Method and device for drawing segmented colored cotton or segmented wool with equal linear density

A linear density and colored cotton technology, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve problems such as difficult to achieve and irregular

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

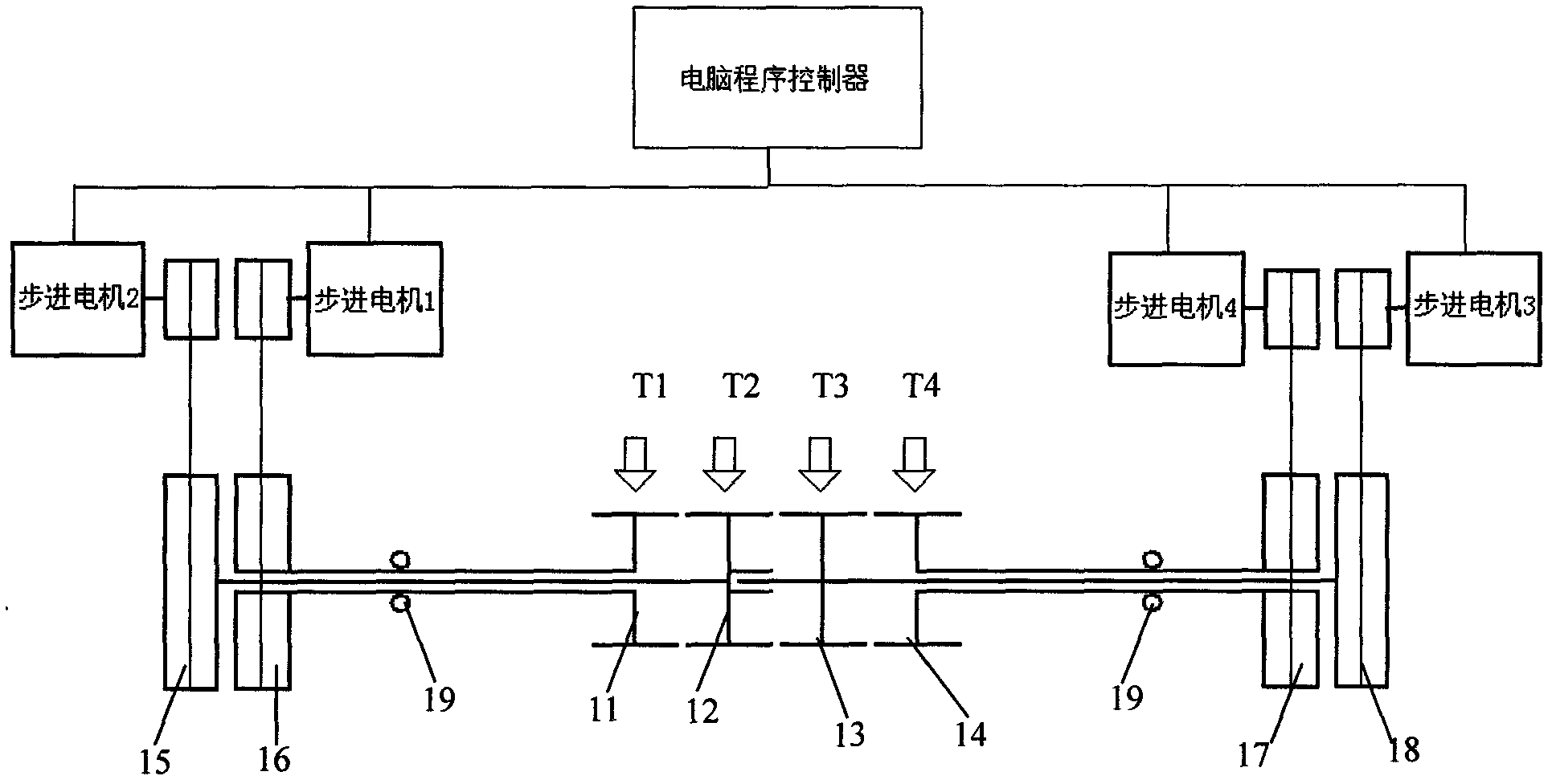

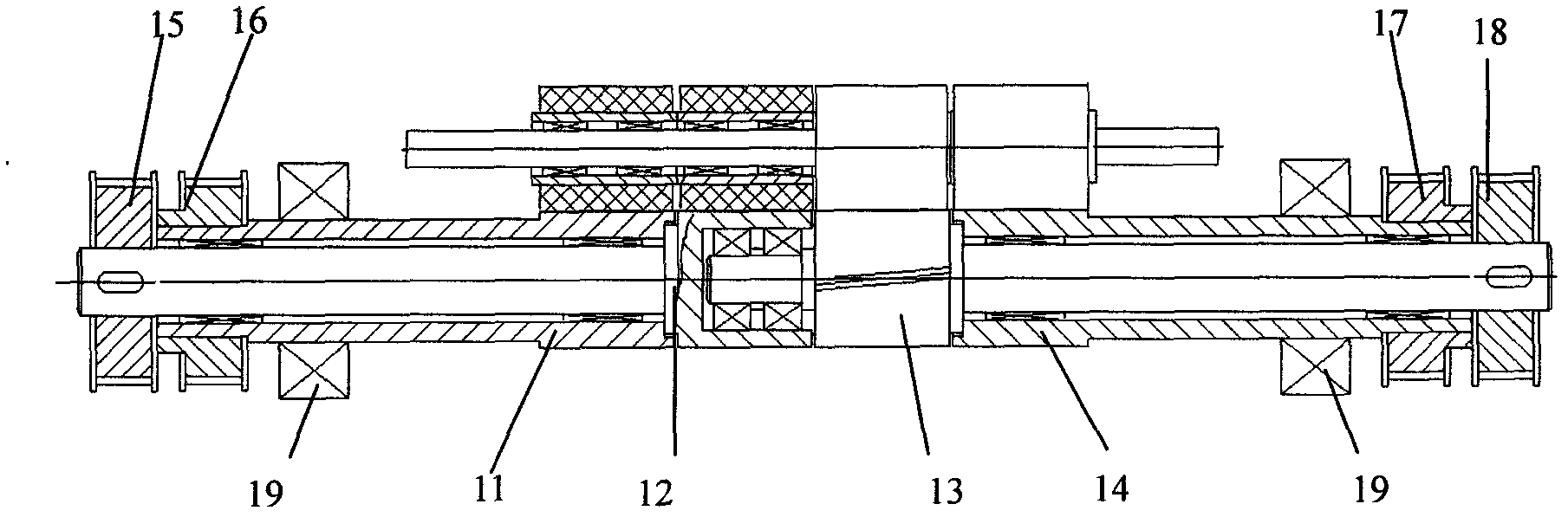

[0024] Such as figure 1 and figure 2 As shown, the coaxial combined roller 1 of this example adopts a four-roller four-control structure, including a roller 11, a roller 12, a roller 13, a roller 14, a toothed wheel 15, a toothed wheel 16, a toothed wheel 17 and a toothed wheel 18.

[0025] Roller 12 shaft end fixed toothed wheel 15, roller 11 is movable sleeved on the shaft, roller 13 shaft end fixed toothed wheel 18, roller 14 is movable sleeved on the shaft, the sleeve end of roller 11 is fixed toothed wheel 16, roller 14 The fixed toothed wheel 17 at the sleeve end, and a whole set of combined rollers is fixed on the wallboard support by bearings and supports 19.

