Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Easy to uniformly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

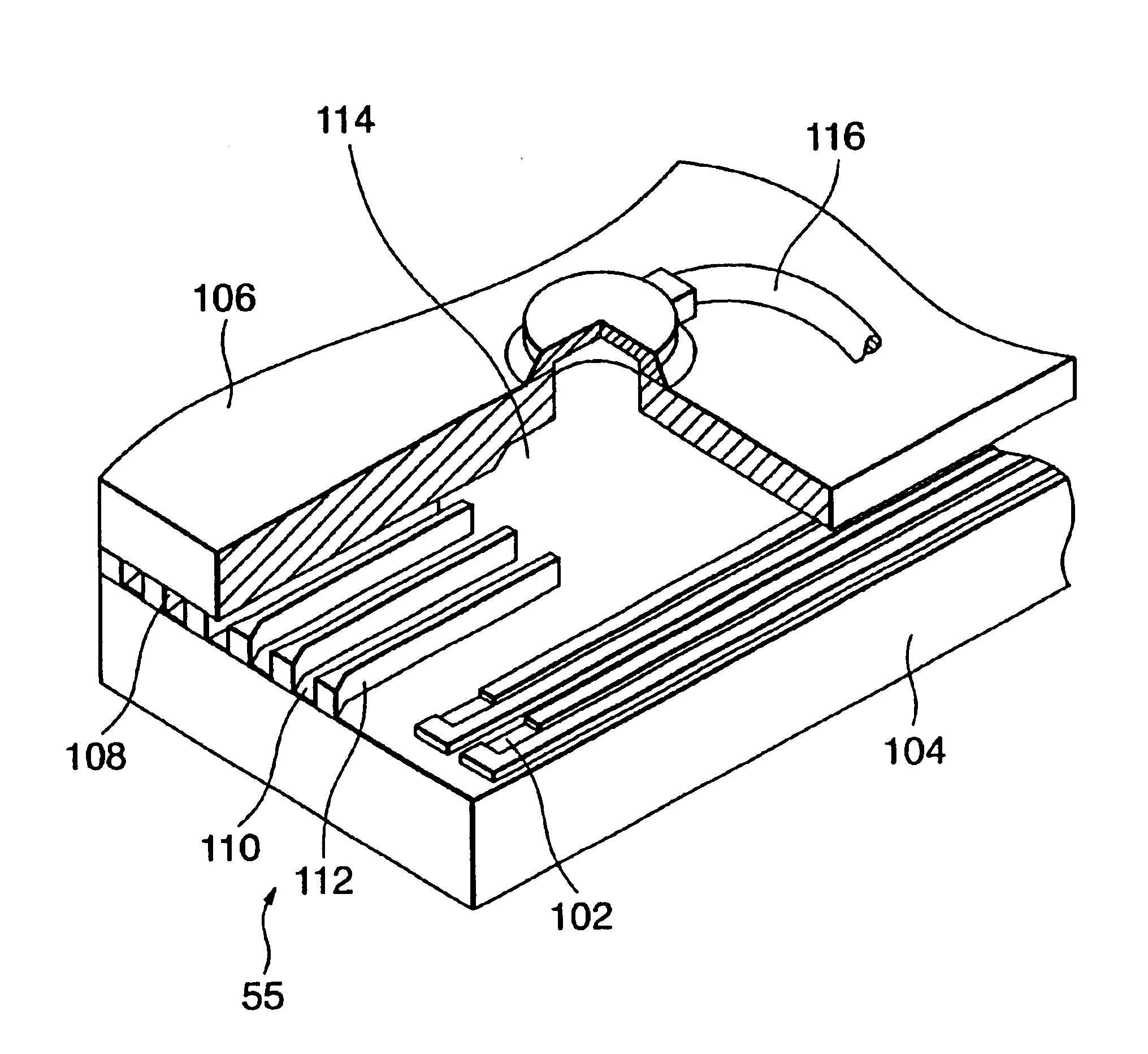

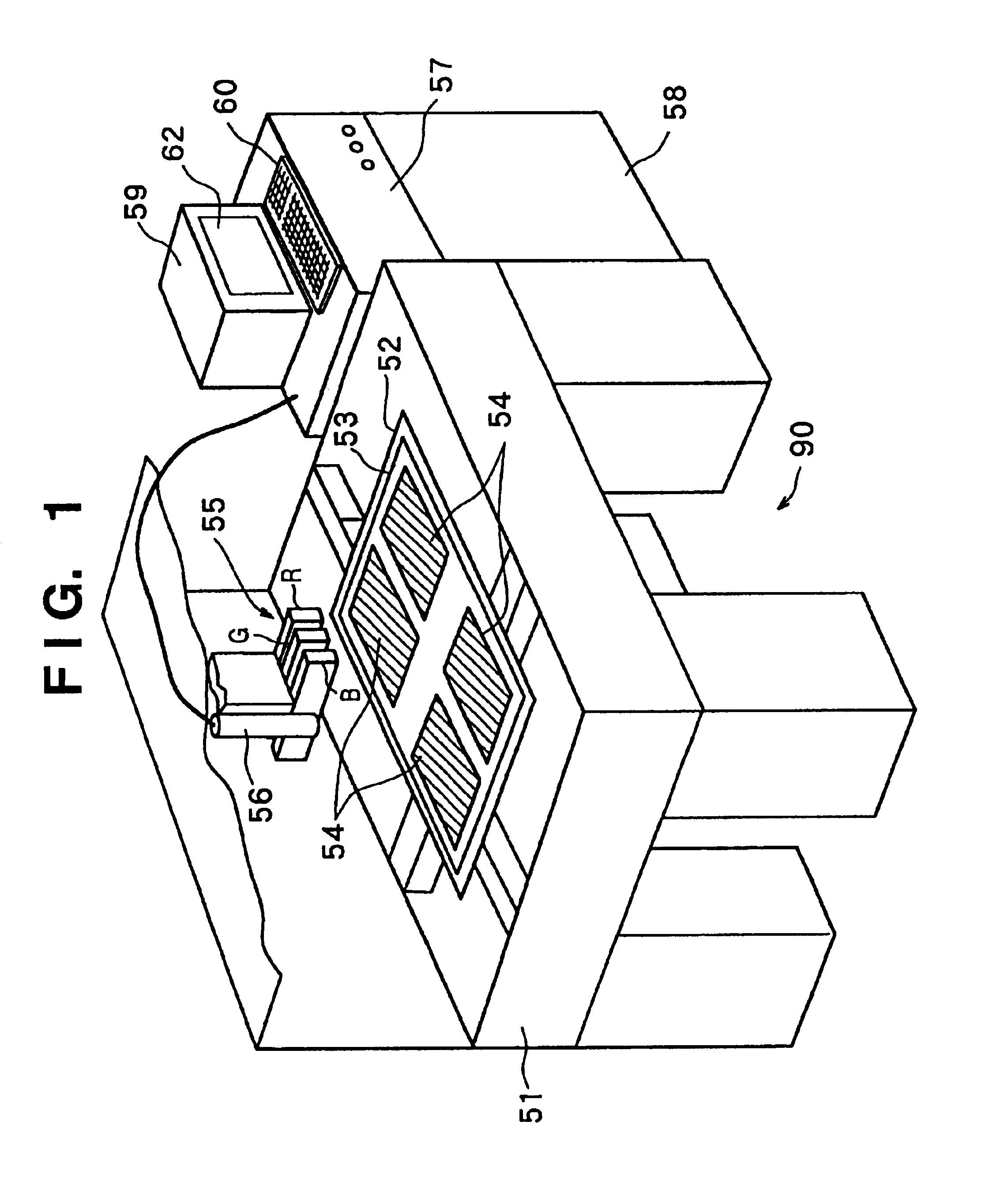

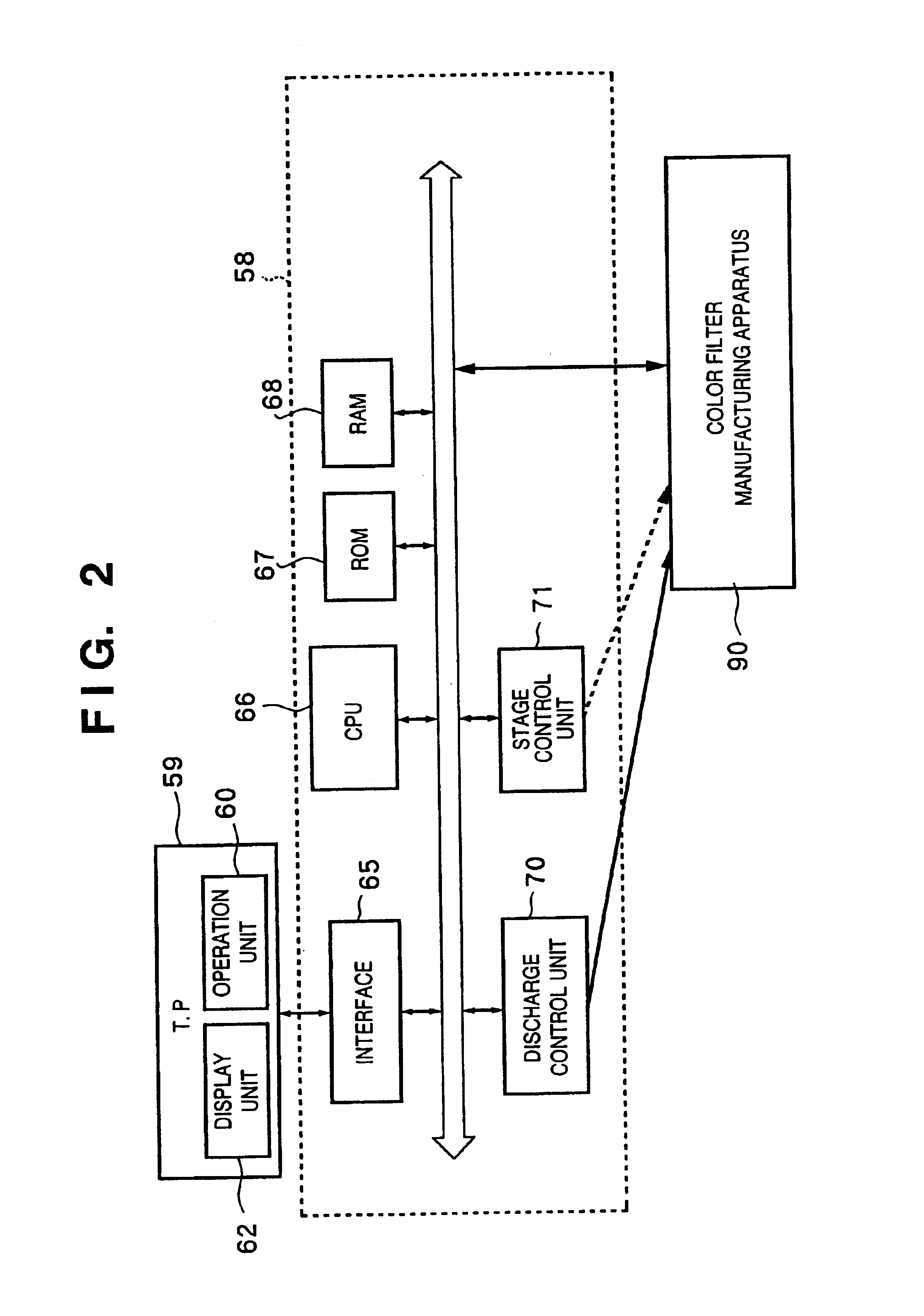

