Low-vibration titanium alloy milling process parameter optimization method

A technology of process parameters, titanium alloy, applied in the direction of instruments, computer control, simulators, etc., can solve the problem of not fully considering the resonance and chatter of machine tool milling, affecting the processing quality, efficiency and tool life, etc., to suppress milling chatter. , The effect of suppressing milling vibration and ensuring milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: The present invention is used to optimize the process parameters in the rough machining stage of titanium alloy TC18 milling.

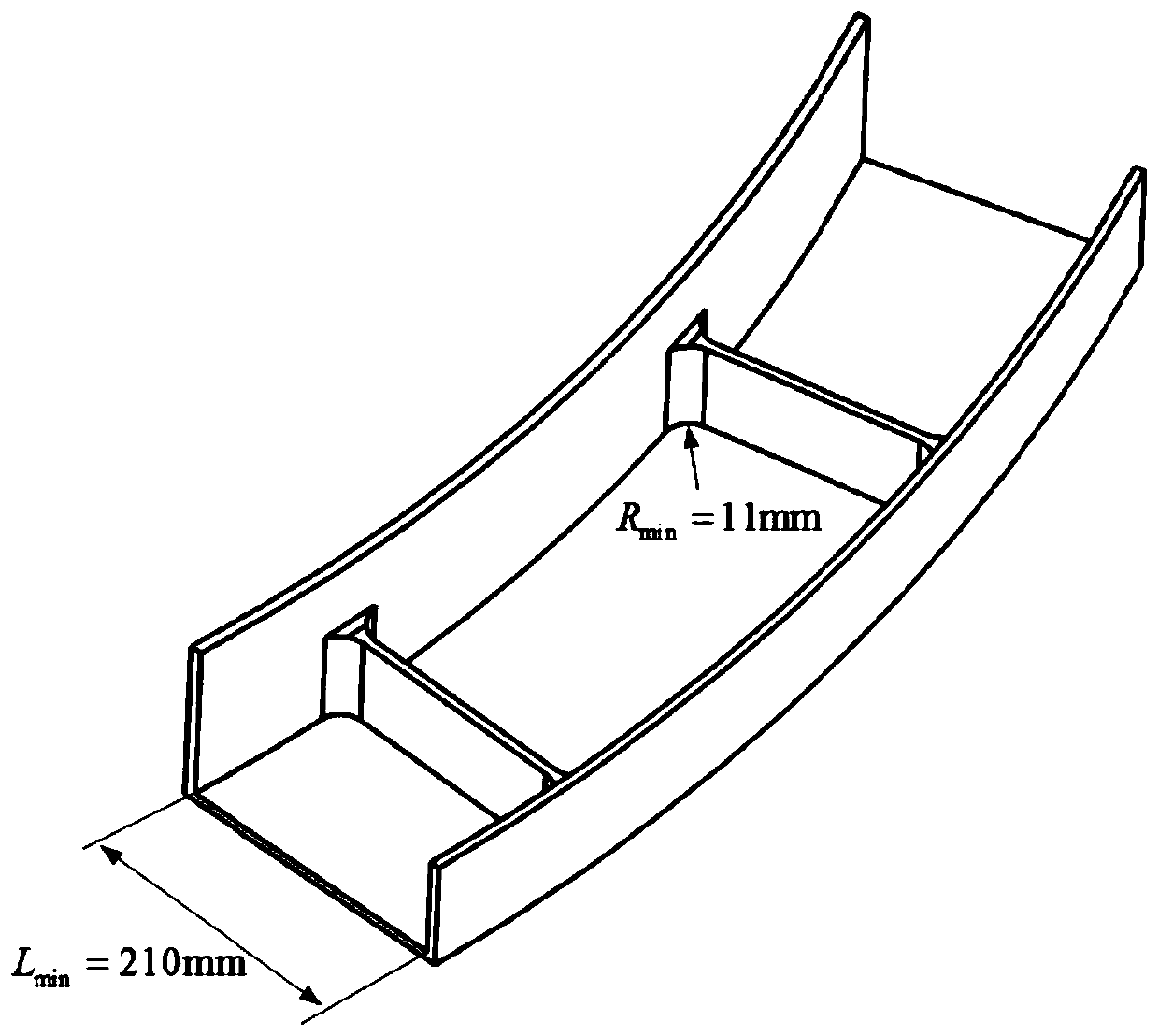

[0043] (1) Refer to the appendix figure 1 , according to the geometric characteristics of the box-shaped parts being processed, that is, the minimum value of the corner radius R min = 11mm and the minimum size of the slot L min =210mm, use the following formula to calculate the maximum diameter D of the allowable tool max :

