Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "No tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slip casting roof bolt with anticorrosive casing pipe

InactiveCN1712670AIncreased durabilityExtended service lifeAnchoring boltsSupporting systemRock bolt

The invention opened an injected anchor arm with the antiseptic spigot, which is composed of the anchor arm body, the connection part of the porthole, the spigot, anchoring head, holding pad, the tight nut and the gasket. The invention can form the supporting anchorage power quickly to control the deforming of the terrene; also it can form a supporting system of multi-antiseptic barrier with the spigot and the double injected plasma.

Owner:吴德兴

Piezoelectric hospital call signal generator

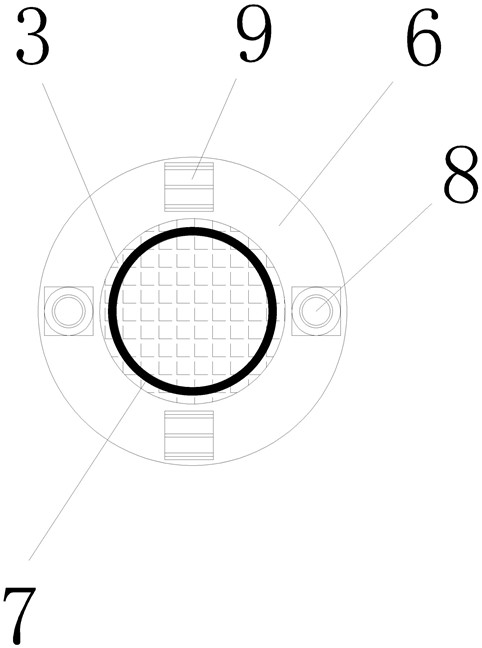

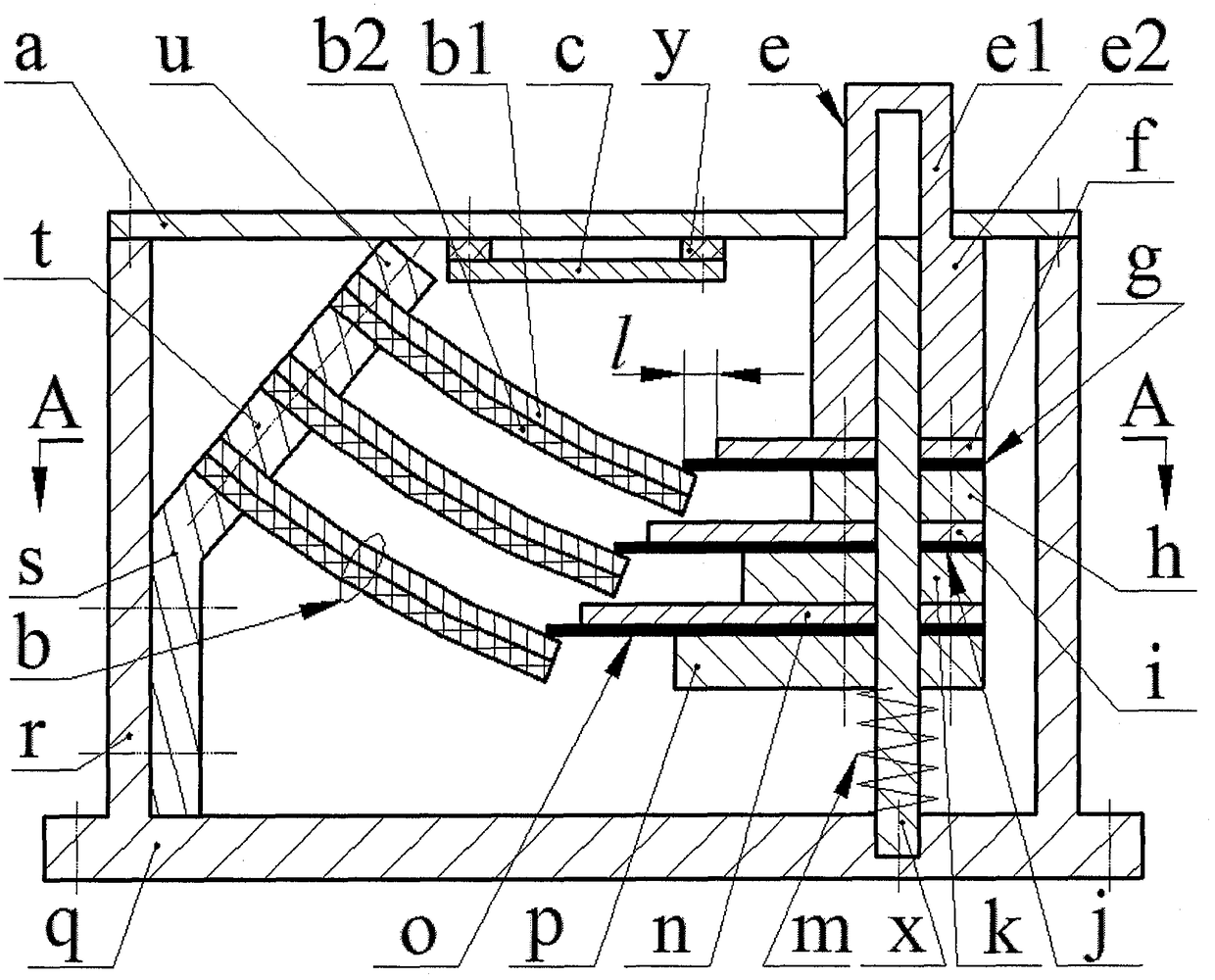

ActiveCN107332469ANo tensile stressIncrease the tensile stressPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsSignal generator

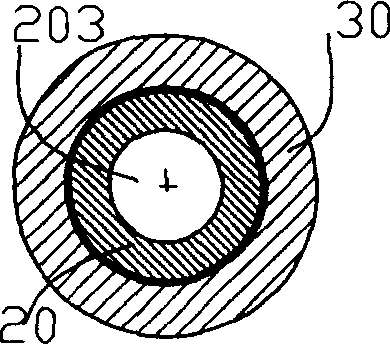

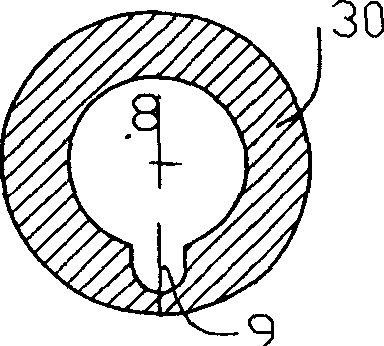

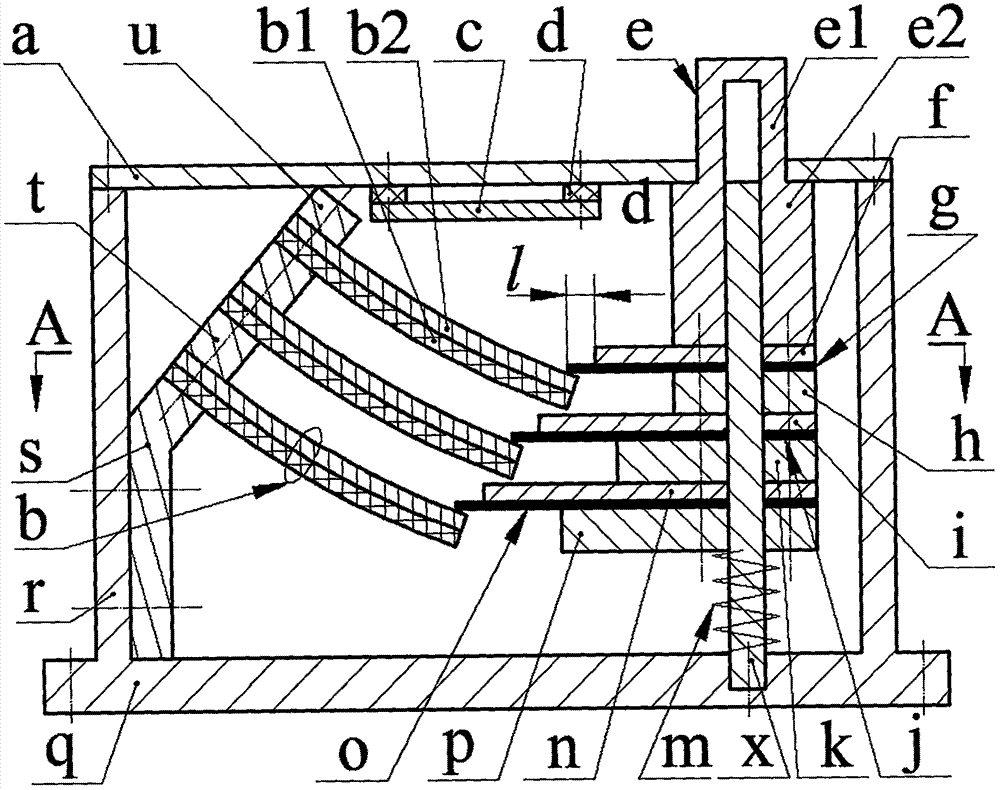

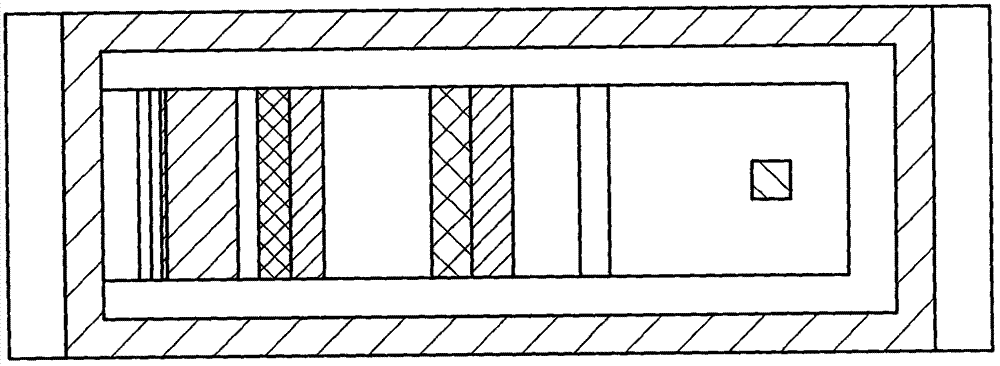

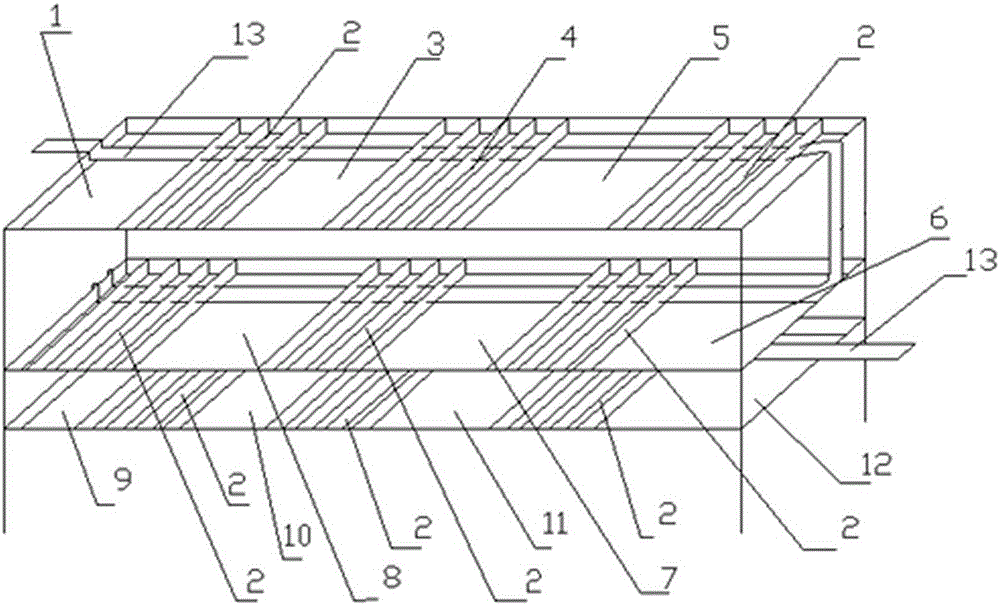

The invention relates to a piezoelectric hospital call signal generator and belongs to the technical field of a medical electronic product. The end portion of a side wall of a housing is connected with an upper cover having a through hole. The upper cover is provided with a circuit board through washers, and the circuit board is provided with an energy conversion circuit and a signal emission system. The side wall of the housing is connected with a vibrator base. The vibrator base is equipped with a group of piezoelectric vibrators through a press plate. The piezoelectric vibrators are separated by separator plates correspondingly. Each piezoelectric vibrator is in an arc structure formed by a substrate and a piezoelectric sheet, which are glued together, wherein the bending radius of the substrate is smaller than the bending radius of the piezoelectric sheet. A bottom wall of the housing is provided with a square sink groove, which is internally equipped with a guide bar. The guide bar is provided with a reset spring, a lower short rigid block, a lower flexible dial slice, a lower long rigid block, a middle short rigid block, a middle flexible dial slice, a middle long rigid block, an upper short rigid block, an upper flexible dial slice, an upper long rigid block and a button in sequence from the bottom up. A small end of the button passes through the through hole in the upper cover, and the upper surface of a big end of the button is abutted against the upper cover; and the bottom wall of the housing is connected to a sickbed.

Owner:ZHEJIANG NORMAL UNIVERSITY

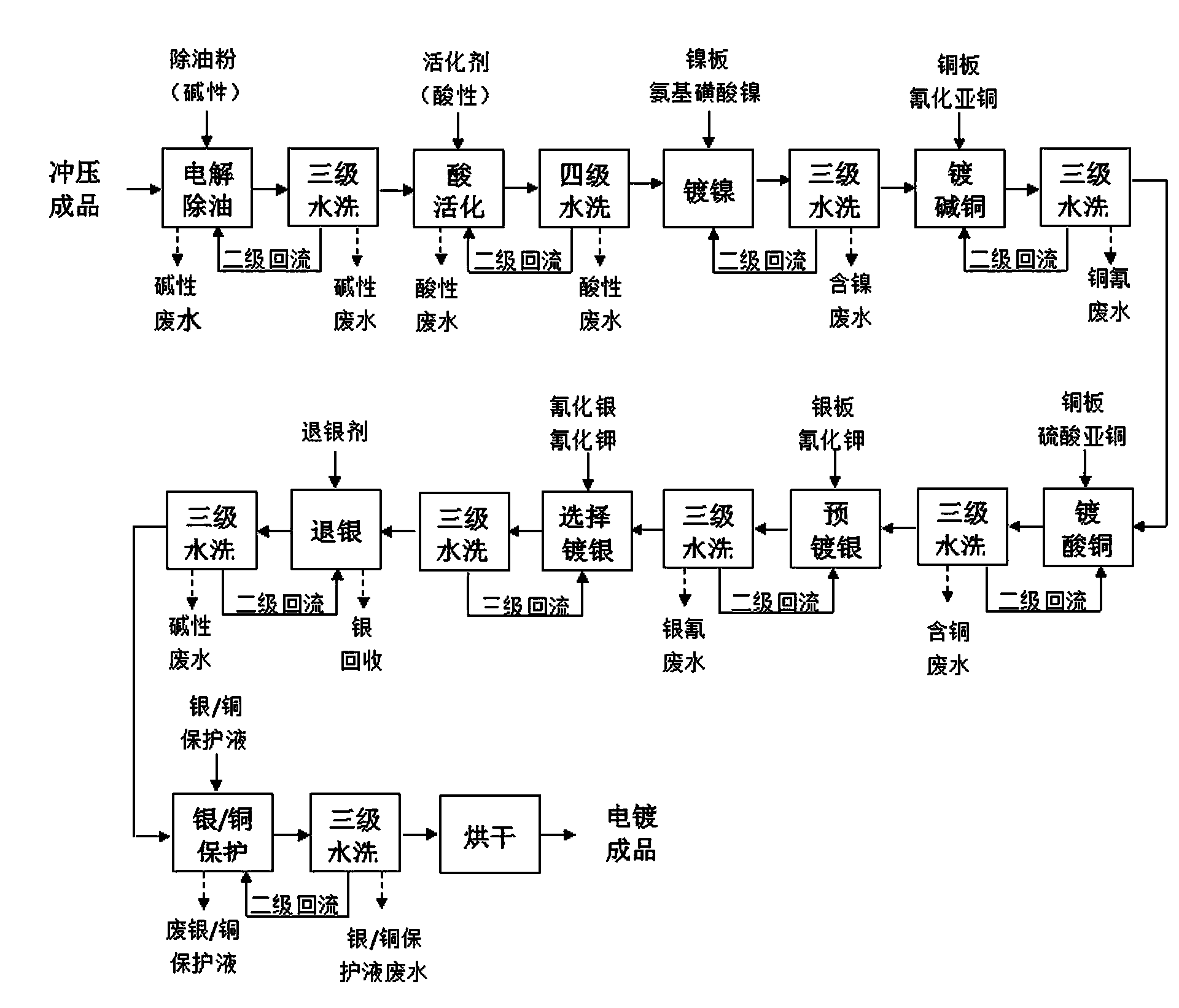

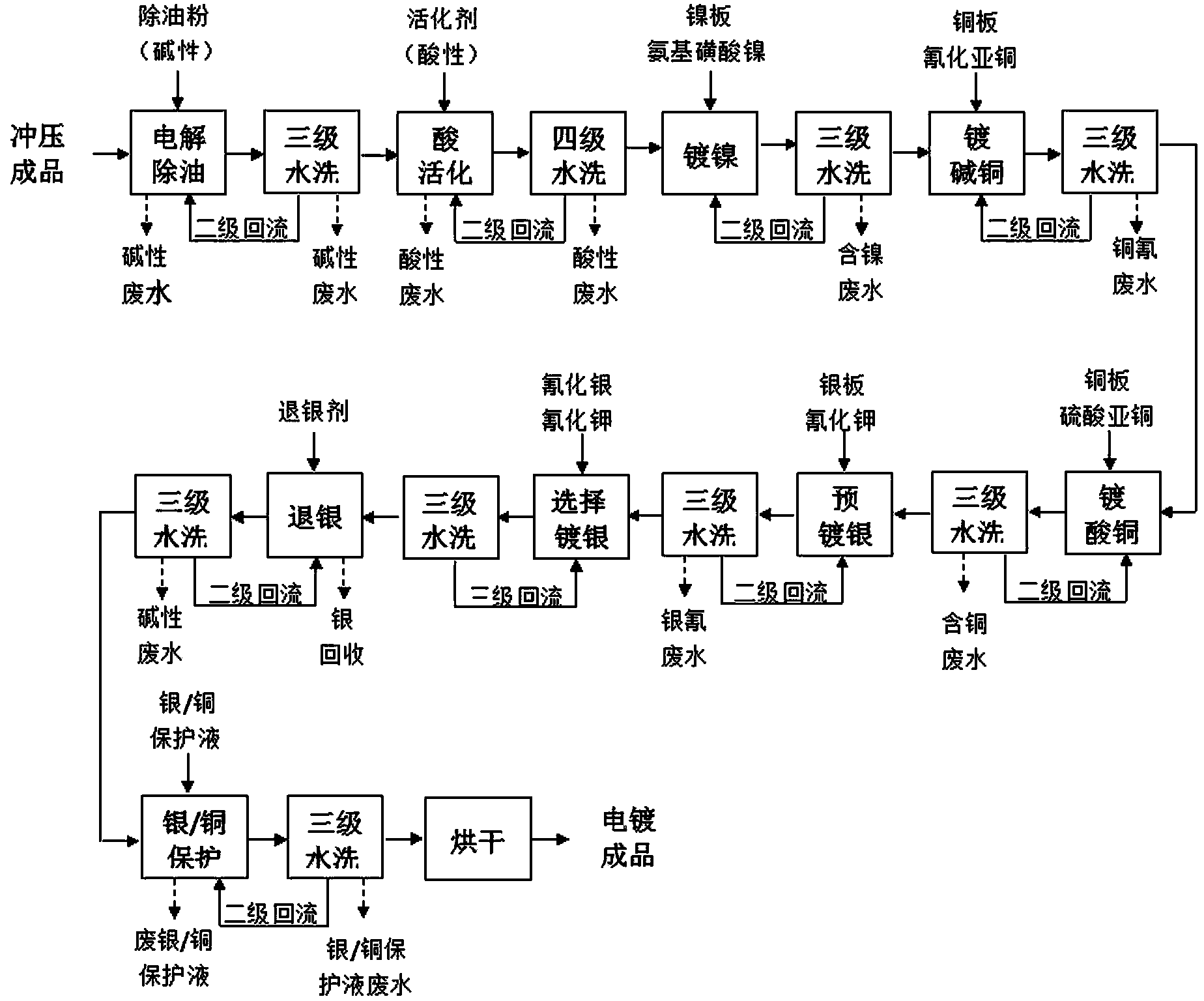

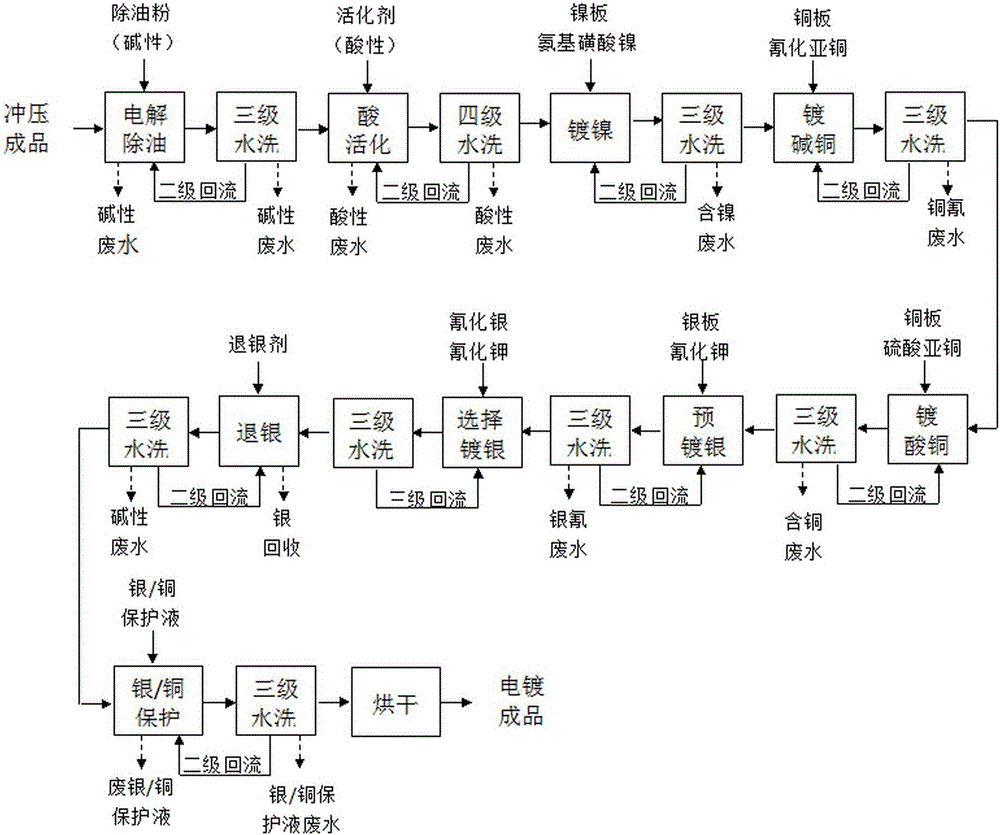

Semiconductor lead frame manufacturing technology

ActiveCN103928302AQuality improvementStrong adhesionSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyCopper plating

The invention relates to a semiconductor lead frame manufacturing technology which comprises the steps of stamping, surface treatment and cut-forming. The technology is characterized in that the surface treatment process specifically comprises the steps of electrolytic degreasing, washing, acid activation, washing, nickel plating, washing, alkaline copper plating, washing, acid copper plating, washing, silver preplating, washing, silver plating, silver removing, washing, protective solution plating, washing and drying. Plated layers of a semiconductor lead frame manufactured with the method are high in adhesive force and do not fall off easily. Meanwhile, the semiconductor lead frame is free of deformation and oversize, high in quality, and long in service life.