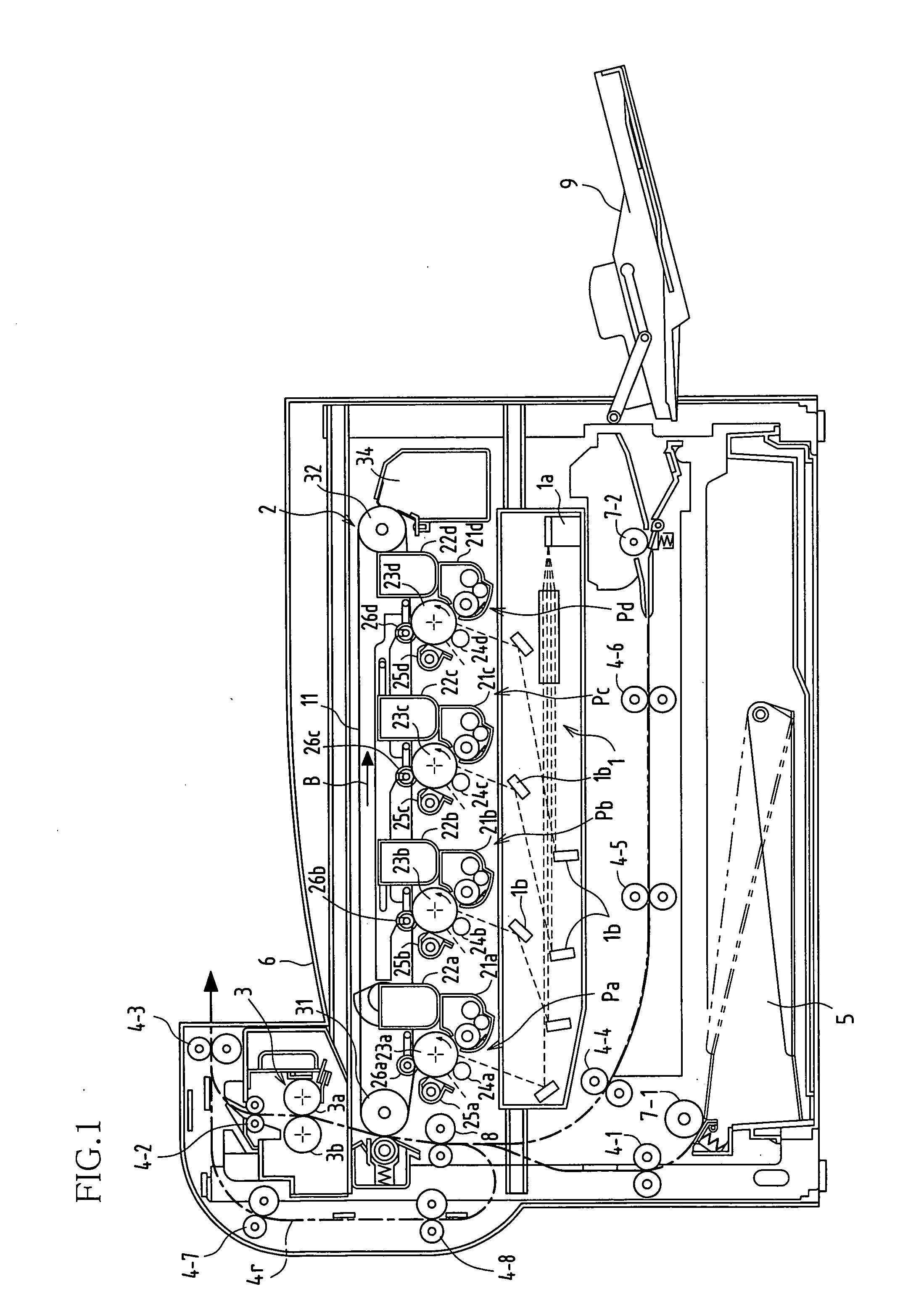

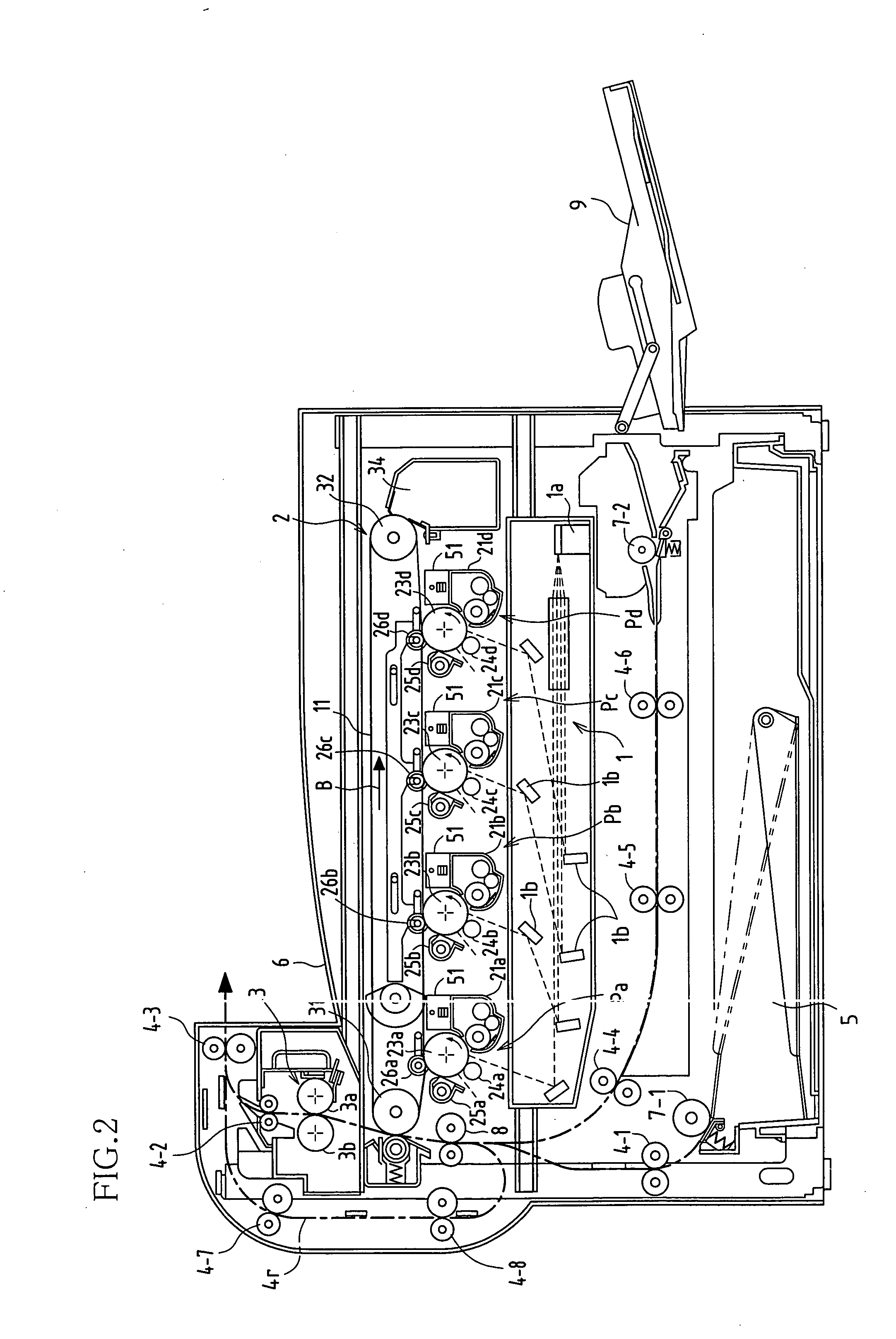

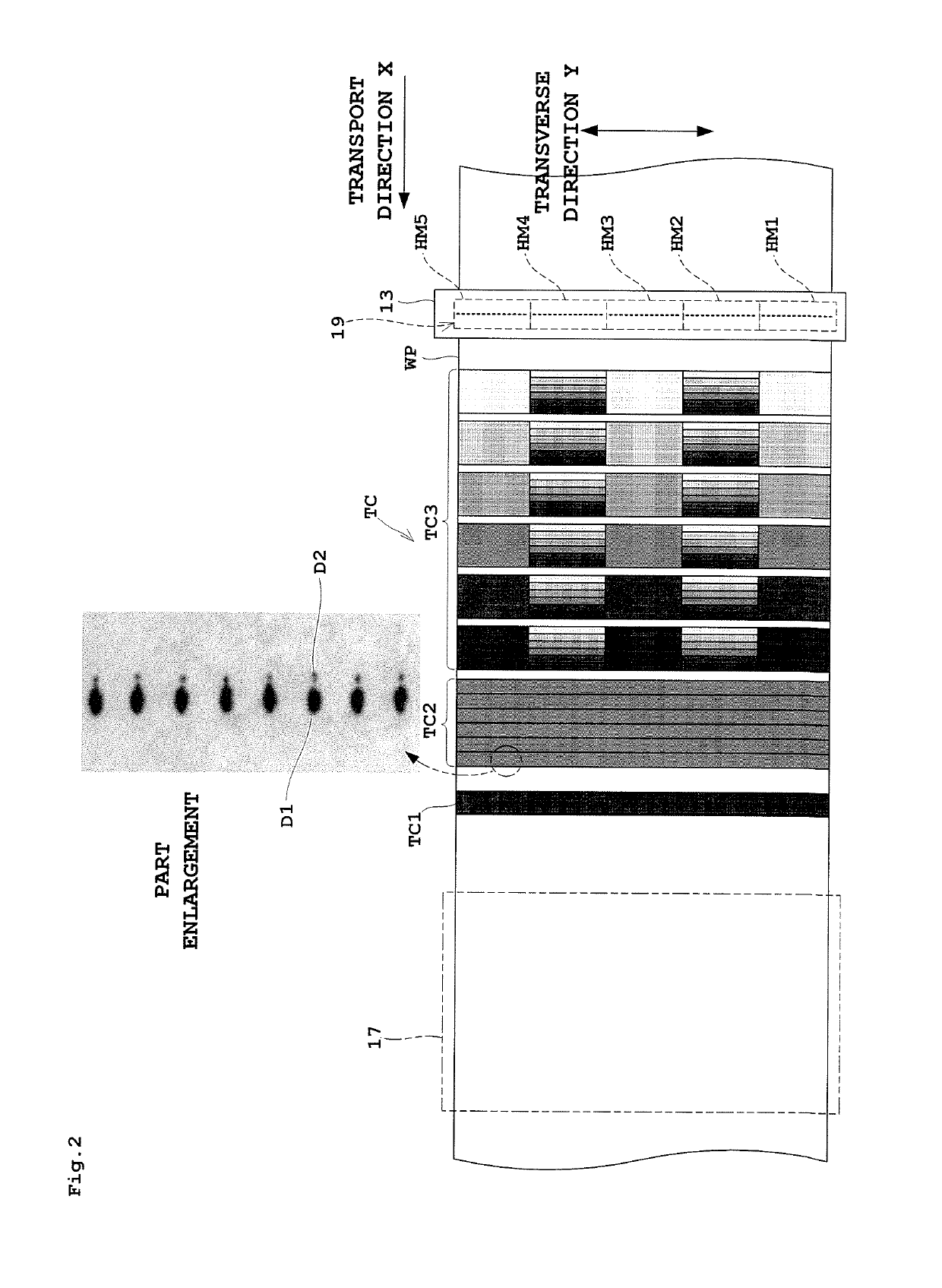

Liquid discharge method and apparatus and display device panel manufacturing method and apparatus

InactiveUS7111755B2Convenient ArrangementEasy to controlOpening closed containersBottle/container closureDisplay deviceDevice Panel

It is an object of this invention to make the amounts of liquid discharged from the nozzles of a liquid discharge head uniform. To achieve this object, there is provided a liquid discharge apparatus for discharging a liquid to a medium using a liquid discharge head having a plurality of nozzles for discharging the liquid, characterized by comprising a discharge amount changing device which can change the amounts of liquid discharged from the respective nozzles of the liquid discharge head independently of each of the plurality of nozzles, the discharge amount changing device including a voltage control device which can change a driving voltage value of a driving pulse to be supplied to each of the plurality of nozzles.

