Preparation method of conductive high-strength graphene-reinforced polymer fiber

A polymer and graphene technology, applied in the manufacture of conductive/antistatic filaments, can solve limitations and other problems, and achieve the effects of low cost, easy availability of raw materials, and good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the graphene-reinforced polymer fiber of conductive high strength comprises the following steps:

[0019] 1) dissolving 1 part by weight of graphene oxide raw material in 50-5000 parts by weight of solvent, and treating it in an ultrasonic bath of 1-50 Hz for 0.1-1 hour to obtain a graphene oxide dispersion;

[0020] 2) Dissolving 1-1000 parts by weight of polymer in 20-4,000,000 parts by weight of solvent to obtain a polymer solution;

[0021] 3) Add the graphene oxide dispersion obtained in step 1) to the polymer solution obtained in step 2), add while stirring, continue stirring for 0.1 to 48 hours after the addition is complete, add a reducing agent, centrifuge or rotary steam, Concentrate, transfer to the spinning device, continuously extrude from the spinning head with a diameter of 5 ~ 1000μm, enter the coagulation liquid, stay for 1S ~ 100h, collect it on the roller after forming, and obtain continuous graphene-reinforced polymer fibers...

Embodiment 1

[0025] 1) Dissolving 1 part by weight of graphene oxide raw material in 50 parts by weight of water, and treating it in a 1 Hz ultrasonic bath for 0.1 hour to obtain a graphene oxide dispersion;

[0026] 2) Dissolving 1 part by weight of polyvinyl alcohol in 20 parts by weight of water to obtain a polyvinyl alcohol solution;

[0027] 3) Add the graphene oxide dispersion obtained in step 1) to the polyvinyl alcohol solution obtained in step 2), add while stirring, continue stirring for 0.1 hour after complete addition, add 1 part by weight of hydrazine, centrifuge, concentrate, transfer to into the spinning device, continuously extruded from a spinning head with a diameter of 5 μm at a constant speed, entered into acetone to stay for 1 second, and then collected on a roller to obtain continuous graphene-reinforced polyvinyl alcohol fibers.

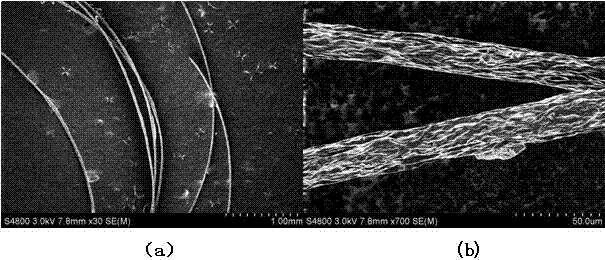

[0028] Through the above steps, the diameter of the obtained polyvinyl alcohol fiber is 3-5 μm, and the graphene sheets are arranged along...

Embodiment 2

[0030] 1) Dissolving 1 part by weight of graphene oxide raw material in 5000 parts by weight of N,N-dimethylformamide, and treating it in an ultrasonic bath at 50 Hz for 1 hour to obtain a graphene oxide dispersion;

[0031] 2) Dissolving 1,000 parts by weight of polystyrene in 4,000,000 parts by weight of N,N-dimethylformamide to obtain a polystyrene solution;

[0032] 3) Add the graphene oxide dispersion obtained in step 1) to the polystyrene solution obtained in step 2), add while stirring, continue to stir for 48 hours after the addition is complete, add phenylhydrazine, spin evaporate, concentrate, turn into the spinning device, continuously extruded from a spinning head with a diameter of 1000 μm at a constant speed, entered into an aqueous calcium chloride solution for 100 hours, and then collected on a roller to obtain continuous graphene-reinforced polystyrene fibers.

[0033] Through the above steps, the diameter of the obtained polystyrene fiber is 500-800 μm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com