Owner:SICHUAN JINWAN ELECTRONICS

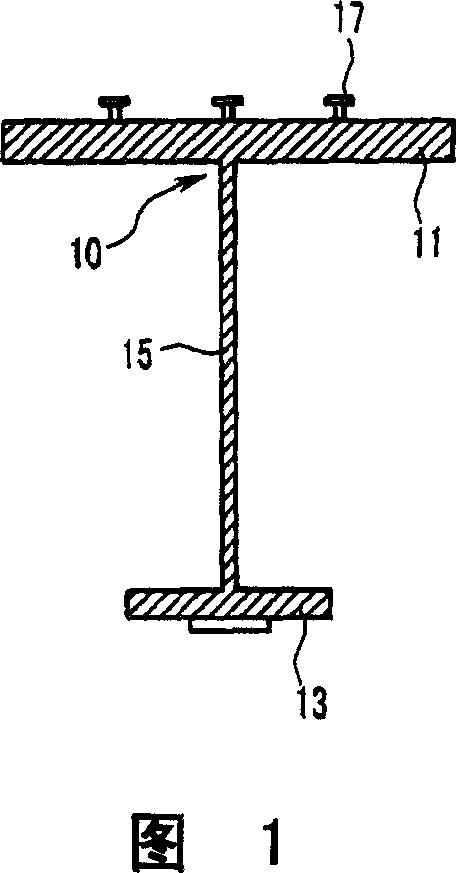

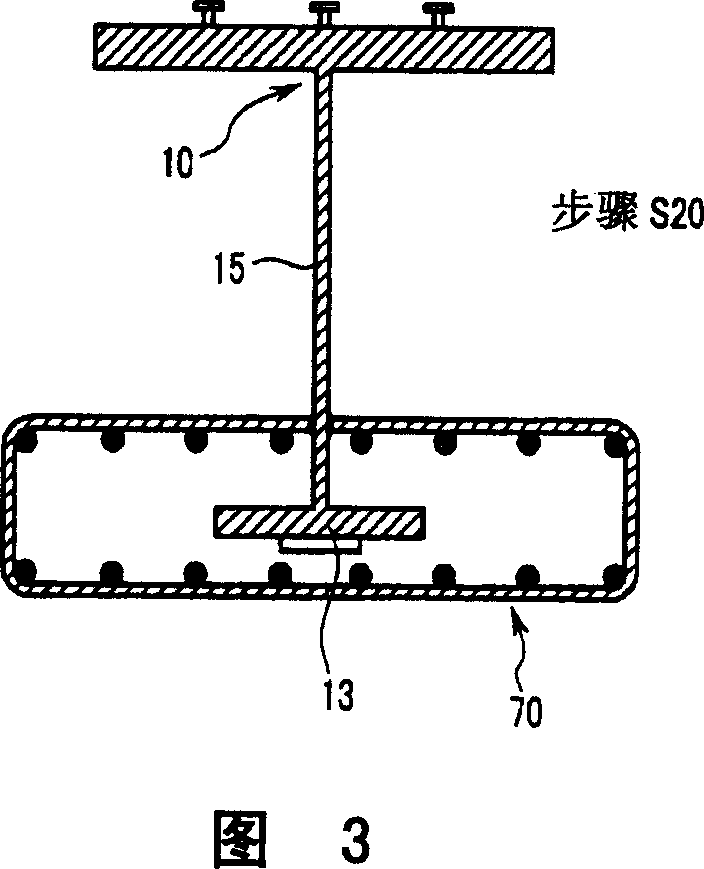

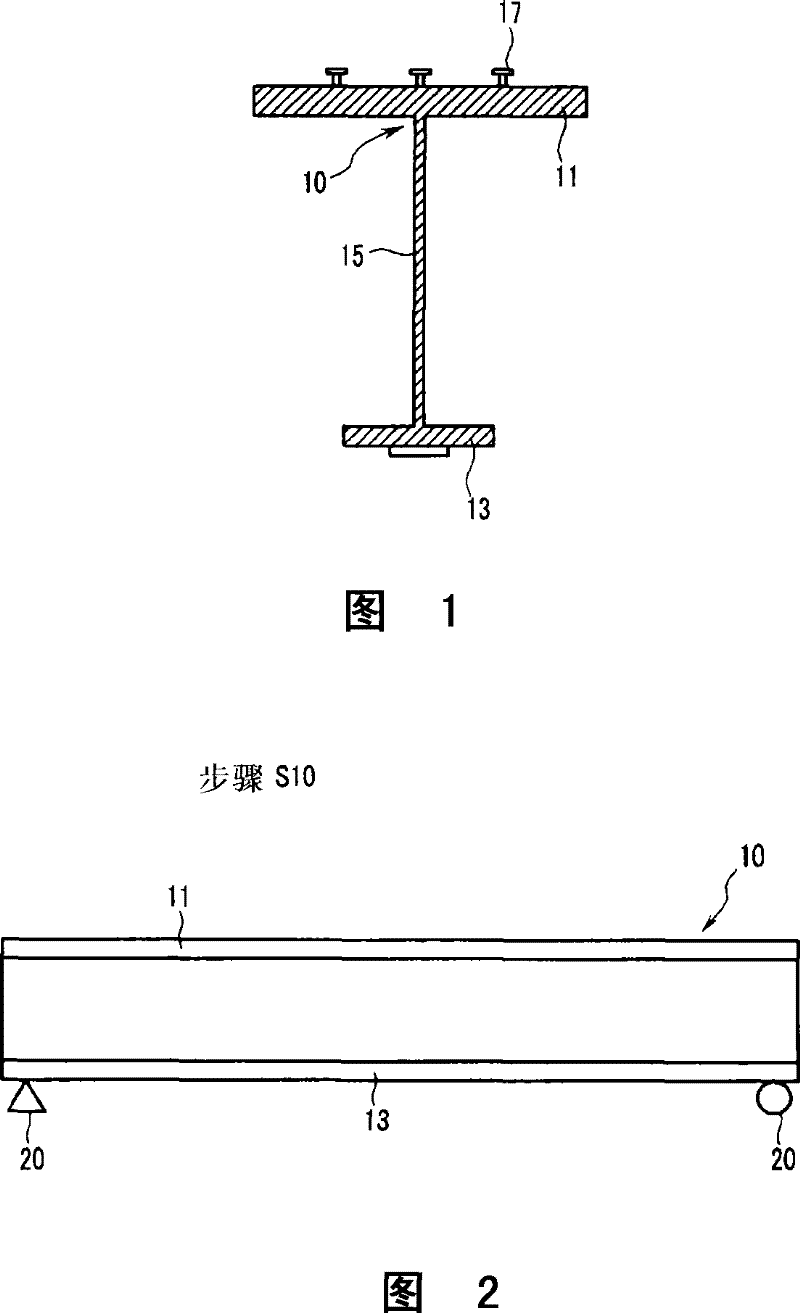

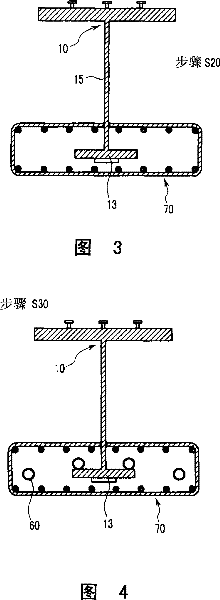

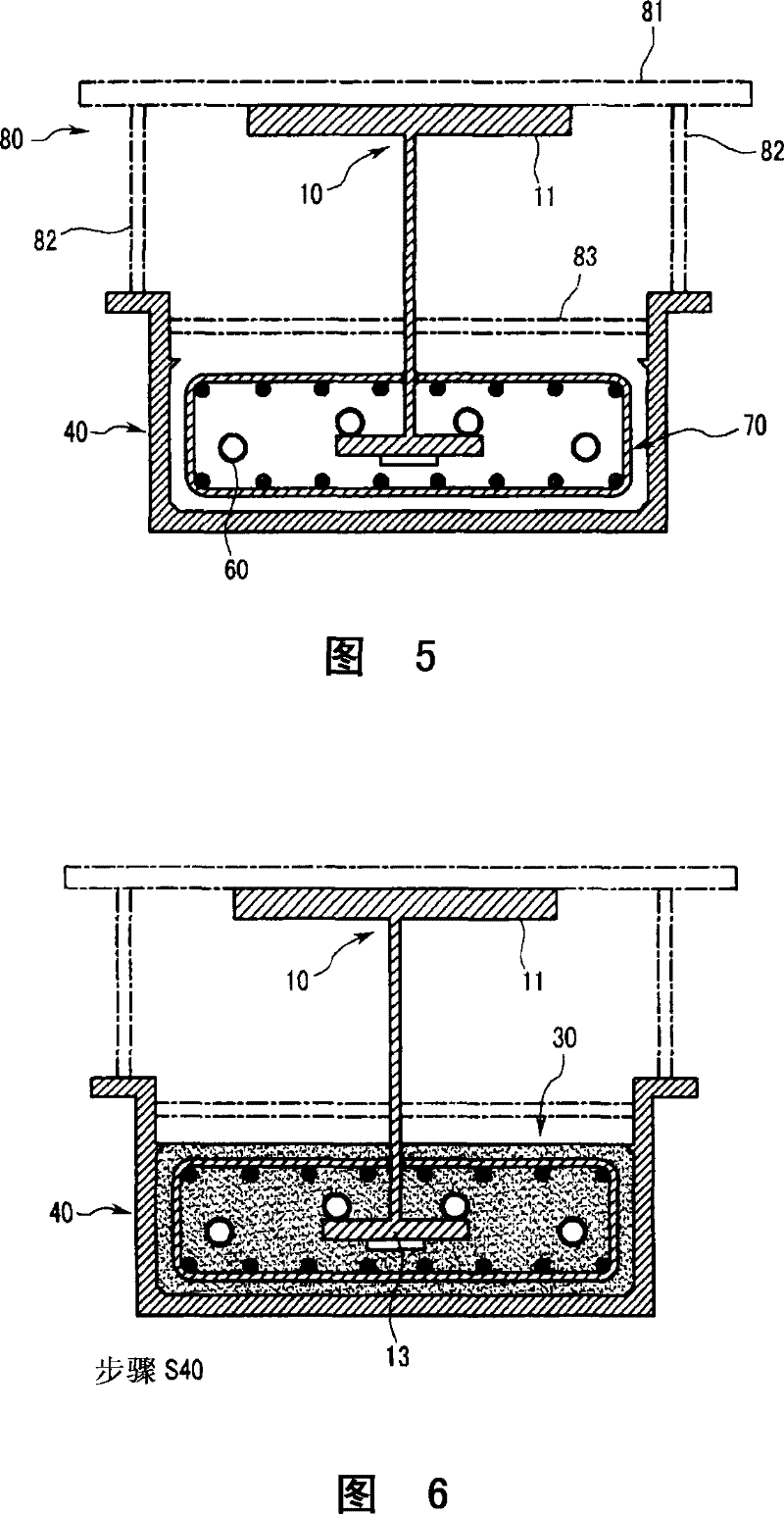

Manufacturing method for prestressed steel composite girder and prestressed steel composite girder thereby

ActiveCN101080534ANo tensile stressNo stress lossBridge erection/assemblyBridge materialsPre stressMaterials science

A prestressed steel composite girder and a method of manufacturing the prestressed steel composite girder are provided by using a steel beam and a concrete. The method includes steps of: placing the steel beam above the ground; installing a form, into which the concrete is to be inserted, to surround at least a portion of the steel beam, the form being suspended by the steel beam; inserting the concrete into an internal space of the form and curing it; and removing the form to compose the steel beam and the concrete. The prestressed steel composite girder includes a steel beam and a concrete composed to surround a portion of the steel beam so that stress caused by its self- weight can be applied on only the steel beam.

Owner:RES INST OF IND SCI & TECH +1

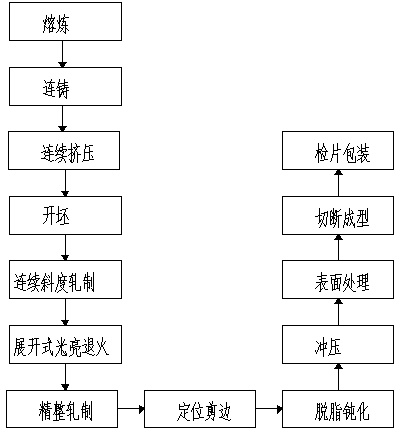

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

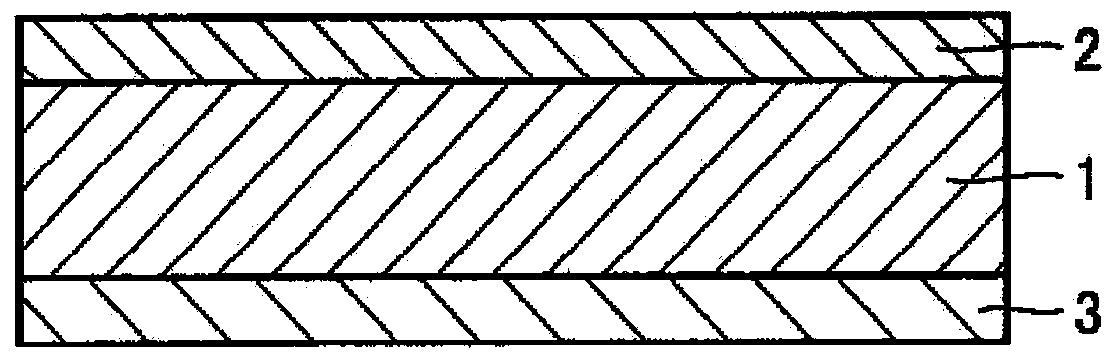

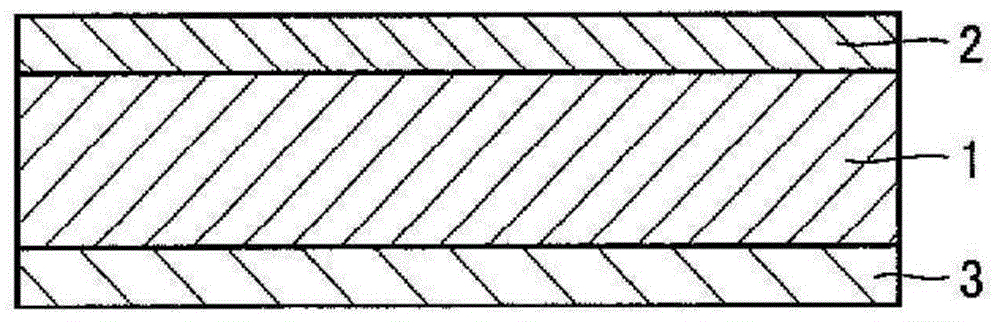

LED epitaxial wafer and preparing method thereof

ActiveCN103579428AImprove luminous efficiencyFacilitate horizontal diffusionSemiconductor devicesElectrical conductorSemiconductor

The invention provides an LED epitaxial wafer and a preparing method thereof. The LED epitaxial wafer comprises a substrate layer, a first semiconductor layer, an interpolating layer, a light-emitting layer and a second semiconductor layer, wherein the substrate layer, the first semiconductor layer, the interpolating layer, the light-emitting layer and the second semiconductor layer are sequentially stacked. The interpolating layer is a GE doping GaN layer, ESD performance can be effectively improved, lighting efficiency is intensified, the brightness of an LED is improved, defects are not generated, the situation that the electrical property of a component becomes poor due to increase of serial-connection resistors cannot occur, and meanwhile the production process is simple.

Owner:BYD SEMICON CO LTD

Static pressure construction technology of prestressed pipe piles

The invention relates to the technical field of construction, in particular to a static pressure construction technology of prestressed pipe piles. The static pressure construction technology of the prestressed pipe piles is characterized in that before the prestressed pipe piles are pressed, a pile driver is reasonably selected according to geological data of a project and the designed requirement for the bearing capacity of the single pile, piling pressure of the pile driver needs to be no lower than 1.2 times a vertical ultimate bearing capacity standard value of the single pile, the positions of the prestressed pipe piles are checked one by one according to a building and structural pile position graph, all present pile tips are measured, related dimensions, such as the external diameter, the wall thickness, a pile body, the length, the bending degree of the pile body, and especially the thickness of the pipe wall, of each prestressed pipe pile are measured, and due to the fact that clamping force in the process of construction through a static pressure method is large, the prestressed pipe piles can be easily broken due to clamping when the wall thickness is not large enough. The static pressure construction technology of the prestressed pipe piles has the advantages that in the process of construction, noise is low, vibration and pollution are not caused, construction can be continuously carried out for 24 hours, and the construction period is shortened.

