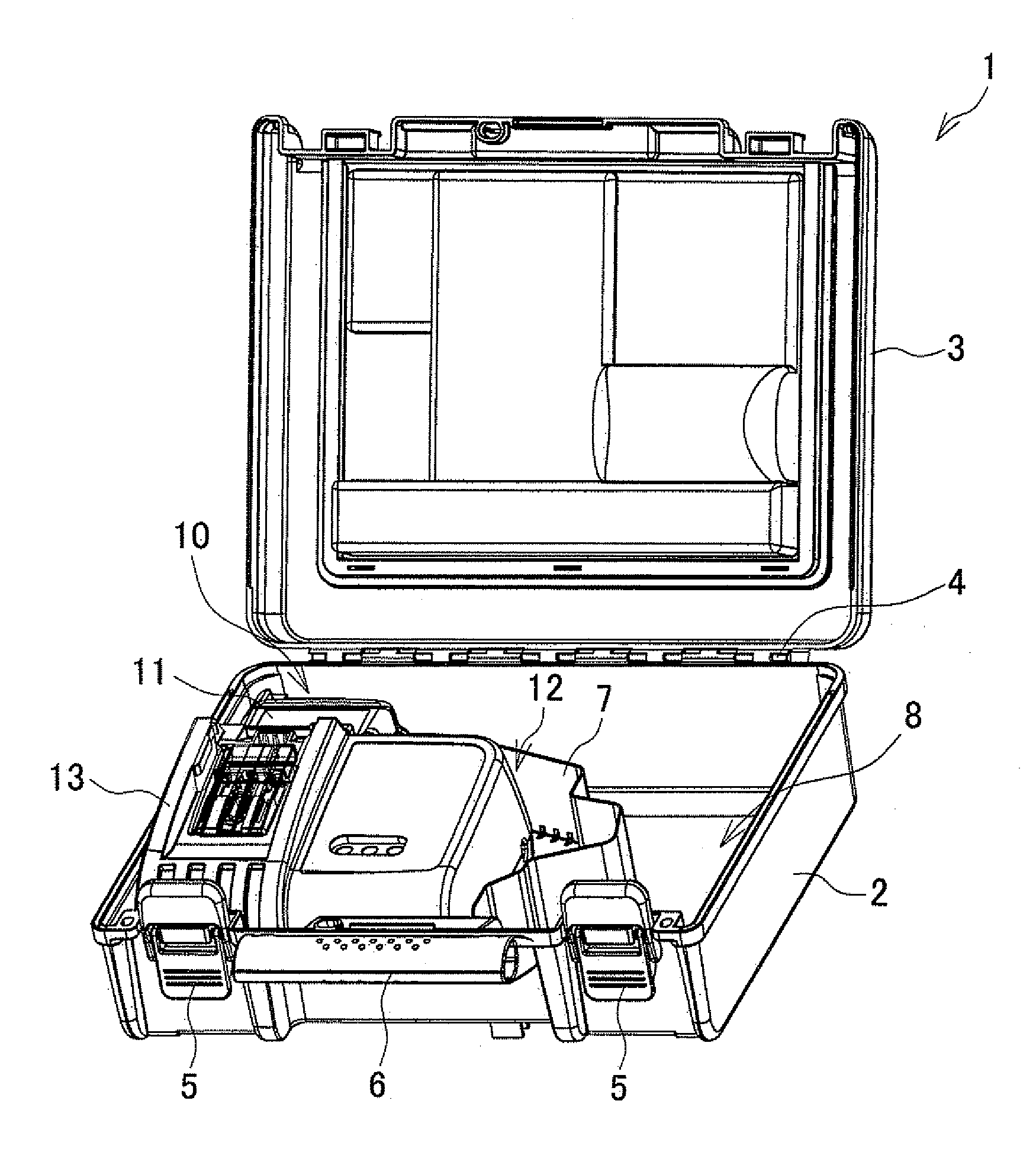

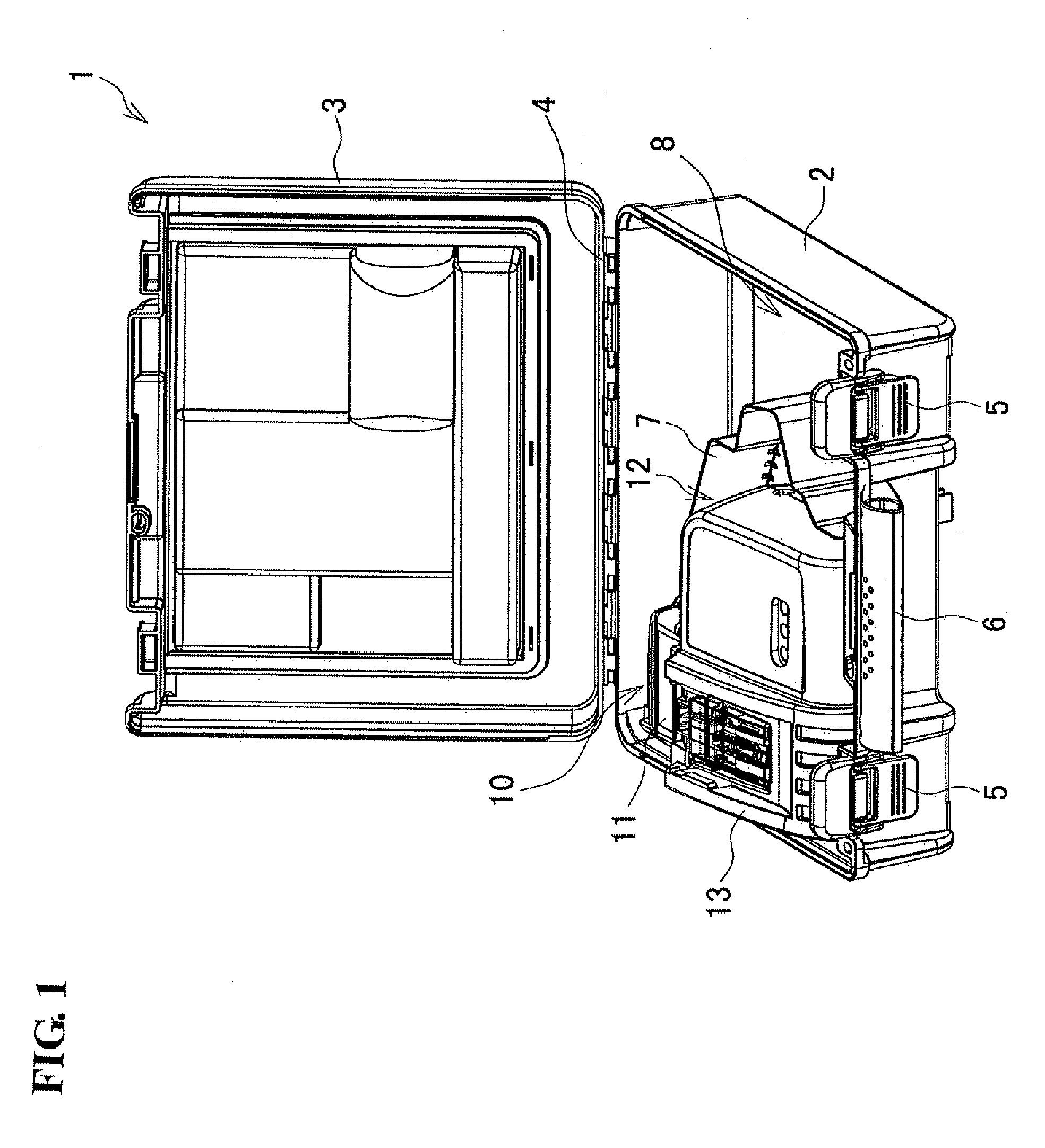

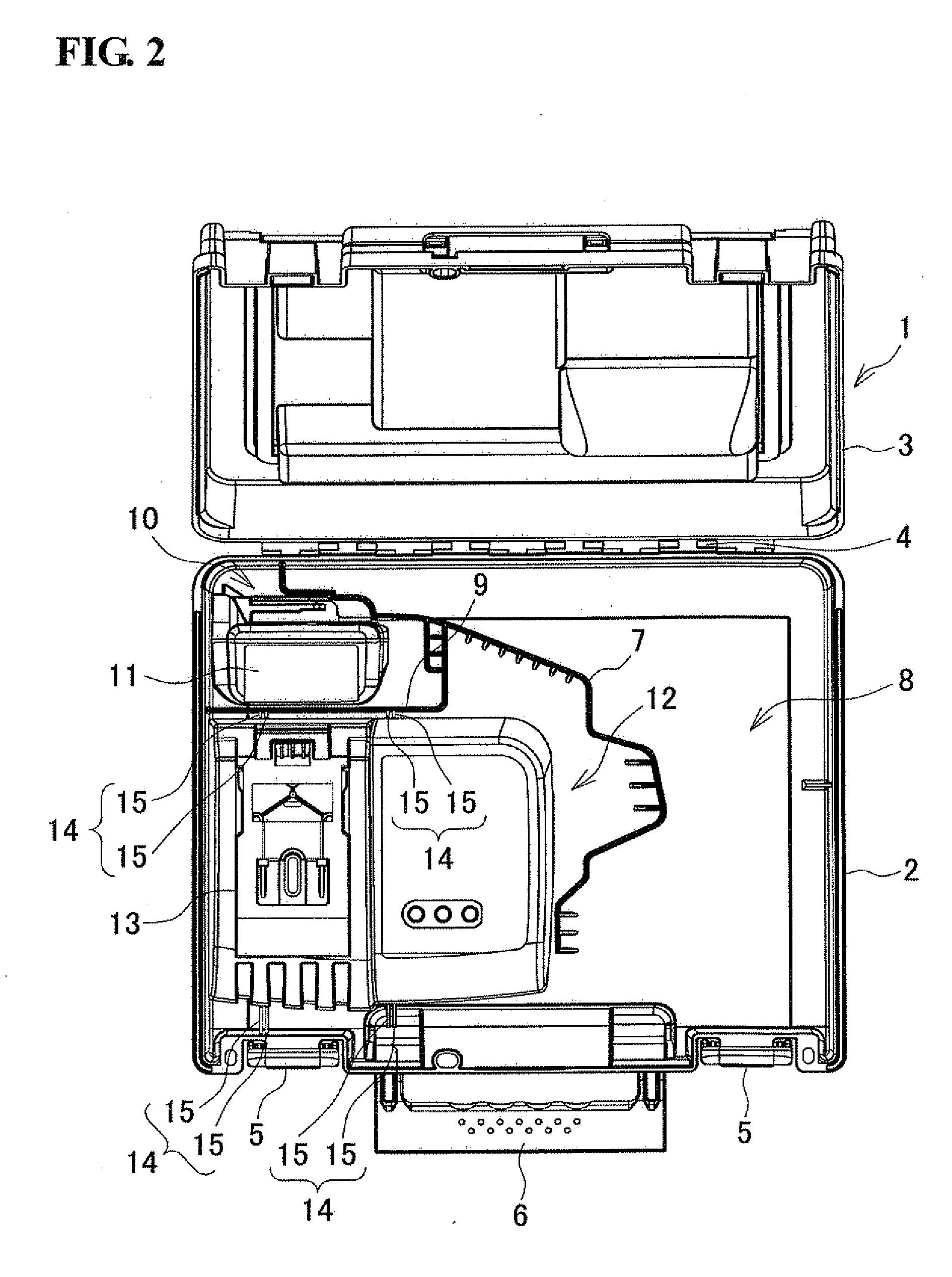

Power tool storage case

InactiveUS20120326669A1Improve usabilityExcellent ease of useBatteries circuit arrangementsElectric powerDual purposeEngineering

A power tool storage case includes a main case that has a tool storage portion, a battery storage portion and a charger storage portion, and a lid that can open and close the main case. The charger storage portion is a dual-purpose storage portion that can hold one of a charger and a battery pack in accordance with selection of one of the charger and the battery pack.

