Five-axis linkage variable-axis plunge milling numerically controlled processing method for blade part of integral impeller

An integral impeller and five-axis linkage technology, applied in metal processing, automatic control devices, metal processing equipment, etc., can solve the problems of large data processing volume, low processing efficiency, and increased processing time, so as to improve processing efficiency and margin Uniformity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

[0029] The specific dimensions, materials and processing parameters of the integral impeller of the present embodiment are as follows:

[0030] The maximum outer diameter of the blade: 936mm;

[0031] The minimum outer diameter of the blade: 482mm;

[0032] The maximum chord width of the blade: 210mm;

[0033] Number of blades: 20;

[0034] Maximum thickness of blade tip: 4.5mm;

[0035] Maximum thickness of blade root: 12.5mm;

[0036] Material: titanium alloy;

[0037] Processing parameters: processing line speed 30 ~ 40m / min;

[0038] The five-axis linkage variable-axis plunge-milling CNC machining method of the integral impeller blade part of the present invention is carried out according to the following steps:

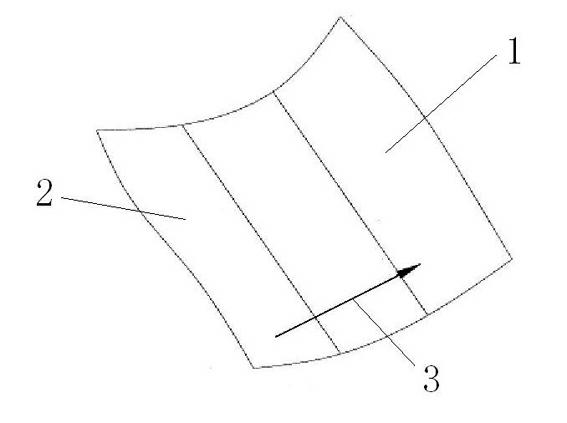

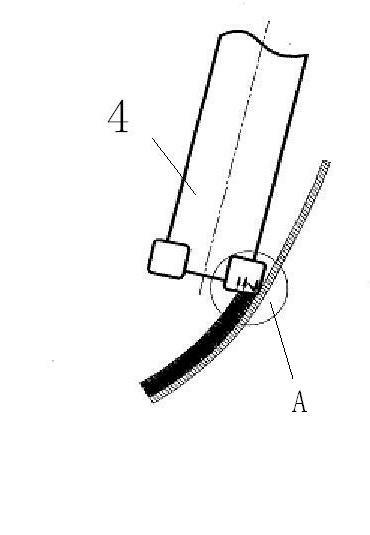

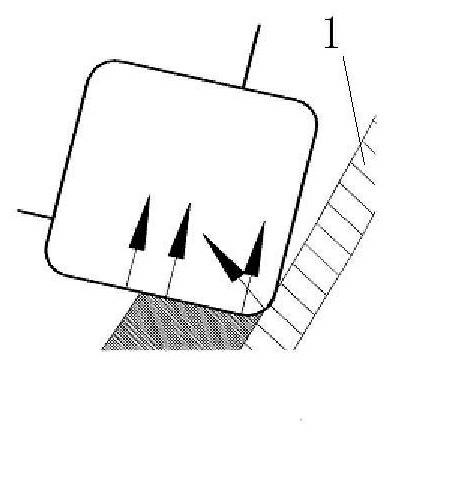

[0039] 1) at figure 1 In the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com