Owner:CANON KK

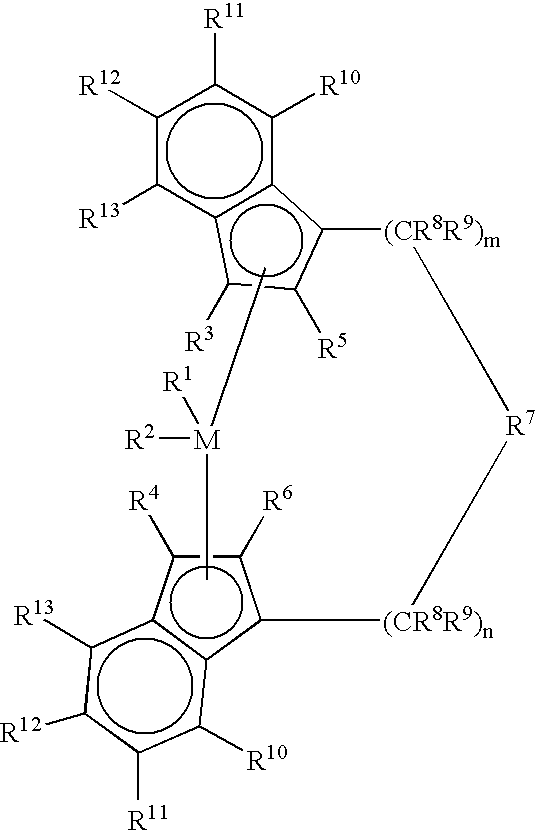

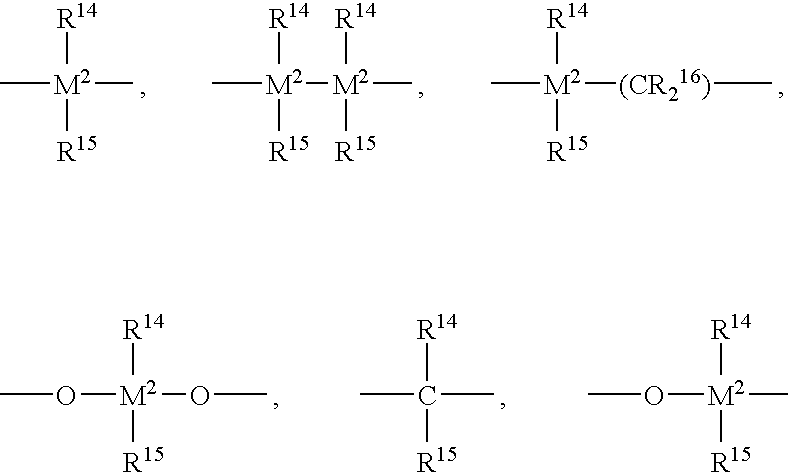

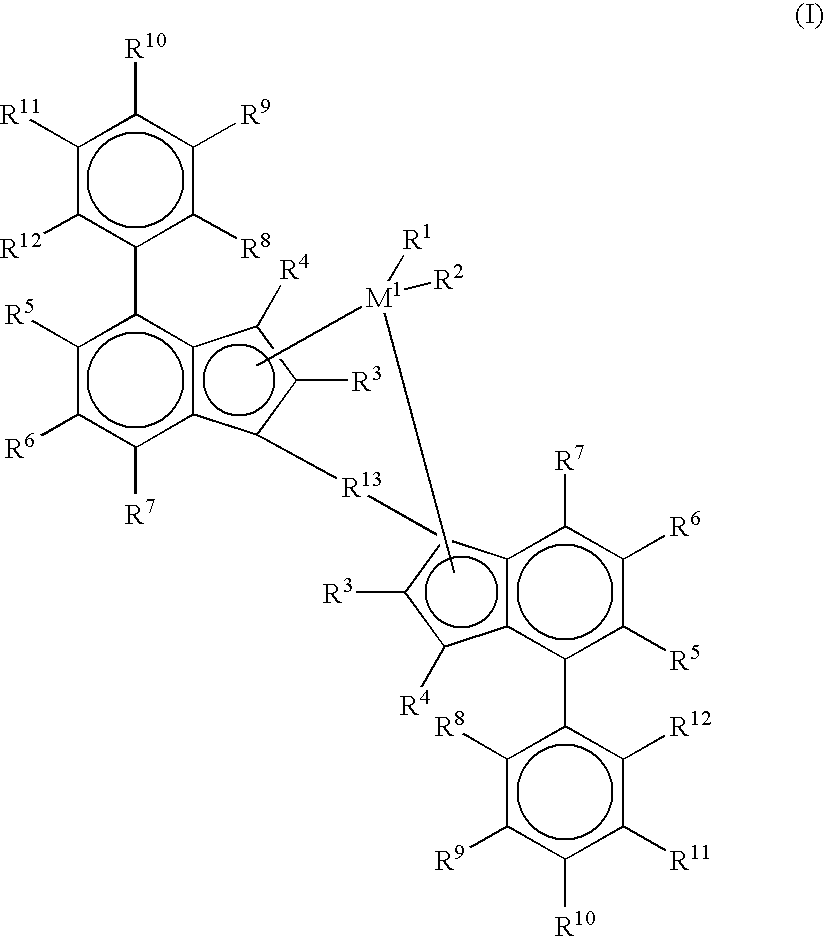

Branched crystalline polypropylene

Branched crystalline polypropylene compositions and methods for the preparation of branched crystalline polypropylene compositions are provided. For example, described herein is a process of preparing a branched crystalline polypropylene composition that includes combining two or more different metallocene catalyst compounds with a polymerization medium that includes propylene, for a time sufficient to provide branched crystalline polypropylene that has from 0.0 wt % to 2.0 wt % ethylene and a heat of fusion of 70 J / g or more.