Owner:MAKITA CORP

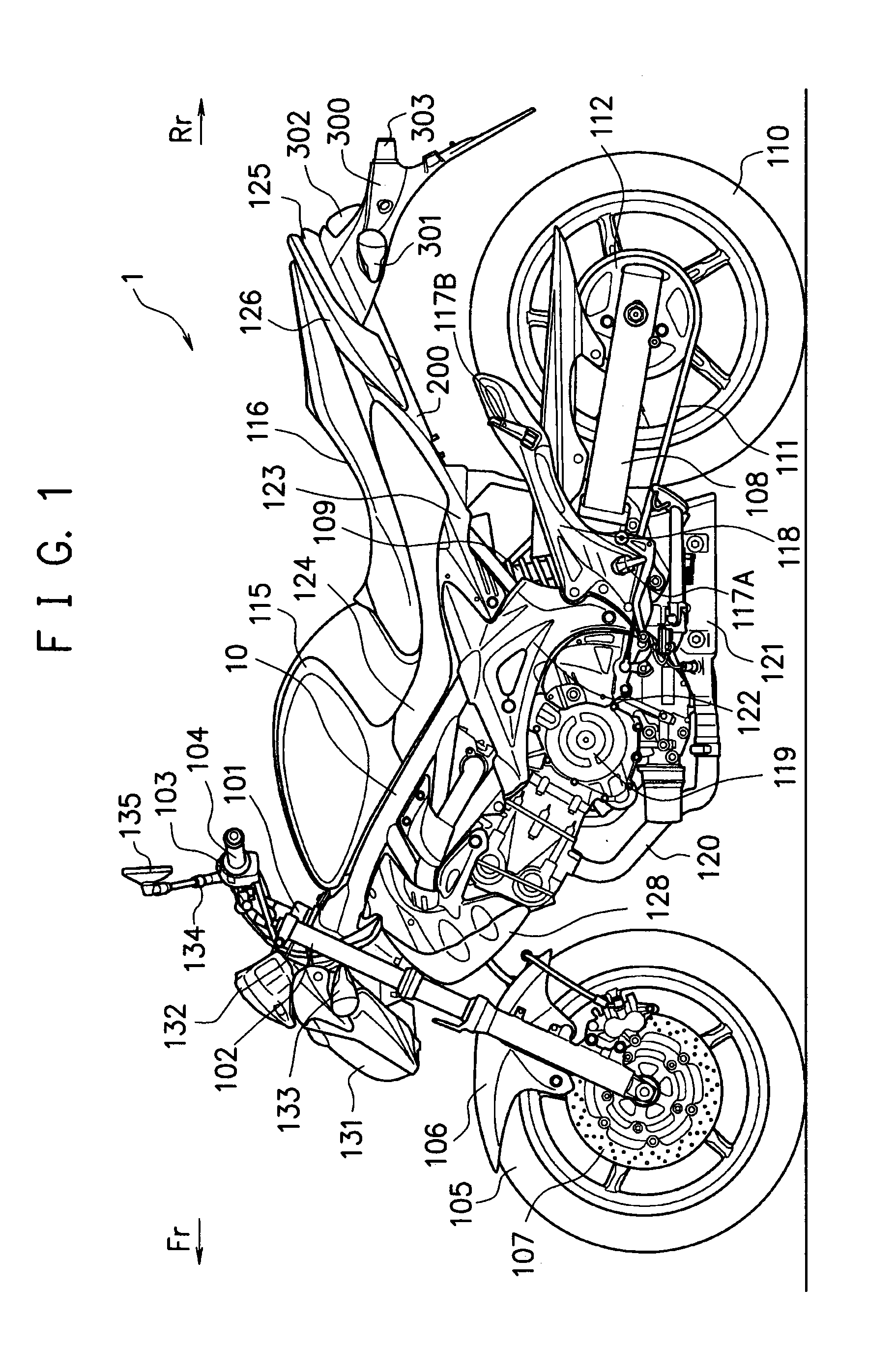

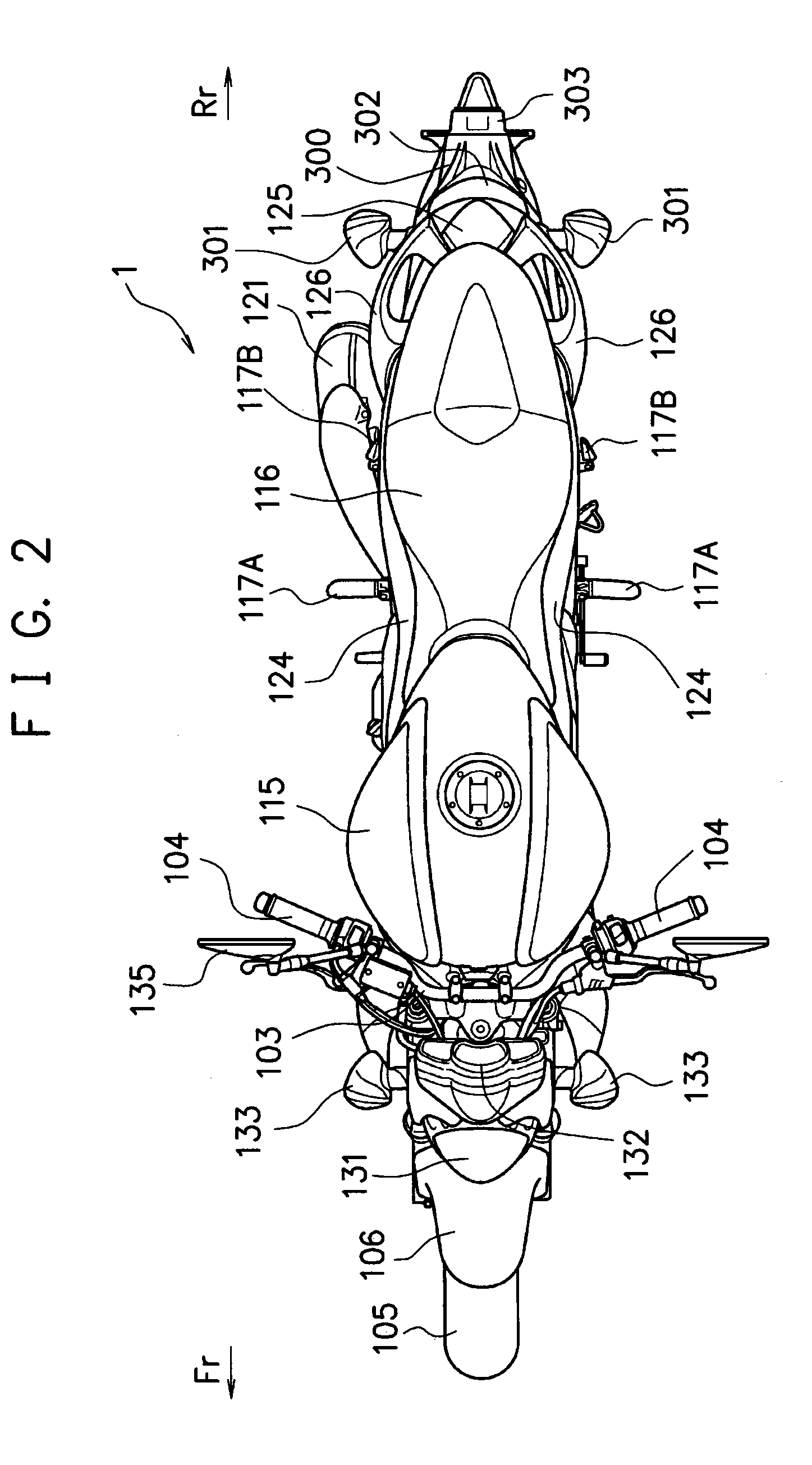

Rear fender structure for motorcycle and motorcycle

ActiveUS20100194149A1Securing rigidityReduce in quantityVehicle seatsSuperstructure subunitsClosed space

A rear rear-fender bracket integrally coupled to an upper portion and a lower portion of a rear rear-fender that is mounted to a rear portion of a vehicle body of a motorcycle, extending rearward and downward, and covering a rear wheel from upward and rearward, is provided to the rear rear-fender, and forms, with an internal surface of the rear rear-fender, a closed space having an inverted triangular shape when viewed from a vehicle side in which a space is gradually narrowed from an upper portion to a lower portion. Further, at the time of mounting, the rear rear-fender and the rear rear-fender bracket are coupled by being screwed together by rear winkers on sides of the vehicle (long holes). Further, a lower portion of the rear rear-fender and a lower portion of the rear rear-fender bracket are coupled by being screwed together by a license plate mounting bracket.

Owner:SUZUKI MOTOR CORP

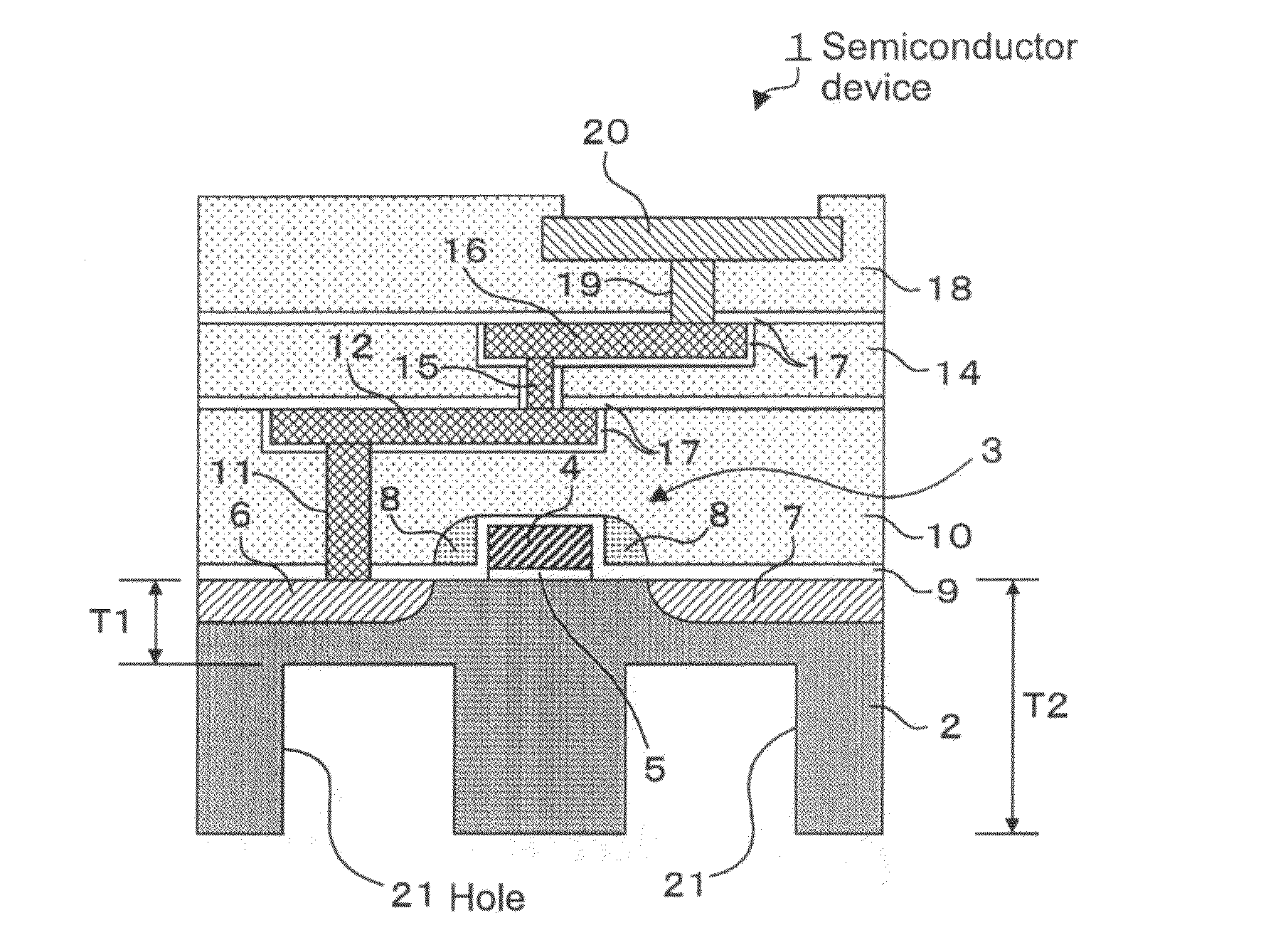

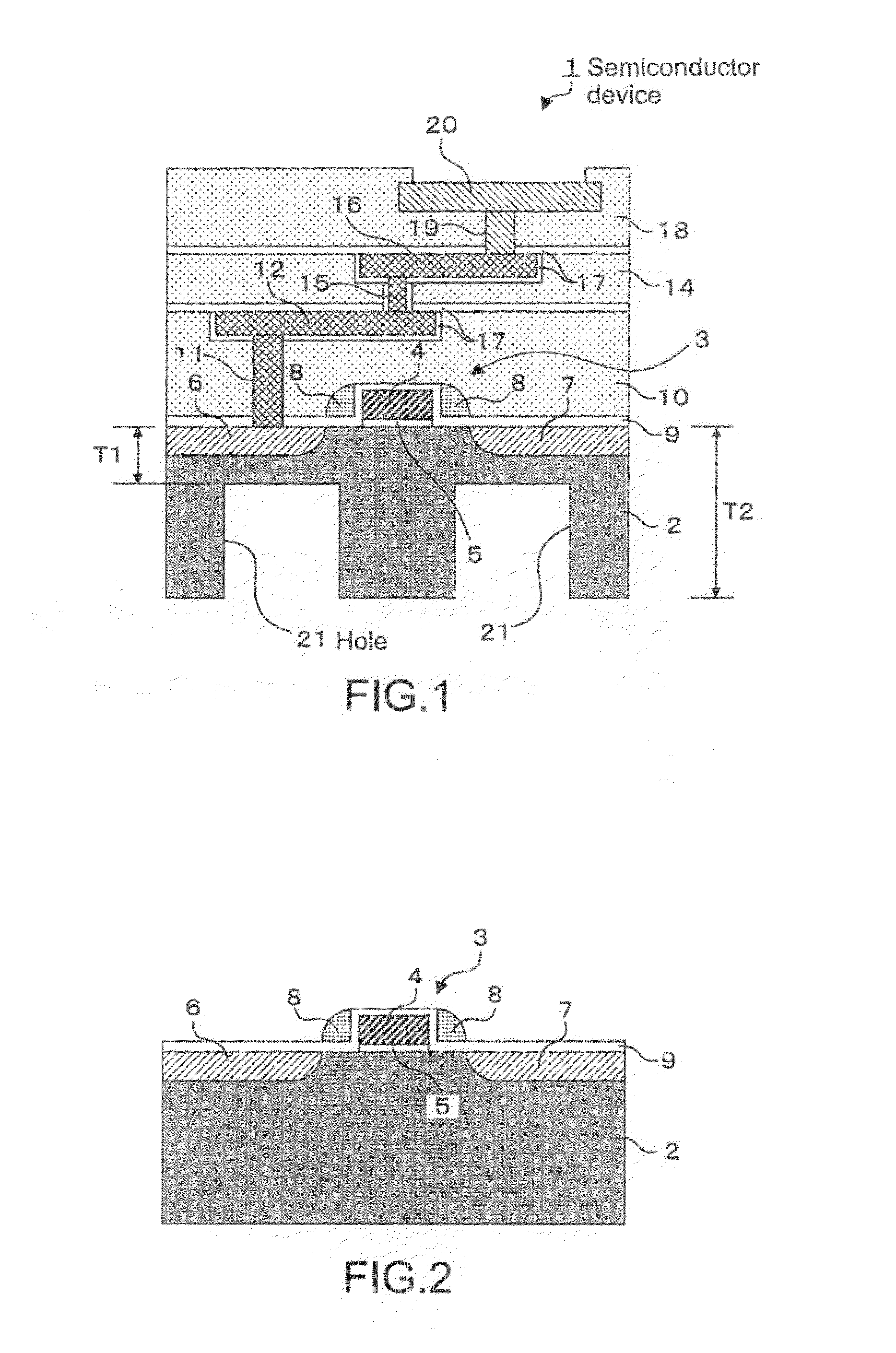

Semiconductor device, method of manufacturing the same, and electronic apparatus

ActiveUS20100193914A1Securing rigidityEfficiently supply hydrogenTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor

Disclosed is a method of manufacturing a semiconductor device including forming a transistor on a first surface of a device substrate, forming a hole in a second surface opposite to the first surface of the device substrate, and supplying hydrogen to a gate insulating film of the transistor from the second surface of the device substrate through the hole.

Owner:SONY SEMICON SOLUTIONS CORP

Rack and manufacturing method thereof

InactiveUS20120186085A1Secure dimensionSecure rigidityMetal-working apparatusGear wheelsEngineeringUltimate tensile strength

To sufficiently secure the width dimension, strength and rigidity of the rack teeth 10, and to realize the light weight construction and the manufacturing method of the rack 8, the rack teeth 10 is formed by plastic working on one side surface in the radial direction of part in the axial direction of a rod unit 9 having a circular cross-sectional shape, and the curvature radius of the portion which is separated in the radial direction from the portion where the rack teeth 10 is formed, is made greater than that of the cross sectional shape of the outer surface of the axial remaining portion of the rod unit 9.

Owner:NSK LTD

Pneumatic tire

InactiveUS20120111466A1Improve drainage capacityMaintaining uneven wear resistanceTyre tread bands/patternsNon-skid devicesEngineering

