Hot forging forming method for cylindrical forged piece

A cylindrical and forging technology, used in forging/pressing/hammer devices, forging/pressing/hammering machinery, applications, etc., can solve the problems of mandrel drawing process forming, the difference between the inner and outer diameters is not large, and the forming cannot be used. , to avoid poor stress conditions, improve production efficiency, and improve the qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

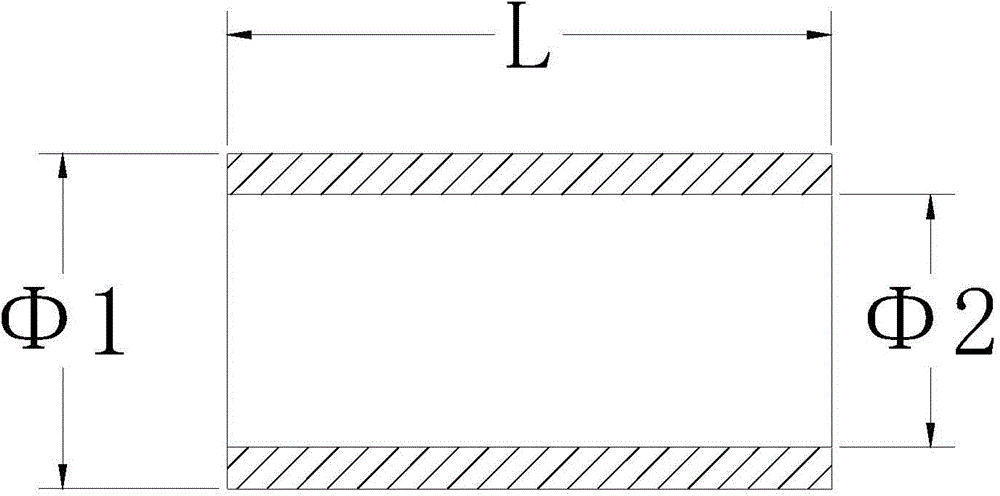

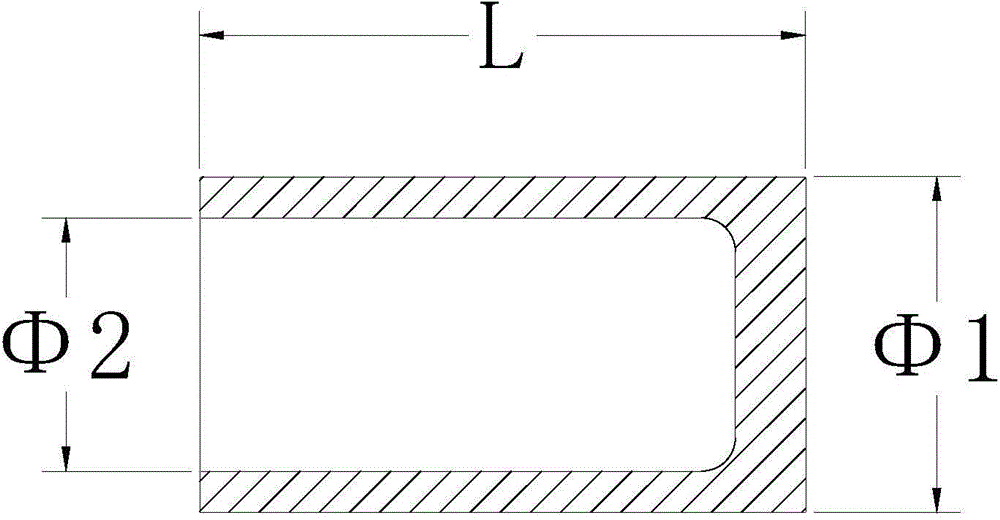

[0055] Manufacture punch 1, cylinder die 2, chassis 3 according to the design size of the cylindrical forging that needs to be manufactured; the design length of the cylindrical forging is L=1740mm, the design outer diameter is Φ1=φ720mm, and the design inner diameter is Φ2=φ430mm, The design depth of the inner cavity is H=1740; the drain plate 5 is manufactured; the minimum diameter of the leak hole on the leak plate 5 is greater than Φ2=φ410mm, which is equal to φ500mm;

[0056] The punch 1 has a diameter of Φ3 and a length of H4, the Φ3=Φ2, H4=1900mm>L; the inner cavity of the barrel mold 2 has an inner diameter of Φ4=Φ720mm and a height of H5=1740mm,

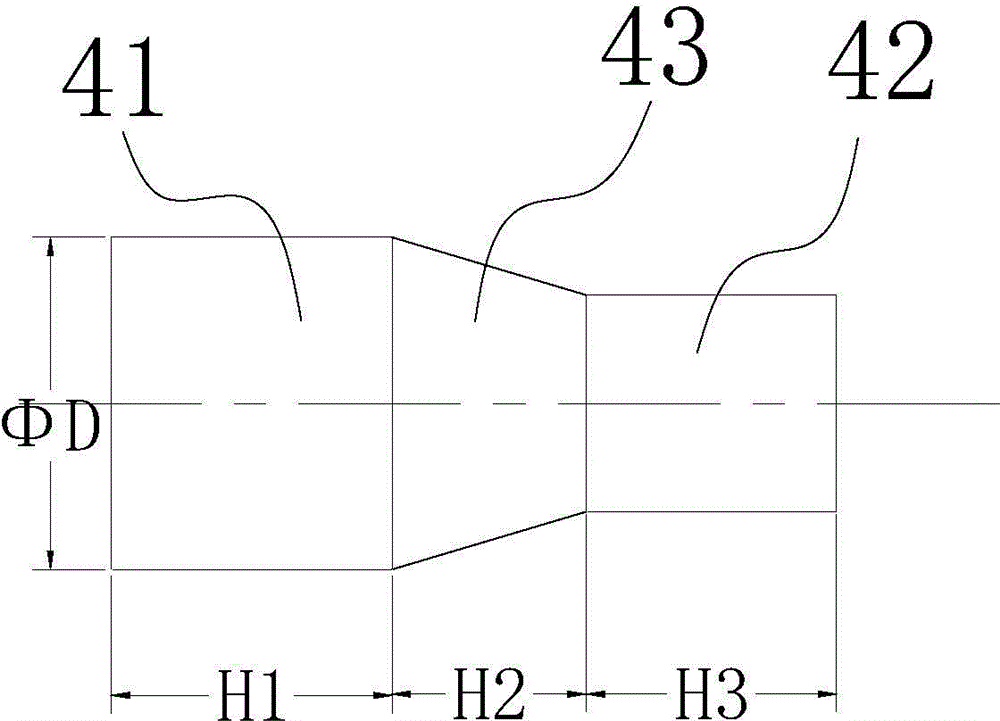

[0057] 2) Heating the steel ingot to within the forging temperature range, elongating and rounding the steel ingot to Φ5; then elongating one end of the electroslag ingot or steel ingot until the total length of the steel ingot is L; the steel ingot is forged into an intermediate blank 4, and the intermediate blank 4 One sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com