Owner:李孝虎

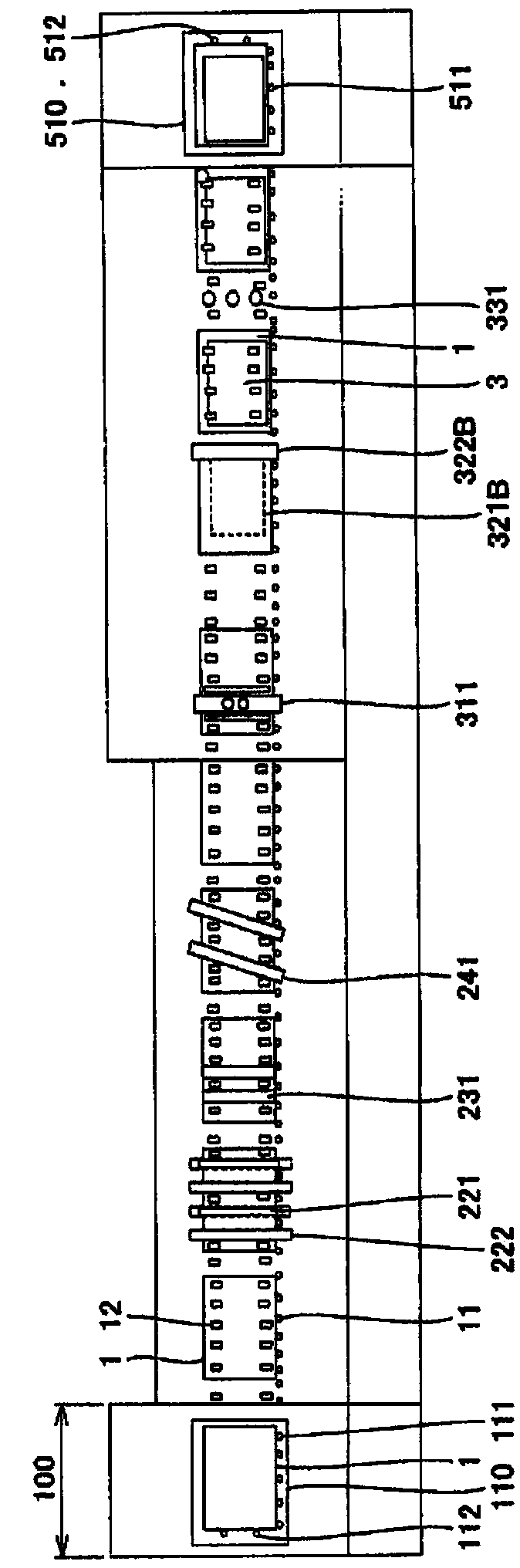

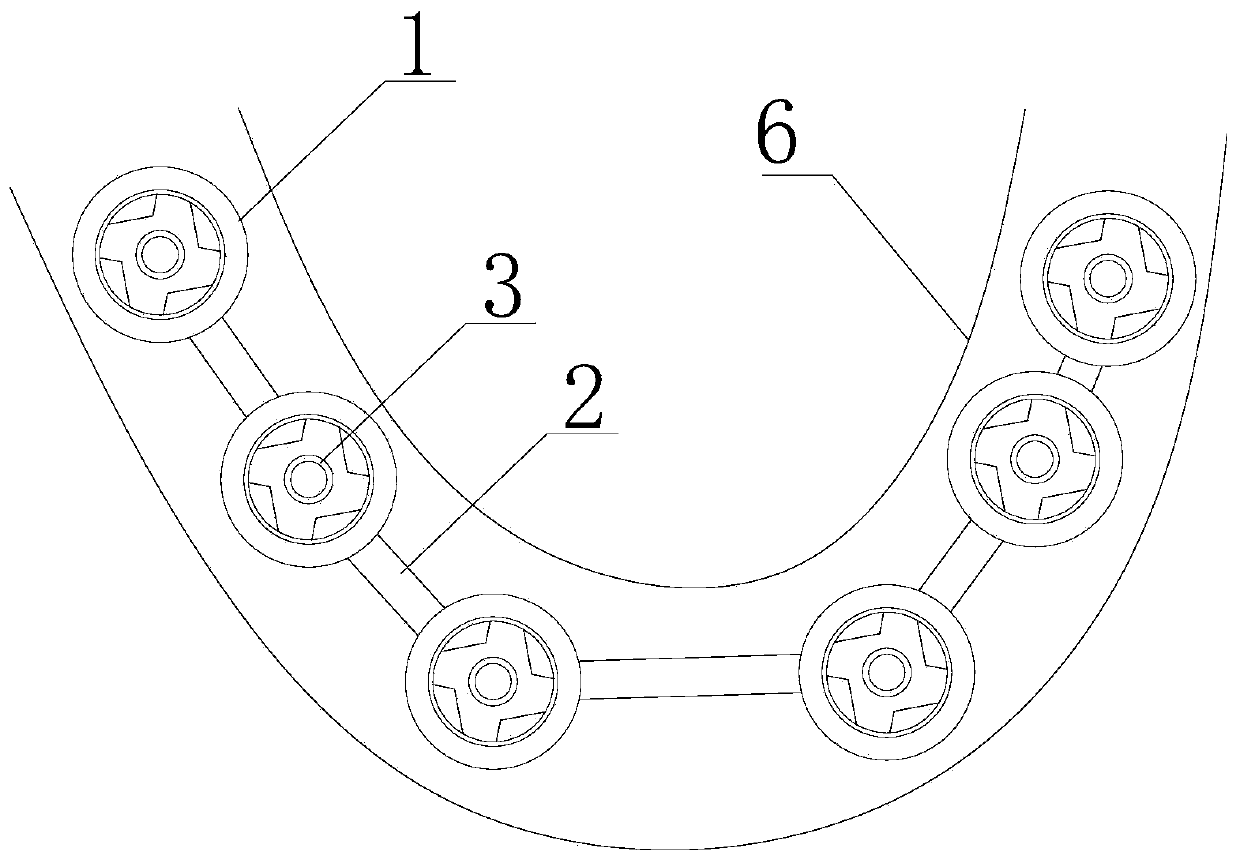

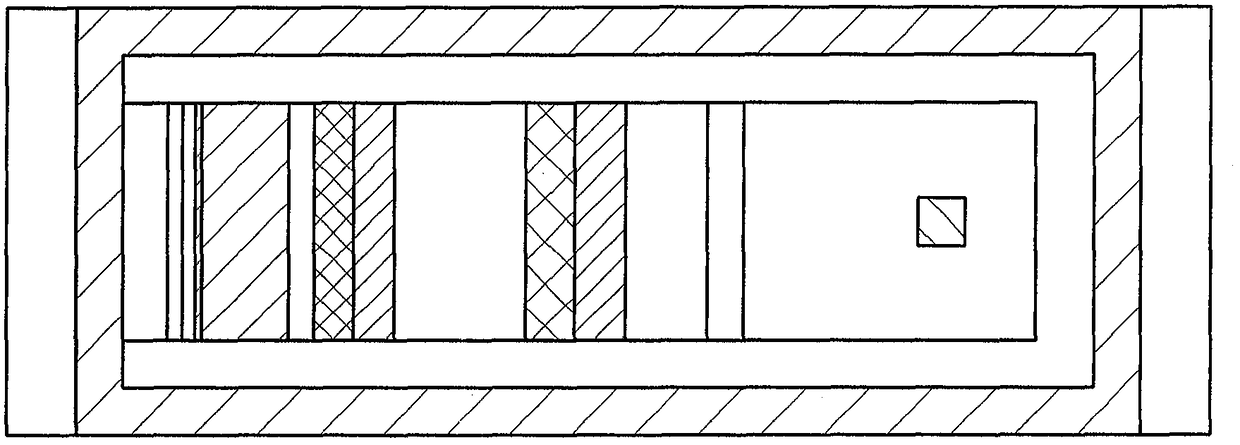

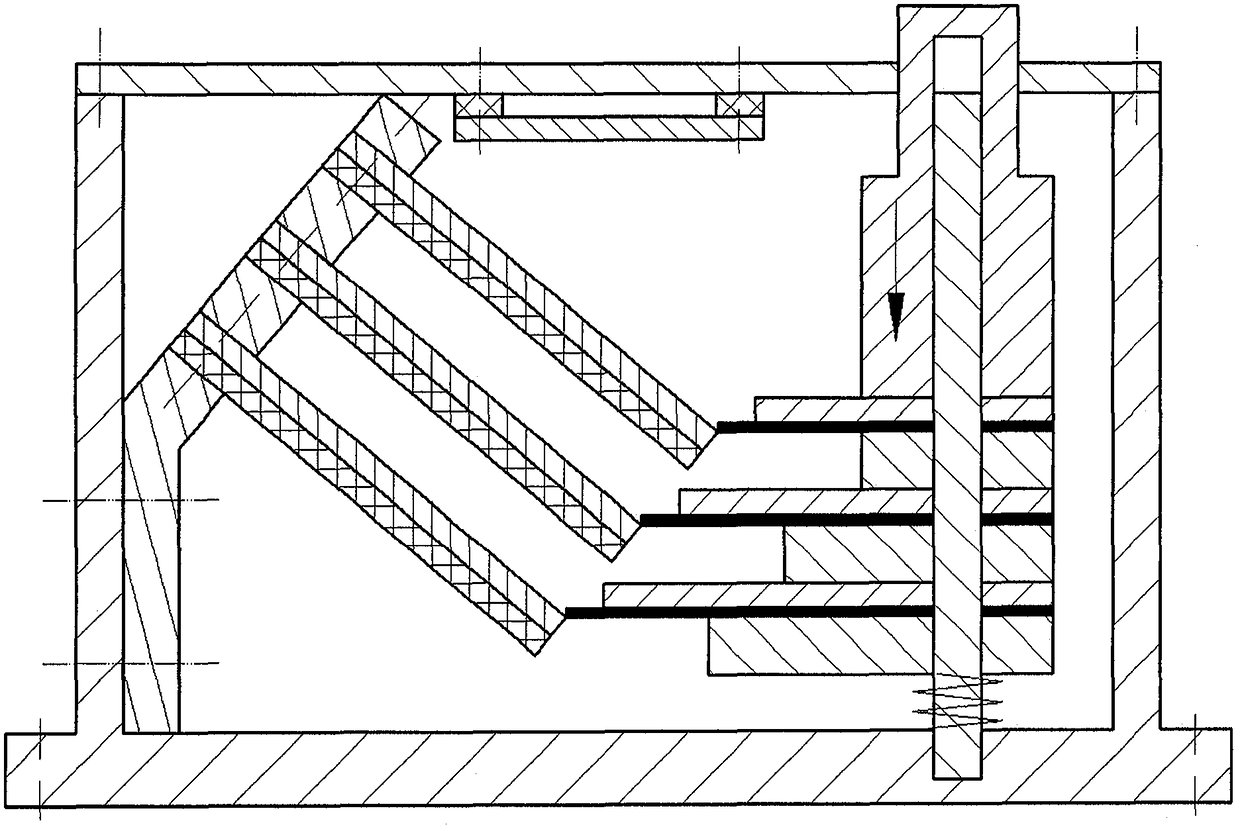

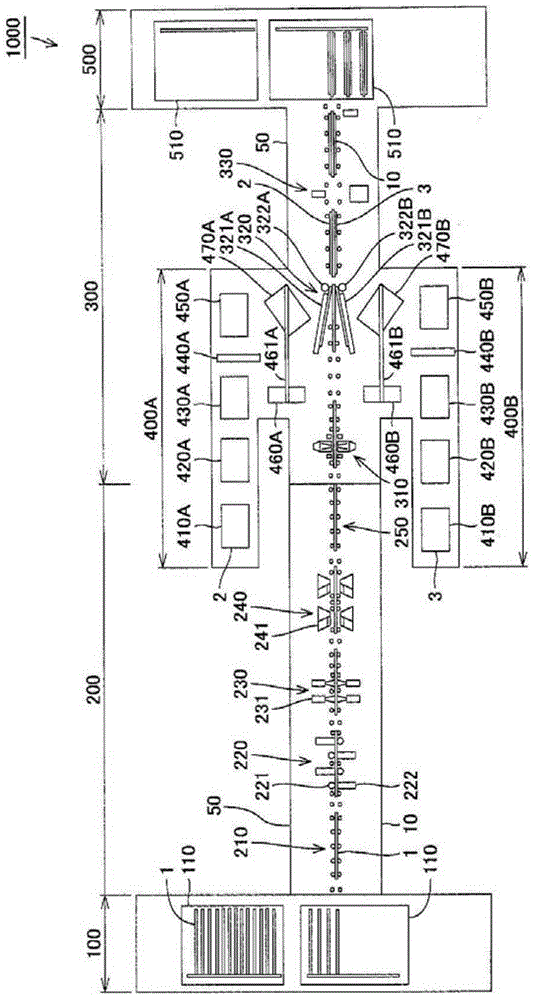

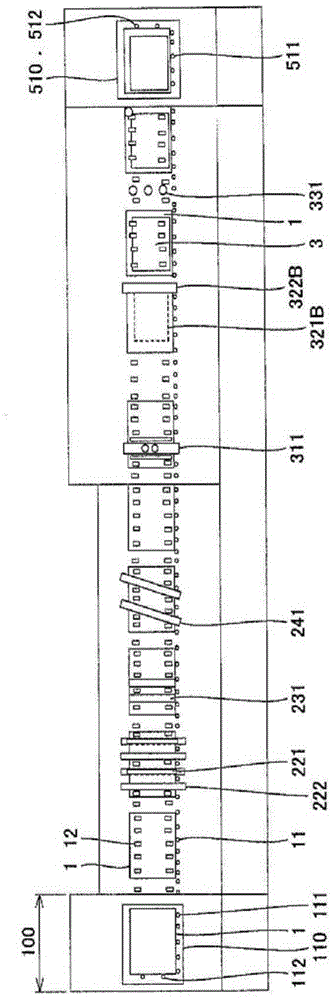

Apparatus for attaching polarized film

InactiveCN103969881ANo bending phenomenonReduce generationLaminationLamination apparatusLiquid crystal

The invention relates to an apparatus for attaching a polarized film, and especially relates an apparatus having characteristics described as follows. In a method of attaching a polarized film onto a liquid crystal element substrate, a problems is that bubbles are generated between the polarized film and the liquid crystal element substrate because the front bending of the polarized film. A caterpillar track type adhesive plate is arranged on an inclination roller and a fixed roller on the left and the right, and a polarized film is attached to the liquid crystal element substrate after the polarized film is arranged on the amooth adhesive plate. Therefore, a phenomenon of overall bending of the polarized film does not occur. When the polarized film is attached onto the surface of the liquid crystal element substrate, the possibility of bubble generation is substantially reduced. Furthermore, the liquid crystal element is prevented from being bent due to the elongation of the polarized film, and the possibility of unqualified products is eliminated.

Owner:YMK

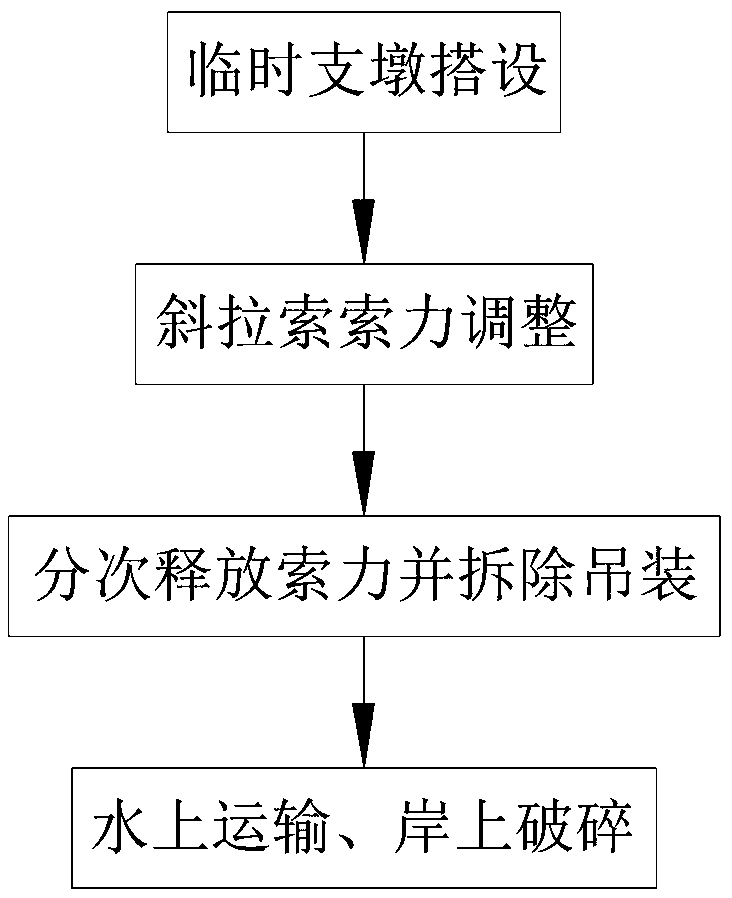

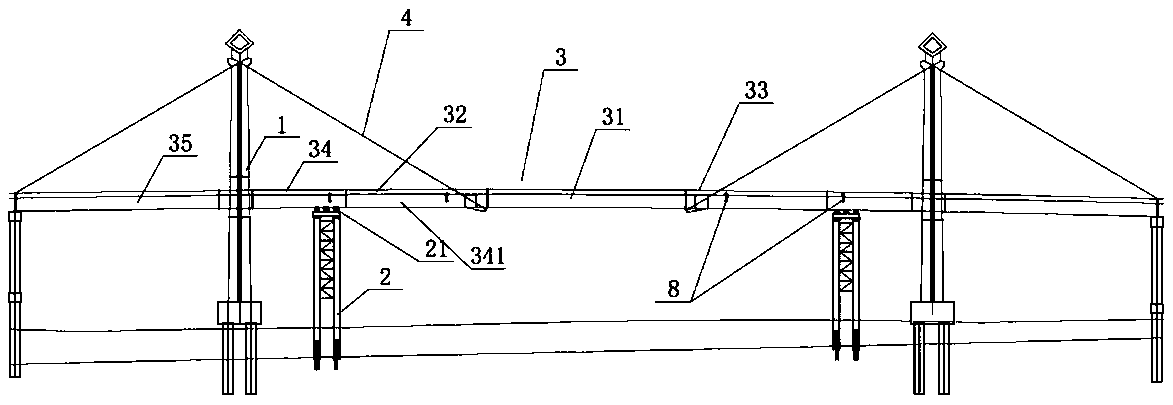

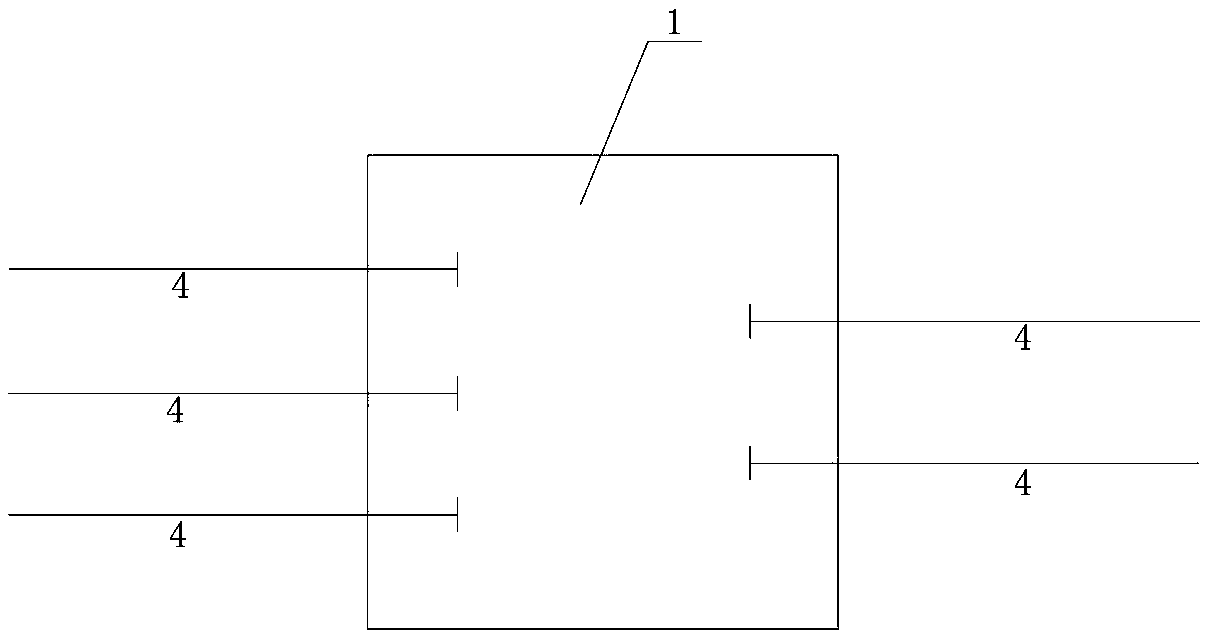

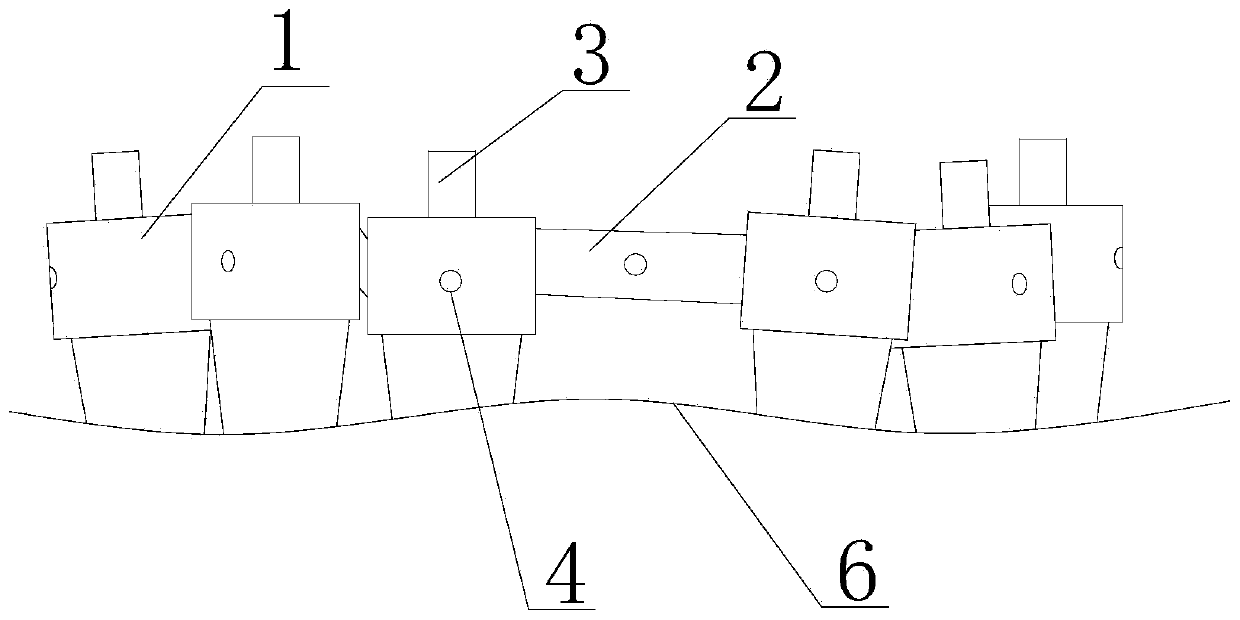

A method for removing an upper structure of an overwater thin-cable system cable-stayed bridge

ActiveCN109695206AReduce time spent on fairwayEnsure safetyCable-stayed bridgeBuilding repairsCable stayedCrusher

The invention discloses an overwater thin-cable system cable-stayed bridge upper structure removing method which comprises the following steps: S1, temporary buttresses are arranged near a main tower,and the temporary buttresses are made to be supported below a solid section of a bridge body main beam; S2, a stay cable on the side span side is removed, and a cable force is adjusted to keep the cable force of the stay cables on the two sides of the main tower in symmetrical balance; S3, the first cable force and the second cable force are symmetrically released, a hanging hole beam is removed,and the hanging hole beam is hoisted by adopting a large floating crane; the third cable force and the fourth cable force are symmetrically released, a mid-span beam is removed and hoisted by adopting the large floating crane; a fifth cable force is symmetrically released, a mid-span cross beam is removed and hoisted by adopting the large floating crane; the stay cables are removed; longitudinalbeams, edge beams and the main tower are disassembled in a segmented mode, and all the components are hoisted through the large floating crane; and S4, the hoisted components are conveyed to a wharf along a designed route and transferred to a sand field and crushed the in the sand field by a crusher, and the components are sent to designated positions in a partitioning manner. The method has the advantages of ensuring normal passage of the channel and being safe and stable.

Owner:SINOHYDRO BUREAU 8 CO LTD

Oral cavity implant stiffener and digital processing method thereof

ActiveCN109717970AGood combination stabilityImprove long-term stabilityDental implantsMedicineTime cost

The invention belongs to the field of oral cavity rehabilitation, and discloses an oral cavity implant stiffener and a digital processing method thereof. The oral cavity implant stiffener comprises aconnecting rod and at least two positioning structural members, wherein the positioning structural members and implanting positions are in corresponding arrangement; each of the positioning structuralmembers is provided with a positioning part, and the running direction of each of the positioning parts is the same as that of the corresponding implanting position; the connecting rod is connected between every two positioning structural members; and the connecting rod and the positioning structural members are made from a rigid material. Compared with steel wires, the oral cavity implant stiffener is higher in rigidity, the force is easier and uniformly transferred to various implants, the entire dispersing action of jaw force is improved, and initial stage synostosis and long-term stability of the implants are facilitated. According to implant pattern digital design, the time cost and the work difficulty can be greatly reduced, a technician does not need special tuning, and the reworkpercentage does not exist almost. Because of the mechanical property and the force conduction advantages, immediate rehabilitation can be realized for more implant cases, and indication is extended.

Owner:CHENGDU DT DENTALLAB CO LTD

Construction process of prestressed static pressure pipe pile

The invention relates to a foundation processing engineering technology, and specifically relates to a construction process of a prestressed static pressure pipe pile, which is characterized in that in construction, the pile pressing force of a pile driver can be not less than 1.2 times the standard value of vertical limit bearing capacity of a single pile, and the deviation of the formed pile is controlled between 2mm and 5mm; the verticality of a pile body is controlled at plus or minus 3mm, and the number of pile extension welding layers is not less than 2; and the time of natural cooling is about 8 to about 10 minutes, and the dislocation deviation of two pile hearts is not greater than 2mm. The method has the beneficial effects that the self weight of a pile driving mechanism of a static pile driver and a counter weight on a pile frame are used as a reaction force to press precast piles into the ground, so that the impact on the surrounding building environment and underground pipelines is reduced, the problems that the pipe pile body is easily broken and crushed or the pipe pile is longitudinally cracked by the too large pile pressing force (clamping force) are solved, and the construction can be carried out in fields in which more underground obstructions or boulders exist.

