Double-point coating production line for hot-melt adhesive padding cloth

A double-point coating and hot-melt bonding technology, which is applied to coatings, devices for coating liquid on the surface, and clothing, can solve the problems of reducing the speed of unwinding interlining, increasing production costs, and affecting product quality. Achieve the effect of improving the qualified rate of finished products, reducing production costs and avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Such as Figure 9 As shown, the hot-melt adhesive interlining double-point coating production line includes a cloth receiving device 1, a windshield screen 2, a slurry discharge roller 3, a heat-absorbing heat-melt powder blowing device 4, and an oven 5 arranged in sequence from front to back , cooling device 6, purple light cloth inspection device 7 and winding device 8.

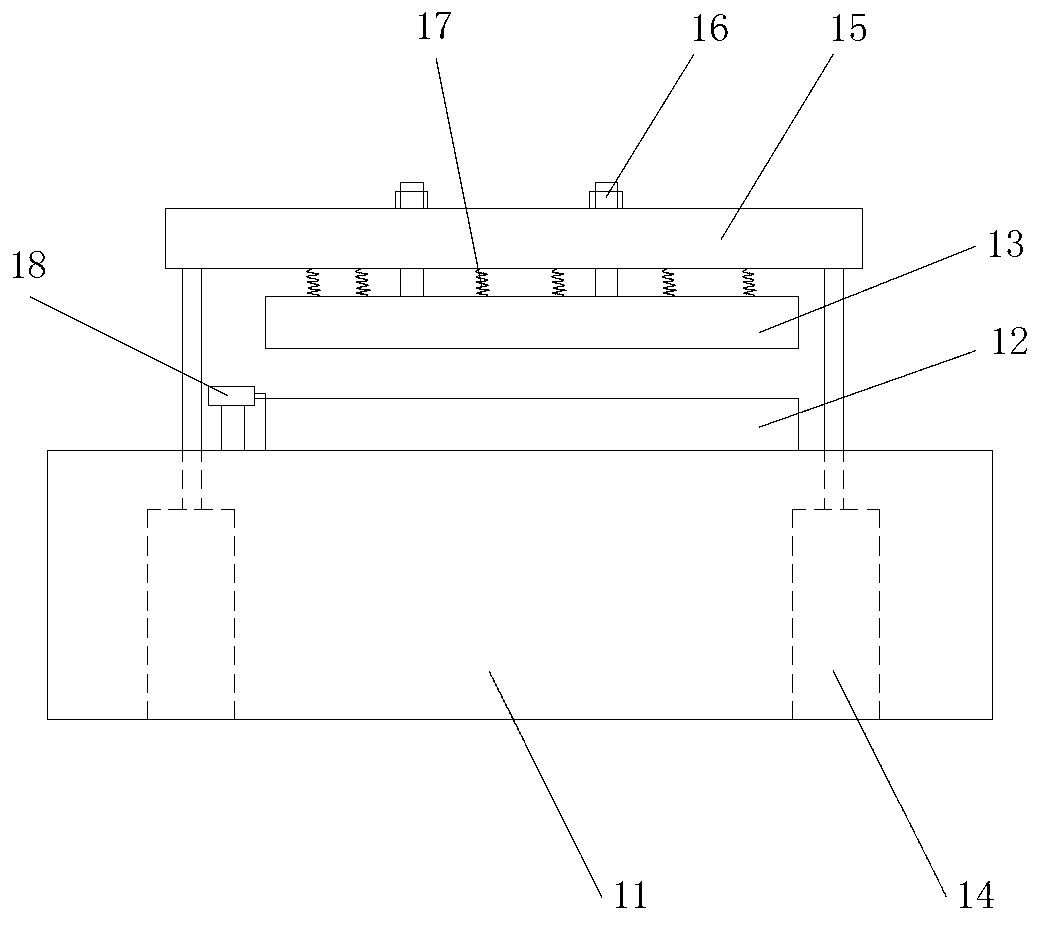

[0035] Such as figure 1 As shown, the cloth connecting device 1 includes a cloth connecting base 11, a lower pressing die 12 arranged on the cloth connecting base 11, a lifting die 12 arranged on the cloth connecting base 11 to cooperate with the lower pressing die 12 to crimp the interlining. Upper die 13. Two cylinders 14 are arranged in the cloth-connecting underframe 11, a support 15 is connected between the piston rods of the two cylinders 14, and the upper die 13 is connected to the bottom of the support 15; The adjusting nut 16 of the distance between the upper die 13 and the support 15; so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com