Glass fiber thin felt for waterproof coiled material tyre base and preparation method thereof

A technology of glass fiber thin mat and waterproof membrane, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., and can solve the problems of short service life, poor resistance to mold corrosion and aging resistance, and membrane resistance to mold corrosion and aging resistance It is impossible to have fundamental improvement and other problems to achieve the effect of good water resistance, good weather resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

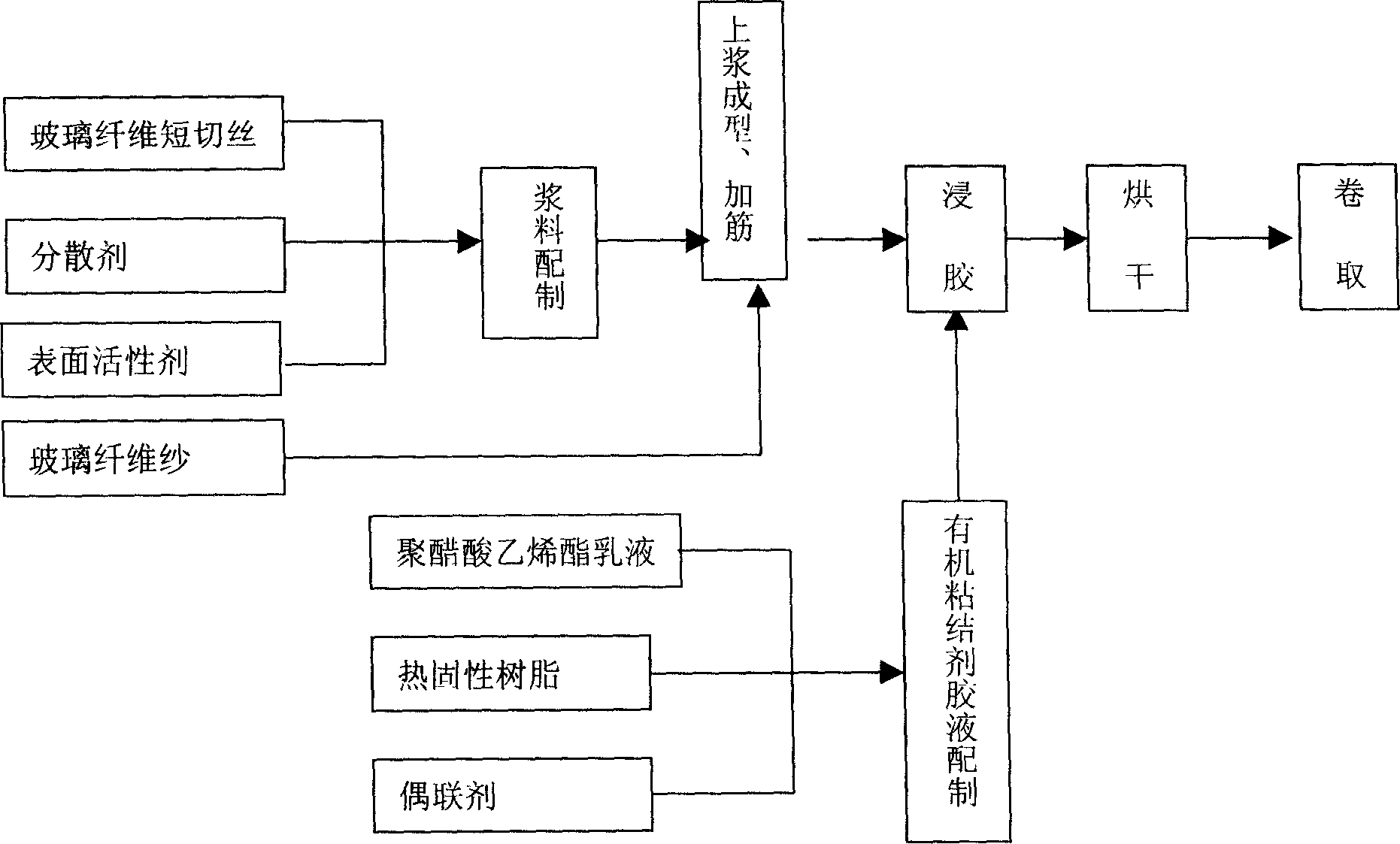

Method used

Image

Examples

Embodiment Construction

[0030] The production specification below is 60 g / m 2 50,000 square meters of thin glass fiber mats used for waterproof coil bases are taken as an example to illustrate the specific production method of the invention:

[0031] 1) Raw material preparation: Purchase 2800kg of medium-alkali glass fiber chopped strands with a diameter of 12-13μm; 120kg of non-alkali glass fiber continuous yarn; 1000kg of dispersant hydroxyethyl cellulose acetate (recycled); 25kg of surfactant (recycled ); thermosetting resin 960kg; KH560 coupling agent 6.72kg.

[0032] 2) Slurry preparation: put glass fiber chopped strands, dispersant, surfactant and water into a mixing tank (stainless steel storage tank) and stir evenly to obtain a slurry, which is pumped into a slurry pool (concrete pool), and the slurry The glass fiber content (percentage by weight) in the material is 0.22%, the addition of hydroxyethyl cellulose acetate is about 10-12kg per 1000 liters of water, and the actual addition is adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com