Method for producing packaging units in a tubular bag-making machine

A technology for tubular and sealing equipment, applied in packaging, transportation packaging, packaged food, etc., can solve the problems of reduced productivity of production equipment and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

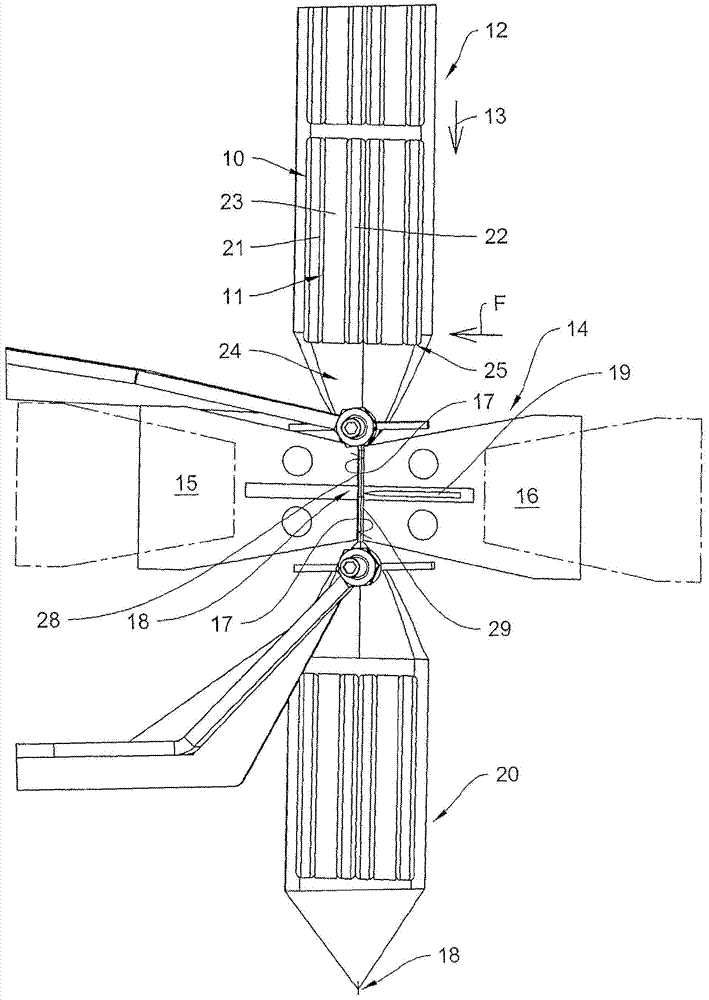

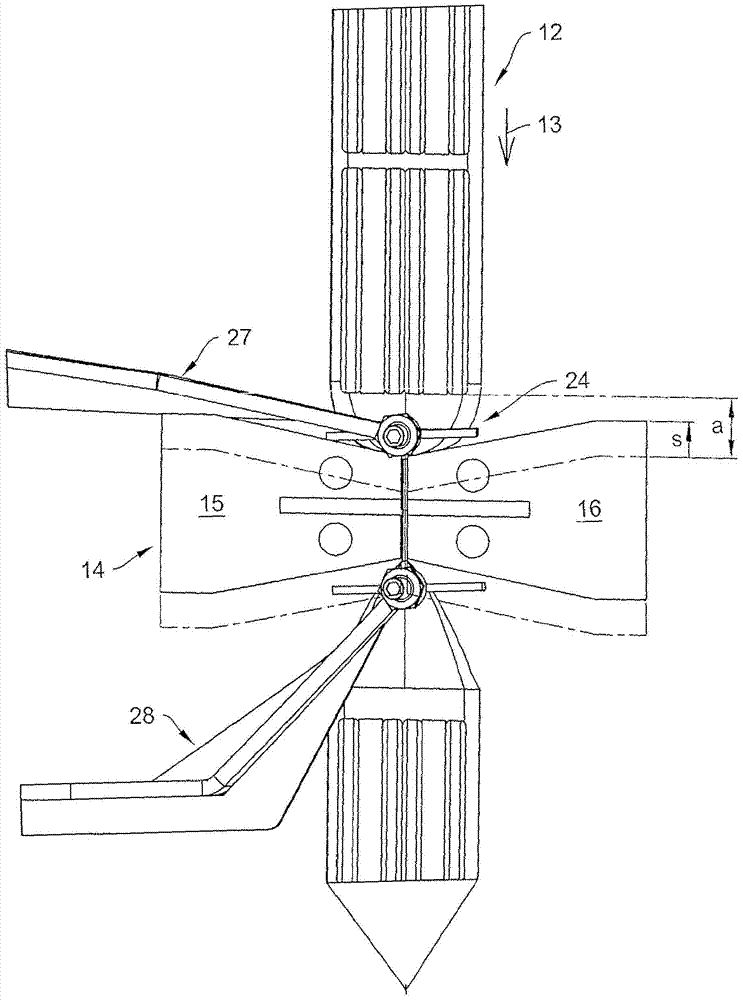

[0019] figure 1 Shown is the lower end of a film tube 12 formed in the tubular bag forming, filling and sealing apparatus for wrapping disc-shaped products 11 positioned one above the other in a partial stack 10 . Through the transfer device (not in figure 1 shown in more detail), the film tube 12 is conveyed in a vertical conveying direction 13 to a transverse sealing device 14 comprising two sealing tools 15, 16 driven by a motion transmission (not shown in detail), Thus, when the two sealing means 15, 16 contact the membrane tube for sealing purposes, the two sealing means 15, 16 bear against the membrane tube 12 arranged between the sealing means 15, 16 via the sealing surface 17, wherein the contact as figure 1 shown.

[0020] exist figure 1 Outside the sealing phase shown, the sealing tools 15, 16 are in figure 1 The entry point indicated by the dotted line, at which the sealing means 15 , 16 are separated so that the film tube 12 containing the product 11 can pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com