Owner:马静蓓

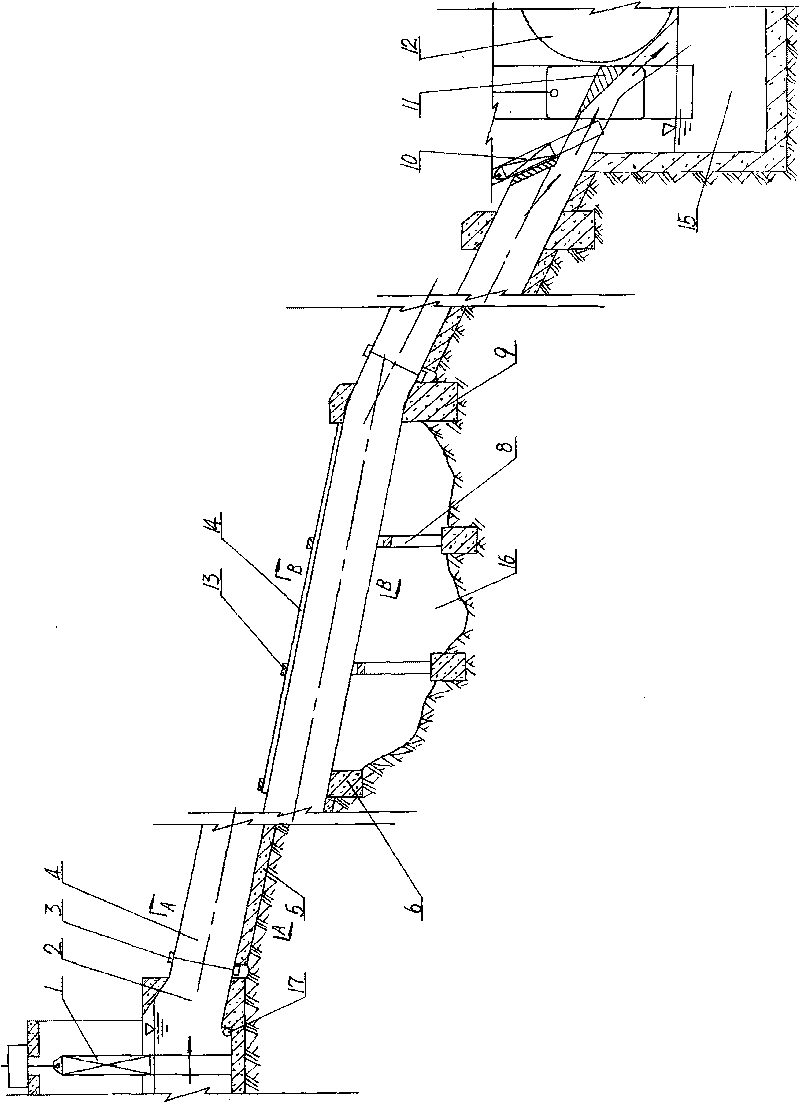

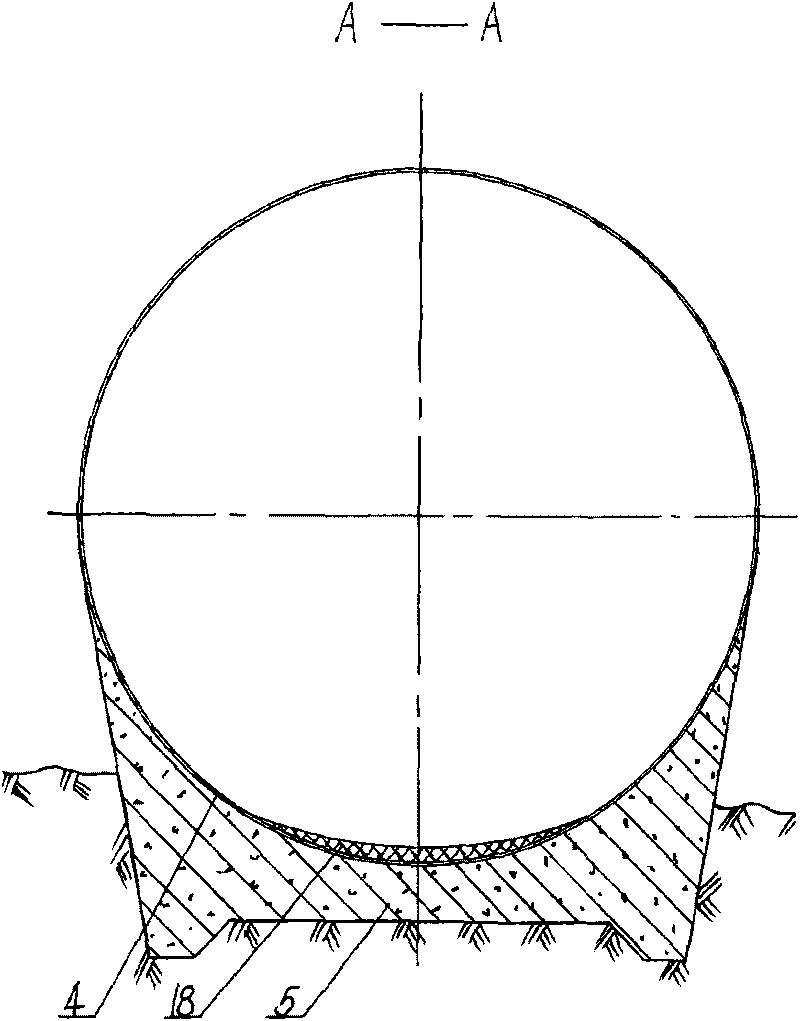

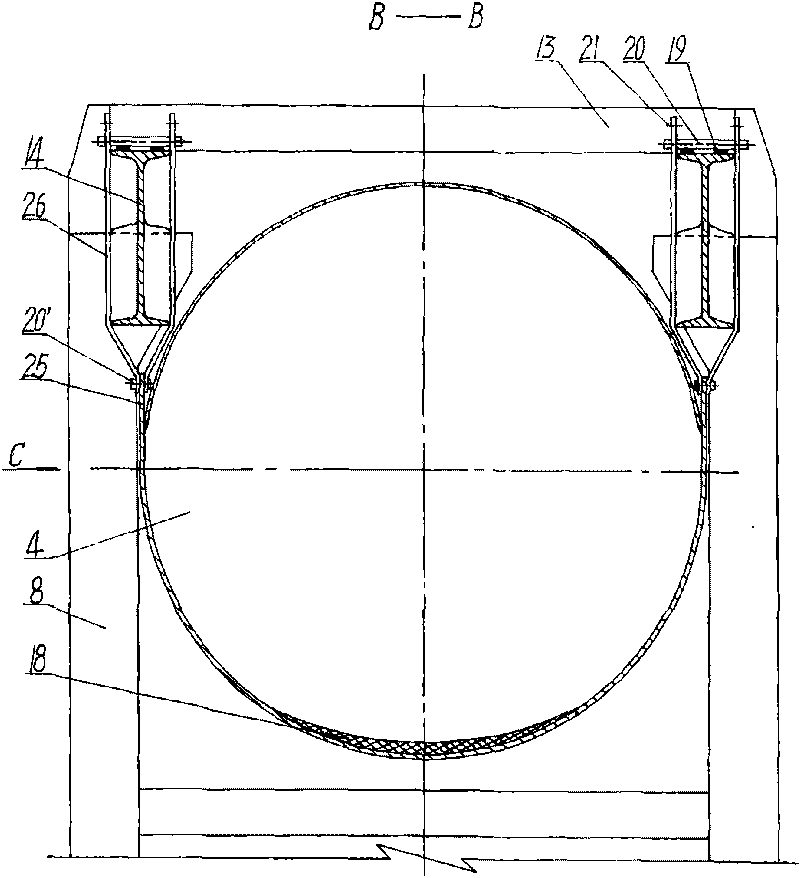

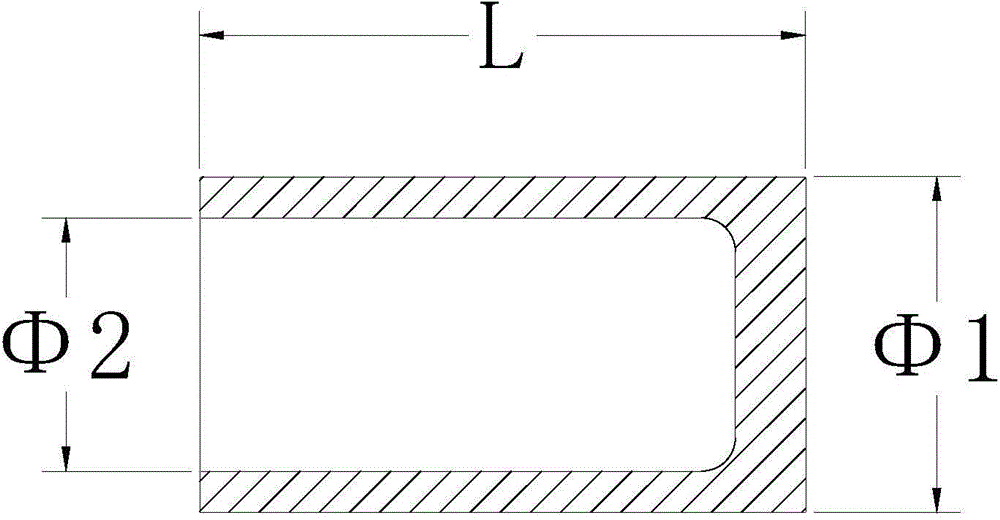

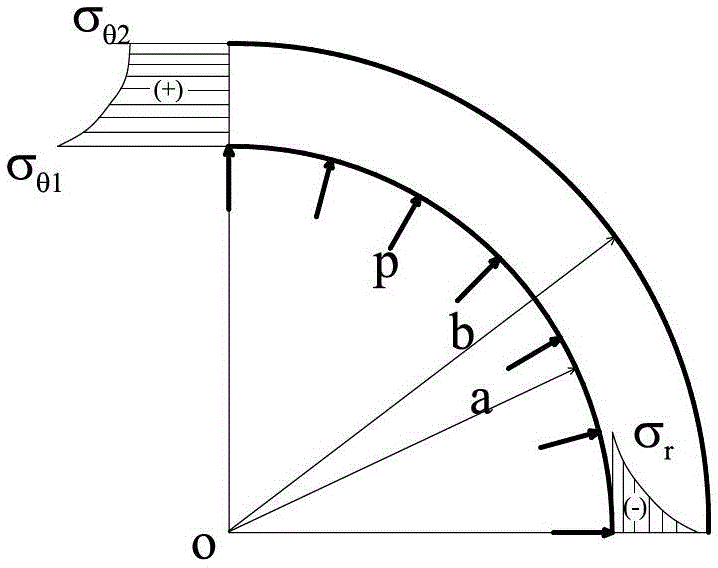

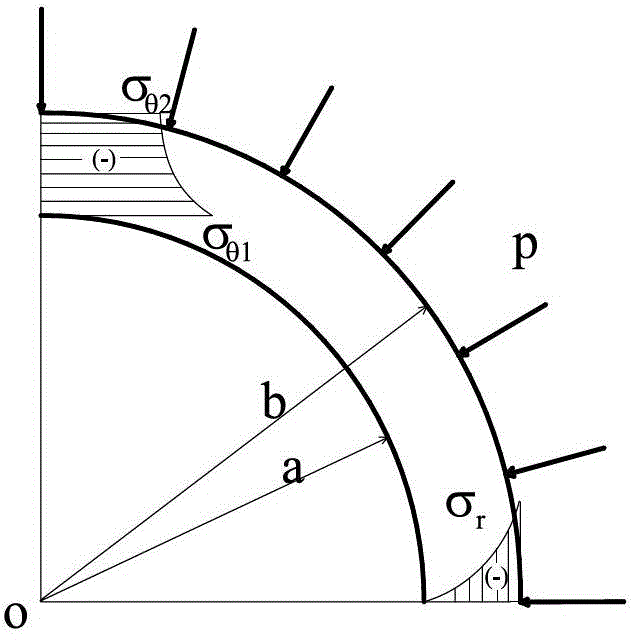

Thin-wall pressure water pipe

InactiveCN101725763ANo compressive stressNo tensile stressPipe laying and repairWater turbineWater flow

The invention relates to a thin-wall pressure water pipe that conveys pressure flow to a water turbine for hydroelectric generation, in particular to a large-scale thin-wall pressure water pipe. The water pipe mainly consists of a pipeline, a pipe bed or a support beam for supporting the pipeline, a support member arranged between the support beam and the pipeline and the like. Due to the superior loading condition, simple and reasonable structure, convenient and accessible manufacturing, mounting and constructing of the water pipe, the wall of the pipe is thin and the cost is low. The whole water pipe is safe and highly reliable with less on-way waterhead loss, thereby meeting water conveying request for large-flow pressure flow.

Owner:黄国宏

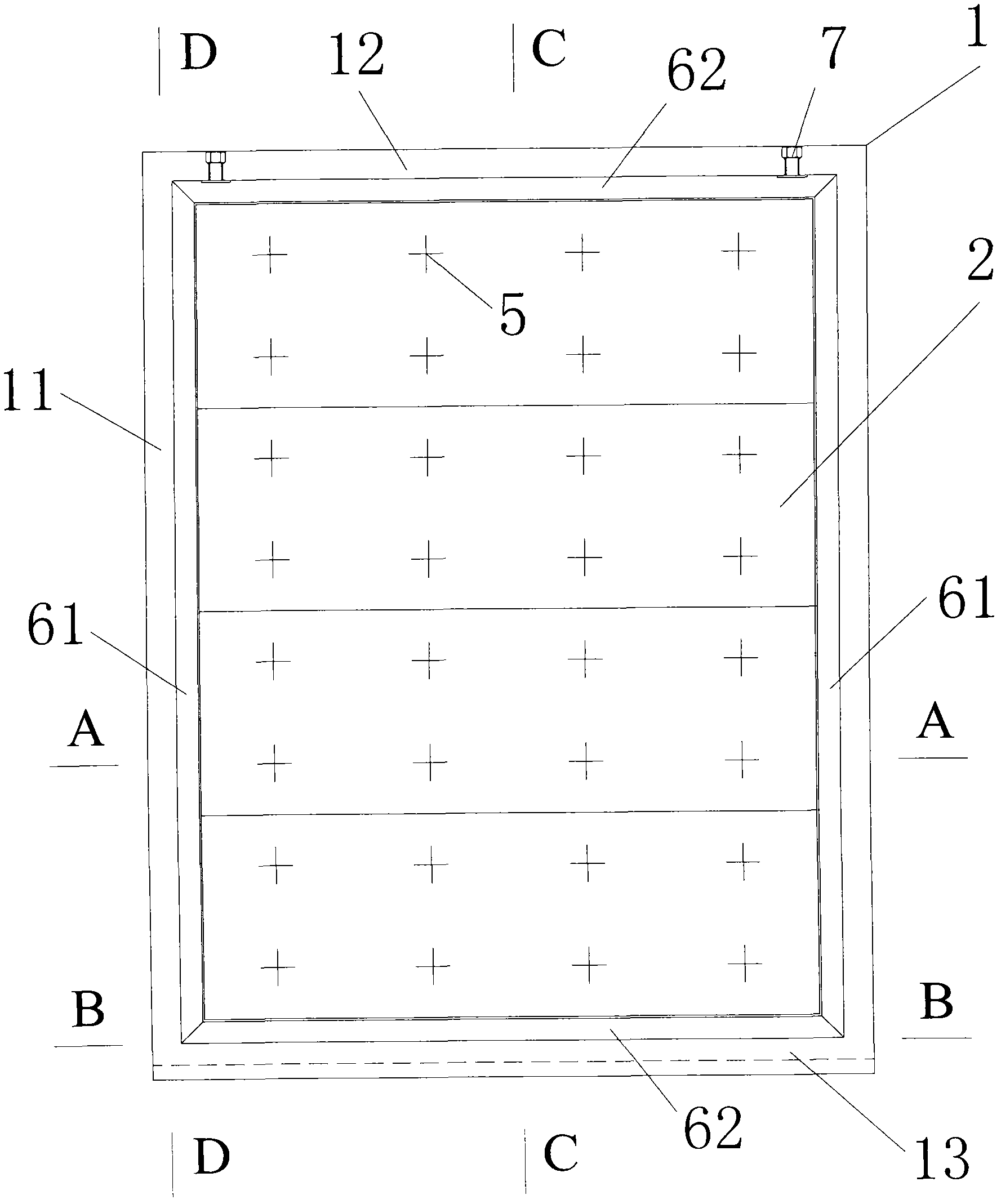

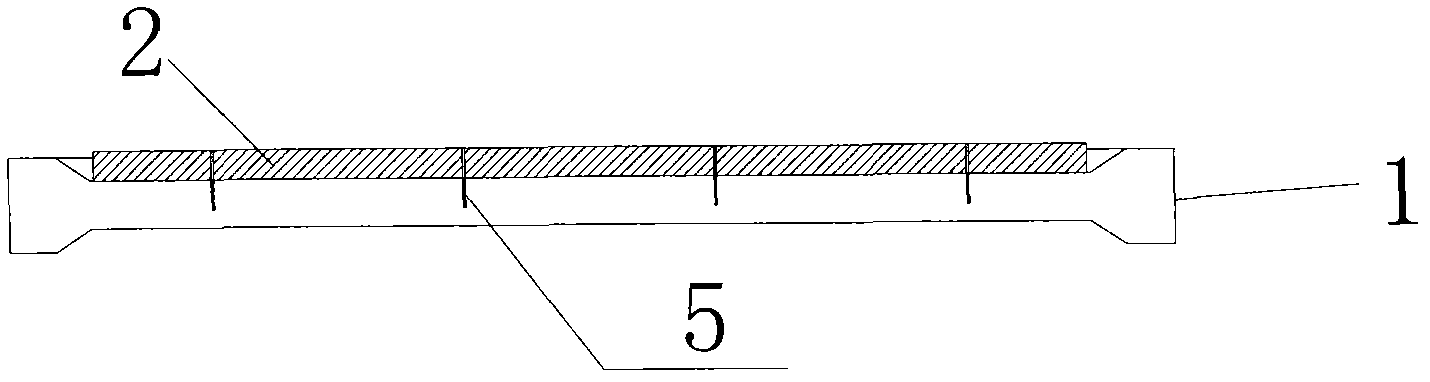

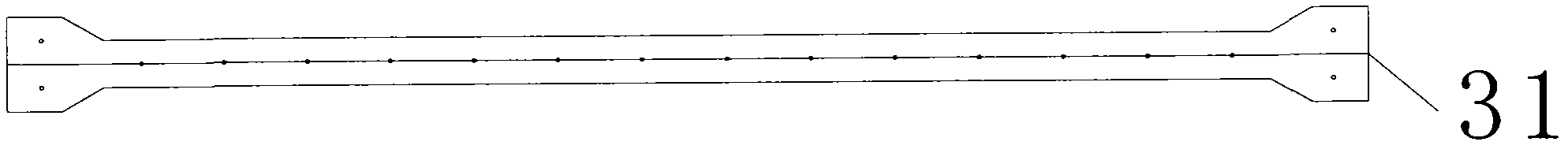

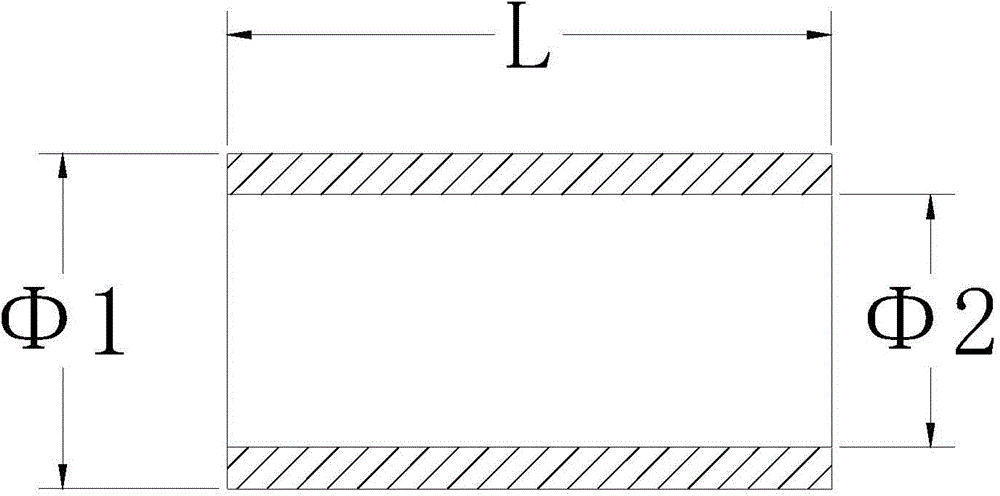

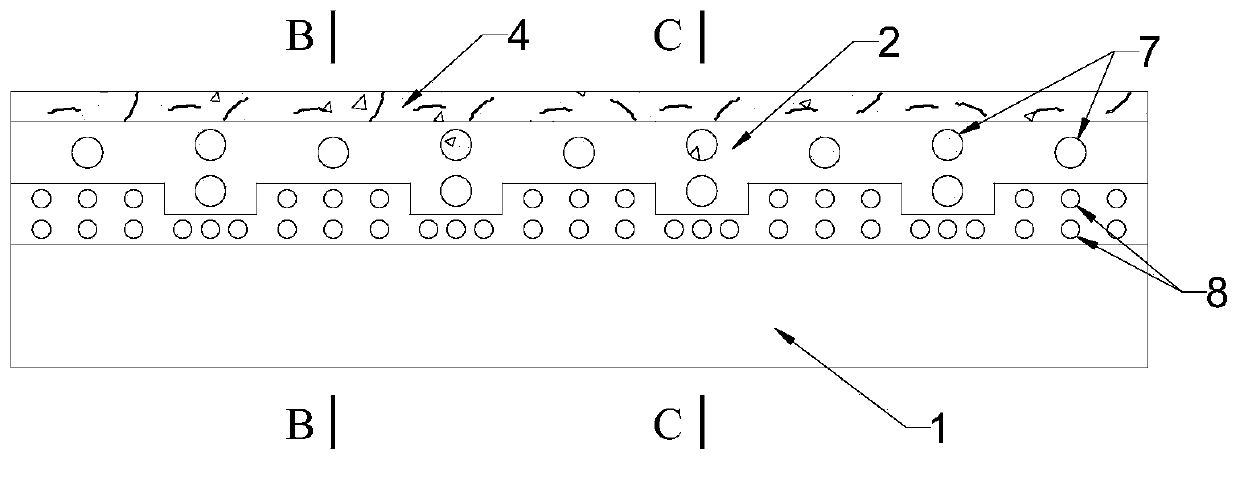

Prestress concrete noise barrier sound absorption inserting plate for high speed railway