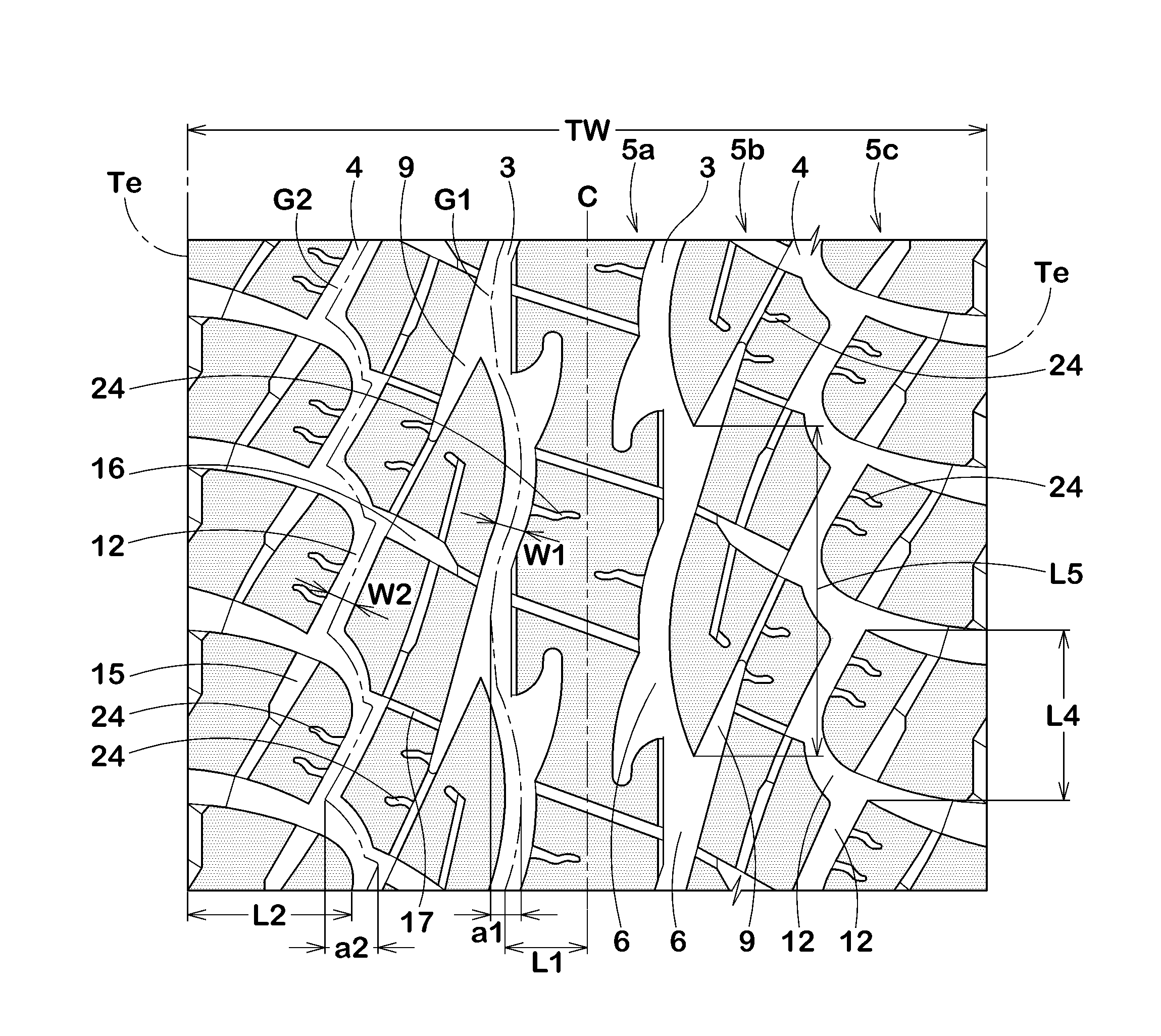

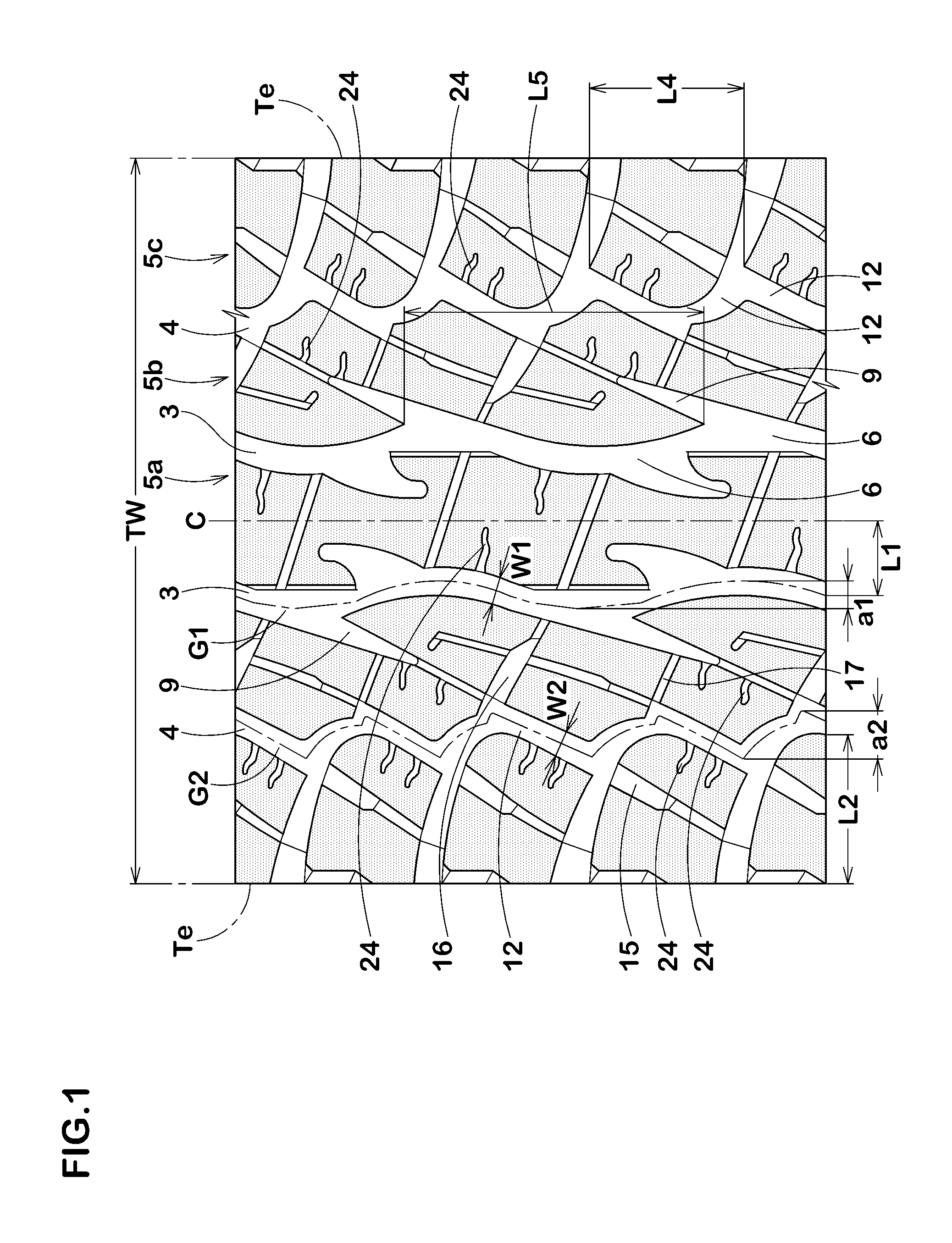

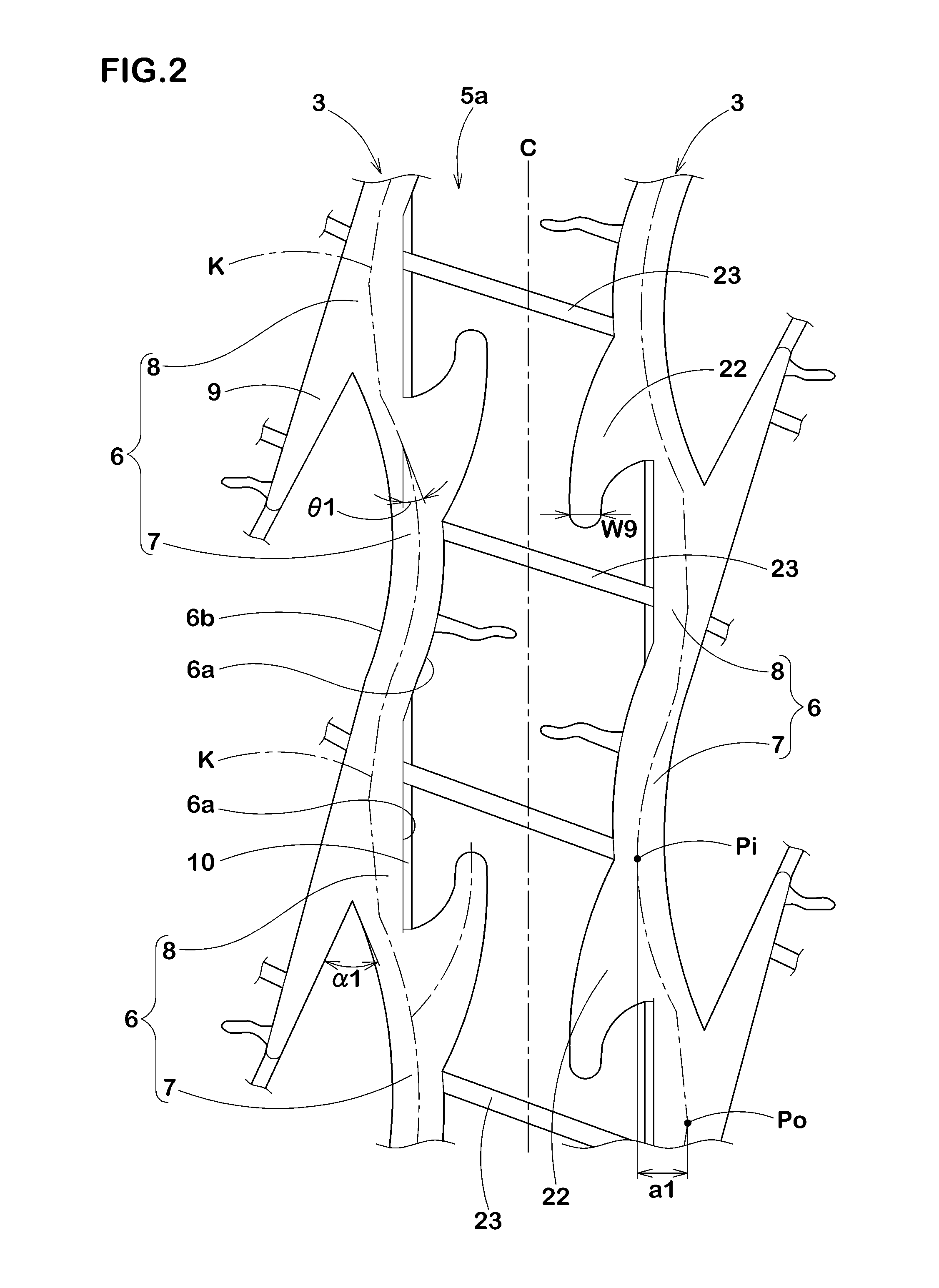

In a pneumatic tire 1, a center land portion 5a between center main grooves 3, a middle land portion 5b between the center main groove 3 and a shoulder main groove 4, and a pair of shoulder land portions 5c extending on outer sides of the shoulder main groove 4 in a tire axial direction are divided from each other. The center main groove 3 includes arc groove pieces 6 which are continuously provided in a tire circumferential direction. The arc groove piece 6 includes an arc portion 7 which is curved to swell toward a tire equator C. The middle land portion 5b is provided with a middle inclined groove 9 which extends from an intersection portion K of the arc groove piece 6 toward the shoulder main groove 4.

Owner:SUMITOMO RUBBER IND LTD

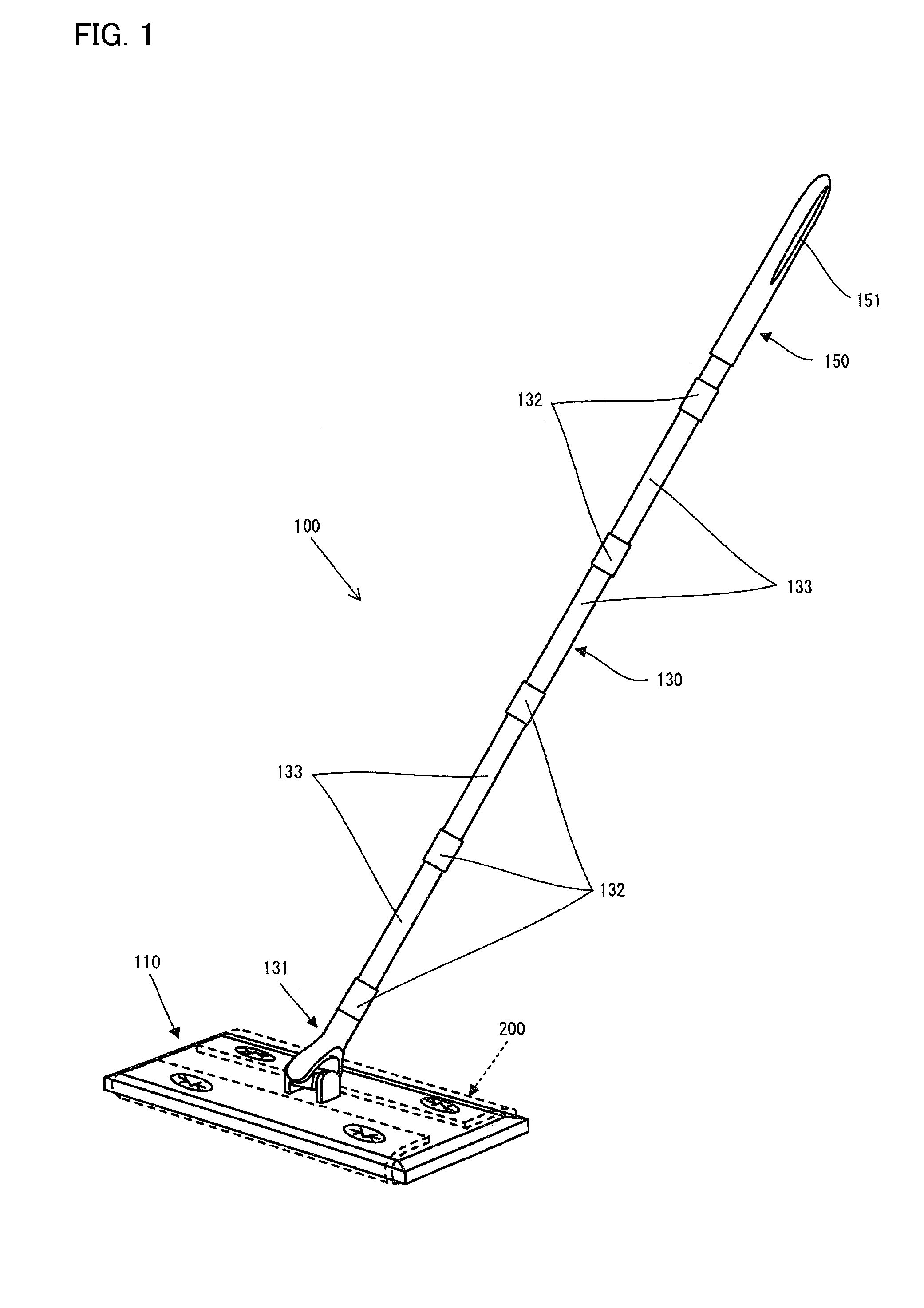

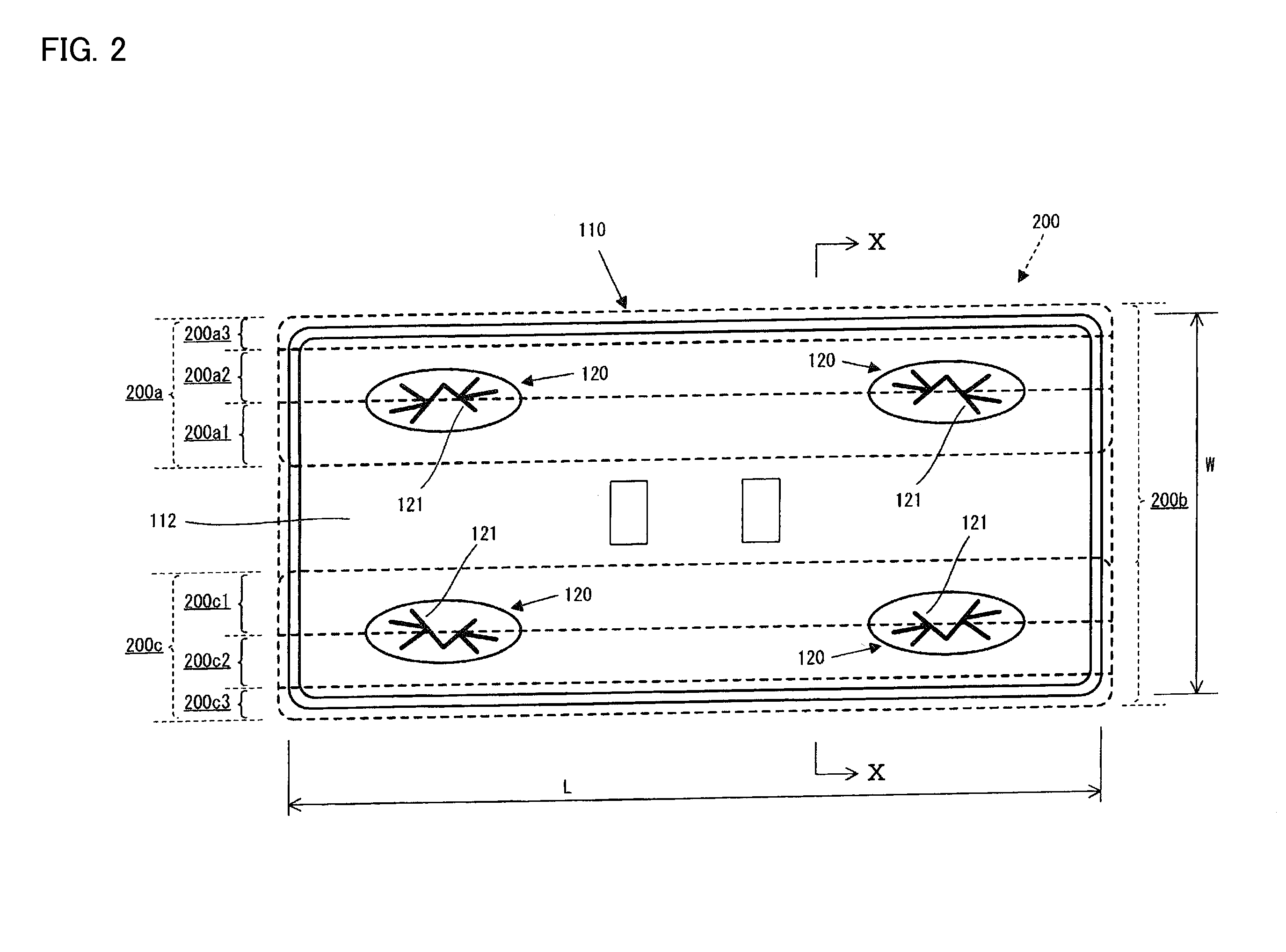

Cleaning sheet and cleaning tool

ActiveUS20120311805A1Increase frictional resistanceEasily brokenCarpet cleanersFloor cleanersEngineeringMechanical engineering

