Thin-wall pressure water pipe

A technology for water transmission pipelines and pipelines, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc. It can solve the problems of large-area land inundation loss, high engineering cost, leakage, etc., and reduce construction costs. And the difficulty of installation, the effect of reducing project cost and saving pipe wall materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

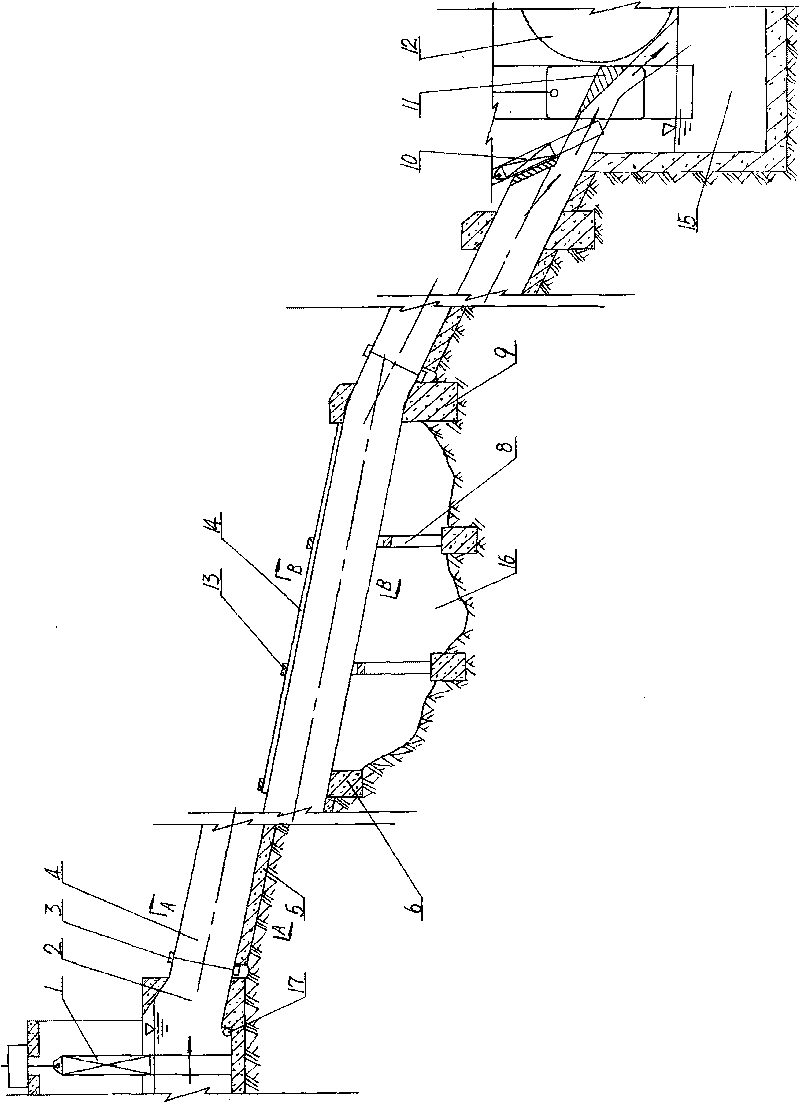

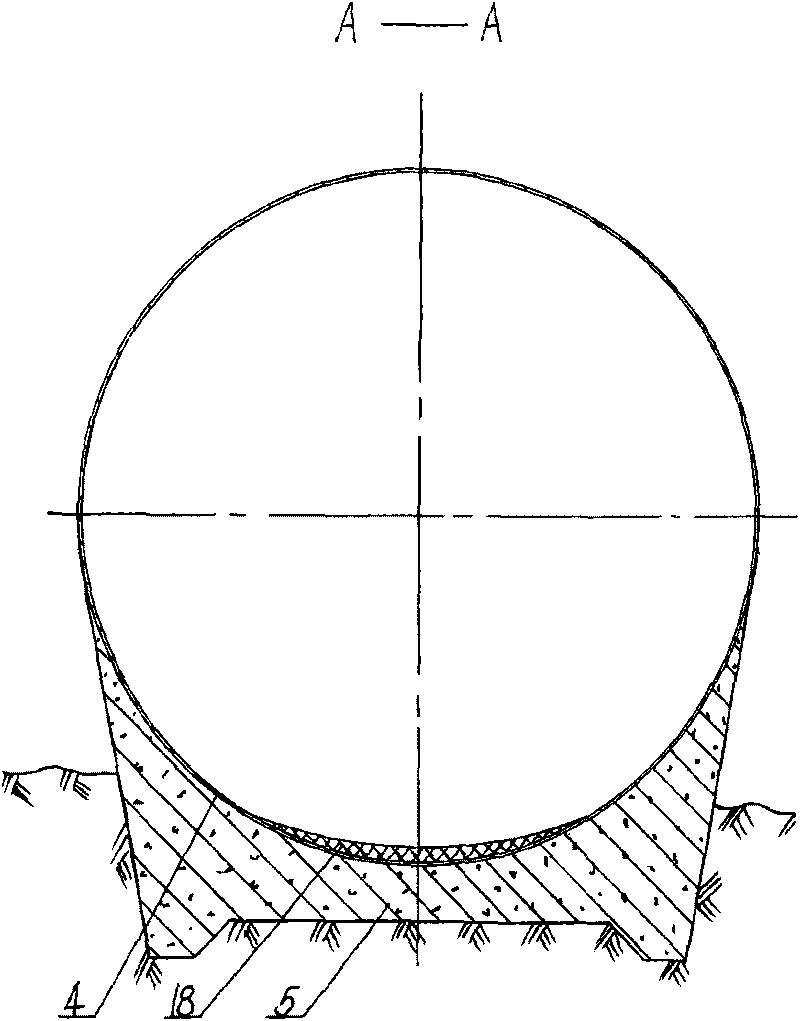

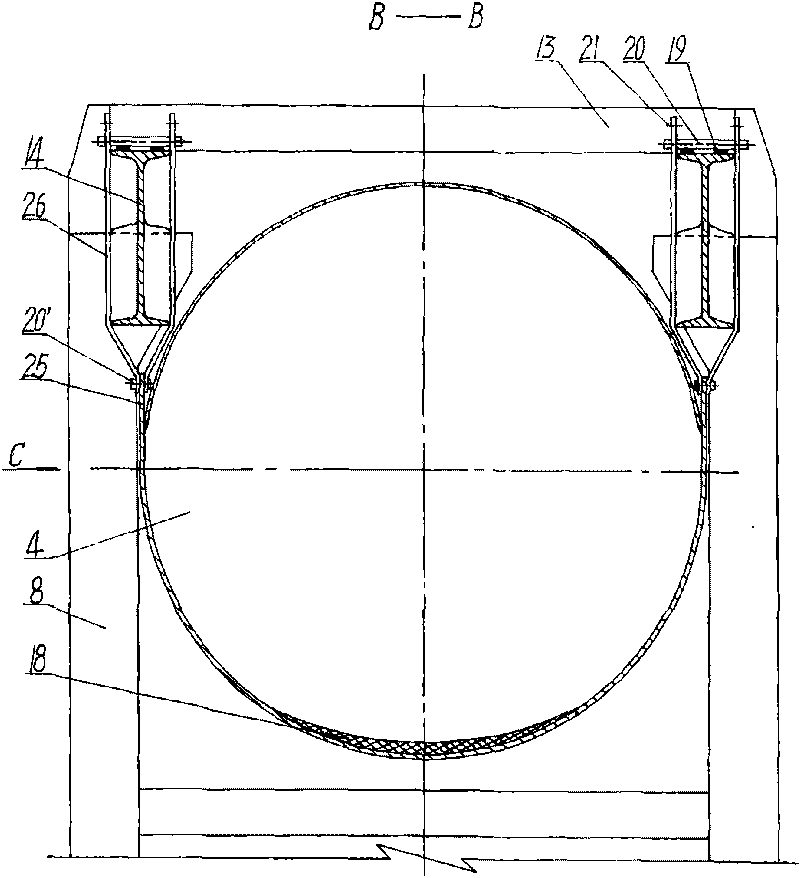

[0039] figure 1 , figure 2 , image 3 with Figure 4 A first embodiment of the invention is shown. This embodiment describes in detail the overall arrangement structure and operation process of using the thin-walled pressure water pipeline to deliver pressure water flow to the impact water turbine.

[0040] Such as figure 1 with figure 2 Shown: Concrete tube bed 5 buried half height below the ground is laid along the surface of the ground. The bottom surface of the tube bed 5 is in the shape of a plane with toothed walls, while the top surface is in the shape of a circular arc with a diameter of 2 meters. groove. A thin-walled pressure pipe 4 with a diameter of 2 meters and a diameter of 2 meters made of a 3 mm thick ordinary steel plate is laid in the arc-shaped groove, and an anti-wear layer 18 of epoxy mortar is provided on the bottom surface of the pipe 4 .

[0041] Such as figure 1 , image 3 with Figure 4 As shown: there are ravines 16 on the ground surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com