ActiveCN102102345AAvoid crackingNo tensile stressNoise reduction constructionThickened ribsPre stress

The invention relates to a prestress concrete noise barrier sound absorption inserting plate for a high speed railway. The prestress concrete noise barrier sound absorption inserting plate for the high speed railway comprises a prefabricated concrete unit inserting plate and a sound absorption panel which are rectangular structural members; the sound absorption panel is connected with the prefabricated concrete unit inserting plate through a bolt; left and right sides of the prefabricated concrete unit inserting plate are provided with thickened rib columns, and the top and the bottom of the prefabricated concrete unit inserting plate are respectively provided with thickened rib beams; a groove is formed on the thickened rib beam at the bottom of the prefabricated concrete unit inserting plate; and horizontal and vertical prestress reinforcing steel bars are arranged in the prefabricated concrete unit inserting plate. The prestress concrete noise barrier sound absorption inserting plate for the high speed railway can effectively resist long-term action of pulse air load and natural typhoon load of the high speed railway of which the highest speed is 380 to 400 kilometers per hour, has good fatigue resistance performance, obvious lasting quality and remarkable noise-reducing effect; and the cost for manufacturing the prestress concrete noise barrier sound absorption inserting plate is low, and the prestress concrete noise barrier sound absorption inserting plate is convenient to install and exchange.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

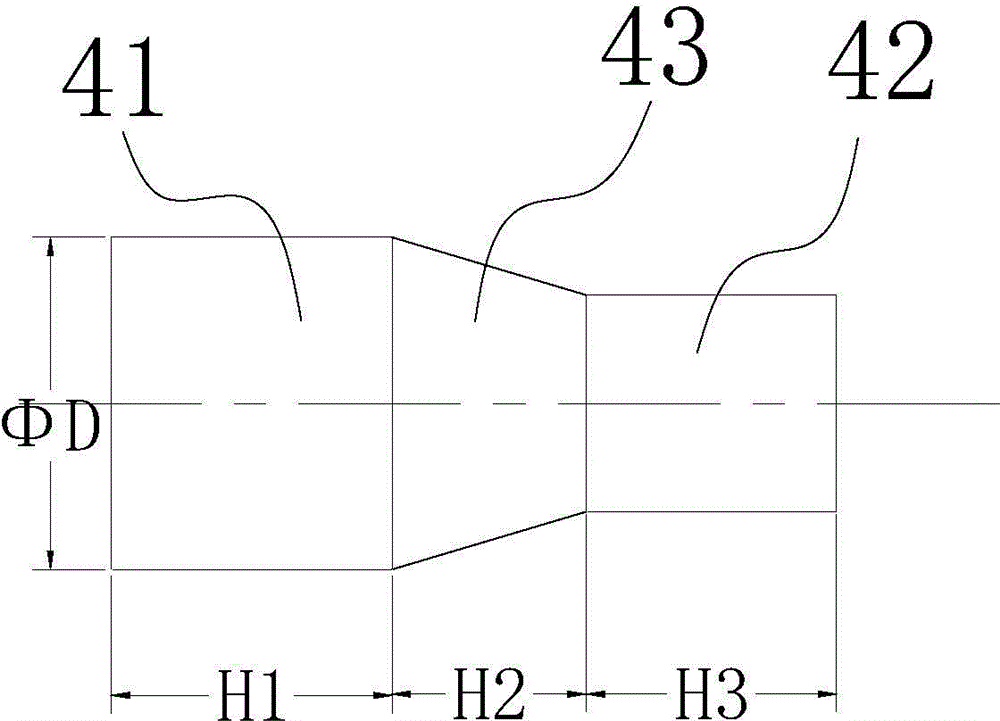

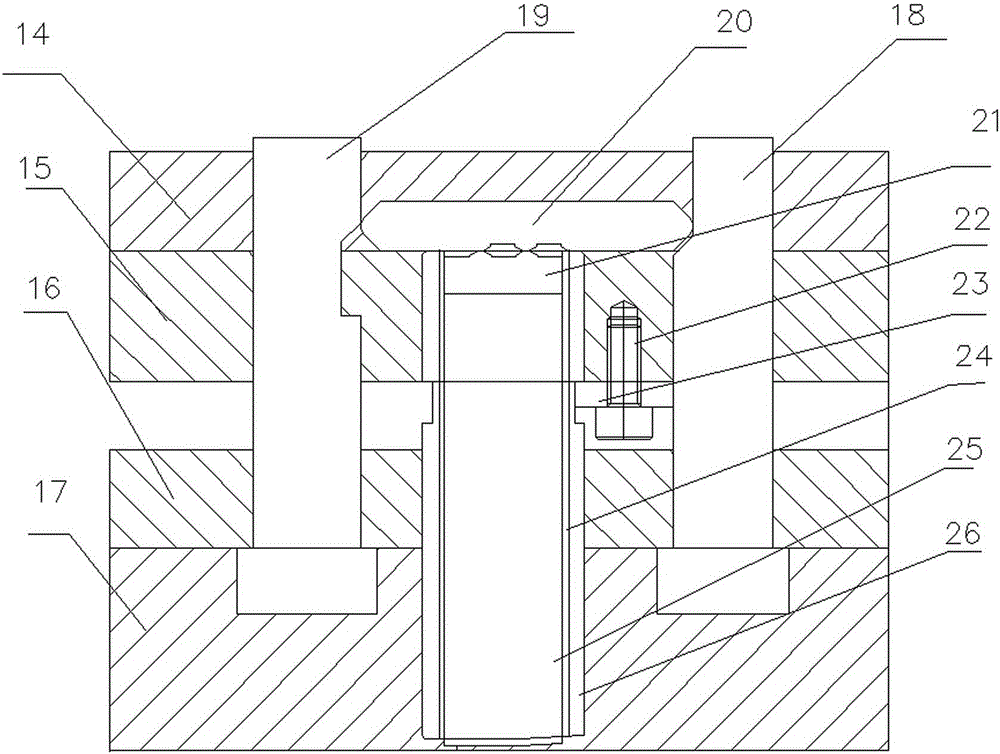

Hot forging forming method for cylindrical forged piece

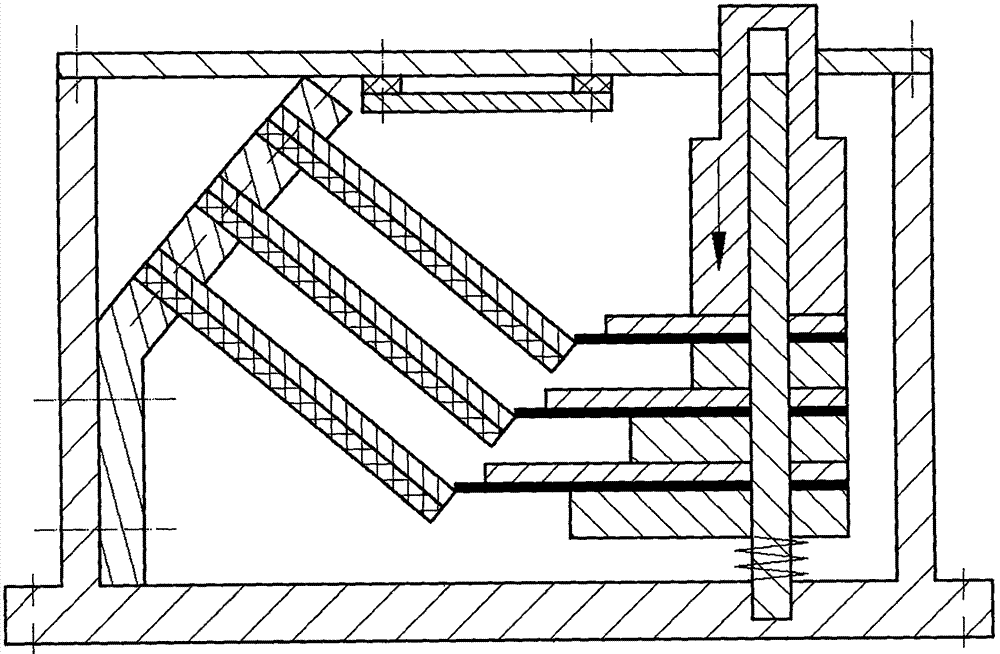

ActiveCN104308056AImprove pass rateImprove yieldForging/hammering/pressing machinesHollow articlesStress conditionsMetallurgy

The invention discloses a hot forging forming method for a cylindrical forged piece. According to the hot forging forming method, hot forging cracks generated in the forming process of the cylindrical forged piece are reduced, and the qualified rate of the cylindrical forged piece is improved; the hot forging forming method is suitable for long blind hole cylindrical forged pieces with thinner wall thicknesses. The hot forging forming method comprises the following steps: firstly, manufacturing a forming die according to the design size of the cylindrical forged piece to be manufactured; secondly, manufacturing an intermediate bank; thirdly, mounting the intermediate blank in the die; fourthly, downwardly pressing a punch by a pressing machine and performing impact extrusion on the intermediate blank. By adopting the hot forging forming method, hot forging cracks generated in the forming process of the cylindrical forged piece can be reduced, the qualified rate of the cylindrical forged piece is improved, the manufacturing period is shortened, and the production efficiency is improved. Besides, according to the hot forging forming method for the cylindrical forged piece, disclosed by the invention, stress conditions of the forging and forming process can be improved, the aims of greatly improving the finished product rate, the manufacturing efficiency and the qualified rate of the forged piece are achieved, and the manufacturing risk and the manufacturing cost are reduced. Meanwhile, the hot forging forming method is suitable for the long blind hole cylindrical forged pieces with the thinner wall thicknesses.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

