A kind of LED epitaxial wafer and preparation method thereof

A technology of LED epitaxial wafers and vapor phase epitaxy, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low LED luminous efficiency, increased device voltage, increased heat generation, etc., to improve ESD performance, easy to implement, The effect of enhancing current uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing the above-mentioned LED epitaxial wafer, comprising: sequentially growing a first semiconductor layer, an insertion layer, a light-emitting layer, and a second semiconductor layer on a substrate layer, wherein the step of growing the insertion layer includes using a vapor phase epitaxy growth method Using trimethylgallium as gallium source, ammonia as nitrogen source, GeH 4 A Ge-doped GaN layer is grown on the first semiconductor layer as a dopant source.

[0028] The vapor phase epitaxial growth method refers to the growth by metal organic chemical vapor deposition (MOCVD method), and the epitaxial lateral growth of different sizes is realized by controlling the pressure, temperature, gas flow ratio and reaction time in the reaction chamber.

[0029] Preferably, the growth temperature for growing the Ge-doped GaN layer is 900-1100°C. H 4 The flow rate of the gas is 1~10 sccm; the flow rate of trimethylgallium...

Embodiment 1

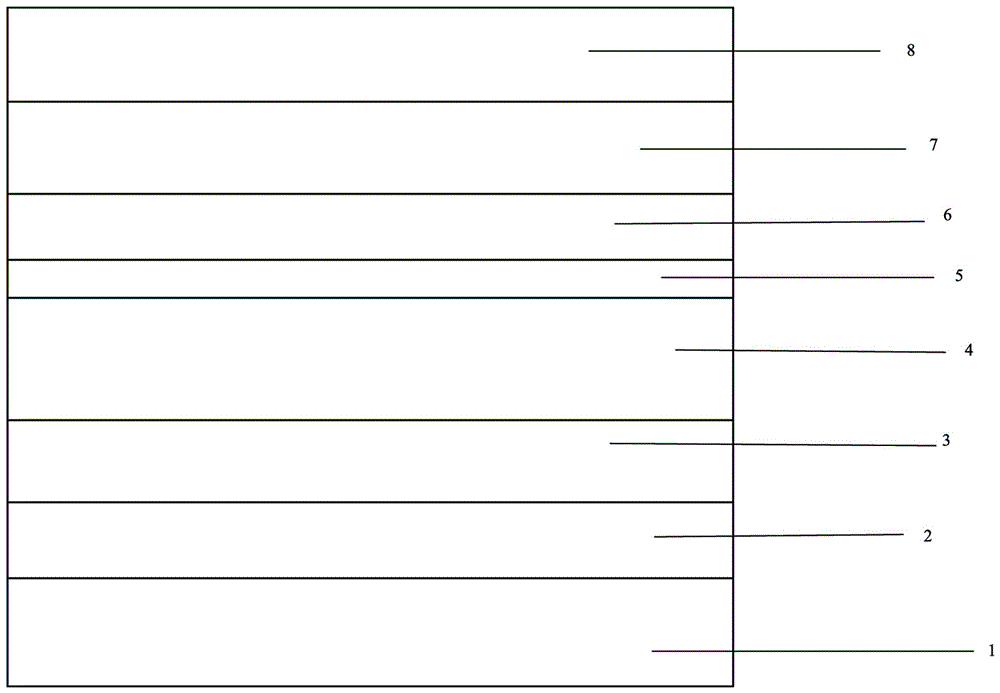

[0058] Pure hydrogen gas (H 2 ) as the carrier gas, the schematic diagram of the prepared sample structure is shown in figure 1 .

[0059] (1) Using sapphire as the substrate layer 1, using NH by MOCVD 3(The flow rate is 20000sccm) Nitriding treatment is first performed on the sapphire substrate layer 1 at 530°C for 150s, and then TMGa (flow rate is 75sccm) is passed through for 140s to deposit a GaN layer with a thickness of about 30nm on the sapphire substrate layer 1, and then go through a high temperature of 1070°C After processing for 270s, a buffer layer 2 is formed on the substrate layer.

[0060] (2) At a temperature of 1050 °C, TMGa (flow rate of 220 sccm) and NH 3 (The flow rate is 36000sccm) as the source, grow for 3800s, and grow a 2 μm non-doped GaN layer 3 on the buffer layer 2 .

[0061] (3) At a temperature of 1050 ° C, TMGa (flow rate of 270 sccm) and NH 3 (The flow rate is 36000sccm) as the source, while using SiH 4 (The flow rate is 6 sccm) for the dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com