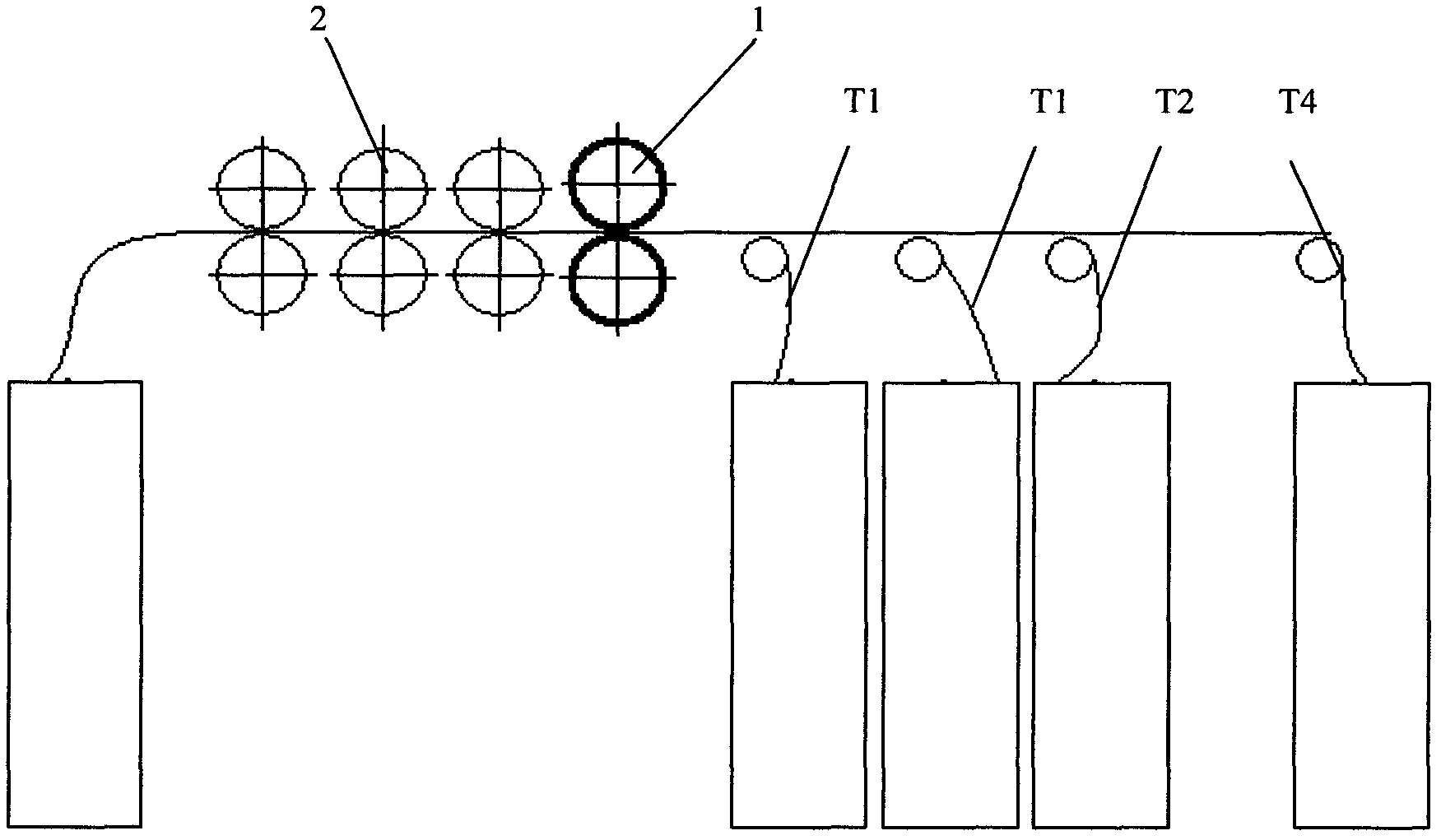

[0026] The four sets of linear density characteristics are respectively T 1 , T 2 , T 3 and T 4 The fiber strips are fed into the roller 11, roller 12, roller 13 and roller 14 in the coaxial combined roller 1 respectively. Roller 11, roller 12, roller 13, roller 14 are driven by toothed wheel 16, toothed ...

Embodiment 2

[0028] Such as Figure 5 As shown, the coaxial combined roller 1 in this example adopts two rollers and two control structures, and after multi-points are applied to the drafting mechanism of the draw frame, the linear density is respectively T 1 , T 2 The fiber strips are fed into the corresponding rollers 11 and 12 of the first pair of coaxial combined rollers through the guide grid or the bell mouth, respectively, and the linear density is T 3 , T 4 The fiber strips are fed into the corresponding rollers 3 and 4 of the second pair of coaxial combined rollers respectively through the guide grid or the bell mouth, and the linear densities are respectively T 5 , T 6 The fiber strips are fed to the corresponding rollers 5 and 6 in the third pair of coaxial combined rollers through the guide bar grid or bell mouth, and so on. The segmental setting of the speed of each roller, in the i-th and i+1 process segments, corresponds to the special number T of each roller in each pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com