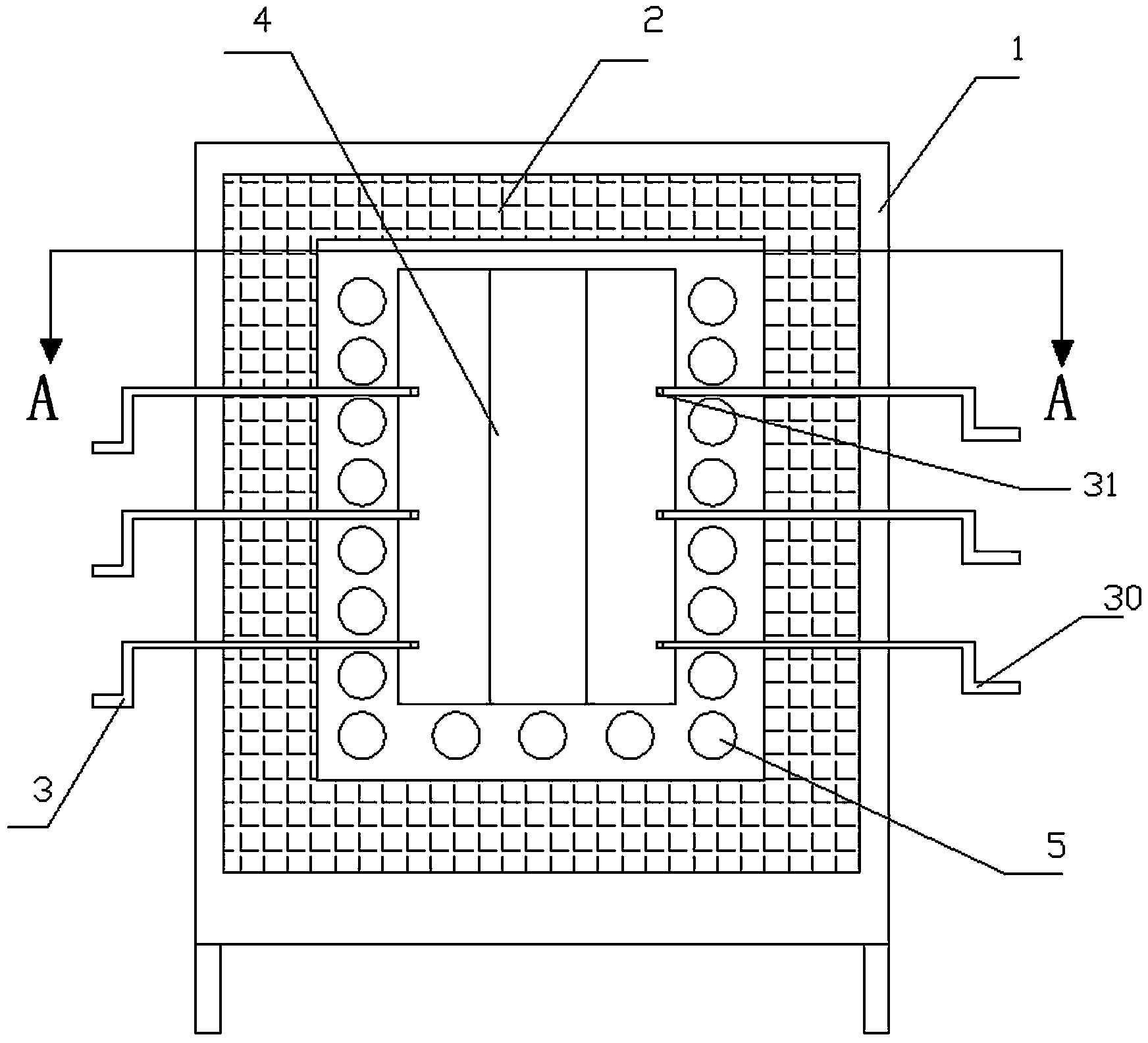

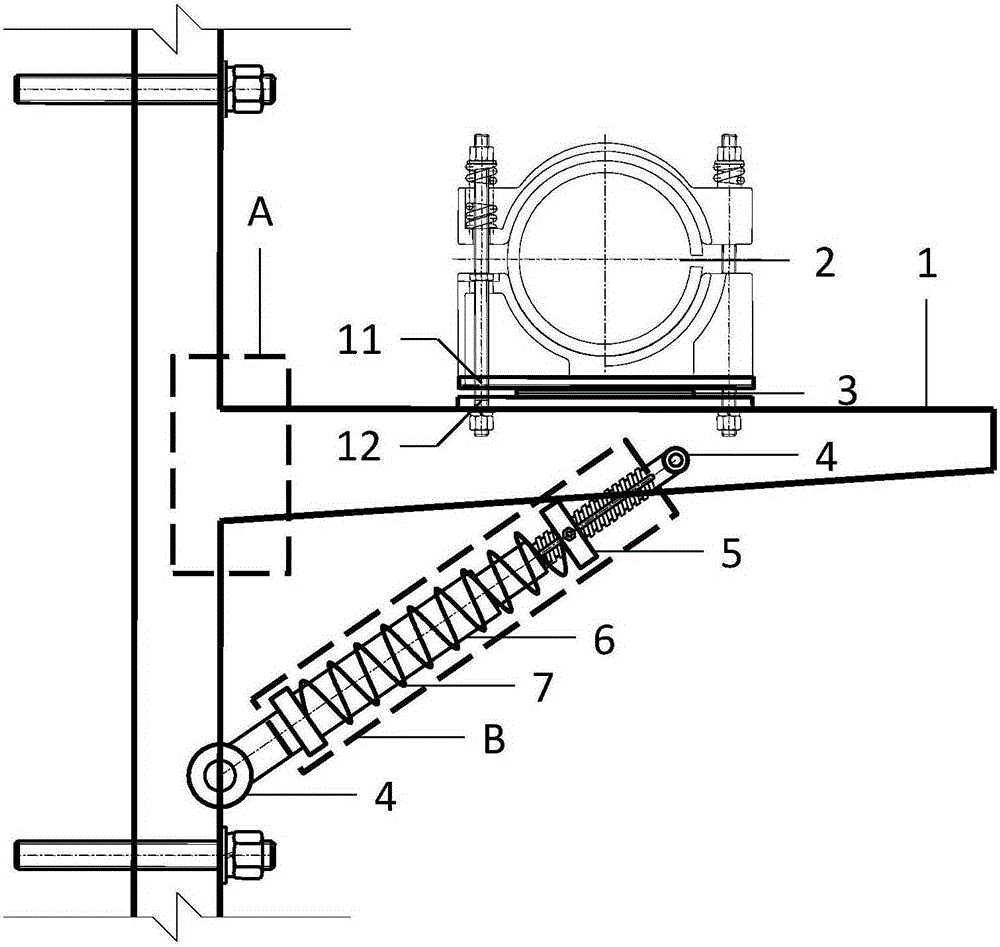

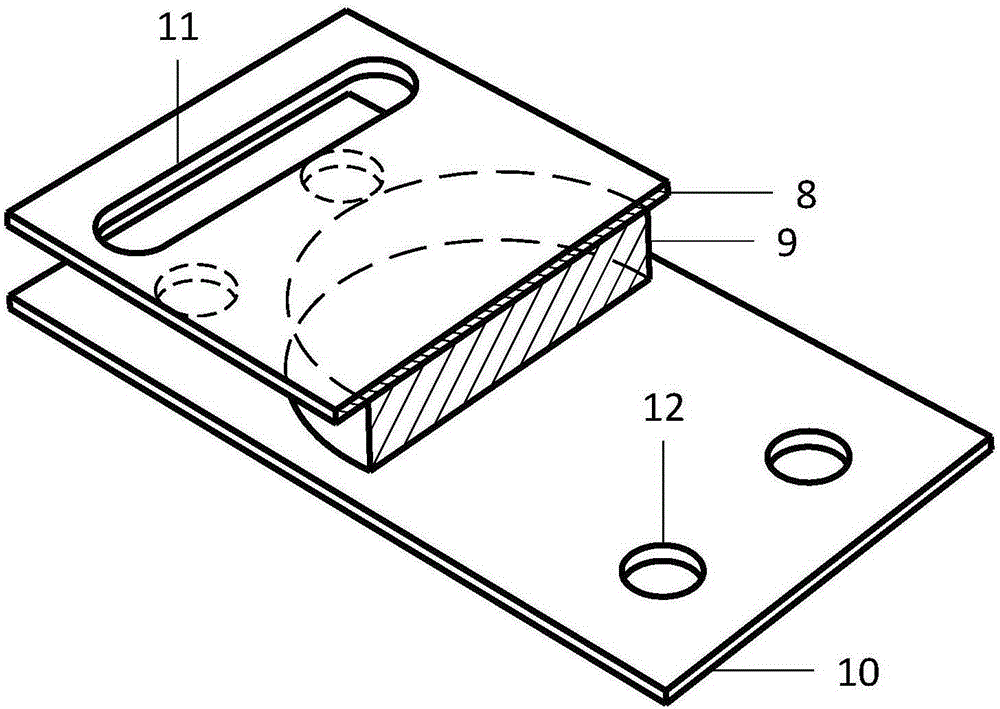

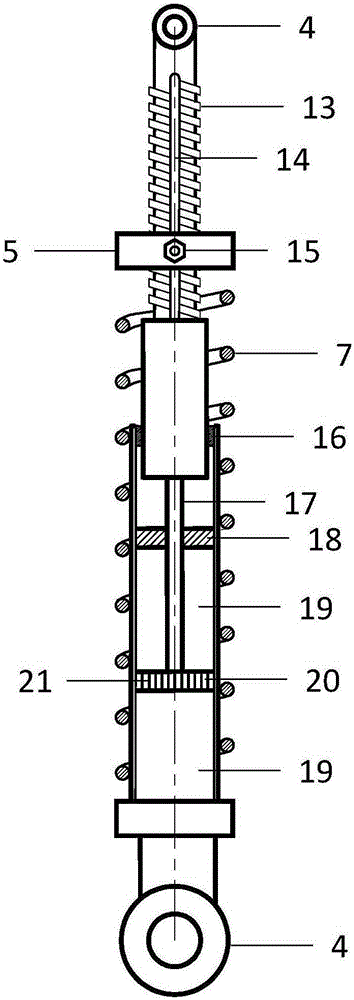

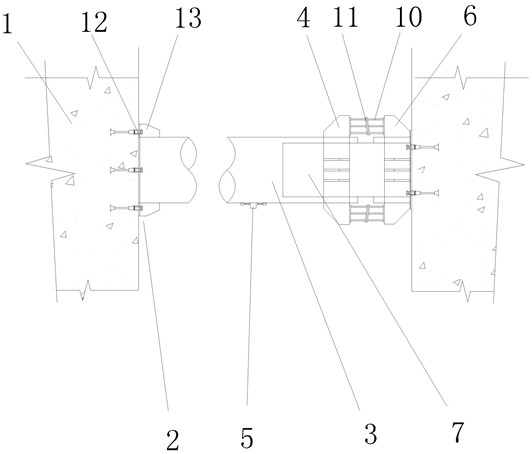

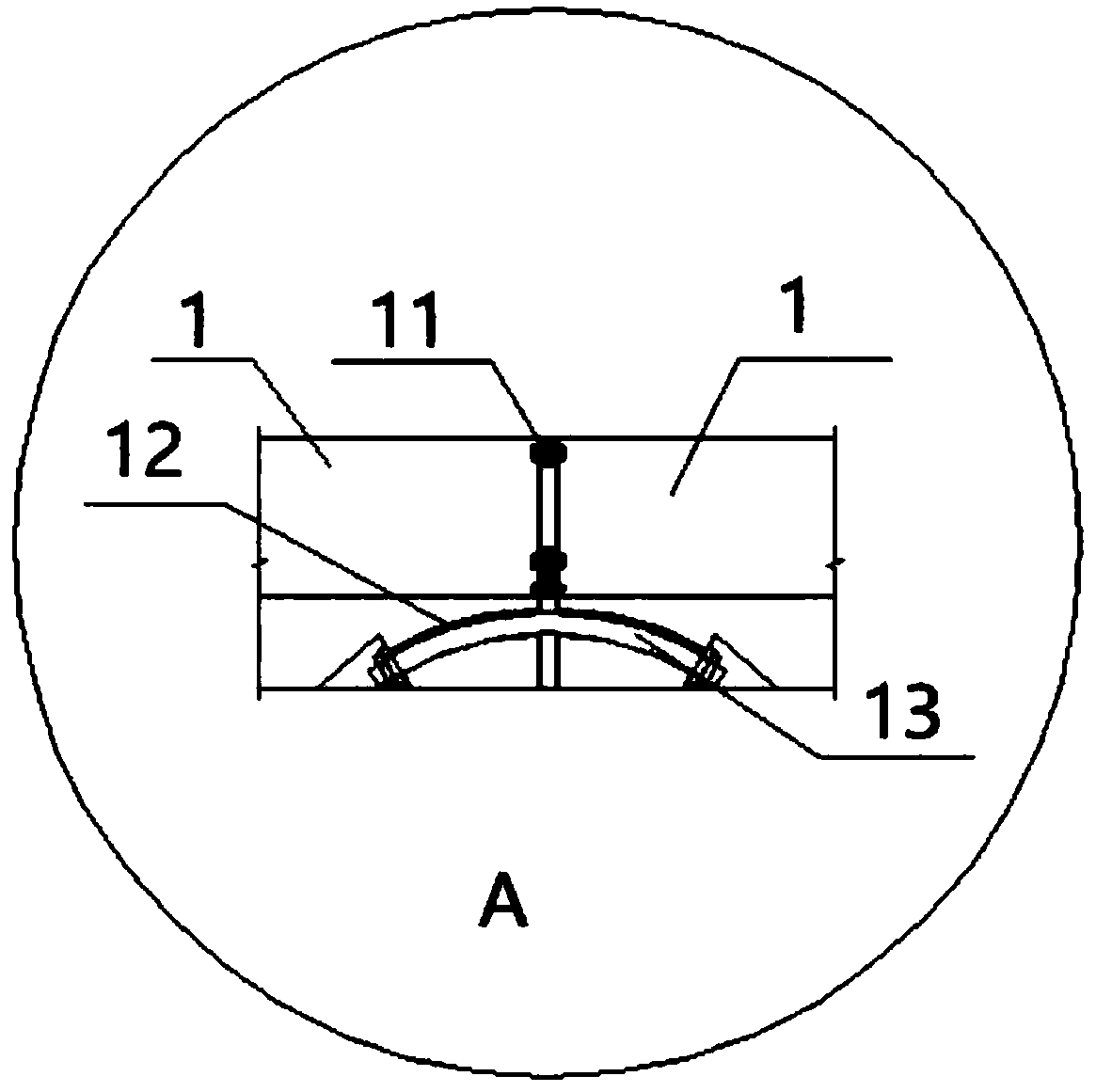

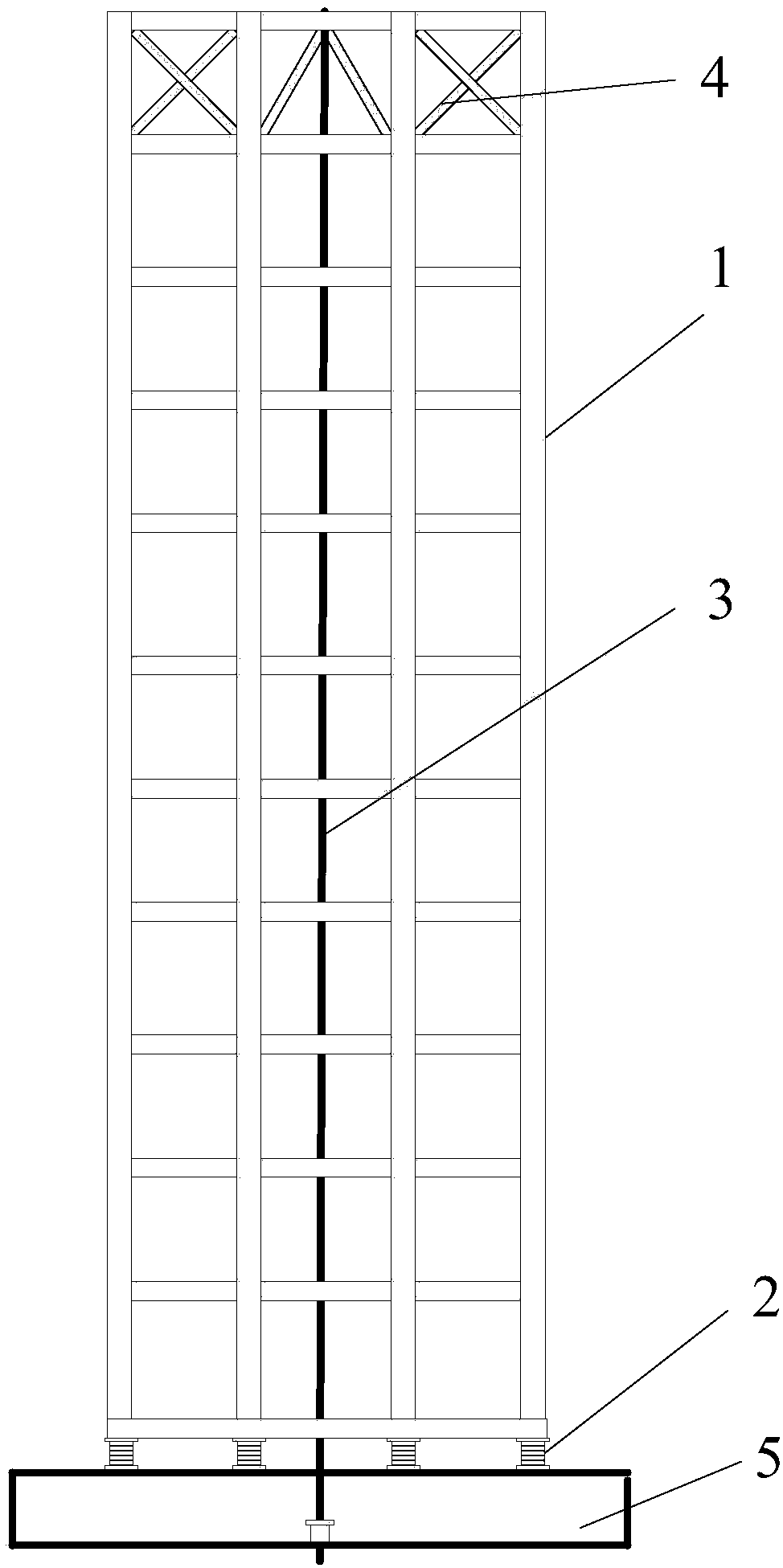

Vibration isolation and reduction bracket for cable structures

InactiveCN105226594ADoes not affect workIncrease redundancyDevices for damping mechanical oscillationsSuspension arrangements for electric cablesFatigue damageClassical mechanics

The invention discloses a vibration isolation and reduction bracket for cable structures, comprising a support member (1), a vibration isolator (3), a hydraulic vibration reducer (6), a spring (7), a regulating nut (5), and a connecting pedestal (4). An adjustable combined vibration reducer (B) is composed of the spring (7), the hydraulic vibration reducer (6) inside the spring and the regulating nut (5), wherein the spring (7) provides support force, stiffness and reset ability, the regulating nut (5) regulates the length of the spring (7) to ensure that there is no tensile stress at a support member the root (A) in the balanced position, and the hydraulic vibration reducer (6) plays a role in in-plane buffer, displacement control, energy consumption and vibration reduction. The vibration isolator (3) produces shear deformation and consumes energy, and can reduce out-of-plane longitudinal vibration caused by action of the support member (1). By adopting the vibration isolation and reduction bracket for cable structures, fracture or fatigue damage of the support member root (A) caused by in-plane and out-of-plane three-direction vibration is solved, the redundancy of cable structures is enhanced, and the safety and using performance of a supported structure (2) are improved.