[0044] D max =min{5R min ,0.3L min}=min{5×11,0.3×210}=55;

[0045] (2) The diameters of the existing milling cutters are 30mm, 35mm, 40mm, 50mm, and 80mm, respectively. max closest to but less than D max The cutter is used as a titanium alloy milling cutter, so choose an indexable milling cutter with a diameter of D=50mm (model: 7792VXD12-A050Z6R);

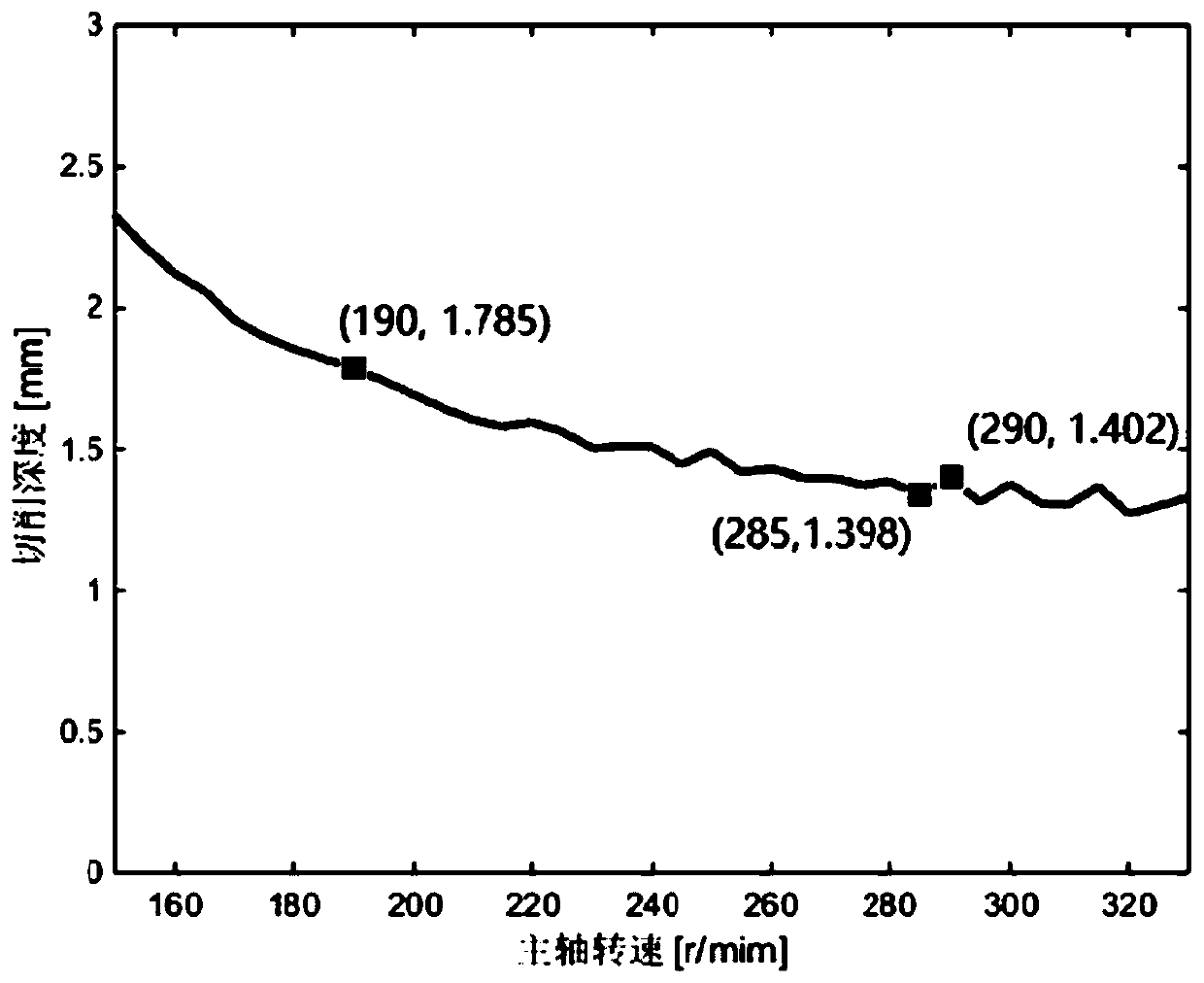

[0046] (3) The minimum cutting speed V of the tool recommended by the tool manufacturer c,min =30m / min and maximum cutting speed V c,max =45m / min, calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com