Method for protecting negative electrode of lithium sulfur battery

A technology for lithium-sulfur batteries and sulfur batteries is applied in the protection field of lithium-sulfur batteries containing metal lithium negative electrodes, and can solve the problems of difficult to withstand batteries, decrease in the conductivity of electrolytes, collapse, etc., and achieve the effect of strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

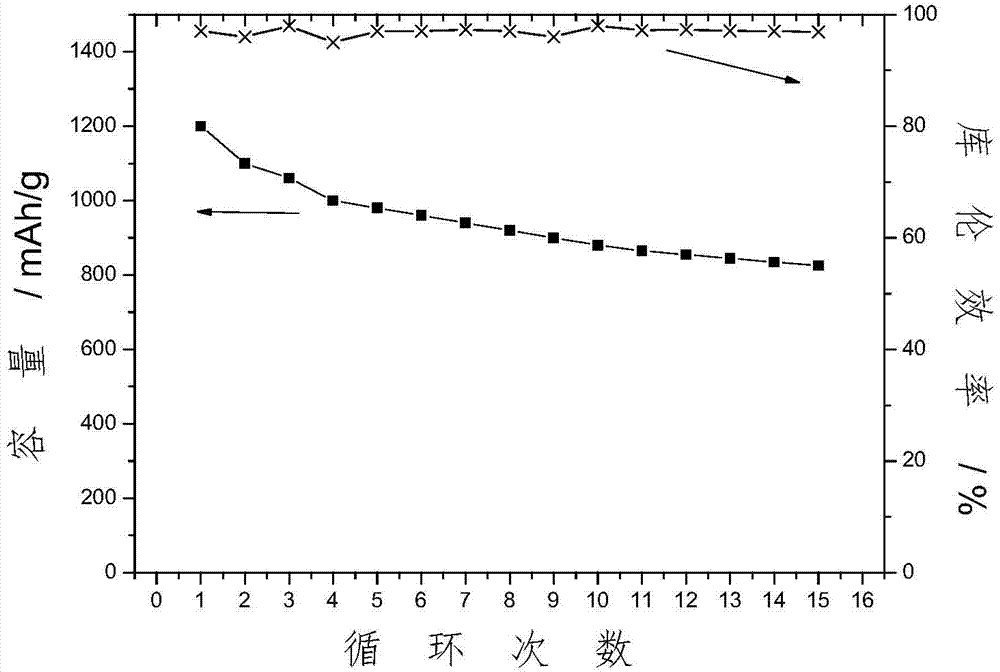

[0039] Add 0.25 g of diethylenetriamine pentacarboxylate (DTPA) into 10 g of 1M LiTFSI / (DME+DOL) electrolyte, and stir vigorously to obtain a clear electrolyte. The composite film obtained above was used to assemble a lithium-sulfur button battery, and its positive electrode was a carbon-sulfur compound (58% sulfur content, PVDF binder). The battery was charged and discharged at a rate of 0.1 for 16 cycles, and the average Coulombic efficiency was 97.5% ( figure 1 );

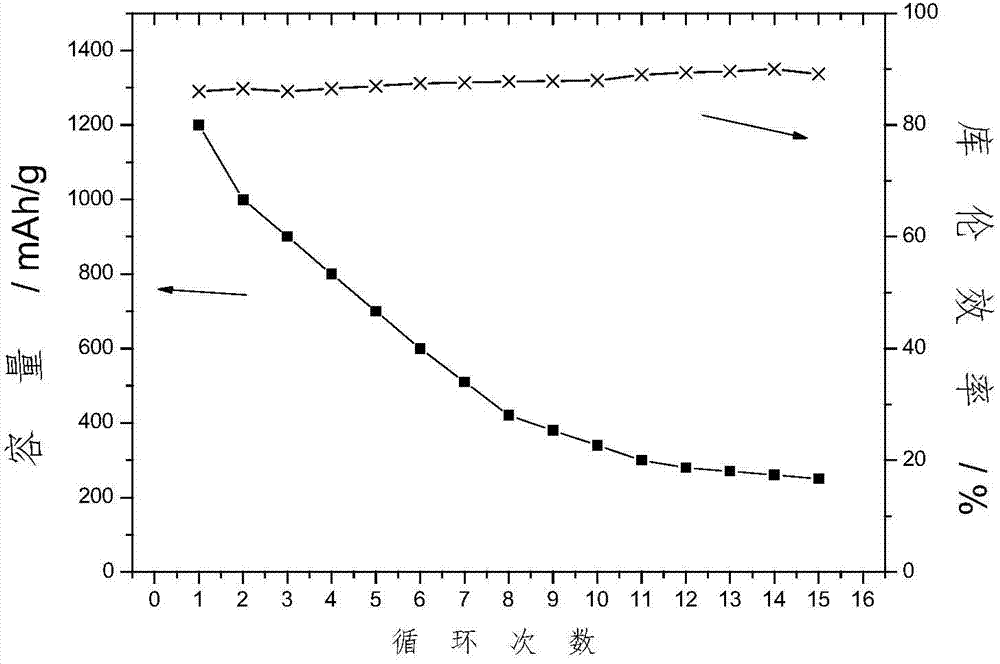

[0040] When the electrolyte without additives is used, and other conditions remain unchanged, the average Coulombic efficiency of the battery is only 88% ( figure 2 ).

Embodiment 2

[0042] Add 0.4 ethylenediaminetetramethylene sodium phosphate (EDTMPS) into 10 g of 1M LiTFSI / (DME+DOL) electrolyte, and stir vigorously to obtain a clear electrolyte. A lithium-sulfur button battery was assembled using the electrolyte obtained above, and its positive electrode was a carbon-sulfur composite (58% sulfur filling, PVDF binder). The battery was charged and discharged at a rate of 0.1 for 13 cycles, and the average Coulombic efficiency was 97.3% ( image 3 ).

Embodiment 3

[0044] Add 0.504 g of amine trimethylene phosphate into 12 ml of LiTFSI / (DME+DOL) electrolyte with a concentration of 1M, and dissolve completely by stirring to obtain a clear electrolyte. A lithium-sulfur button battery was assembled using the electrolyte obtained above, and its positive electrode was a carbon-sulfur composite (58% sulfur filling, PVDF binder). The battery was charged and discharged at a rate of 0.1 for 37 cycles, and the average Coulombic efficiency was 98.7% ( Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com