Medical titanium alloy screw balloon magnetorheological brush polishing machine

A magnetorheological brush and titanium alloy technology, which is applied in the field of medical titanium alloy screw airbag magnetorheological brush polishing machine, can solve the problems of difficult surface polishing, achieve high surface quality, high efficiency, and eliminate/reduce the effect of dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

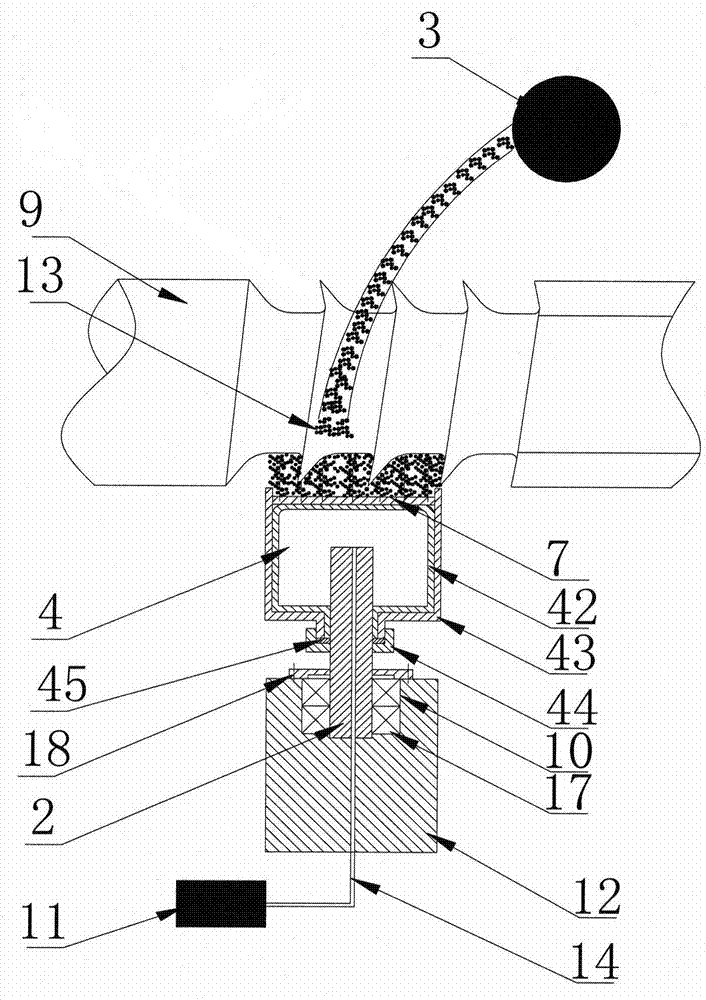

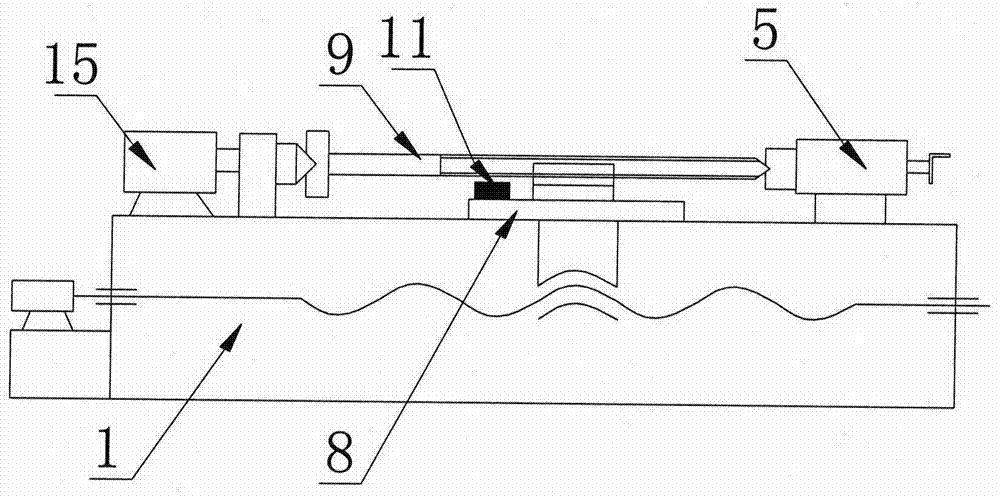

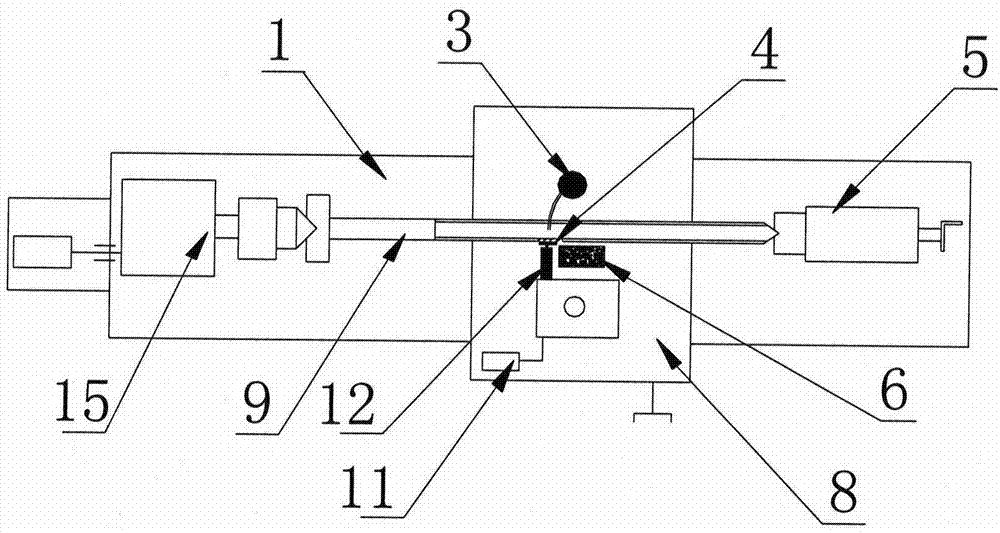

[0014] refer to figure 1 , figure 2 It is an embodiment of the medical titanium alloy screw airbag magneto-rheological brush polishing machine of the present invention. The medical titanium alloy screw airbag magneto-rheological brush polishing machine includes a lathe 1, a polishing liquid 13 containing magnetorheological fluid, and is fixed on the lathe 1 tool holder The magnetic polishing assembly on the carriage 8 and the pump body 3 that sprays the polishing liquid 13 on the magnetic polishing assembly.

[0015] Such as image 3 As shown, the magnetic polishing assembly includes a clamping handle 12 fixed on the tool rest carriage 8 of the lathe 1, a magnetic field transmitter 2 disposed on the clamping handle 12, an air bag assembly 4 disposed on the magnetic field transmitter 2, a movable setting The magnetic conduction brush plate 7 on the air bag assembly 4, the magnetic conduction brush plate is a brush that adopts the magnetic conduction material bristle, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com