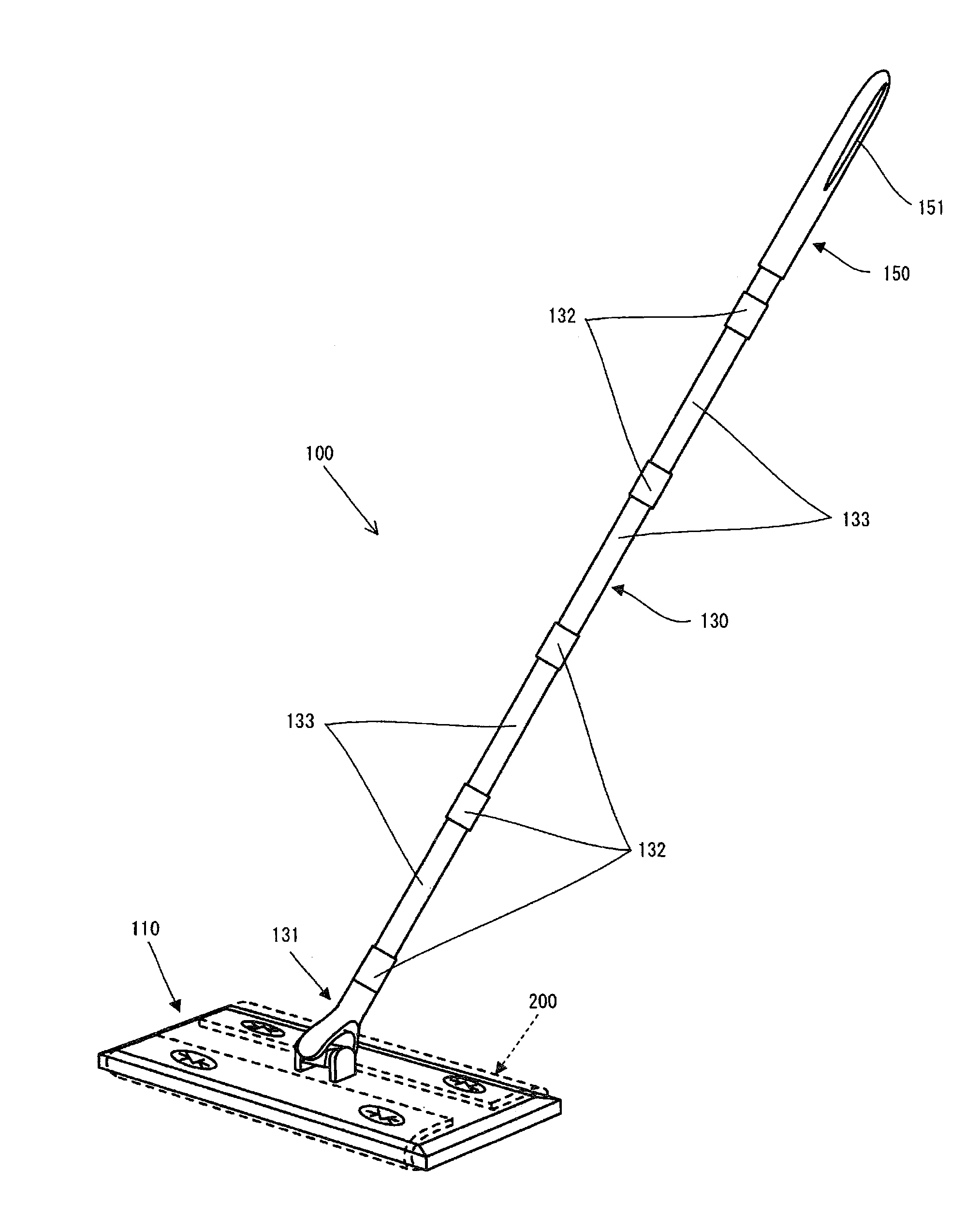

A cleaning sheet and a cleaning tool which have improved usability. The cleaning sheet is attachable to a cleaning-sheet mounting member. The cleaning sheet has a center section made up of a cleaning surface and at least one end section disposed at one or more sides with respect to the center section in a predetermined direction. The end section has a first portion having a first elongation percentage and a second portion having a second elongation percentage which is higher than that of the first portion. The second portion is disposed in said direction between the first portion and the center section and is constructed so as to be supported by the cleaning-sheet mounting member at the boundary between the first and second portions. The cleaning tool is provided with the cleaning sheet.

Owner:UNI CHARM CORP

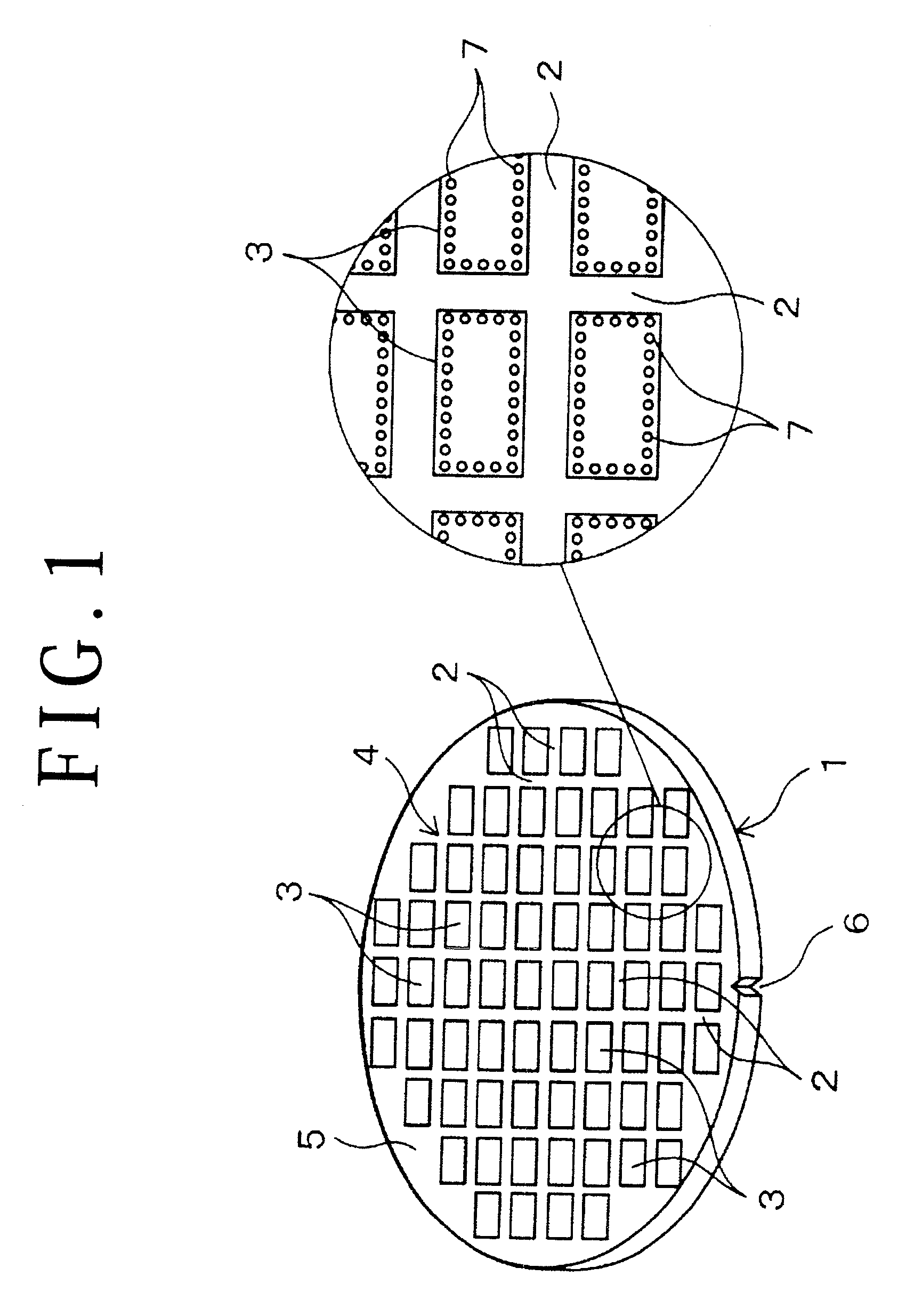

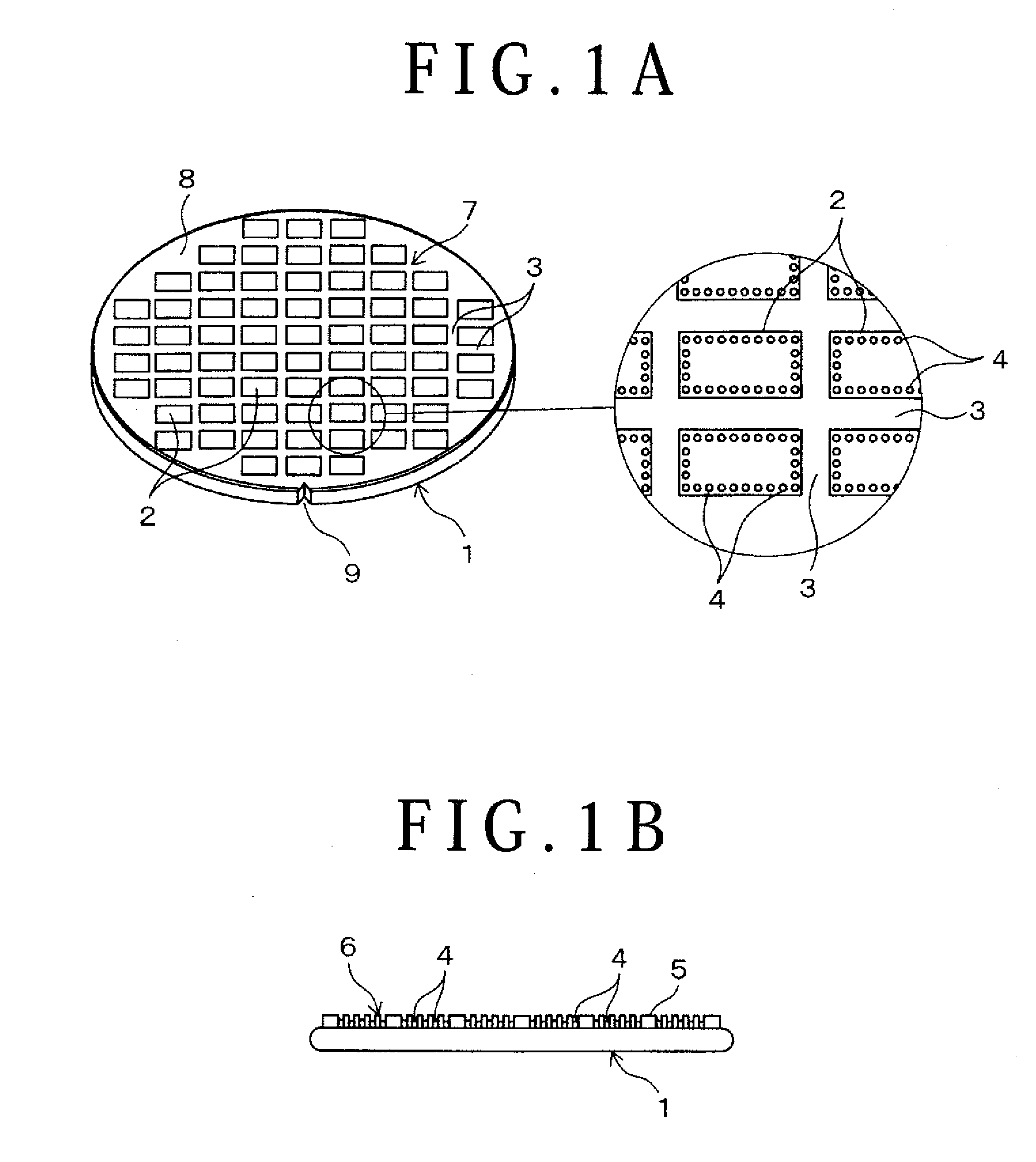

Method of machining substrate

ActiveUS20080318497A1Solve the lack of heightUniform heightEdge grinding machinesPolishing machinesResistEngineering

A method of machining a wafer is disclosed, in which the wafer is held by sucking its back-side surface directly onto a suction surface of a chuck table, and the tips of protruding electrodes and a resist layer are cut to make them flush with each other (appendant part cutting step). Next, the wafer is held by sucking the surface of the cut appendant part directly onto the suction surface of the chuck table, and the back-side surface of the wafer is ground (back-side surface grinding step), followed by removing the resist layer. The wafer is held onto the chuck table without using any protective tape but by directly holding the wafer, whereby the wafer can be ground to have a uniform thickness.

