Milling stability domain prediction method under multi-modal coupling

A forecasting method and multi-modal technology, which can be used in forecasting, data processing applications, computing, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

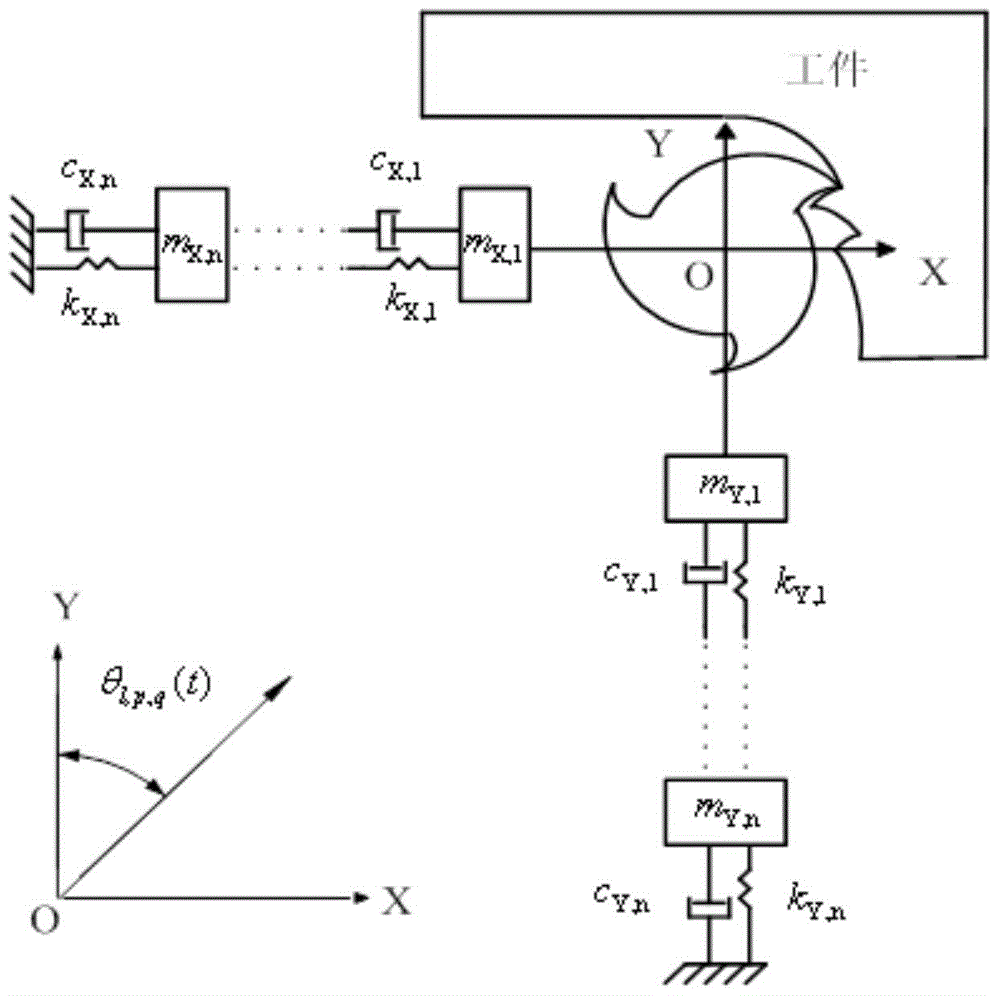

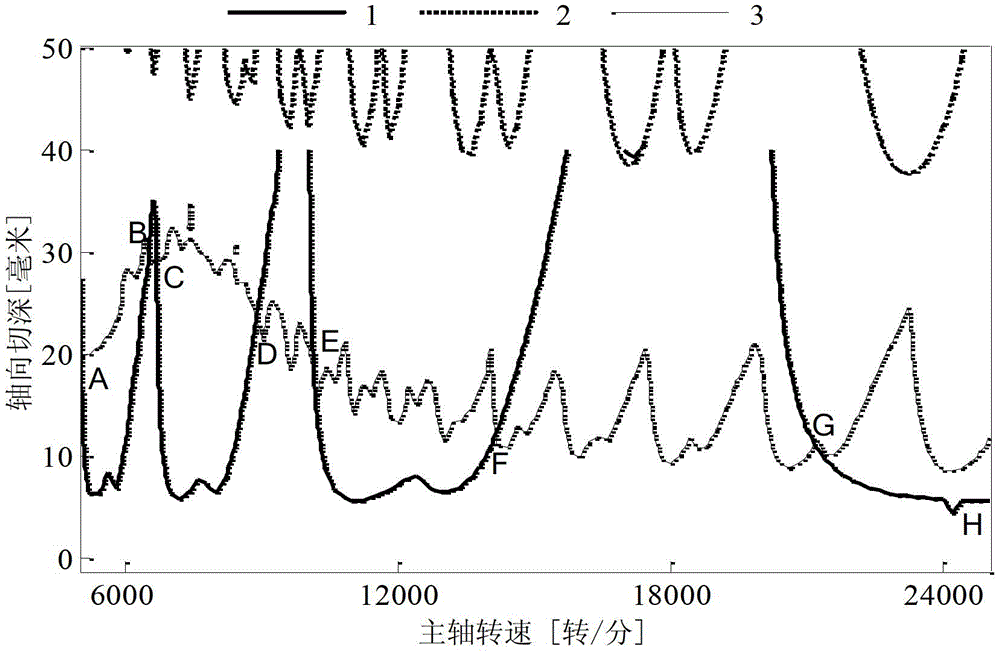

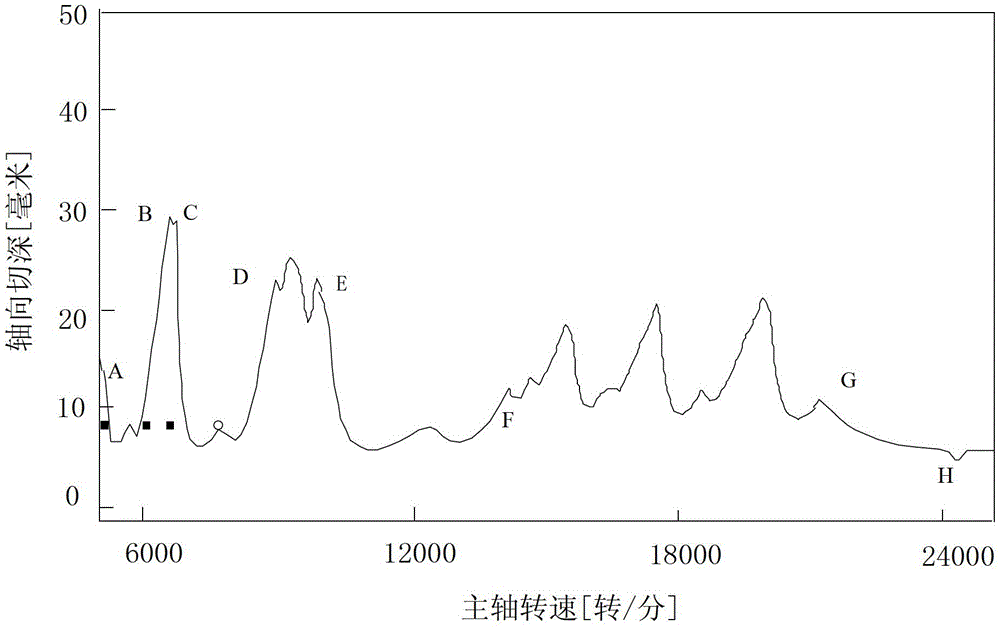

[0034] The specific steps of the milling stable region prediction method under multi-modal coupling in the present invention are as follows.

[0035] 1) Install a milling cutter with a radius of 12mm, a helix angle of 30°, and a number of teeth N of 3 on the tool holder and then on the machine tool spindle system, and then use the standard impact test to test the modal of the milling cutter-tool holder-machine tool spindle system Parameters, the modal parameters of each order obtained from the test, as shown in the following table:

[0036] Table 1. Modal parameters

[0037]

[0038] 2) Combine the modal parameters in the X direction and Y direction measured in step 1), that is, the first-order modal parameters in the X direction and the first-order modal parameters in the Y direction are combined into a group and recorded as a model State 1; Similarly, the second-order modal parameters in the X direction and the second-order mode in the Y direction are combined into a group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com