Concrete-lined tunnel structure, circular flat jack and high-pressure tunnel technology

A flat jack and ring-shaped technology, applied in the field of high-pressure tunnel construction technology, can solve the doubts about the durability of the unbonded anchorage system, reduce the durability of the structure, construction troubles, etc. The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

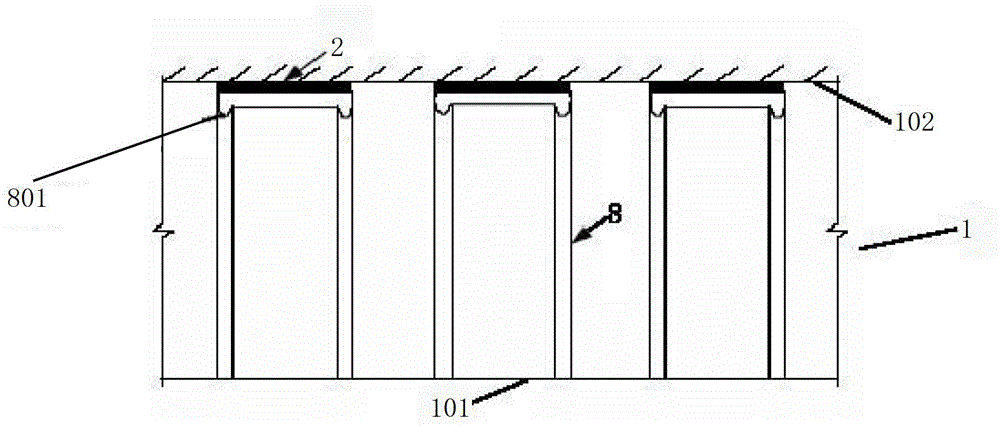

[0054] The specific implementation of the novel prestressed concrete lining tunnel structure, circular flat jack and high-pressure tunnel construction technology of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0055] Such as Figure 5 , Figure 5A , Figure 5B and Figure 6 As shown, it is the annular flat jack 8 for the prestressed tunnel concrete lining structure according to the present invention, which is made of steel plate, and the body of the annular flat jack 8 is provided with an outer ring 802; an inner ring 803 ; and two sides 804 , the two sides 804 form a cavity 805 with the outer ring 802 and the inner ring 803 . The cross-section of the annular flat jack body is a relatively flat rectangle, and there is a cavity inside the body that can be injected with a pressure medium. In this embodiment, the pressure medium is water or cement slurry, and the inner ring Or the outer ring can deform along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com