Owner:DISCO CORP

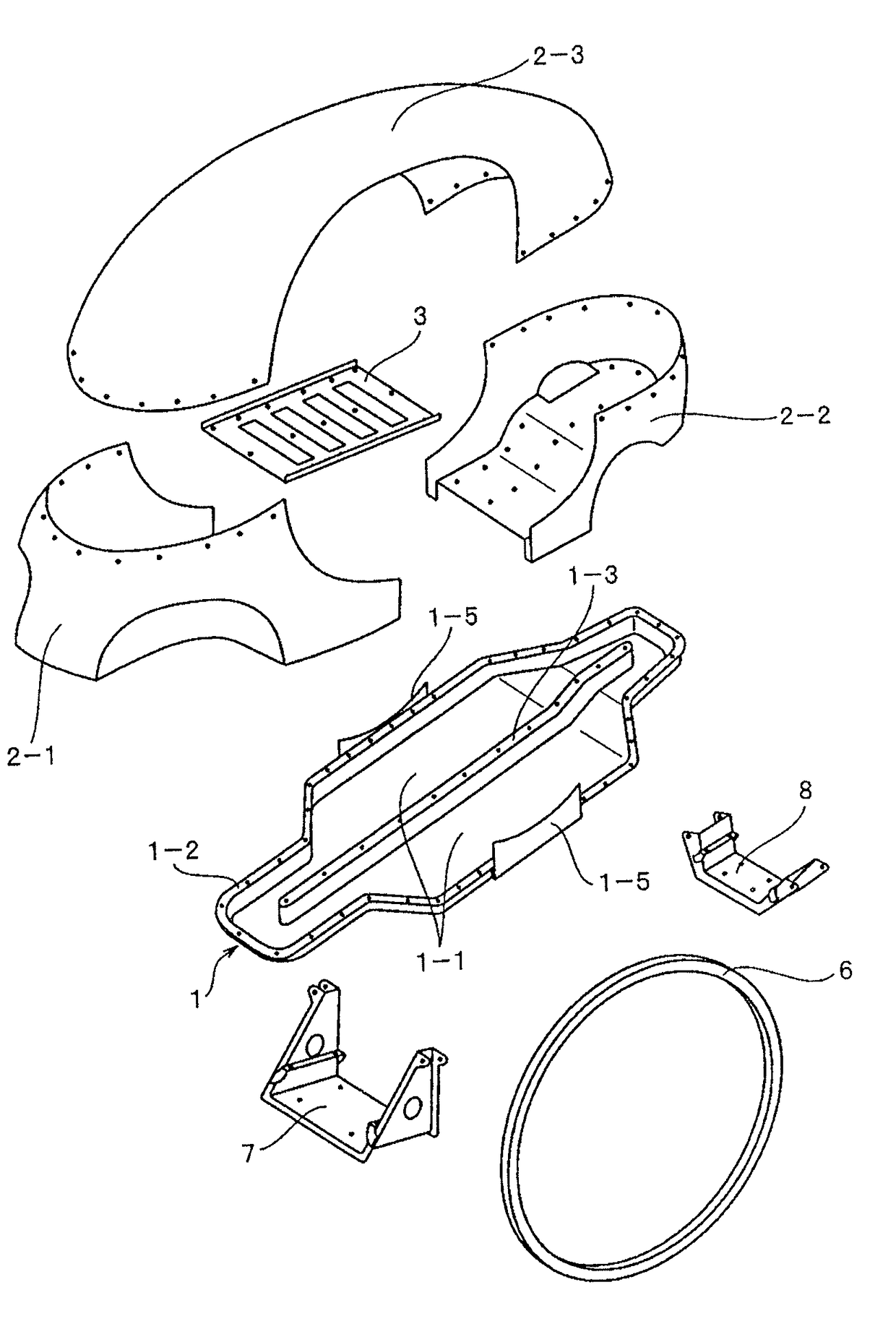

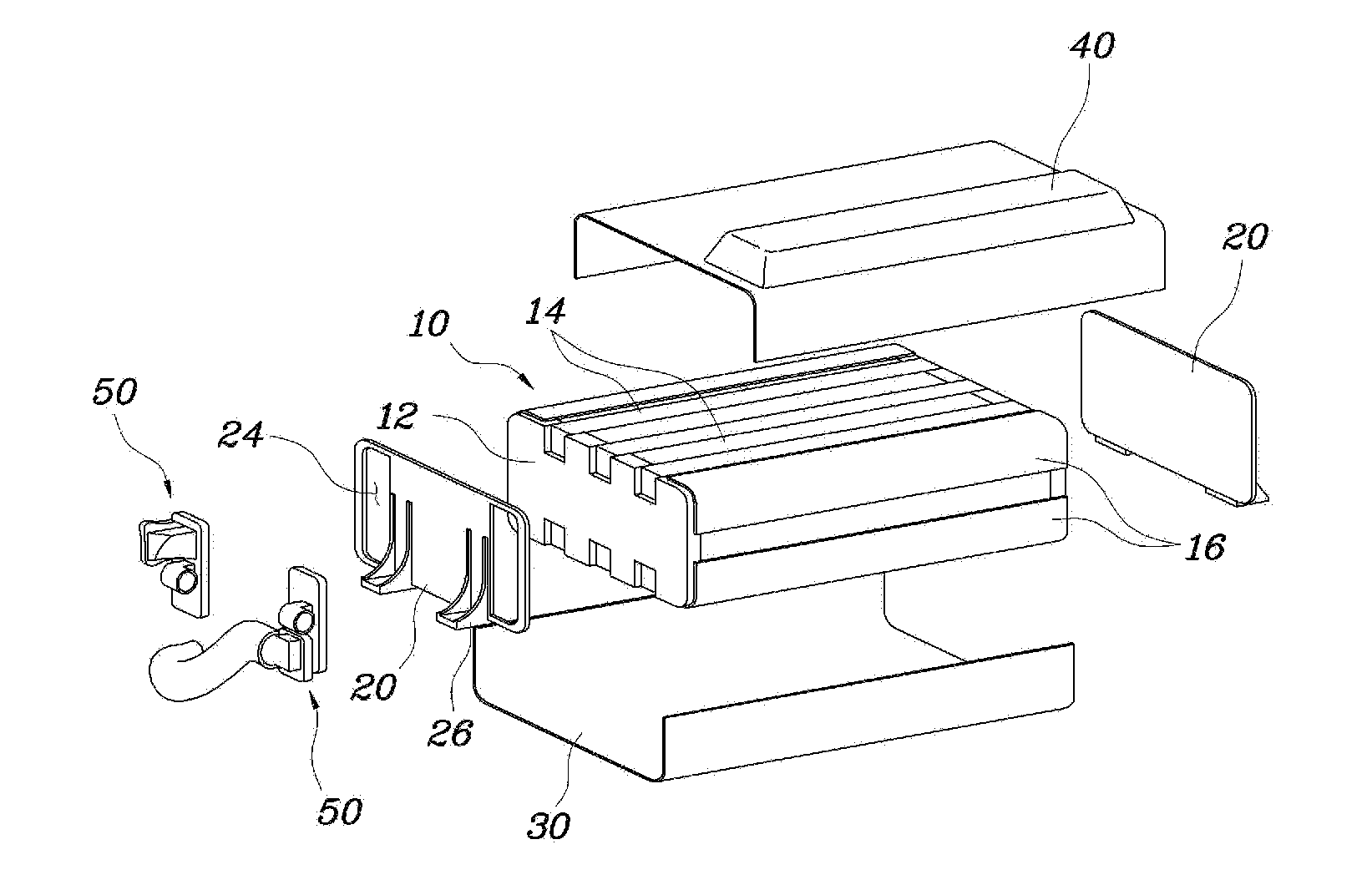

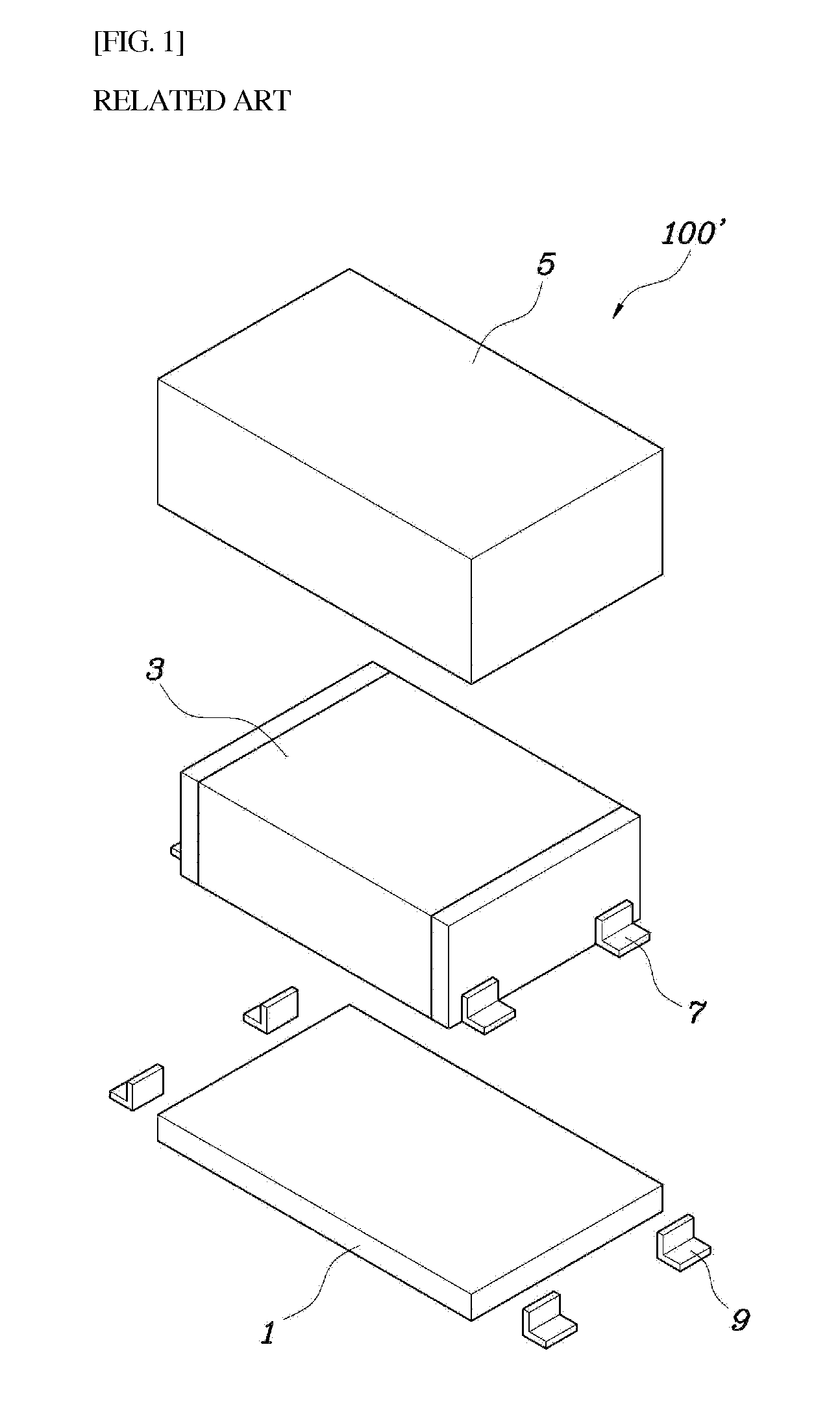

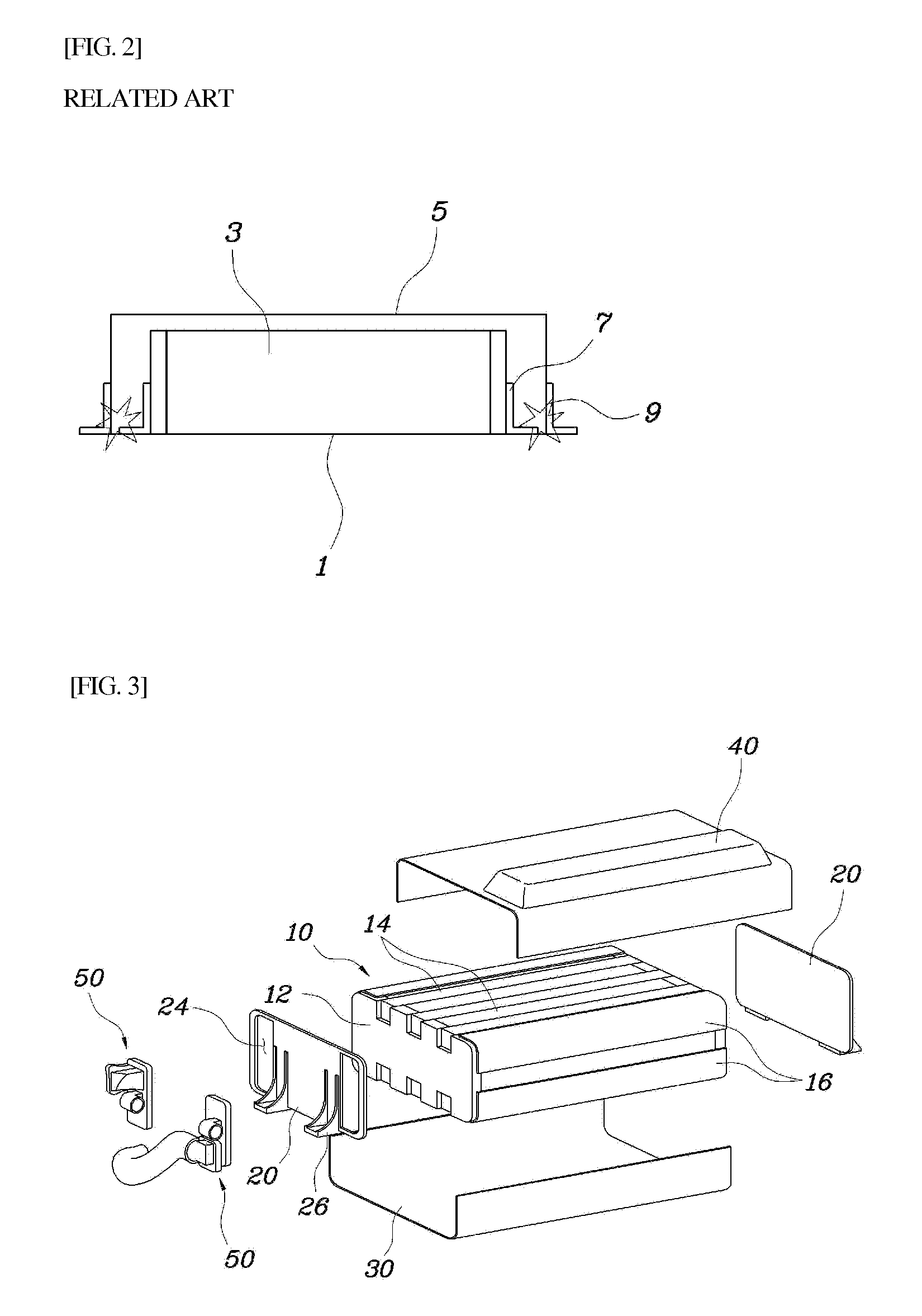

Fuel cell stack enclosure

ActiveUS20150194696A1Lower the volumeSecuring rigidityFuel cells groupingCell component detailsFuel cellsMechanical engineering

A fuel cell stack enclosure is provided that includes side covers configured to be joined with each of end of a stack module respectively. A lower cover is also configured to be provided under the stack module and formed to partially cover a lower portion and a first side portion of an outer surface of the side cove. An upper cover may be provided over the stack module, and be formed to partially cover an upper portion and a second side portion of the outer surface of the side cover to enclose the stack module along with the lower cover while joining with the side covers.

