Preparation method for polymer-grafted graphene laminated fiber with electrical conductivity and high-strength

A technology of grafting graphite and polymer, which is applied in the manufacture of conductive/antistatic filaments, single-component synthetic polymer rayon, chemical characteristics of fibers, etc. Realization and other issues, to achieve the effect of good conductivity, simple functionalization process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of conductive high-strength polymer grafted graphene layered fiber comprises the following steps:

[0023] 1) dissolving 1 part by weight of graphene oxide raw material in 50-5000 parts by weight of solvent, and treating it in an ultrasonic bath of 1-50 Hz for 0.1-1 hour to obtain a graphene oxide dispersion;

[0024] 2) Dissolving 1-20 parts by weight of polymer in 20-80000 parts by weight of solvent to obtain a clear polymer solution;

[0025] 3) Add the graphene oxide dispersion obtained in step 1) to the polymer solution in step 2), add it while stirring, continue stirring for 0.1 to 48 hours after adding it completely, and add a reducing agent to reduce the graphene oxide to Graphene;

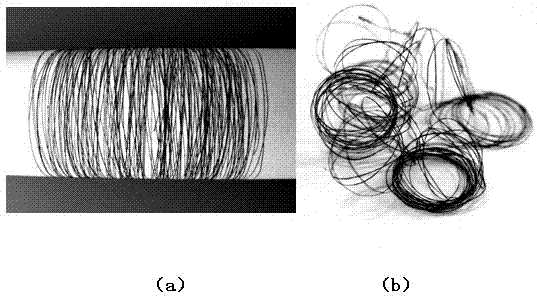

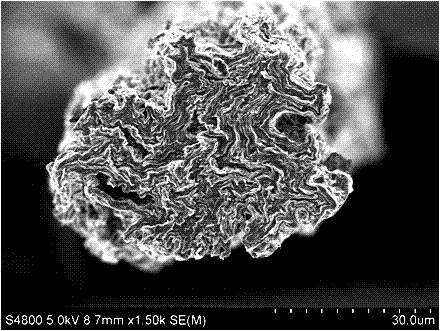

[0026] 4) Centrifuge the reaction solution in step 3), wash away the free polymer, and obtain the polymer-grafted graphene sol; and transfer it to the spinning device, and continuously extrude it from the spinning head with a diameter of 5-1000 μm out, ente...

Embodiment 1

[0033] 1) Dissolving 1 part by weight of graphene oxide raw material in 50 parts by weight of water, and treating it in a 50 Hz ultrasonic bath for 0.1 hour to obtain a graphene oxide dispersion;

[0034] 2) Dissolving 20 parts by weight of polyvinyl alcohol in 80,000 parts by weight of water to obtain a polyvinyl alcohol solution;

[0035] 3) Add the graphene oxide dispersion obtained in step 1) to the polyvinyl alcohol solution in step 2), add while stirring, continue stirring for 0.1 hour after adding completely, add 1 weight part of hydrazine hydrate, 95 O C was reacted for 1 hour, and graphene oxide was reduced to graphene;

[0036] 4) Transfer the reaction solution in step 3) into a centrifuge tube, centrifuge at 15,000 rpm for 30 minutes, pour off the supernatant, add ultrapure water to redissolve the centrifuged sediment, and then centrifuge, repeat this for more than 5 times, and wash away free polyvinyl alcohol, so as to obtain the graphene sol grafted by polyvinyl ...

Embodiment 2

[0039] 1) Dissolving 1 part by weight of graphene oxide raw material in 5000 parts by weight of ethylene glycol, and treating it in a 50 Hz ultrasonic bath for 1 hour to obtain a graphene oxide dispersion;

[0040] 2) dissolving 20 parts by weight of polyethylene glycol in 20 parts by weight of ethylene glycol to obtain a polyethylene glycol solution;

[0041] 3) Add the graphene oxide dispersion obtained in step 1) to the polyethylene glycol solution in step 2), add while stirring, continue stirring for 48 hours after adding completely, add 1 weight part of NaOH, 110 O C was reacted for 1 hour, and graphene oxide was reduced to graphene;

[0042] 4) Transfer the reaction solution in step 3) into a centrifuge tube, centrifuge at 15,000 rpm for 30 minutes, pour off the supernatant, add ethylene glycol to redissolve the centrifuged sediment, and then centrifuge, repeat this for more than 5 times, and wash away free polyethylene glycol, so as to obtain the graphene sol grafted w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com