Slip casting roof bolt with anticorrosive casing pipe

A technology for grouting bolts and anti-corrosion casings, which is applied in the installation of bolts, mining equipment, and earth-moving drilling, etc., can solve the problems of difficulty in ensuring the fullness of the slurry, affecting the service life, and affecting the reliability of the bolt body. To achieve the effect of superior cost performance, durability and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

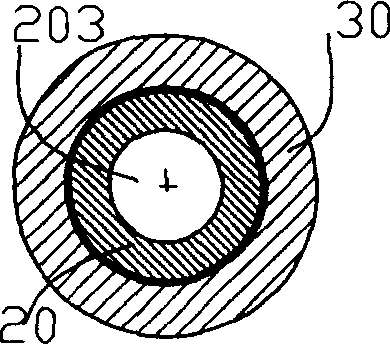

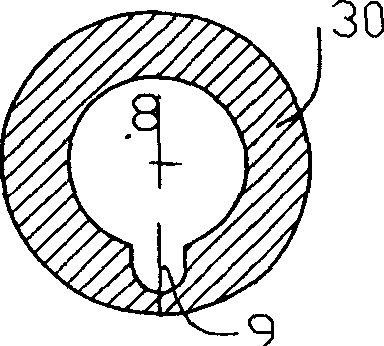

[0052] Such as Figure 1~3 As shown, a bolt with an anti-corrosion casing is composed of a bolt body 1, an orifice connecting section 2, a casing 4, an anchor head 5, a support plate 6, a fastening nut 7, and a washer 70. The anchor rod body 1 has a sleeve 4 , one end of which is inserted into the cavity of one end surface 301 of the orifice connection section and threaded, and the other end 102 is connected with the anchor head 5 . The sleeve 4 is arranged along the longitudinal axis of the anchor body 1 , and its one end 42 is connected to the same end face where the orifice connecting section is connected to the anchor body; the other end face 41 of the sleeve extends to the vicinity of the anchor head 5 . The orifice connecting section 2 is a short straight pipe with a partially threaded inner surface and a longitudinal communication hole. The cavity at one end is matched with the anchor rod body, and the other end is sequentially equipped with fastening nuts 7 from its en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com