Owner:HYUNDAI MOTOR CO LTD +1

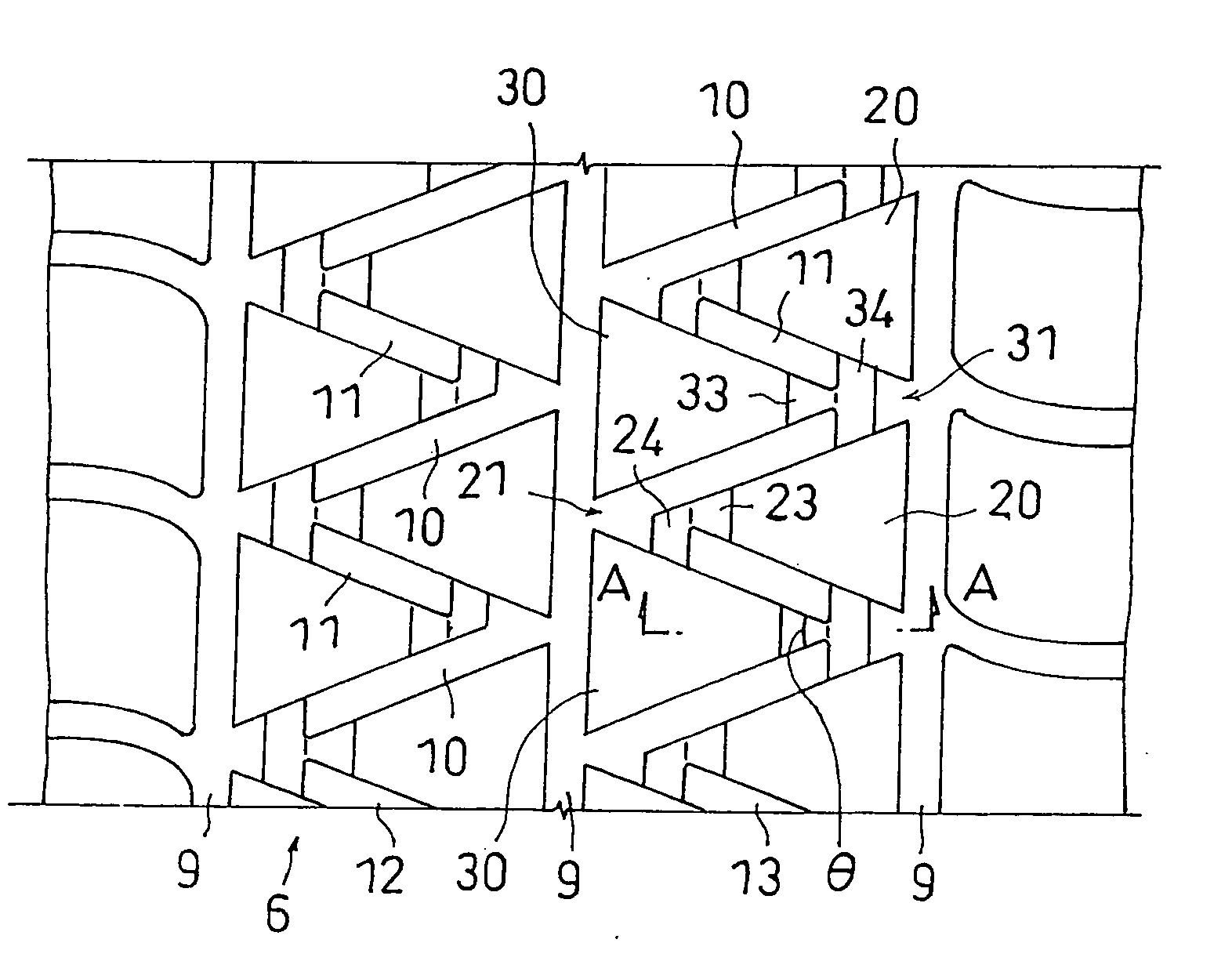

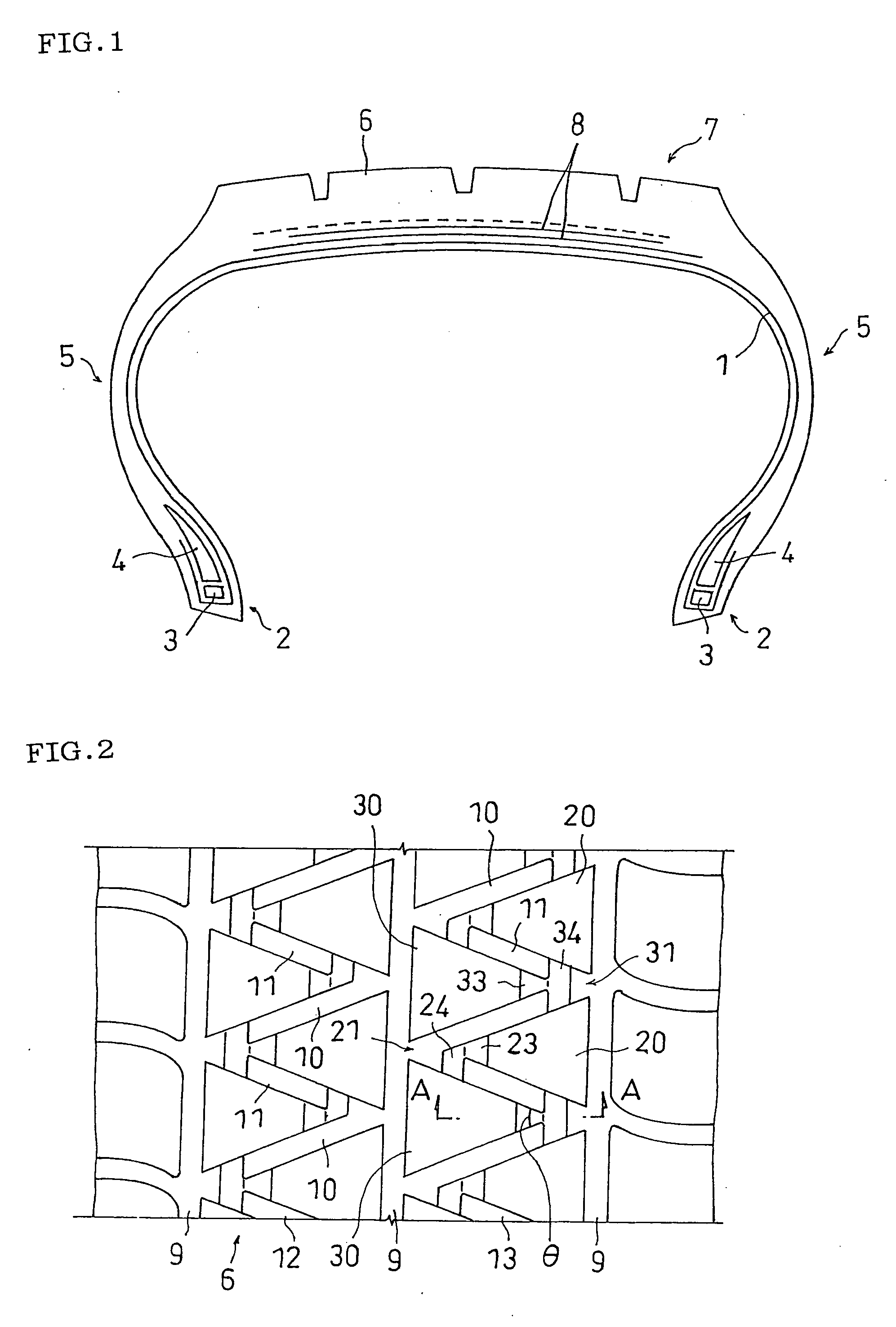

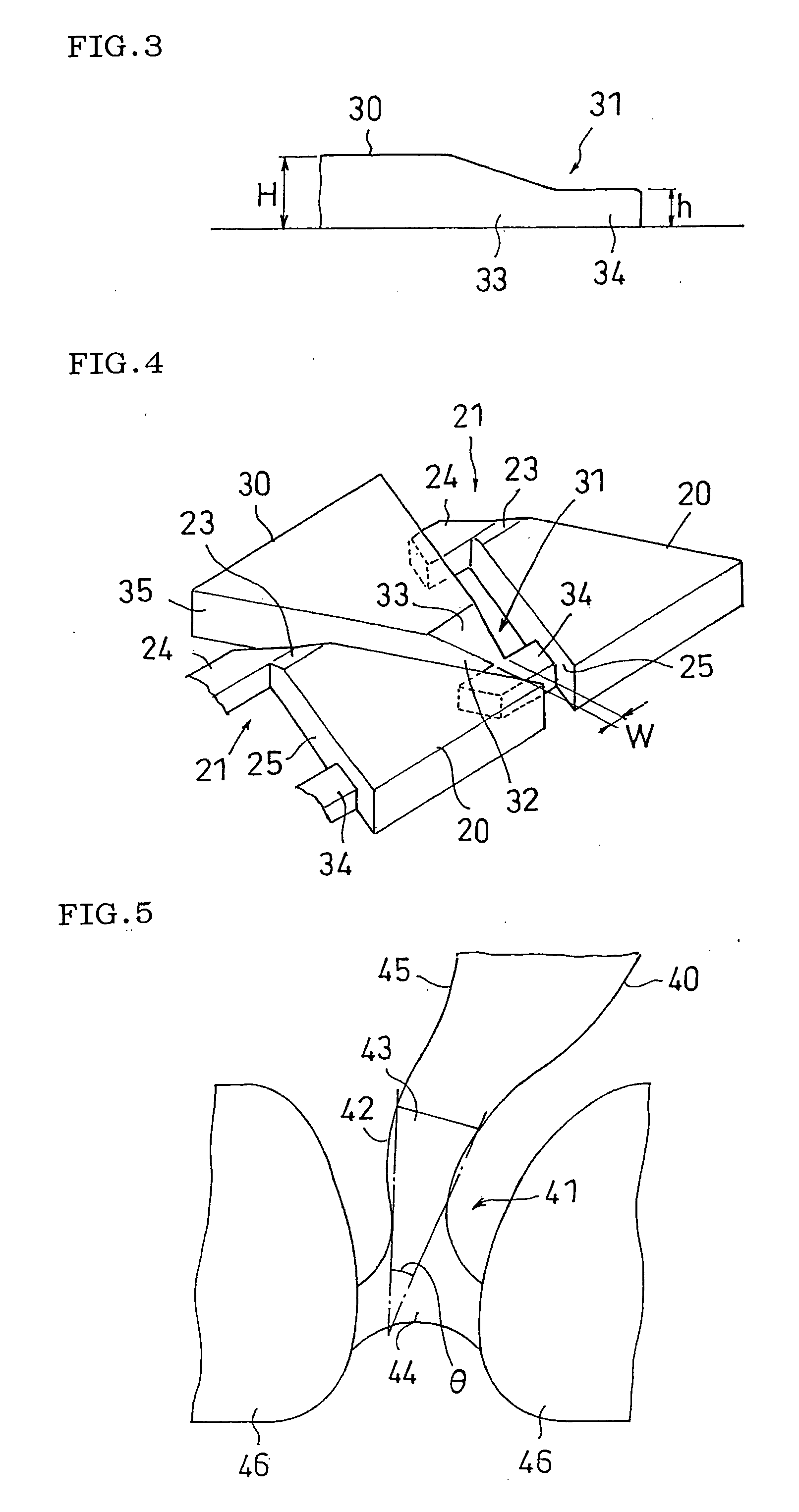

Pneumatic tire

ActiveUS20060108040A1Avoid partial wearEffective protectionTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

It is an object of the present invention to provide a pneumatic tire capable of securing rigidity of a tip end of a block, and effectively preventing deviated wear of a tread surface. In a tread surface of a pneumatic tire formed with a block 30 having a tip end 31 which is tapered as viewed from above, and a block 20 having a sidewall surface 25 opposed to a sidewall surface 32 of the block 30, the tip end 31 of the block 30 is provided with a taper cut portion 33 whose land portion height is gradually reduced toward its tip end side, and a bridge portion 34 which is connected to the sidewall surface 25 of the block 20 at a substantially constant land portion height from the tip end of the taper cut portion 33.

Owner:TOYO TIRE & RUBBER CO LTD

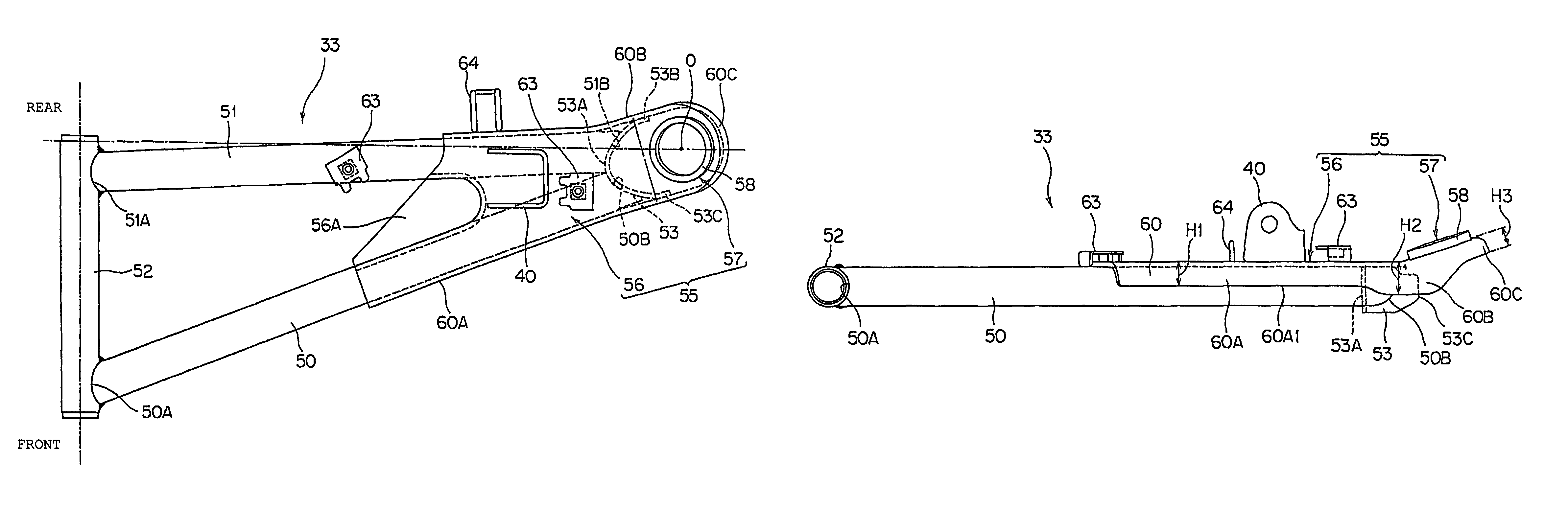

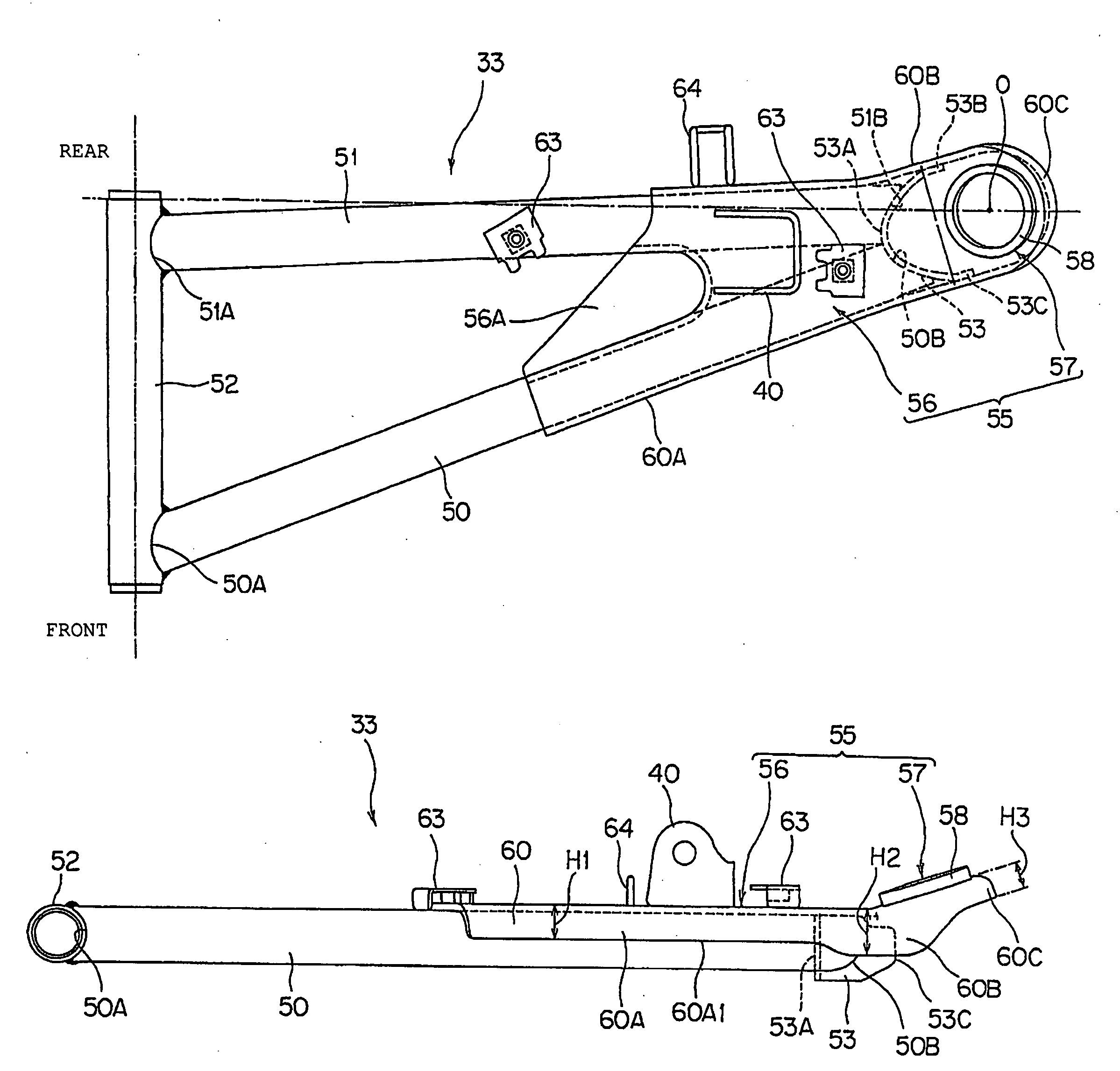

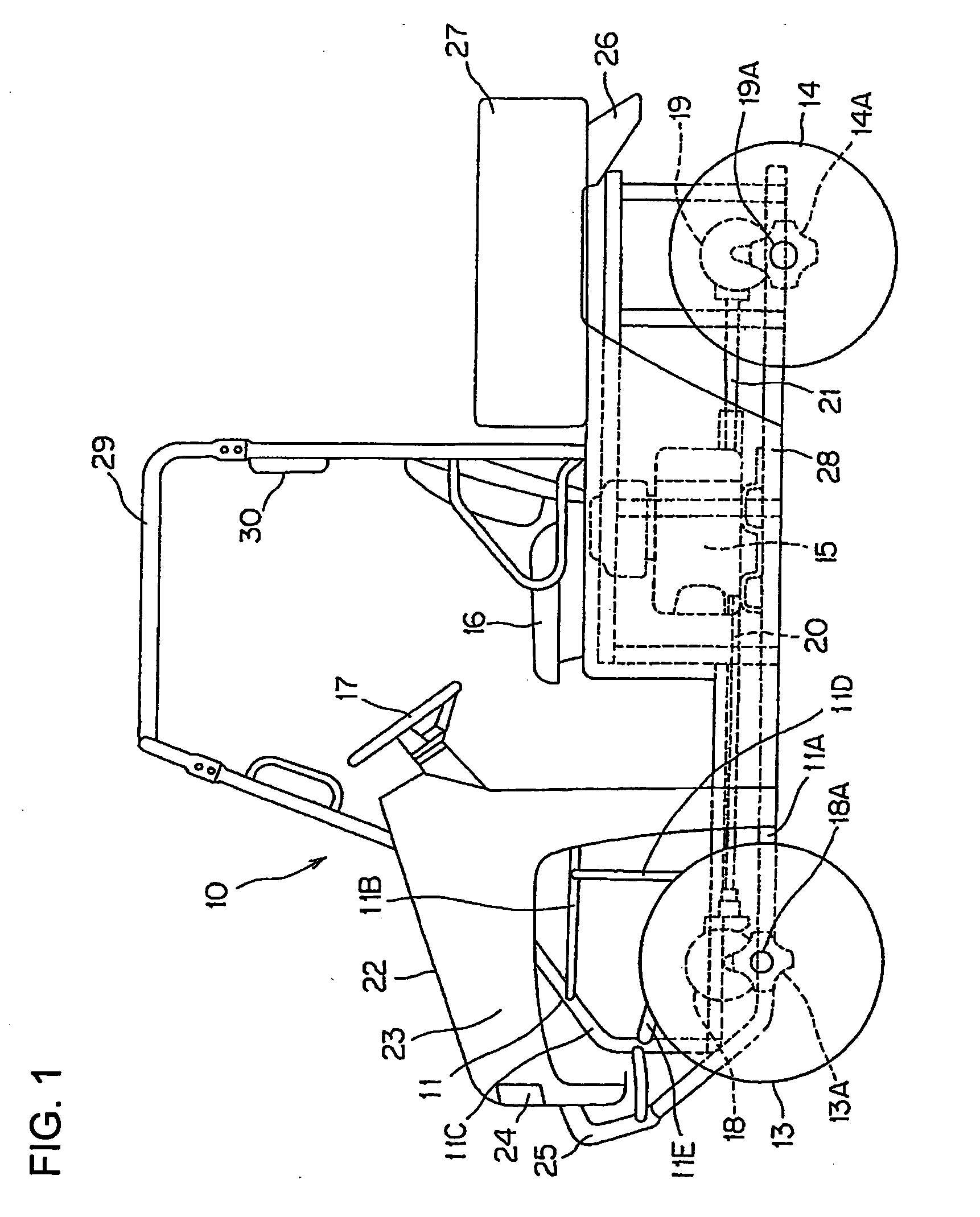

Suspension arm assembly for a vehicle, and vehicle incorporating same

ActiveUS20100059945A1Improve connection strengthIncrease the areaVehicle seatsItem transportation vehiclesJoint componentEngineering

A suspension arm assembly for a vehicle includes a pivot pipe pivotally attached to a vehicle body frame, a pair of pipes extending in a lateral direction of a vehicle body, a joint member attached to distal end portions of the pipes, and a substantially U-shaped band. Proximal end portions of the pipes are connected to the pivot pipe and spaced apart from each other in a front-rear direction, and distal end portions thereof are arranged close to each other, thereby forming a substantially triangular profile. The joint member includes a plate portion and a boss portion having a knuckle attached thereto. The distal end portions of the pipes are operatively connected to a convex surface of the U-shaped band, and the plate portion of the joint member is attached to the pipes for covering the U-shaped band.

