Variable-pitch variable-rotating-speed milling flutter active and passive suppression method considering helical angle effect

A technology for milling chatter and helix angle, which is applied in the field of active and passive suppression of milling chatter with variable pitch and variable speed, and the prediction and suppression of milling chatter. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

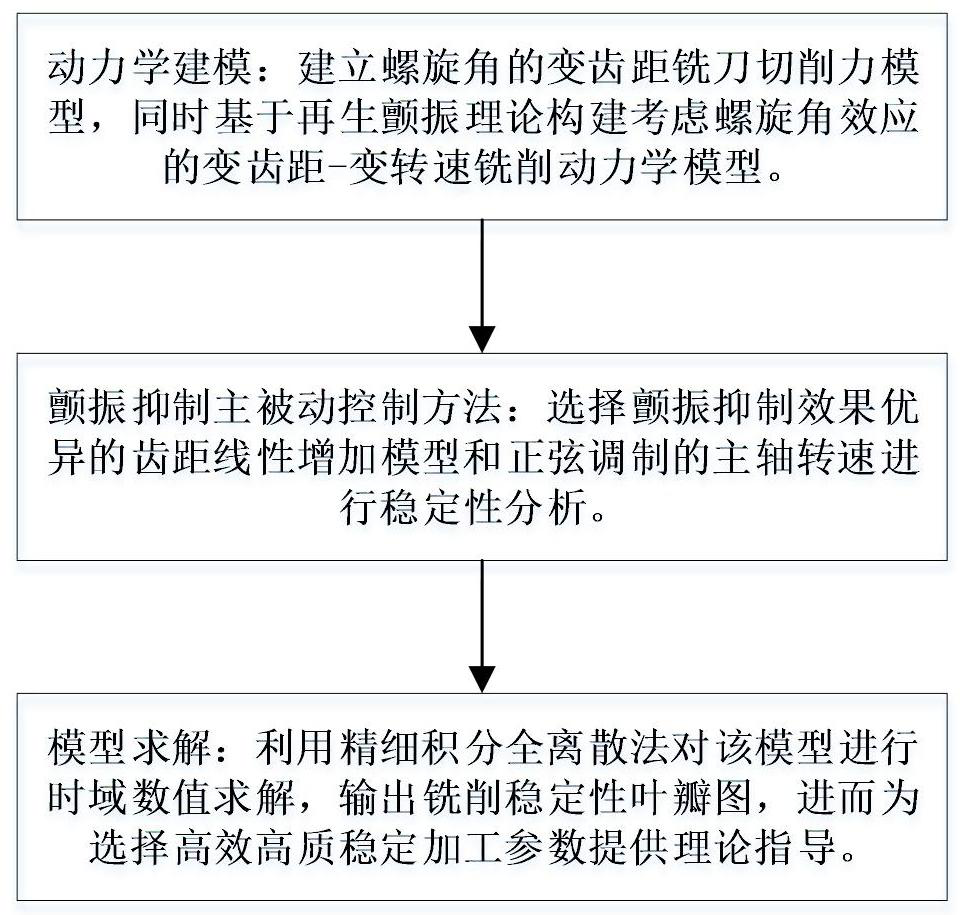

[0121] Such as figure 1 As shown, the active and passive suppression method of milling with variable pitch and variable speed considering the effect of helix angle includes the following steps:

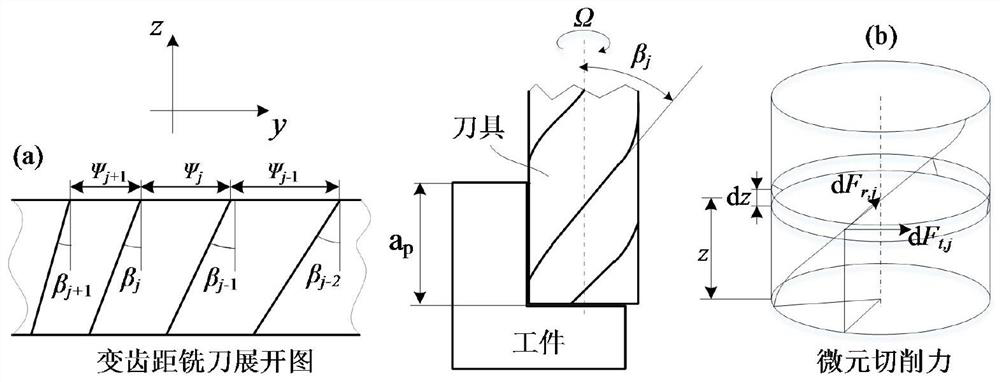

[0122] S1: Constructing the differential equation of milling dynamics with variable pitch and variable speed considering the effect of helix angle