Owner:JIANGSU ELECTRIC POWER CO +3

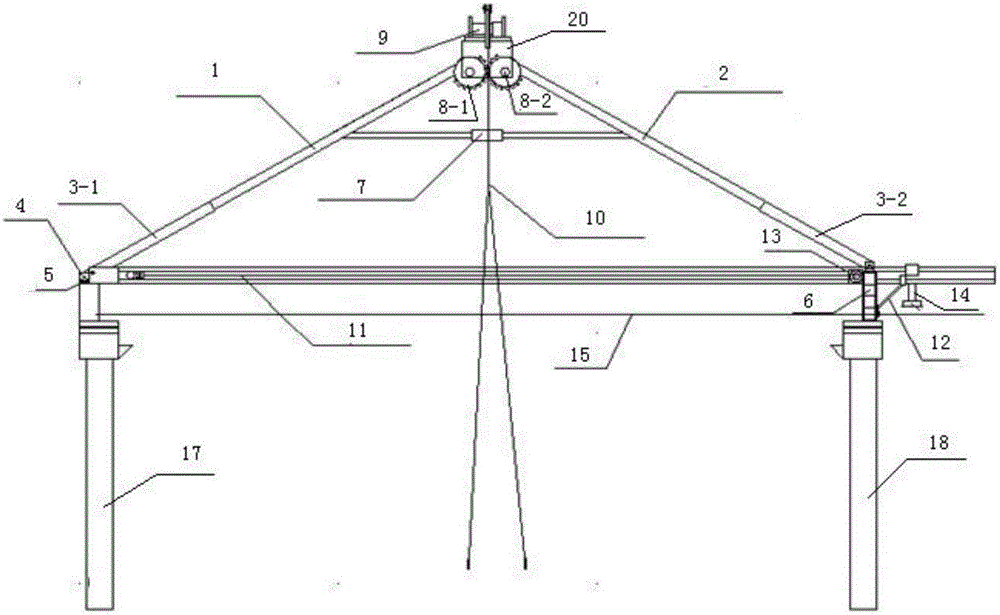

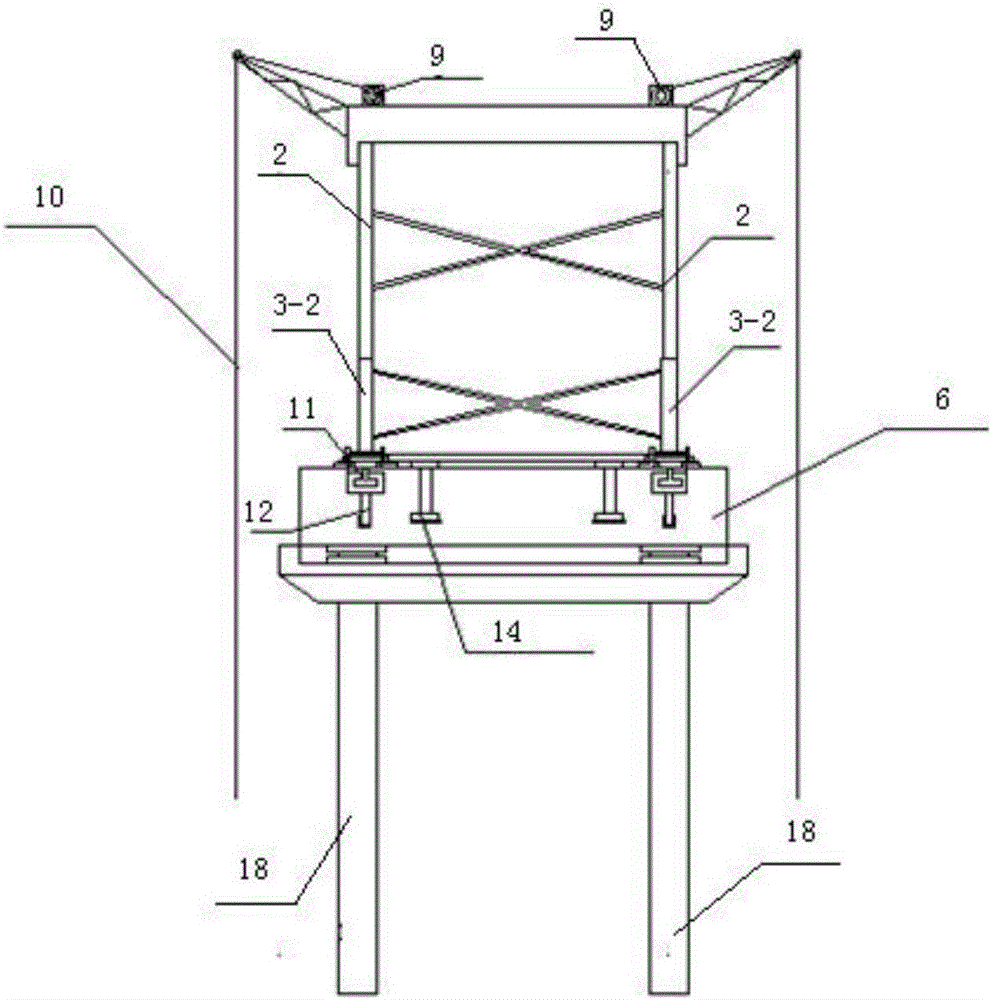

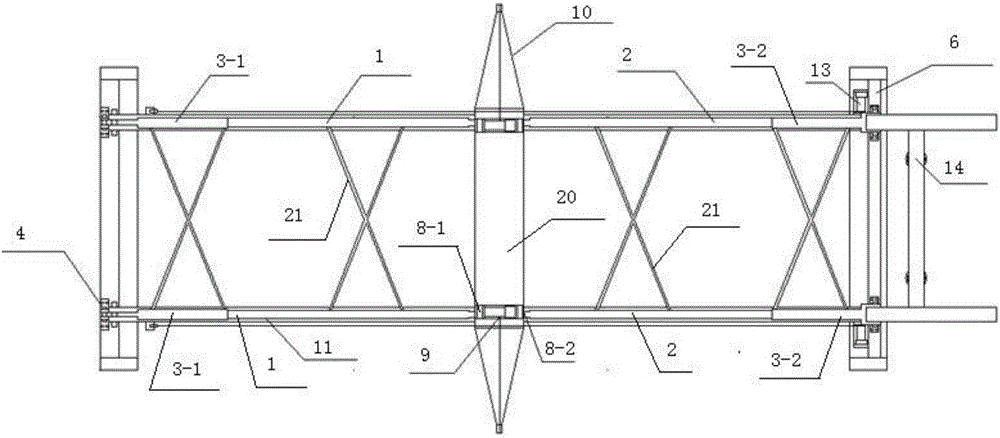

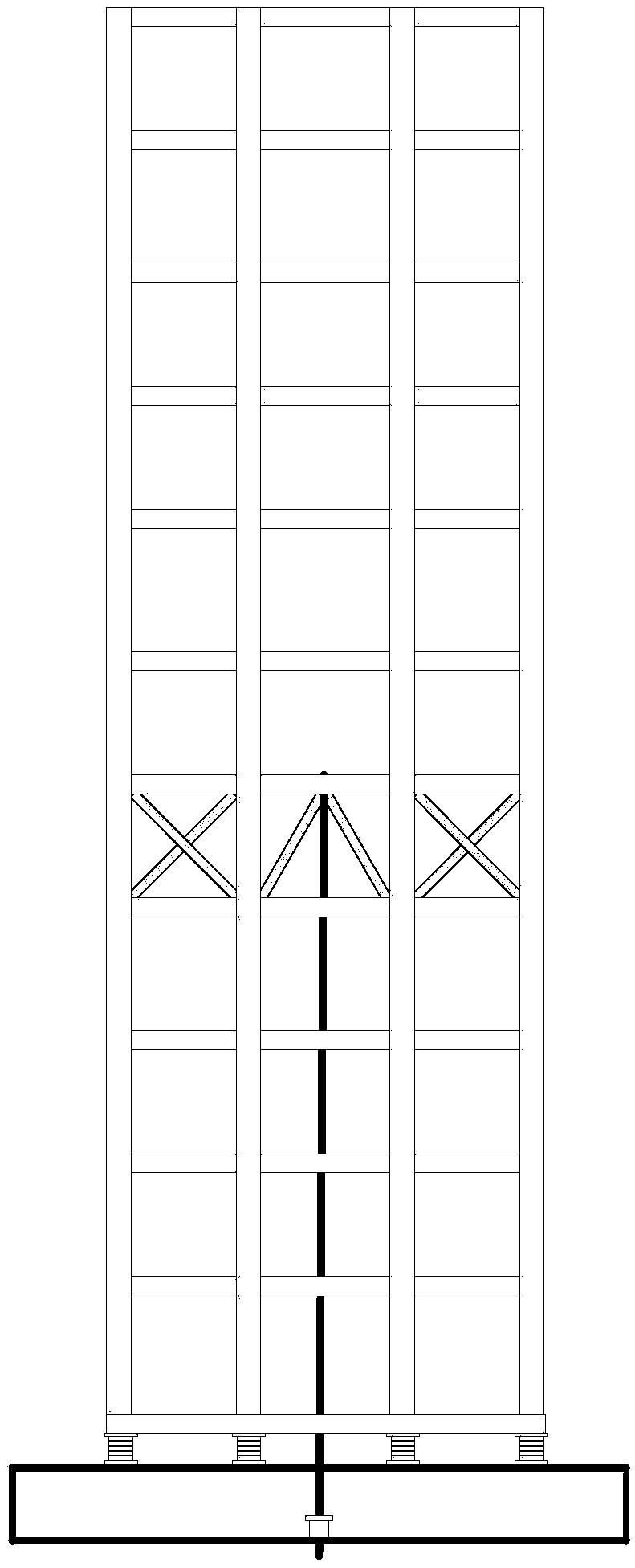

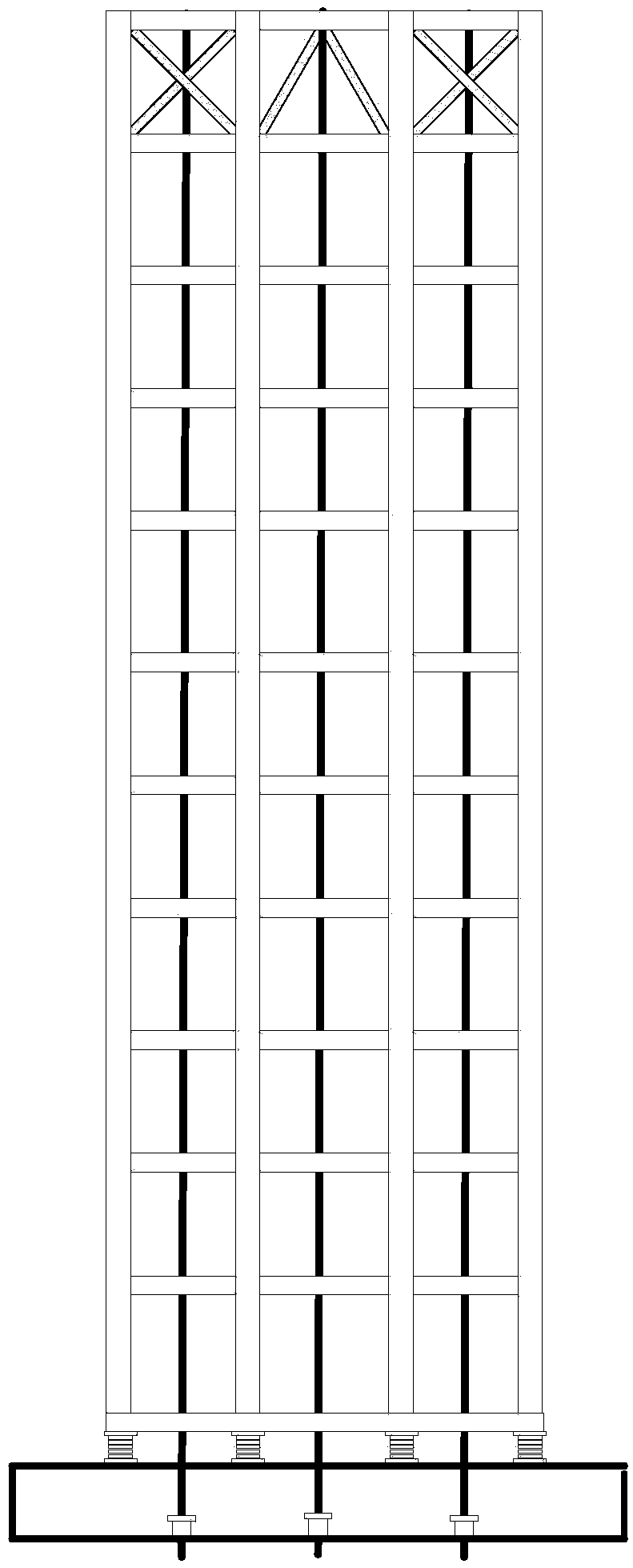

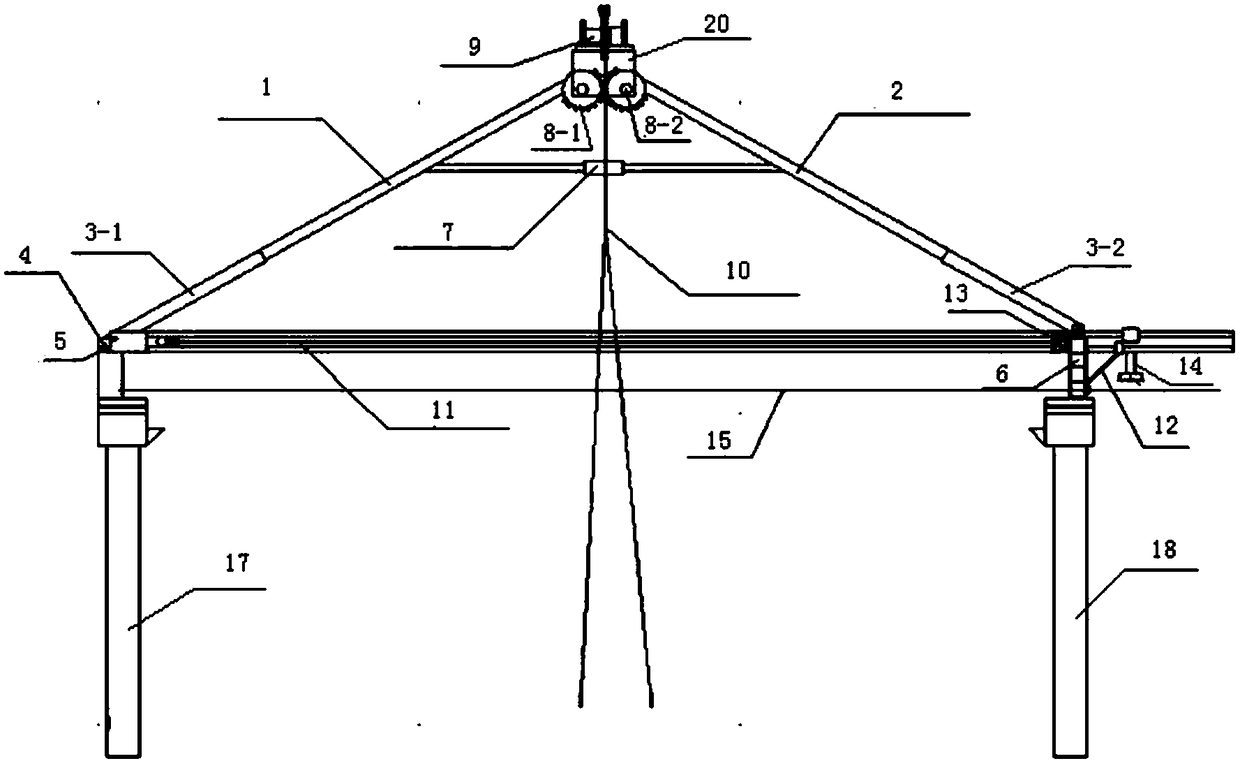

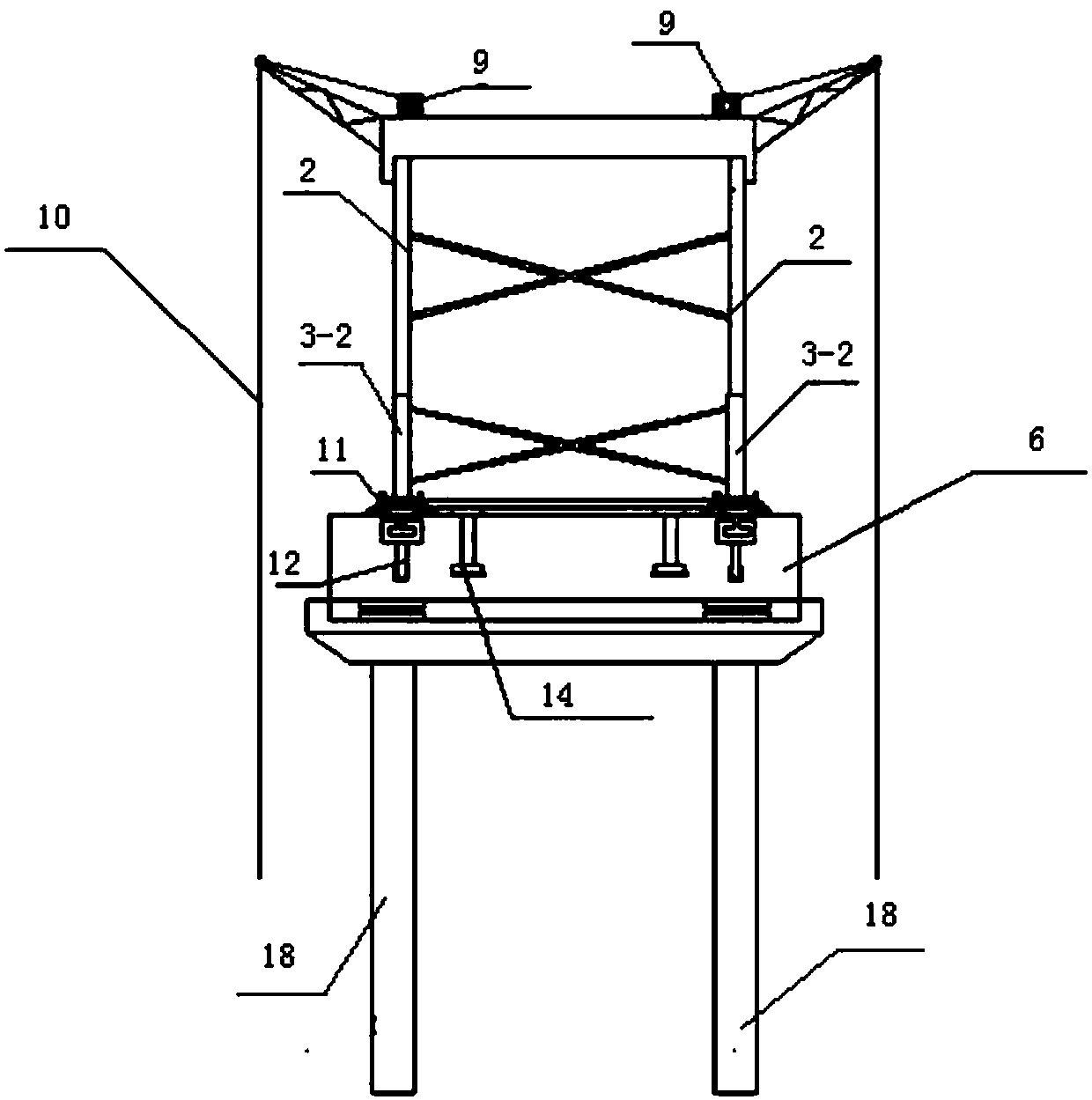

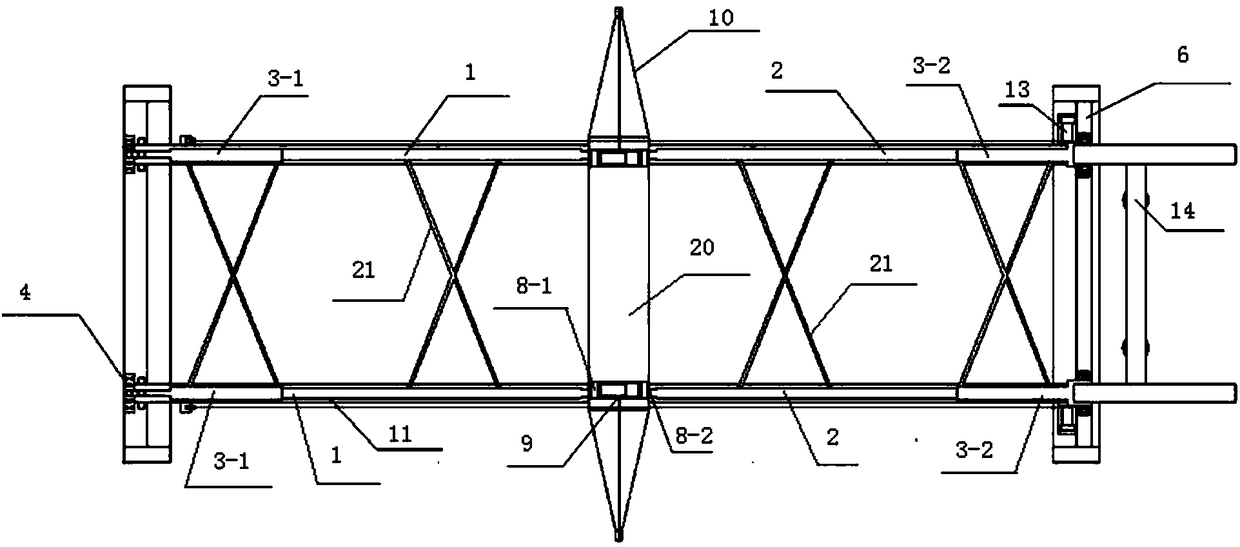

Herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine and application method

The invention discloses a herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine. The herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine comprises a herringbone steel frame, a pushing device, a top windlass, an I-shaped steel rail, a rail windlass, a supporting jack, a pre-stressed steel bar and an integrated bottom die; the herringbone steel frame comprises a front supporting leg set and a rear supporting leg set; the front supporting leg set comprises a second top gear, a front supporting leg, a second retractable sleeve and a slidable transverse beam, which are connected in sequence; the rear supporting leg set comprises a first top gear, a rear supporting leg, a first retractable sleeve and a fixed end anchoring part, which are connected in sequence; the fixed end anchoring part is connected with an embedded part on a first-row bridge pier; the first top gear is engaged with the second top gear; the pushing device is connected with the front supporting leg and the rear supporting leg; the slidable transverse beam is connected with the second retractable sleeve, and can slide on the I-shaped steel rail; one end of the tensioned pre-stressed steel bar is anchored at a pier top of the first-row bridge pier, and the other end of the tensioned pre-stressed steel bar is anchored on the slidable transverse beam through an anchor clamping sheet. The herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine does not occupy a space under a bridge, and the construction efficiency of the bridge is improved.

Owner:WUHAN UNIV OF TECH

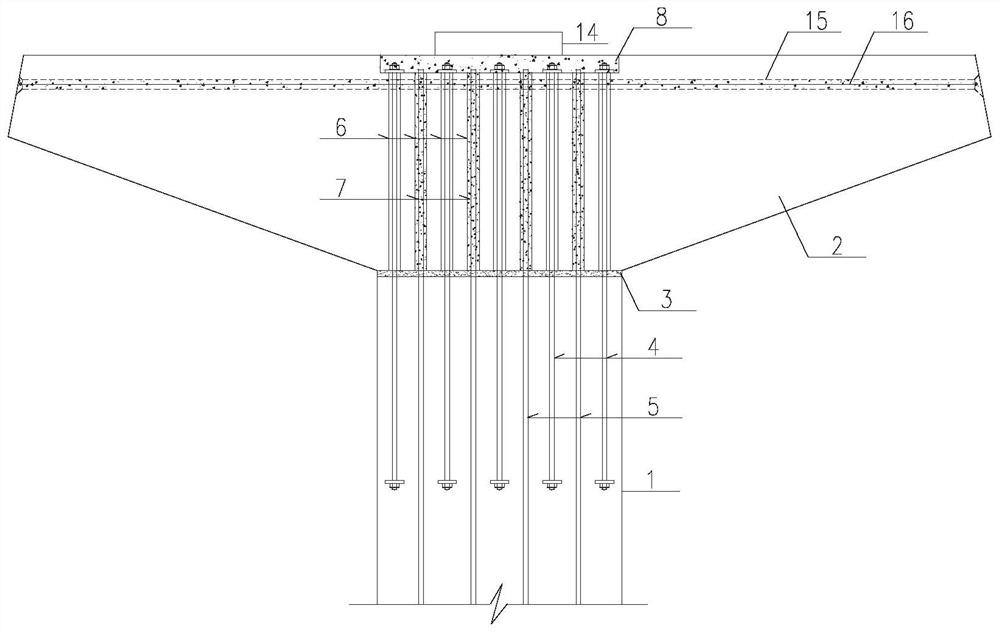

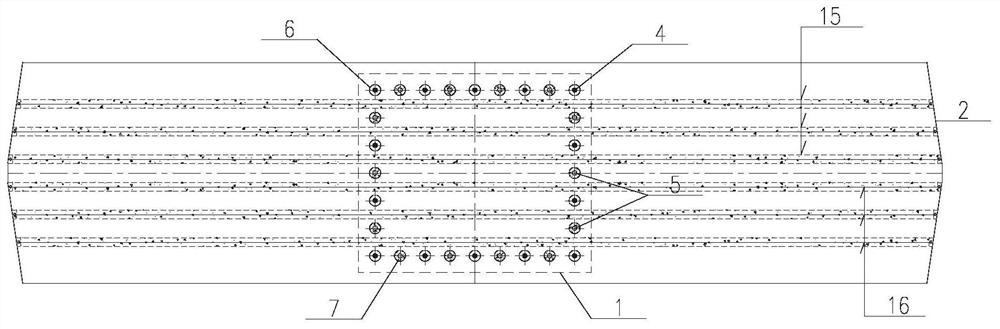

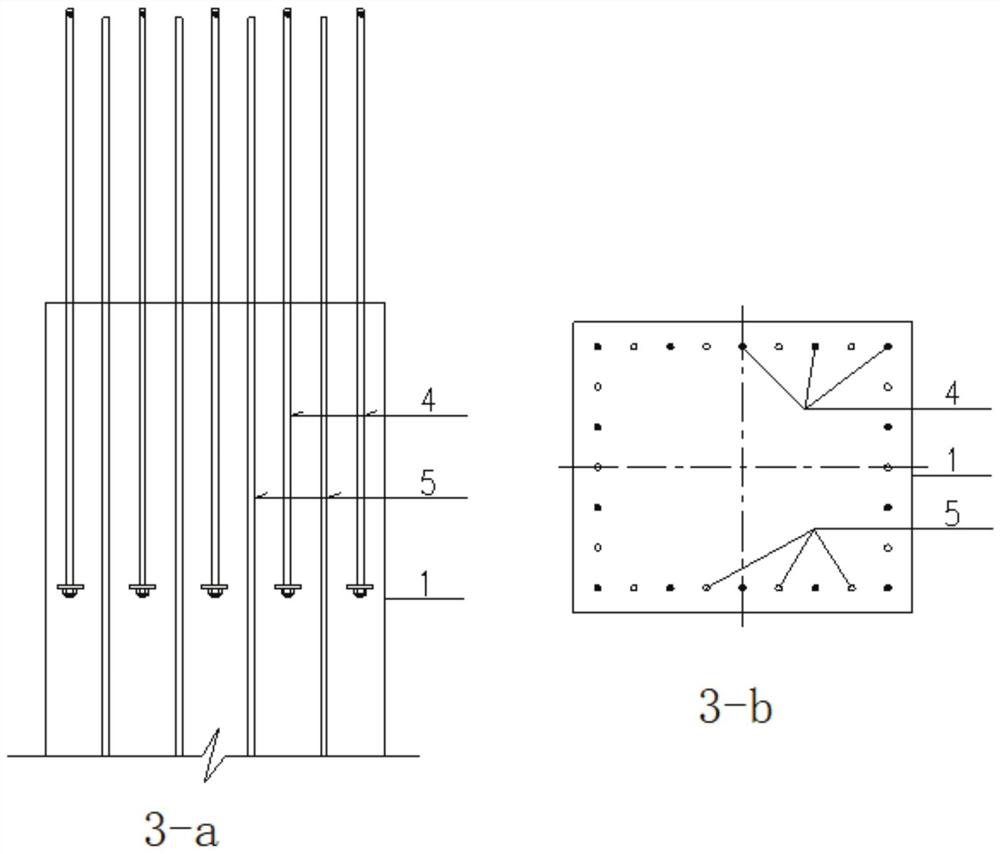

Prefabricated assembly type pier column and top cap connecting structure and construction method thereof

InactiveCN113202017AFast assembly and constructionLittle construction disturbanceBridge structural detailsBridge erection/assemblyCrack resistanceReinforced concrete

The invention provides a prefabricated assembly type pier column and top cap connecting structure and a construction method thereof. The connecting structure comprises a prefabricated pier column and a prefabricated top cap, an anti-shearing tenon is arranged on the top of the prefabricated pier column, an anti-shearing groove is formed in the bottom of the prefabricated top cap, prestressed tendons and connecting steel bars are arranged in the prefabricated pier column, and a plurality of embedded corrugated pipes are arranged in the prefabricated top cap; and pore channels are reserved in the pre-buried corrugated pipes, the pore channels correspond to the prestressed tendons and the connecting steel bars one to one, and the prefabricated pier column and the prefabricated top cap are spliced through splicing seams. The prestressed tendons are arranged, so that the crack resistance of the splicing seams is improved, and the post-earthquake self-resetting capability and the connection reliability are enhanced; the splicing seams are made of ultra-high performance concrete or epoxy mortar, so that the splicing seams can bear certain tensile stress without cracking, and the durability of the splicing seams is improved; the reinforced concrete anti-shear tenons and the anti-shear grooves are arranged to form a mortise and tenon structure, and the joint anti-shear capacity is high; and the connecting structure is particularly suitable for splicing the prefabricated pier column and the top cap in a large cantilever top cap T-shaped pier or an overline frame type pier.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Manufacturing method for prestressed steel composite girder

ActiveCN101080534BNo tensile stressNo stress lossBridge erection/assemblyBridge materialsPre stressMaterials science

A prestressed steel composite girder and a method of manufacturing the prestressed steel composite girder are provided by using a steel beam and a concrete. The method includes steps of: placing the steel beam above the ground; installing a form, into which the concrete is to be inserted, to surround at least a portion of the steel beam, the form being suspended by the steel beam; inserting the concrete into an internal space of the form and curing it; and removing the form to compose the steel beam and the concrete. The prestressed steel composite girder includes a steel beam and a concrete composed to surround a portion of the steel beam so that stress caused by its self- weight can be applied on only the steel beam.

Owner:RES INST OF IND SCI & TECH +1

Bamboo-steel fiber reinforced concrete composite beam

InactiveCN109914691AImprove bending resistanceAvoid separationGirdersJoistsAdhesive gluePerforated metal

The invention discloses a bamboo-steel fiber reinforced concrete composite beam, comprising a bamboo beam, a perforated metal plate, adhesive glue and a cast-in-place steel fiber reinforced concrete layer. The bamboo beam is provided with a reserved seam in the length direction and provided with grooves at intervals; the bamboo beam and the cast-in-place steel fiber reinforced concrete layer are connected through the perforated metal plate; the lower part of the perforated metal plate is embedded into the reserved seam; the upper part and the lower part of the perforated metal plate are respectively provided with a circular upper hole and a circular lower hole; the reserved seam and the lower hole of the bamboo beam are filled with the bonding glue; the cast-in-place steel fiber reinforcedconcrete layer and the bonding glue respectively form an upper pin bolt and a lower pin bolt in the upper hole and the lower hole of the perforated metal plate; and the cast-in-place steel fiber reinforced concrete layer forms shear tenons at the positions of the grooves. Compared with a common bamboo structure, the bending rigidity of the section of the bamboo structure is greatly improved, theadverse situation of rigidity control design of the bamboo structure is thoroughly changed, and the bamboo-steel fiber reinforced concrete composite beam has the advantages of being high in bearing capacity and large in rigidity.

Owner:HOHAI UNIV

Tower-beam thrust connection device and self-anchored suspension bridge rapid construction method

The invention provides a tower-beam thrust connection device and a self-anchored suspension bridge rapid construction method. The beam end resistor is fixedly installed on the beam end reserved steelplate in the tower beam thrust connection device, the tower end resistor is fixedly installed on the tower end pressure-bearing steel plate, and the beam end resistor is connected with the tower end resistor through a thrust conductor. The method comprises the following steps: step 1, synchronously constructing the main girder and the bridge tower of the side span; step 2, installing a tower-beamthrust connection device to temporarily connect the main girder of the side span with the bridge tower; step 3, synchronously constructing the main cable erection and the main beam installation; step4, detaching the tower beam thrust connection device to complete the first system conversion; step 5, pulling the boom, removing the bracket, and completing the second system conversion. The method ofthe invention adopts the tower beam thrust connection device to realize the cooperative installation of the main cable and the main beam safely and economically, thereby greatly saving the field operation time; Its characteristic is to increase the system conversion of the main girder by one time compared with the traditional process.

Owner:CHANGAN UNIV

Adjustable pressure induction type active transverse supporting device

PendingCN111962387AAdjustable lengthSimple structureBridge structural detailsBridge erection/assemblyClassical mechanicsPipe

The invention discloses an adjustable pressure induction type active transverse supporting device. The device is characterized by comprising a main steel pipe assembly and an adjusting pipe assembly which are matched with each other. The main steel pipe assembly comprises a concrete mounting base pre-buried in concrete. A main steel pipe is connected to the concrete mounting base; a far-end mounting seat is arranged at the end part of the main steel pipe; meanwhile, a surface type intelligent string strain gauge is also arranged on the outer wall of the main steel pipe; the adjusting pipe assembly comprises a near-end mounting base pre-buried in concrete. An adjusting pipe is connected to the near-end mounting base; the outer diameter of the adjusting pipe is matched with the inner diameter of the main steel pipe, two symmetrically-distributed jacks and two symmetrically-distributed wedge-shaped supporting mechanisms are arranged between the far-end mounting seat and the near-end mounting base, each wedge-shaped supporting mechanism is composed of two supporting blocks, and each supporting block is provided with an inclined face.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 1ST ENG +1

A piezoelectric hospital call signal generator

ActiveCN107332469BNo tensile stressIncrease the tensile stressPiezoelectric/electrostriction/magnetostriction machinesEngineeringSignal generator

The invention relates to a piezoelectric hospital call signal generator and belongs to the technical field of a medical electronic product. The end portion of a side wall of a housing is connected with an upper cover having a through hole. The upper cover is provided with a circuit board through washers, and the circuit board is provided with an energy conversion circuit and a signal emission system. The side wall of the housing is connected with a vibrator base. The vibrator base is equipped with a group of piezoelectric vibrators through a press plate. The piezoelectric vibrators are separated by separator plates correspondingly. Each piezoelectric vibrator is in an arc structure formed by a substrate and a piezoelectric sheet, which are glued together, wherein the bending radius of the substrate is smaller than the bending radius of the piezoelectric sheet. A bottom wall of the housing is provided with a square sink groove, which is internally equipped with a guide bar. The guide bar is provided with a reset spring, a lower short rigid block, a lower flexible dial slice, a lower long rigid block, a middle short rigid block, a middle flexible dial slice, a middle long rigid block, an upper short rigid block, an upper flexible dial slice, an upper long rigid block and a button in sequence from the bottom up. A small end of the button passes through the through hole in the upper cover, and the upper surface of a big end of the button is abutted against the upper cover; and the bottom wall of the housing is connected to a sickbed.