Owner:HONDA MOTOR CO LTD

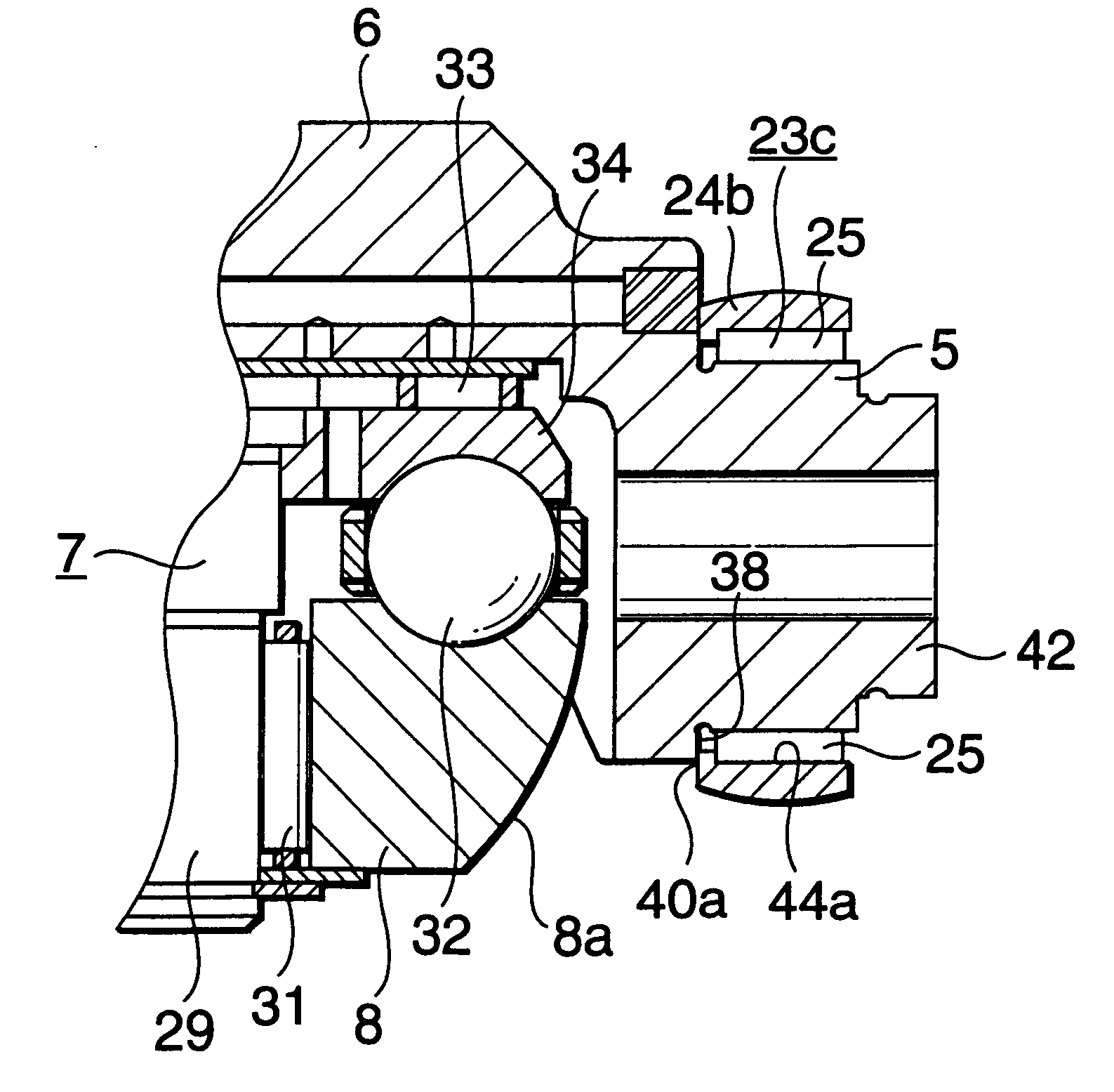

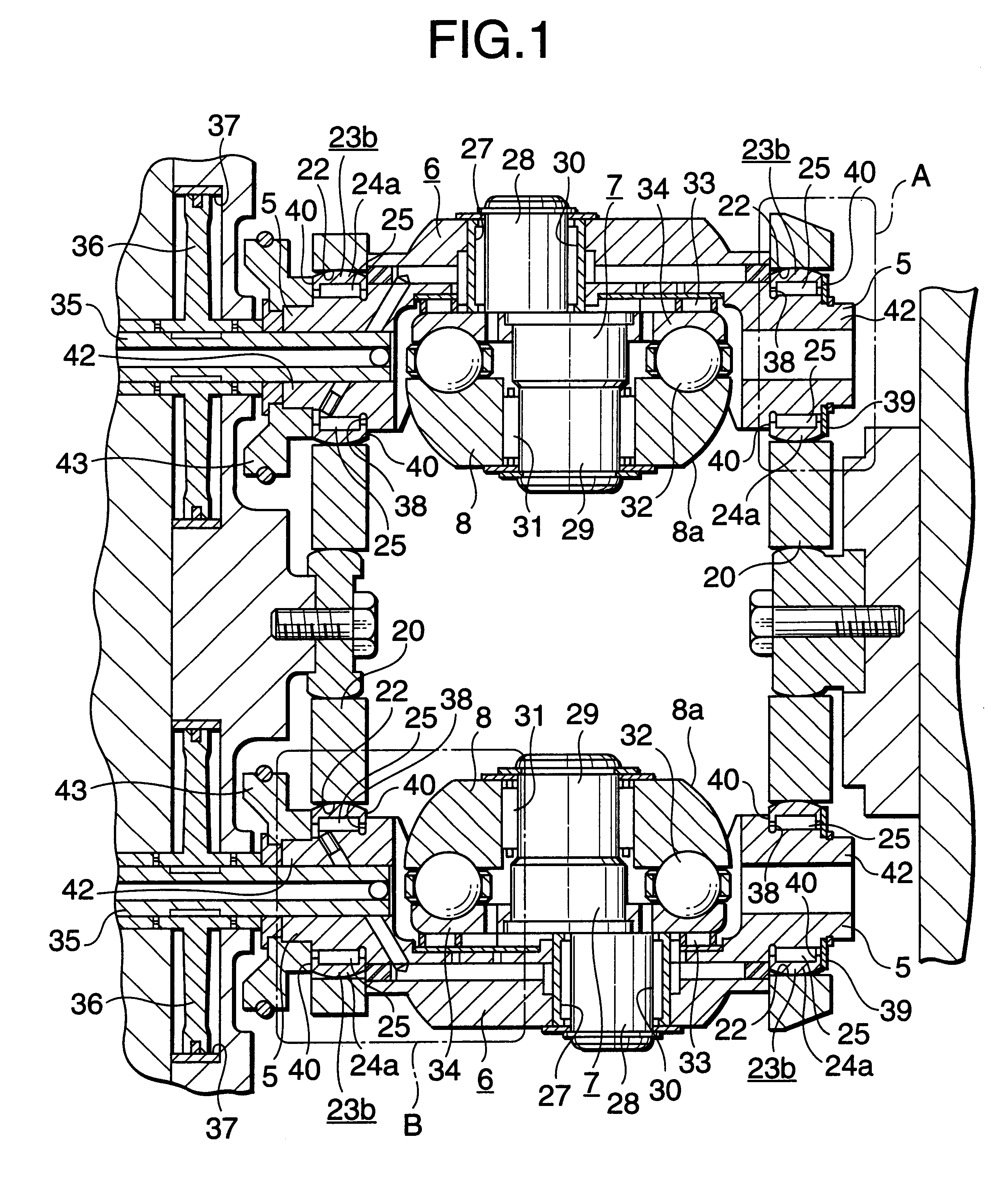

Toroidal-type continuously variable transmission

InactiveUS6416439B1Solve the real problemSolve insufficient capacityRolling contact bearingsBearing componentsNeedle roller bearingSpherical form

In a toroidal-type continuously variable transmission, a plurality of trunnions is respectively swingable about a pair of mutually concentric pivot shafts through a plurality of radial needle roller bearings respectively supporting the pivot shafts. Each of the radial needle roller bearings includes: an outer race interposed between an outer peripheral surface of the pivot shaft and an inner peripheral surface of the circular hole of the support plate, the outer race having an outer peripheral surface formed in a spherically convex surface; and a plurality of needle rollers respectively disposed on the inside diameter side of the outer race. The outer race is formed with an inwardly facing flange portion on the inner peripheral surface of the end portion thereof.

Owner:NSK LTD

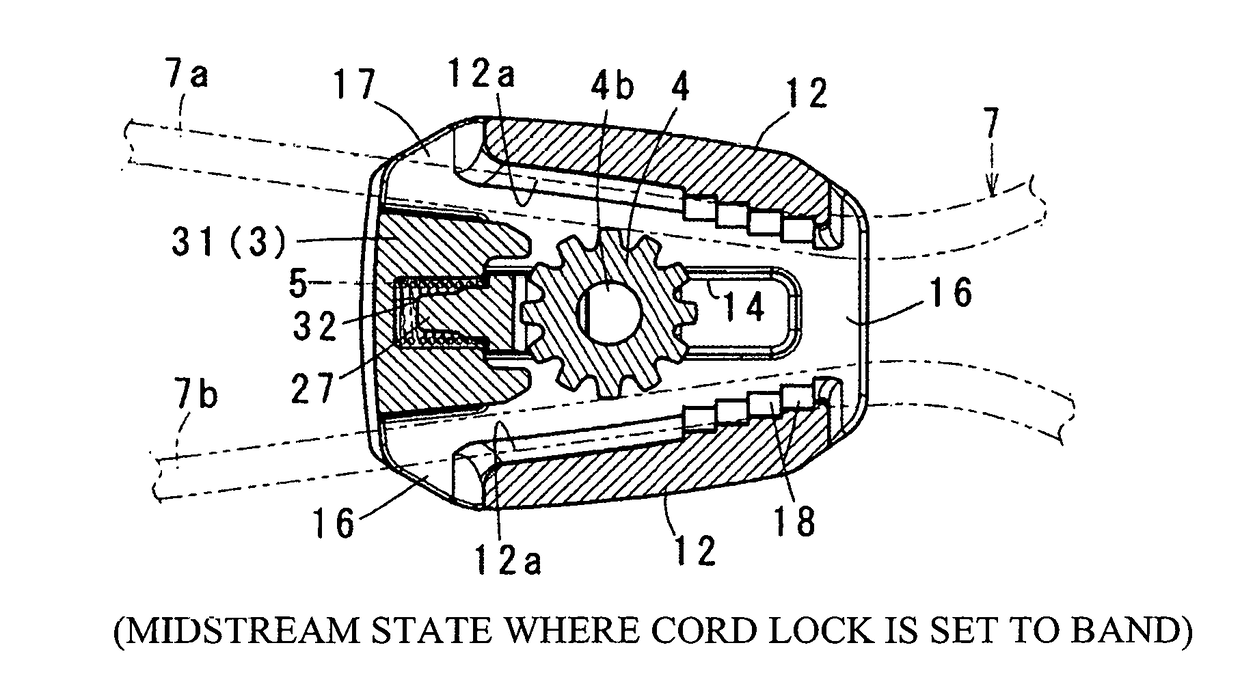

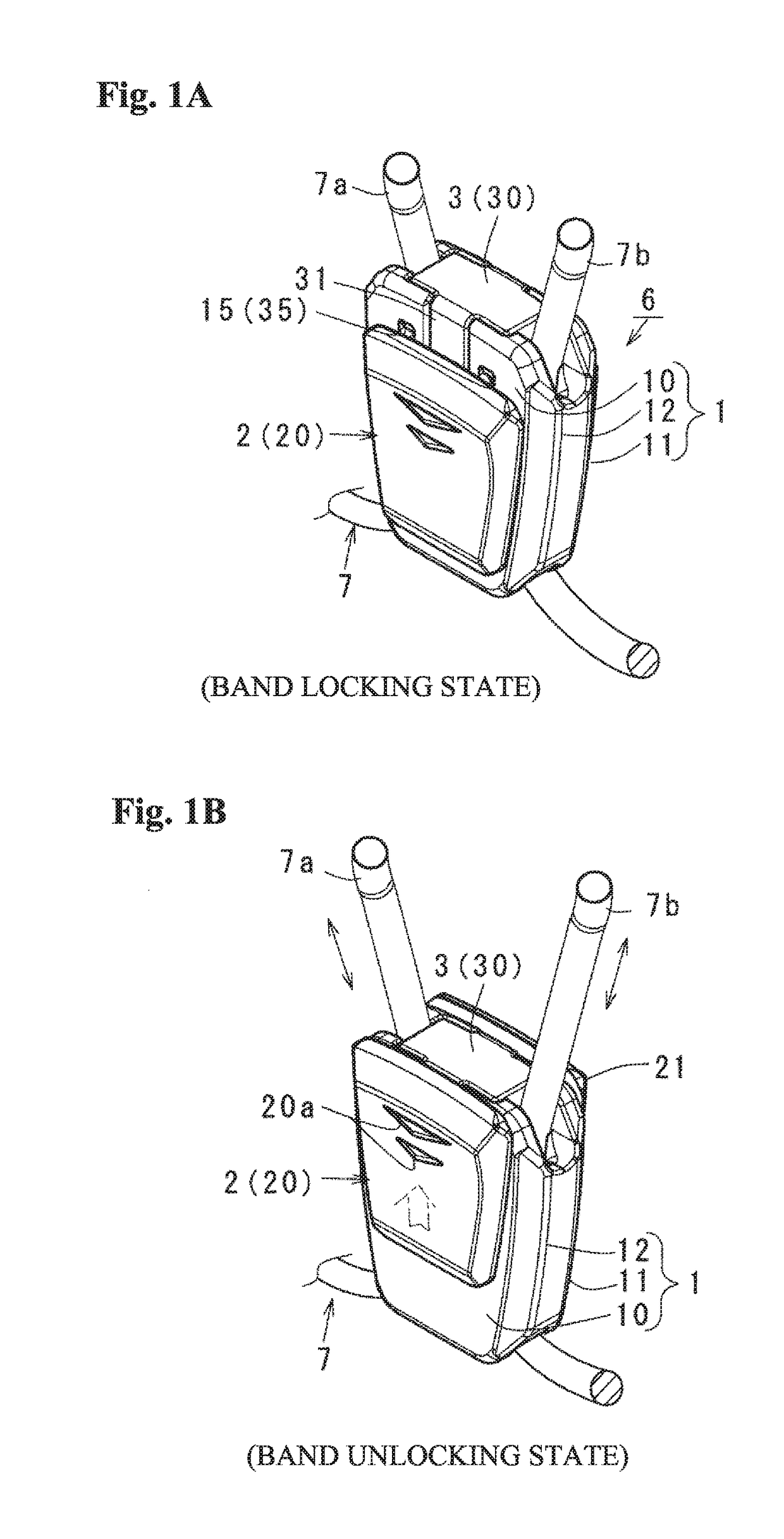

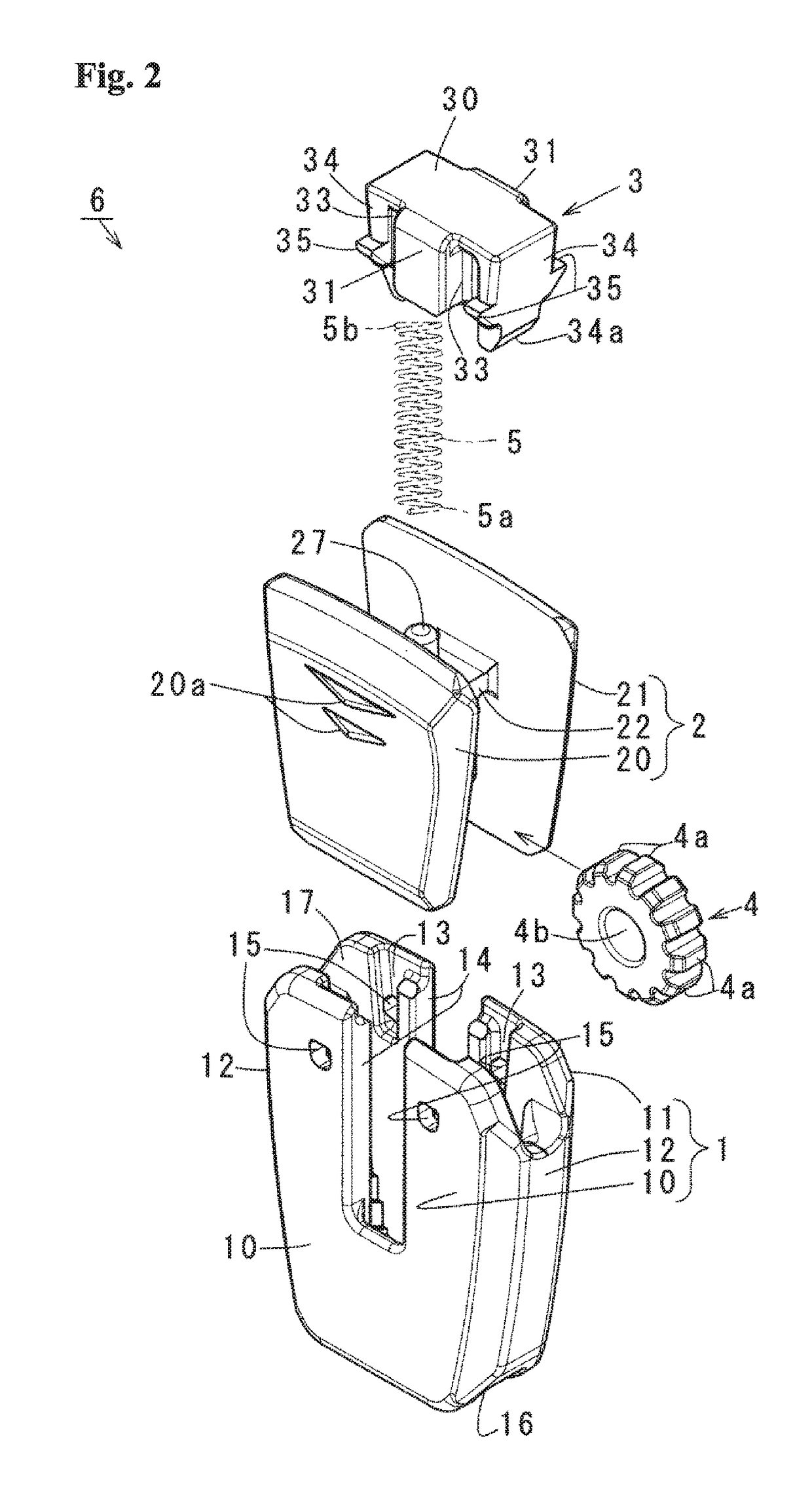

Cord lock

ActiveUS20180153262A1Easy to operateStrong clamping forceRopes and cables for vehicles/pulleyShoe lace fasteningsMechanical engineering