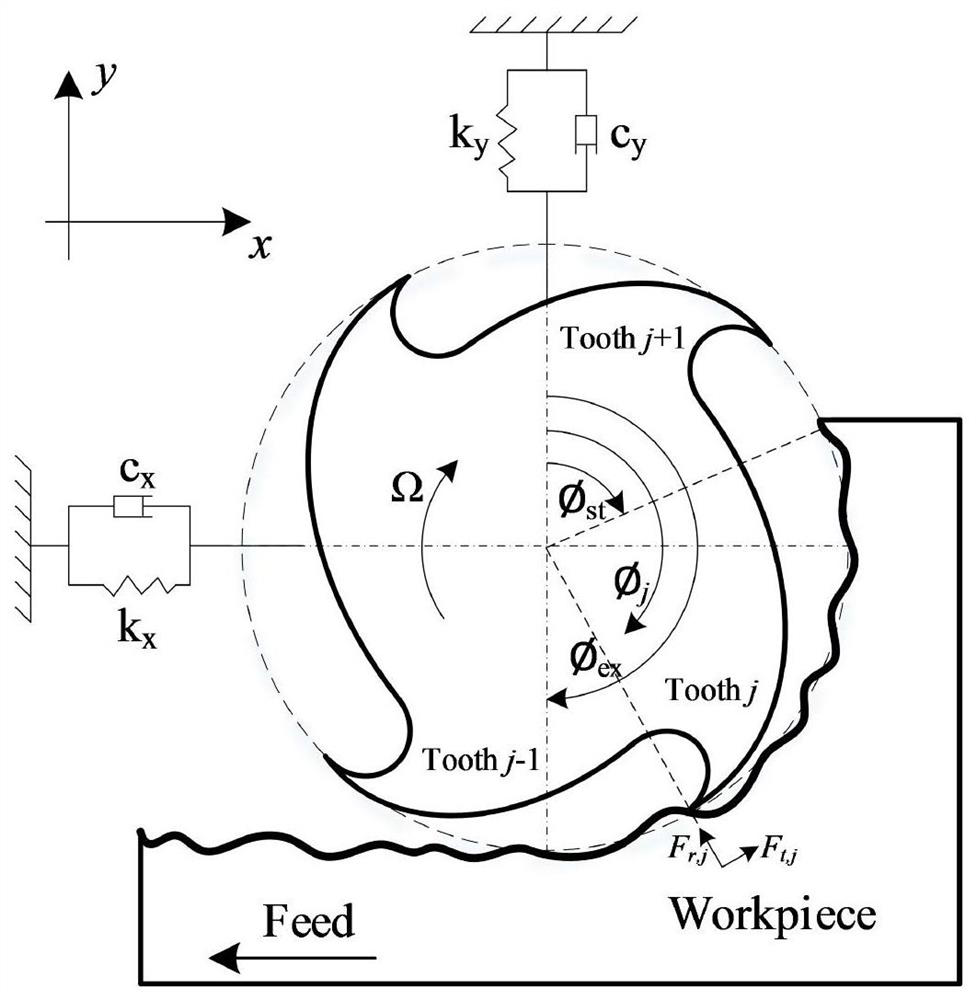

[0123] S1.1. Simplify the tool-workpiece milling system as figure 2 For the two-degree-of-freedom system shown, under the framework of structural dynamics, the milling dynamic equation can be expressed as the following differential equation:

[0124]

[0125] Among them, m tx , ζ x and ω x are the modal mass, damping ratio and natural frequency of the tool system in the x direction; m ty , ζ y and ω y are the modal mass, damping ratio and natural frequency of the tool system in the y direction; F x (t) and F y (t) are the dynamic cutting forces acting in the x and y directions, respectively.

[0126] S1.2. Solve the dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com