Owner:ZHEJIANG NORMAL UNIVERSITY

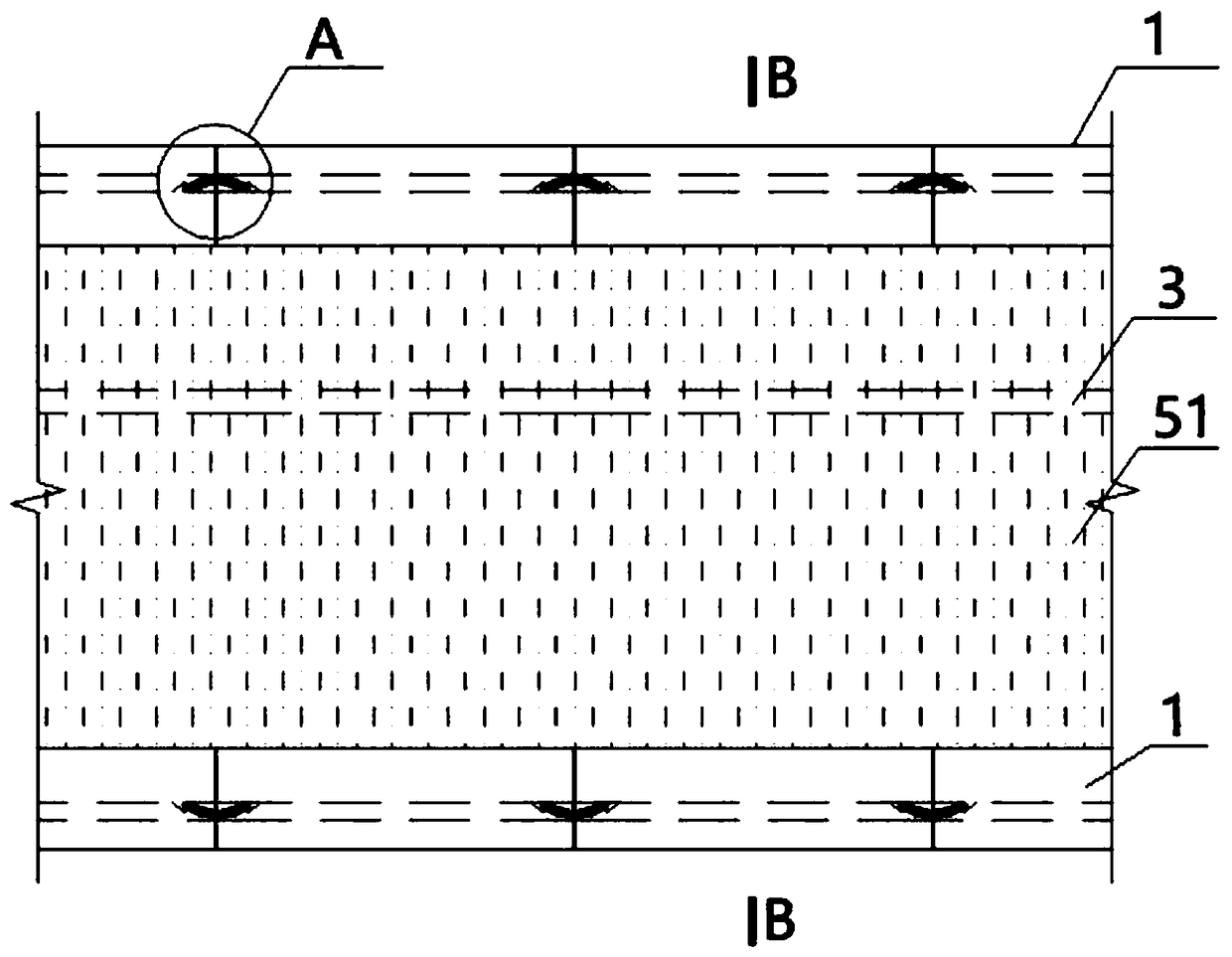

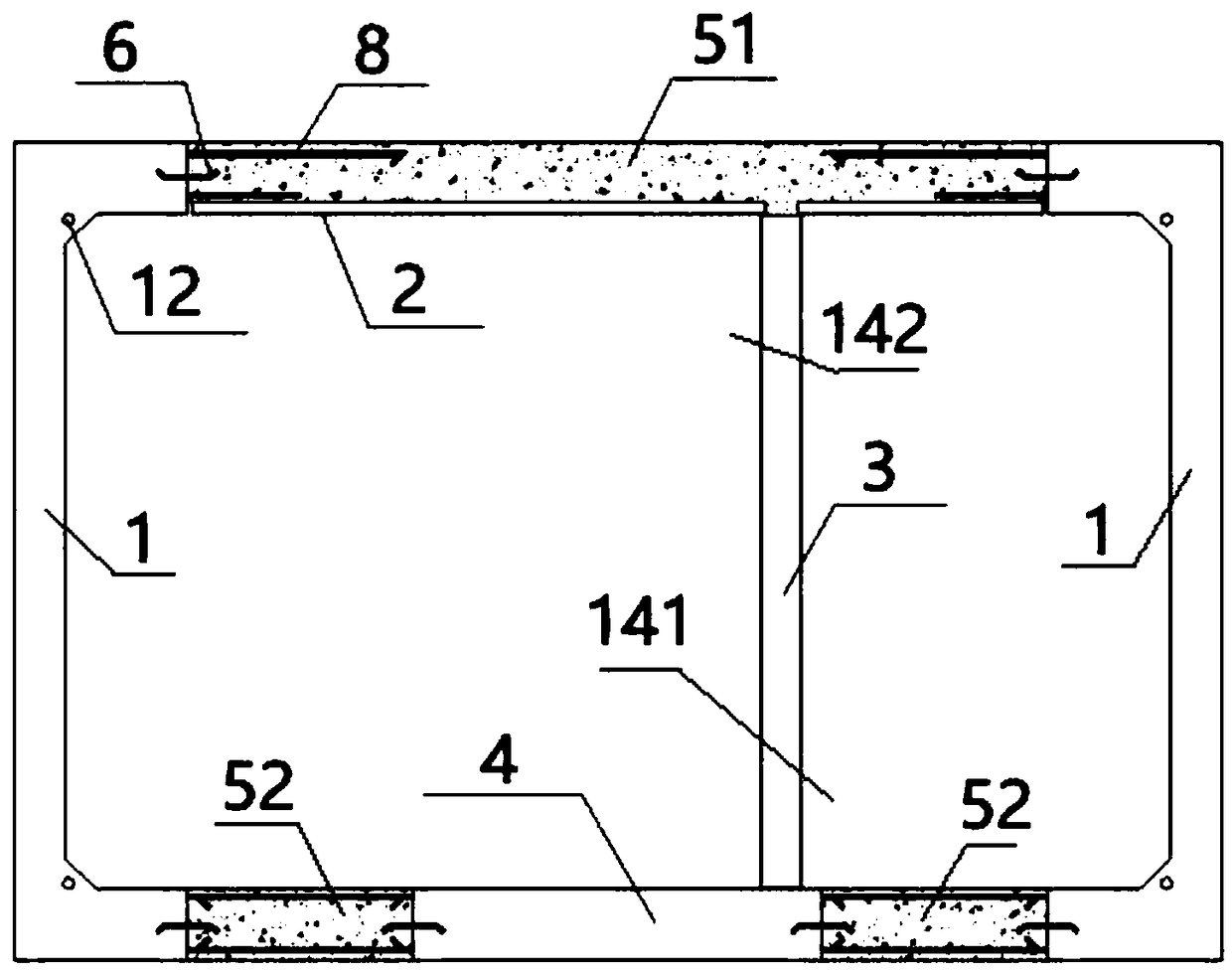

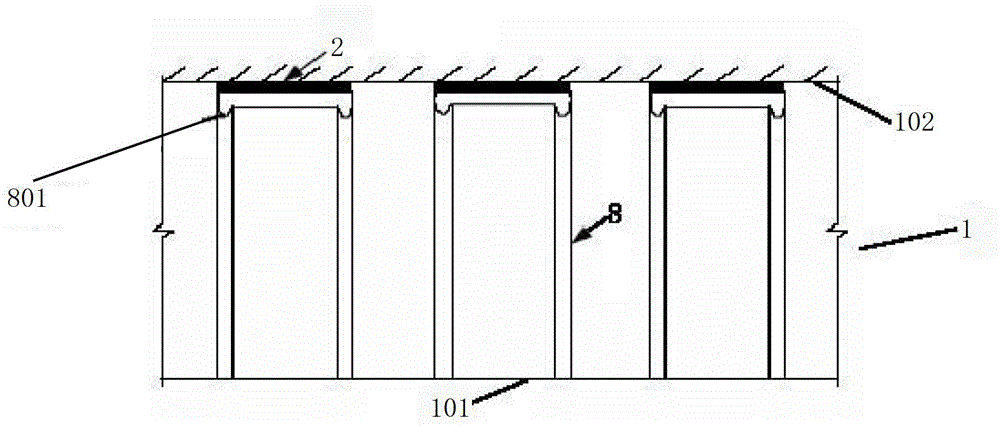

Environment-friendly prefabricated integral comprehensive pipe gallery and assembling method thereof

PendingCN109469103AImprove waterproof performanceGuaranteed drynessArtificial islandsProtective foundationRebarWall plate

The invention discloses an environment-friendly prefabricated integral comprehensive pipe gallery and an assembling method thereof. The environment-friendly prefabricated integral comprehensive pipe gallery comprises multiple pipe gallery units which are sequentially arranged in the length direction of the comprehensive pipe gallery, and each pipe gallery unit comprises a prefabricated bottom plate, a first cast-in-situ wall plate, a second cast-in-situ wall plate, a prefabricated bin separating plate and two prefabricated C-shaped outer wall plates; each prefabricated C-shaped outer wall plate comprises a main wall plate extending in the height direction of the comprehensive pipe gallery and two auxiliary wall plates which are oppositely arranged at the two ends of the main wall plate; anchoring reinforcement bars used for stretching into the first cast-in-situ wall plates are embedded into the first auxiliary wall plates; anchoring reinforcement bars used for stretching into the second cast-in-situ wall plates are embedded into the second auxiliary wall plates; and the prefabricated bin separating plates partition a pipe gallery channel into a plurality of independent pipe gallery subchannels. According to the environment-friendly prefabricated integral comprehensive pipe gallery and the assembling method thereof, all the prefabricated parts are small in section area, low inweight, simple in structure, low in comprehensive cost and excellent in structural strength and shear resistance, and site construction pollution is low.

Owner:SHANGHAI JOHNSON ARCHITECTURAL & ENG DESIGN CONSULTANTS

Self-resetting shock insulation structure system capable of preventing shock insulation layer from being pulled

InactiveCN109610669ANo tensile stressThere will be no tension damageProtective buildings/sheltersShock proofingInsulation layerPre stress

The invention discloses a self-resetting shock insulation structure system capable of preventing a shock insulation layer from being pulled, and belongs to the field of building structure engineeringshock insulation. Vertical pre-stressed cables are arranged in a high-rise structure, and an inclined reinforcing support is arranged on a structure connecting layer, so that the self-resetting shockinsulation structure system with the shock insulation layer not pulled is formed. The high-rise structure is connected with a foundation through a shock insulation support, the vertical pre-stressed cable is arranged in the high-rise structure, the lower end of the vertical pre-stressed cable is anchored to the foundation, the upper end of the vertical pre-stressed cable is connected to the structure, and the inclined reinforcing support is arranged on the structure connecting layer. By adjusting the vertical pre-stress level, it is guaranteed that the shock insulation layer is not subjected to tensile stress, the shock insulation support is not subjected to tensile damage, and therefore the structure shock insulation effect under a large shock effect is guaranteed; and by adjusting the vertical pre-stress level, the height-width ratio of the shock insulation structure system can break through the limitation of a standard range, and the height of the shock insulation structure can be continuously increased compared with the height of a common shock insulation structure.

Owner:BEIJING UNIV OF TECH

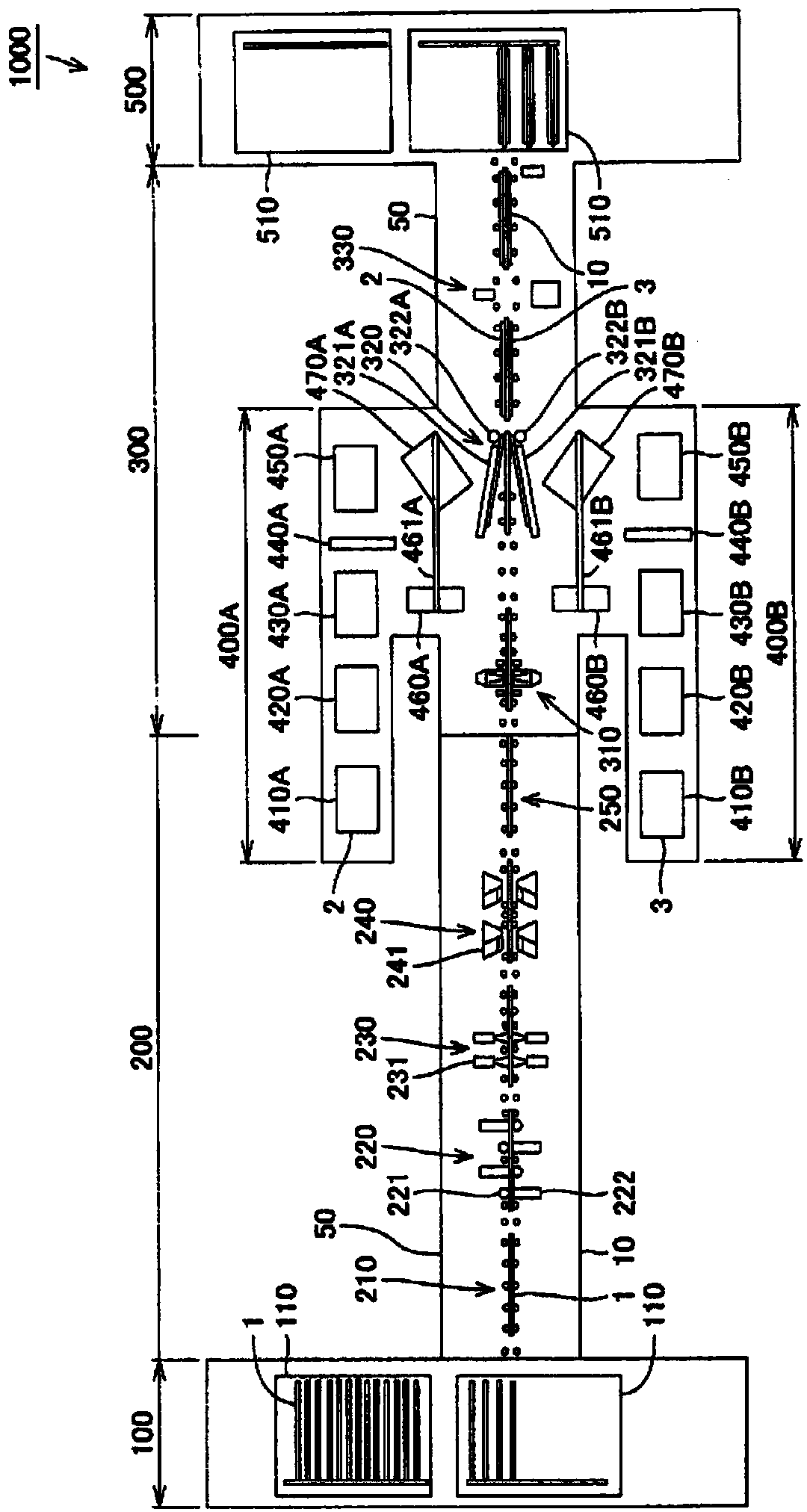

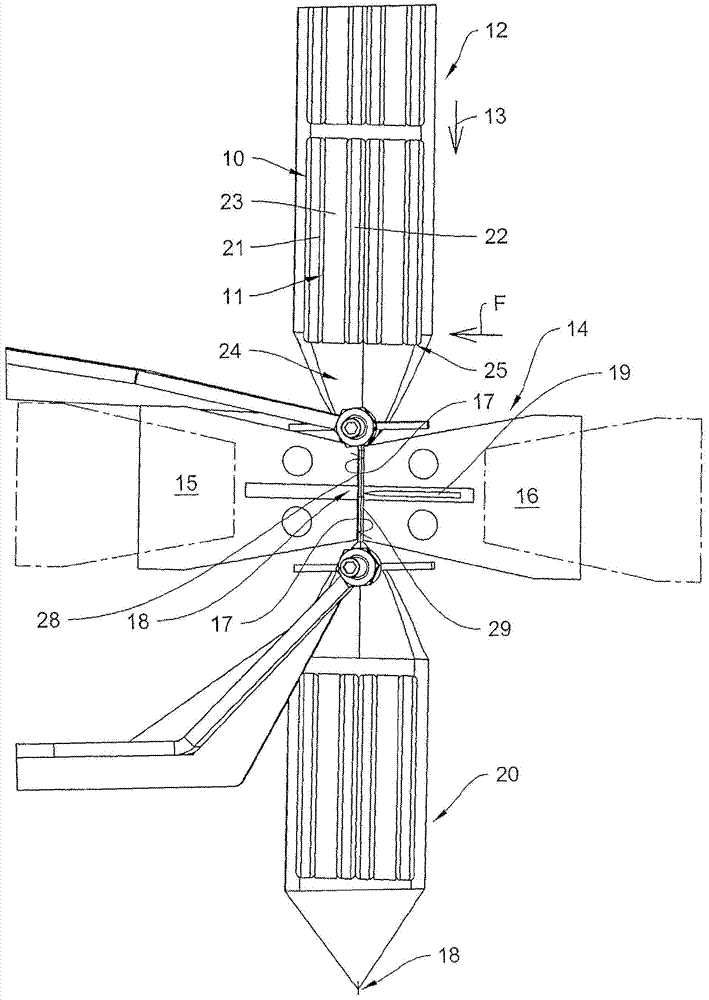

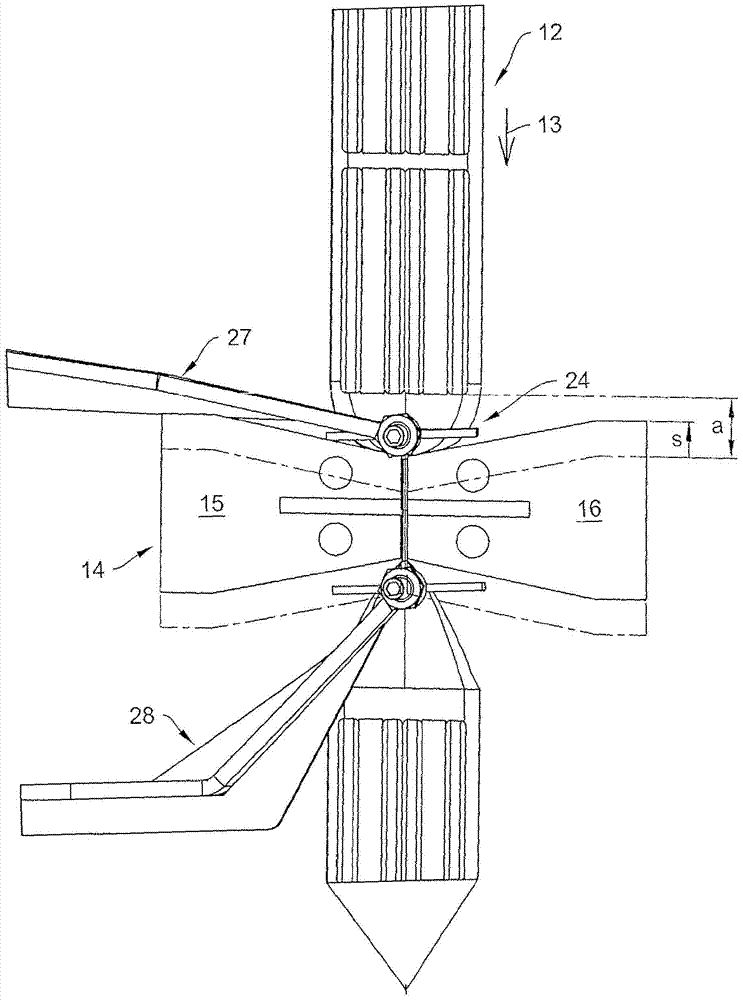

Method for producing packaging units in a tubular bag-making machine

InactiveCN104812673ASandwich stableNo tensile stressWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

The invention relates to a method for producing packaging units (20) in a tubular bag-making machine. Disk-shaped products (11) which lie one above the other in portion stacks (10) are conveyed vertically and wrapped with a film web conveyed parallel to the products by means of a film take-off device. In order to form a film tube (12), the film web is provided with a longitudinal sealed seam by means of a longitudinal sealing device and subsequently with transverse sealed seams (18) above and below the portion stack by means of a transverse sealing device (14) which is driven by a drive device independently of the film take-off device and which moves in the same direction as the film web while the sealing device contacts the film web for sealing purposes. The transverse sealing device carries out a vertical movement relative to the film tube in the direction opposite the conveying direction of the film tube while the sealing device contacts the film tube for sealing purposes.

Owner:HASTAMAT VERPACKUNGSTECHN

A kind of semiconductor lead frame manufacturing process

ActiveCN103928302BQuality improvementStrong adhesionSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyCopper plating

The invention relates to a semiconductor lead frame manufacturing technology which comprises the steps of stamping, surface treatment and cut-forming. The technology is characterized in that the surface treatment process specifically comprises the steps of electrolytic degreasing, washing, acid activation, washing, nickel plating, washing, alkaline copper plating, washing, acid copper plating, washing, silver preplating, washing, silver plating, silver removing, washing, protective solution plating, washing and drying. Plated layers of a semiconductor lead frame manufactured with the method are high in adhesive force and do not fall off easily. Meanwhile, the semiconductor lead frame is free of deformation and oversize, high in quality, and long in service life.

Owner:SICHUAN JINWAN ELECTRONICS

Concrete-lined tunnel structure, circular flat jack and high-pressure tunnel technology

InactiveCN103696406BReduce usageNo rust problemsWater-power plantsLifting devicesPre stressArchitectural engineering

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

Polarizing film attachment device

InactiveCN103969881BNo bending phenomenonReduce generationLaminationLamination apparatusOptoelectronicsLiquid crystal

The invention relates to an apparatus for attaching a polarized film, and especially relates an apparatus having characteristics described as follows. In a method of attaching a polarized film onto a liquid crystal element substrate, a problems is that bubbles are generated between the polarized film and the liquid crystal element substrate because the front bending of the polarized film. A caterpillar track type adhesive plate is arranged on an inclination roller and a fixed roller on the left and the right, and a polarized film is attached to the liquid crystal element substrate after the polarized film is arranged on the amooth adhesive plate. Therefore, a phenomenon of overall bending of the polarized film does not occur. When the polarized film is attached onto the surface of the liquid crystal element substrate, the possibility of bubble generation is substantially reduced. Furthermore, the liquid crystal element is prevented from being bent due to the elongation of the polarized film, and the possibility of unqualified products is eliminated.

Owner:YMK

Herringbone Prestressed Concrete Pretensioning Bridge Erection Machine and Its Application Method

The invention discloses a herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine. The herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine comprises a herringbone steel frame, a pushing device, a top windlass, an I-shaped steel rail, a rail windlass, a supporting jack, a pre-stressed steel bar and an integrated bottom die; the herringbone steel frame comprises a front supporting leg set and a rear supporting leg set; the front supporting leg set comprises a second top gear, a front supporting leg, a second retractable sleeve and a slidable transverse beam, which are connected in sequence; the rear supporting leg set comprises a first top gear, a rear supporting leg, a first retractable sleeve and a fixed end anchoring part, which are connected in sequence; the fixed end anchoring part is connected with an embedded part on a first-row bridge pier; the first top gear is engaged with the second top gear; the pushing device is connected with the front supporting leg and the rear supporting leg; the slidable transverse beam is connected with the second retractable sleeve, and can slide on the I-shaped steel rail; one end of the tensioned pre-stressed steel bar is anchored at a pier top of the first-row bridge pier, and the other end of the tensioned pre-stressed steel bar is anchored on the slidable transverse beam through an anchor clamping sheet. The herringbone pre-stressed concrete pre-tensioning-method bridge erecting machine does not occupy a space under a bridge, and the construction efficiency of the bridge is improved.

Owner:WUHAN UNIV OF TECH

A kind of LED epitaxial wafer and preparation method thereof

ActiveCN103579428BImprove luminous efficiencyFacilitate horizontal diffusionSemiconductor devicesElectrical conductorSemiconductor package

The invention provides an LED epitaxial wafer and a preparing method thereof. The LED epitaxial wafer comprises a substrate layer, a first semiconductor layer, an interpolating layer, a light-emitting layer and a second semiconductor layer, wherein the substrate layer, the first semiconductor layer, the interpolating layer, the light-emitting layer and the second semiconductor layer are sequentially stacked. The interpolating layer is a GE doping GaN layer, ESD performance can be effectively improved, lighting efficiency is intensified, the brightness of an LED is improved, defects are not generated, the situation that the electrical property of a component becomes poor due to increase of serial-connection resistors cannot occur, and meanwhile the production process is simple.

Owner:BYD SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com