Parallel time domain method for predicating milling chatter stability based on thin-wall part

A technology of stability prediction and milling chatter, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to accurately predict chatter stability in milling of thin-walled parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

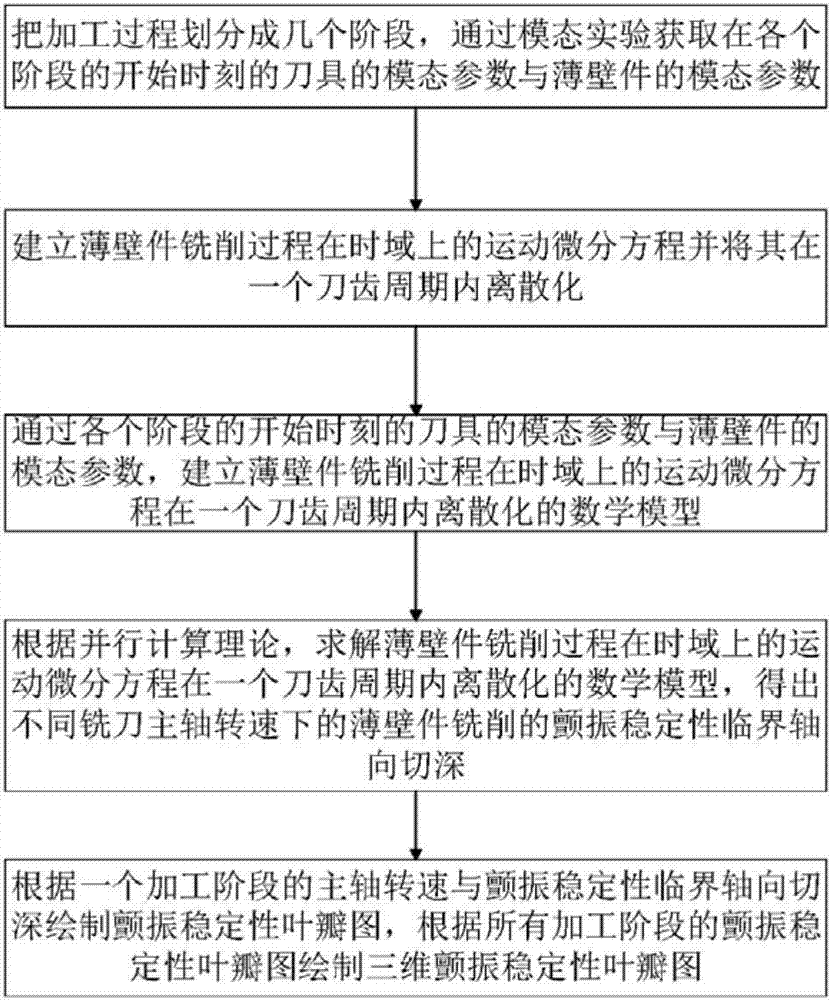

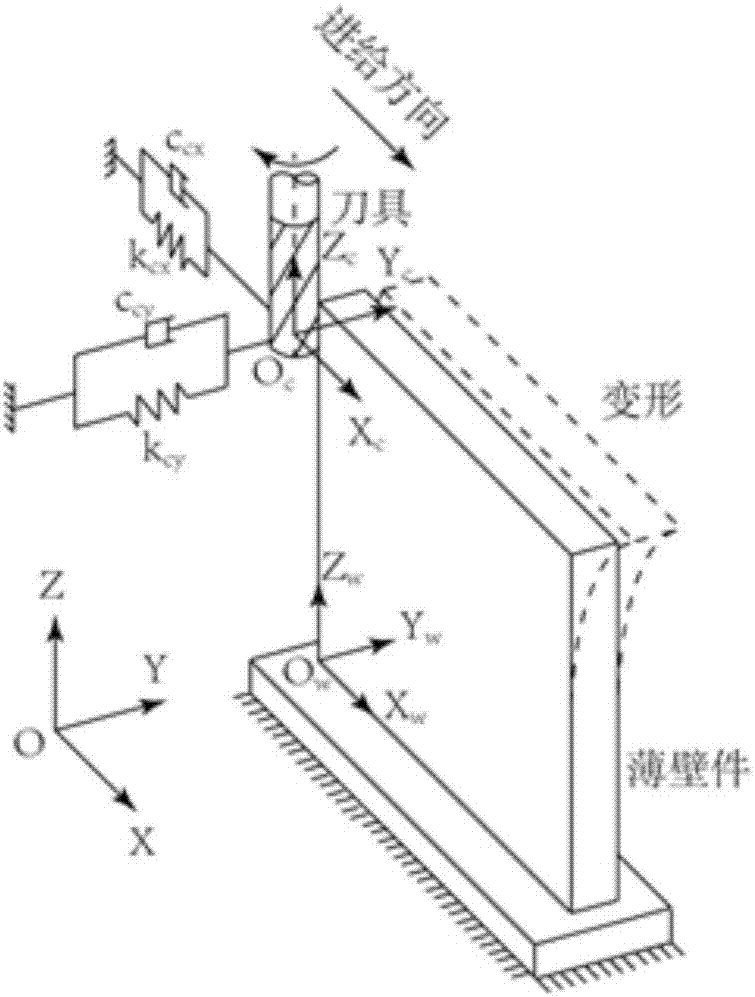

[0089] Such as Figure 1-Figure 6 A parallel time-domain method for milling chatter stability prediction based on thin-walled parts is shown,

[0090] Has the following steps:

[0091] S1. Divide the machining process into several stages, and obtain the modal parameters of the tool and the modal parameters of the thin-walled parts at the beginning of each stage through modal experiments:

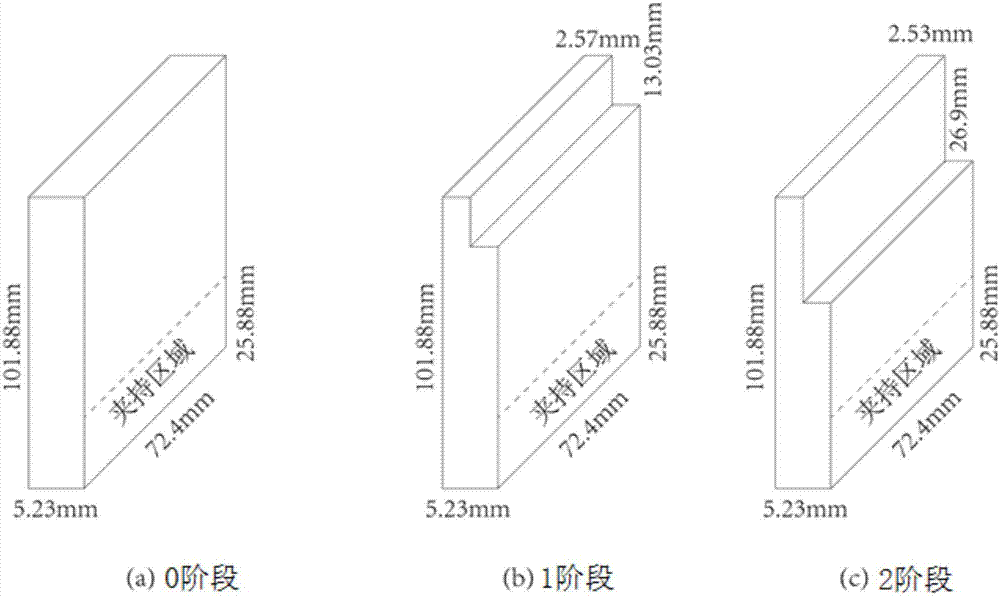

[0092] S11. Divide the processing process into 3 stages, stage 0, stage 1, and stage 2. The shape of the thin-walled parts in each stage is as follows figure 2 shown;

[0093] S12. Conduct modal experiments on different shapes of thin-walled parts at various stages,

[0094] Install the knife into the handle. Install the dynamometer on the machine tool platform, because the dynamometer will be installed in the follow-up experiment, so in order to maintain the consistency of the modal data, the dynamometer should also be installed when measuring the mode. Install the vise on the dynamom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com