Owner:NIFCO INC

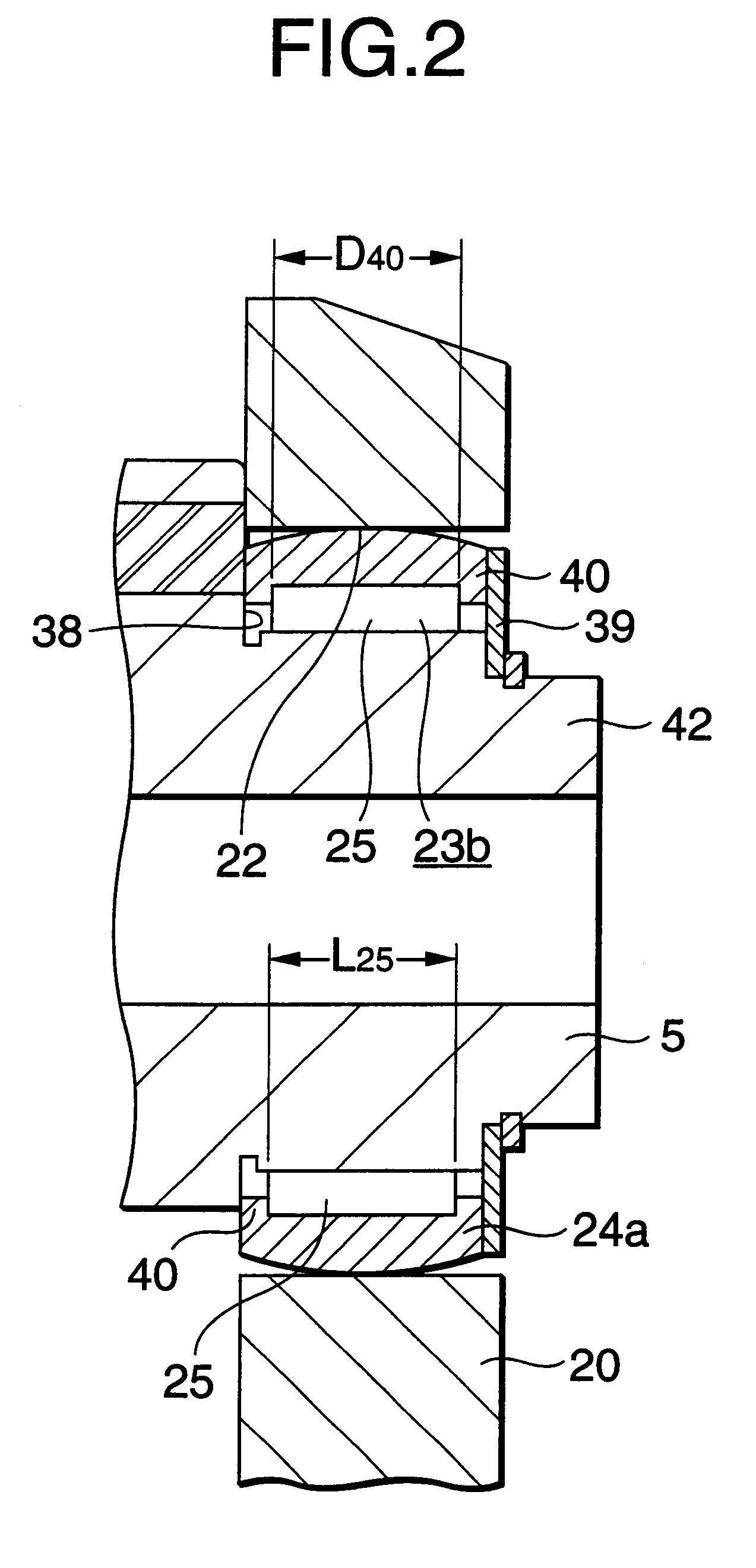

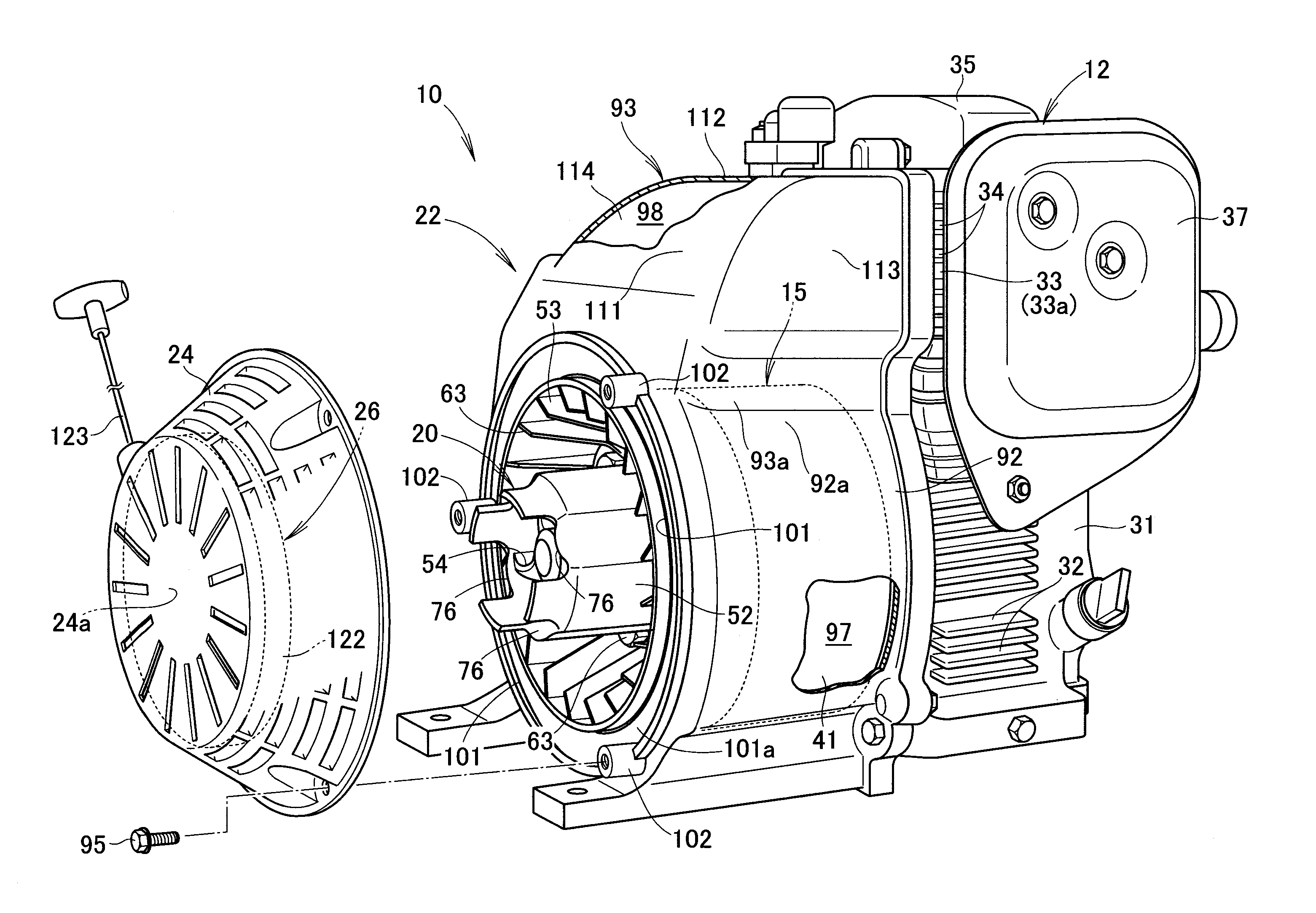

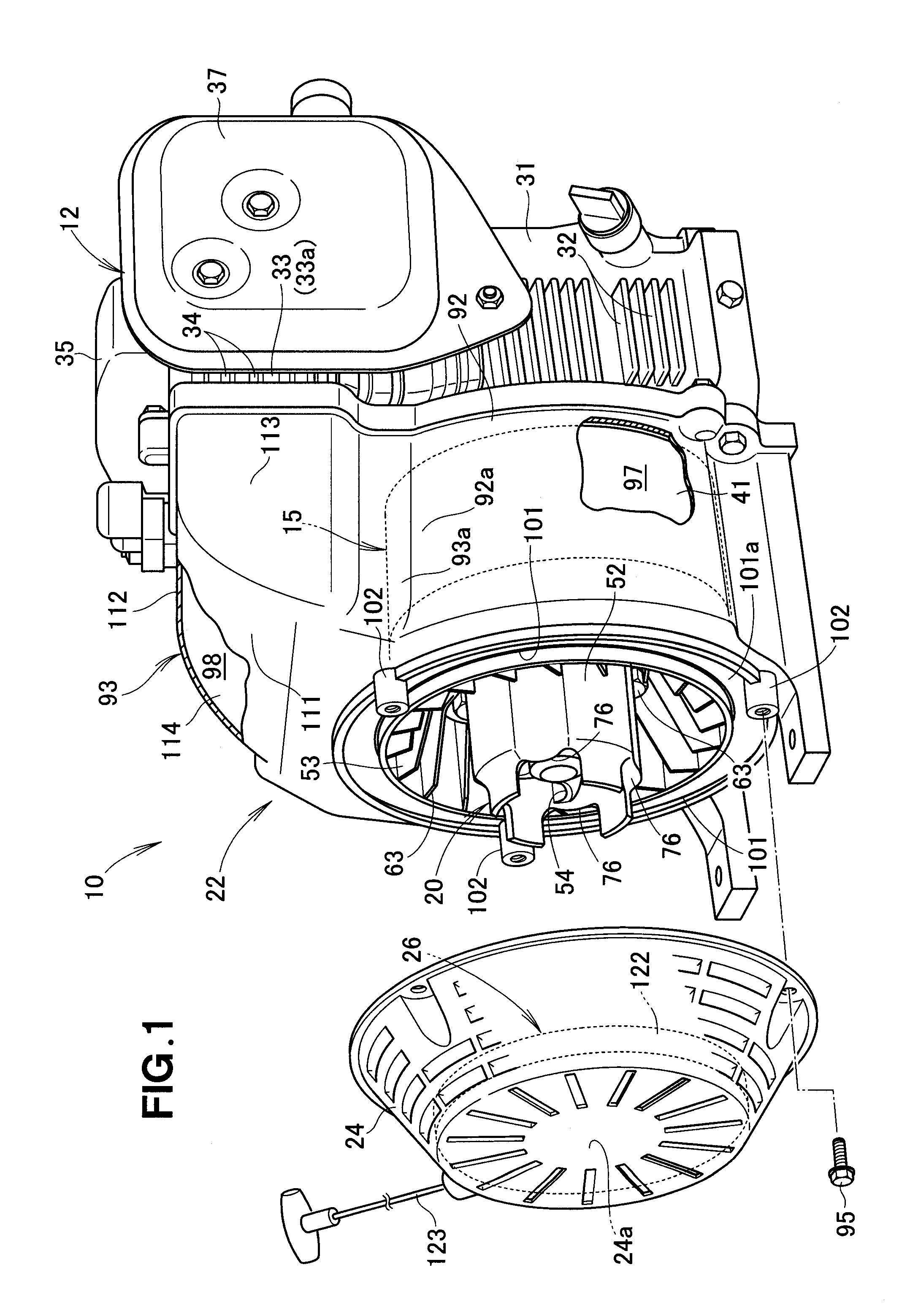

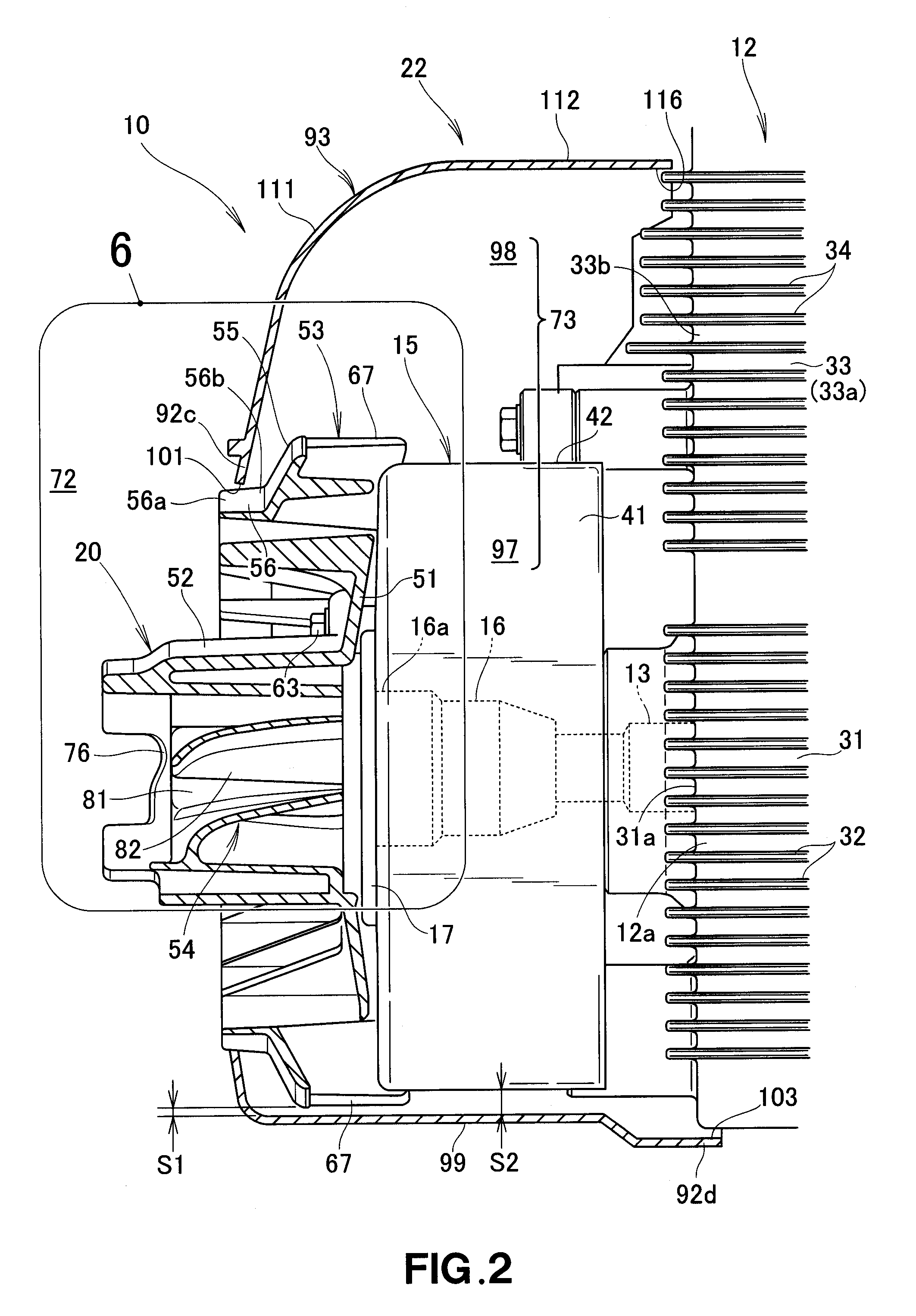

Engine-driven generator

ActiveUS20160281597A1Improve cooling effectSmall thicknessPower operated startersPump componentsMixed flowDrive shaft

An engine-driven generator includes an engine having a crankshaft, a generator unit having a drive shaft connected to the crankshaft, a cooling fan connected to the drive shaft, and a recoil starter engageable with the cooling fan. The cooling fan includes a starting pulley engageable with the recoil starter, a centrifugal fan formed on a circumferential outer side of the pulley, and a mixed flow fan formed on a circumferential inner side of the pulley. The pulley, the centrifugal fan, the mixed flow fan are molded integrally with one another.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com