Owner:EXXONMOBIL CHEM PAT INC

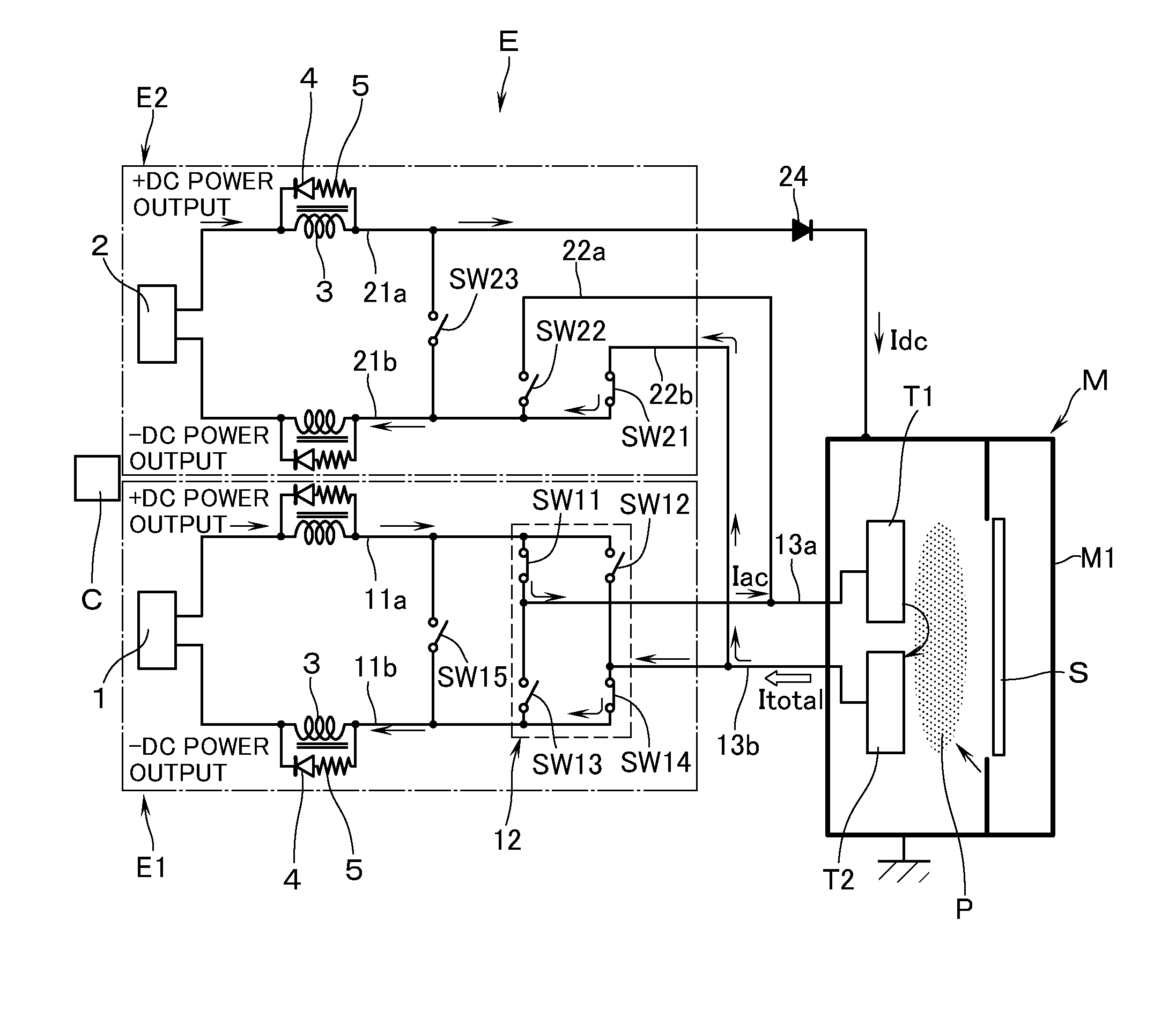

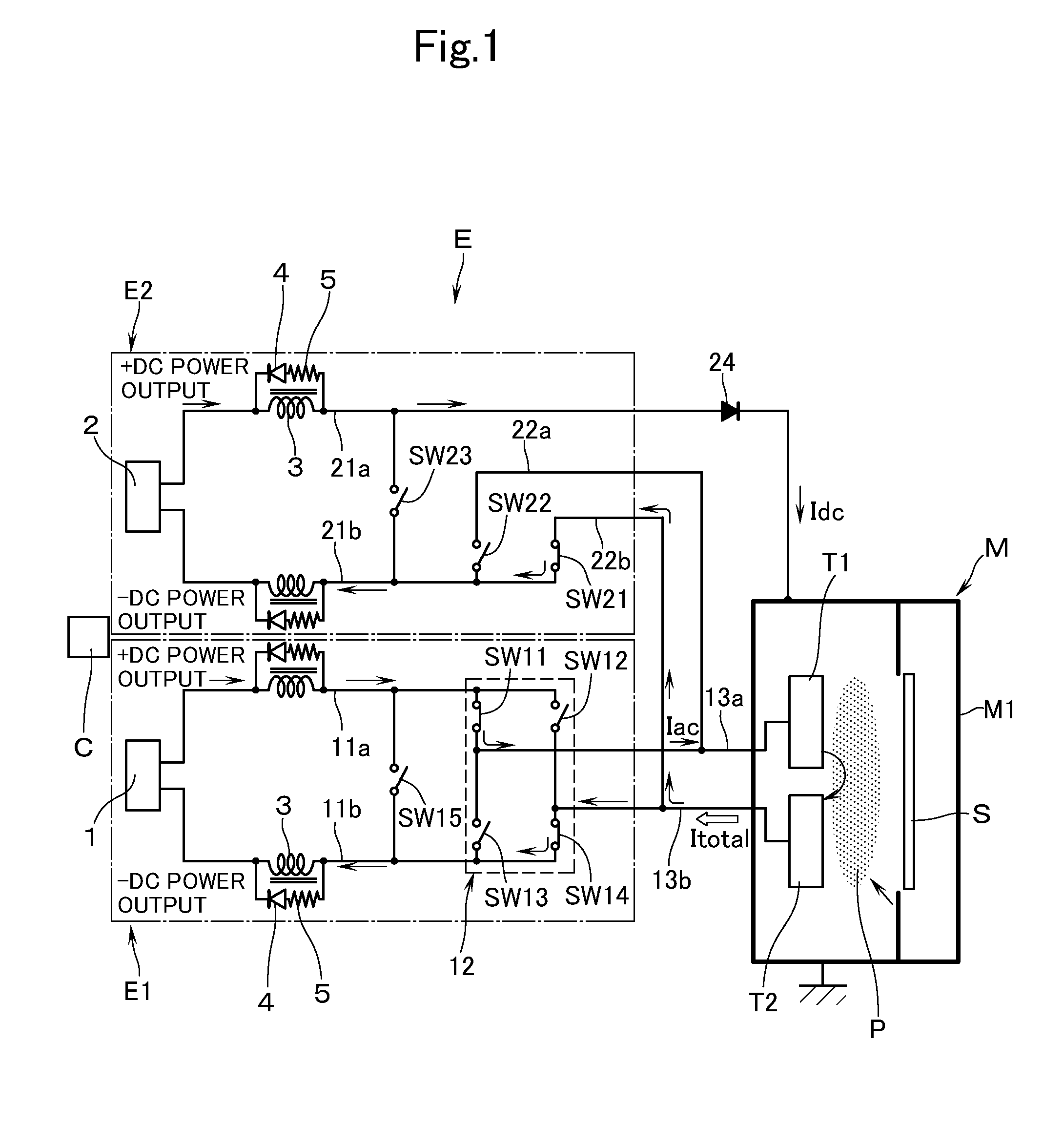

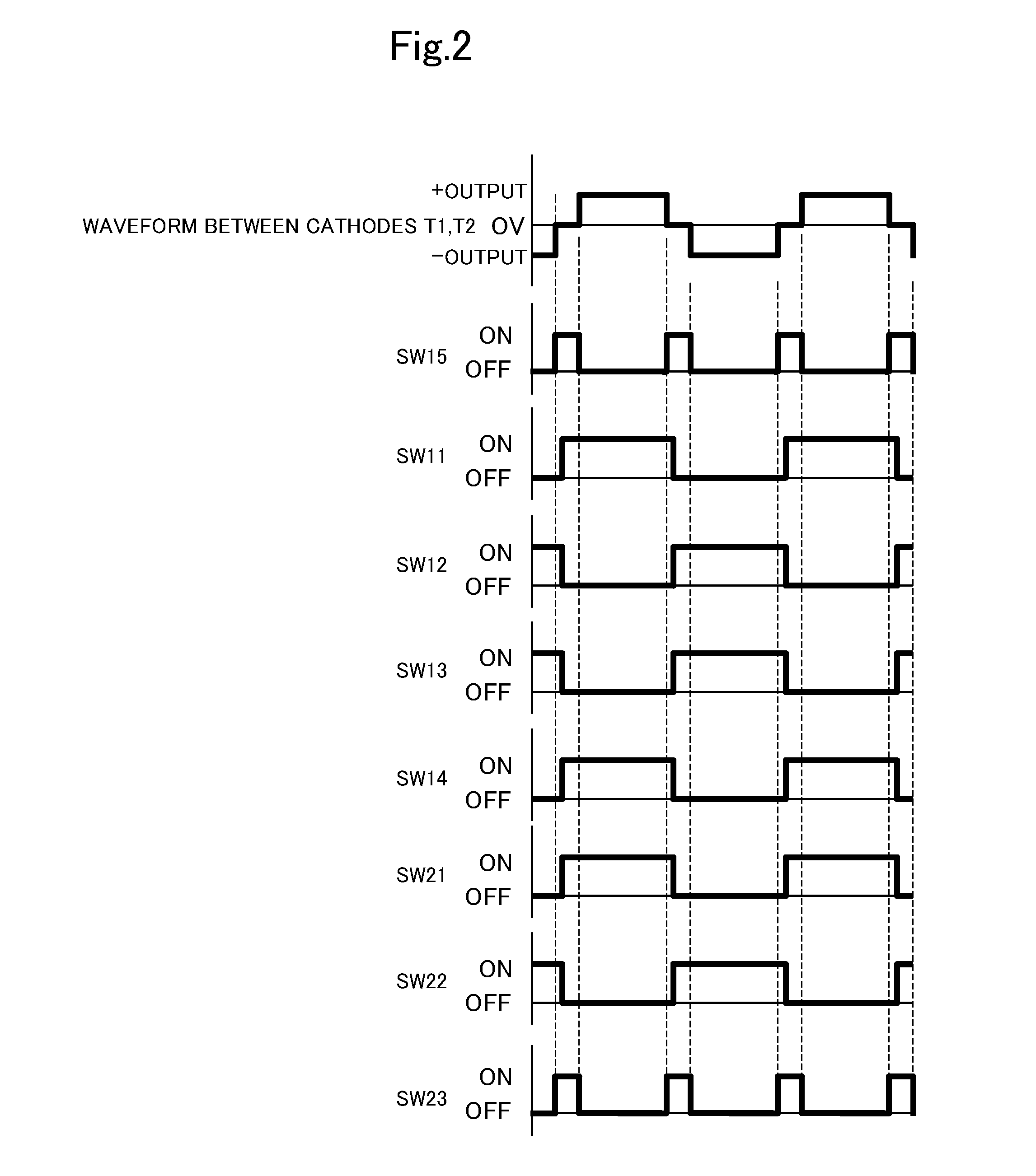

Power supply apparatus

ActiveUS20110100807A1Distribution moreEasy to uniformlyCellsMultiple-port networksEngineeringPower apparatus

There is provided a power supply apparatus which is easy in attempting to unify the thickness distribution of a thin film to be formed on the surface of a substrate even at the time of charging pulsed potential at a low frequency to targets that make respective pairs. The power supply apparatus of this invention has: a first discharge circuit which alternately charges predetermined potential to a pair of targets that are in contact with a plasma at a predetermined frequency; and a second discharge circuit which charges predetermined potential between the ground and the target, out of the pair of targets, that is not receiving output from the first discharge circuit.

Owner:ULVAC INC

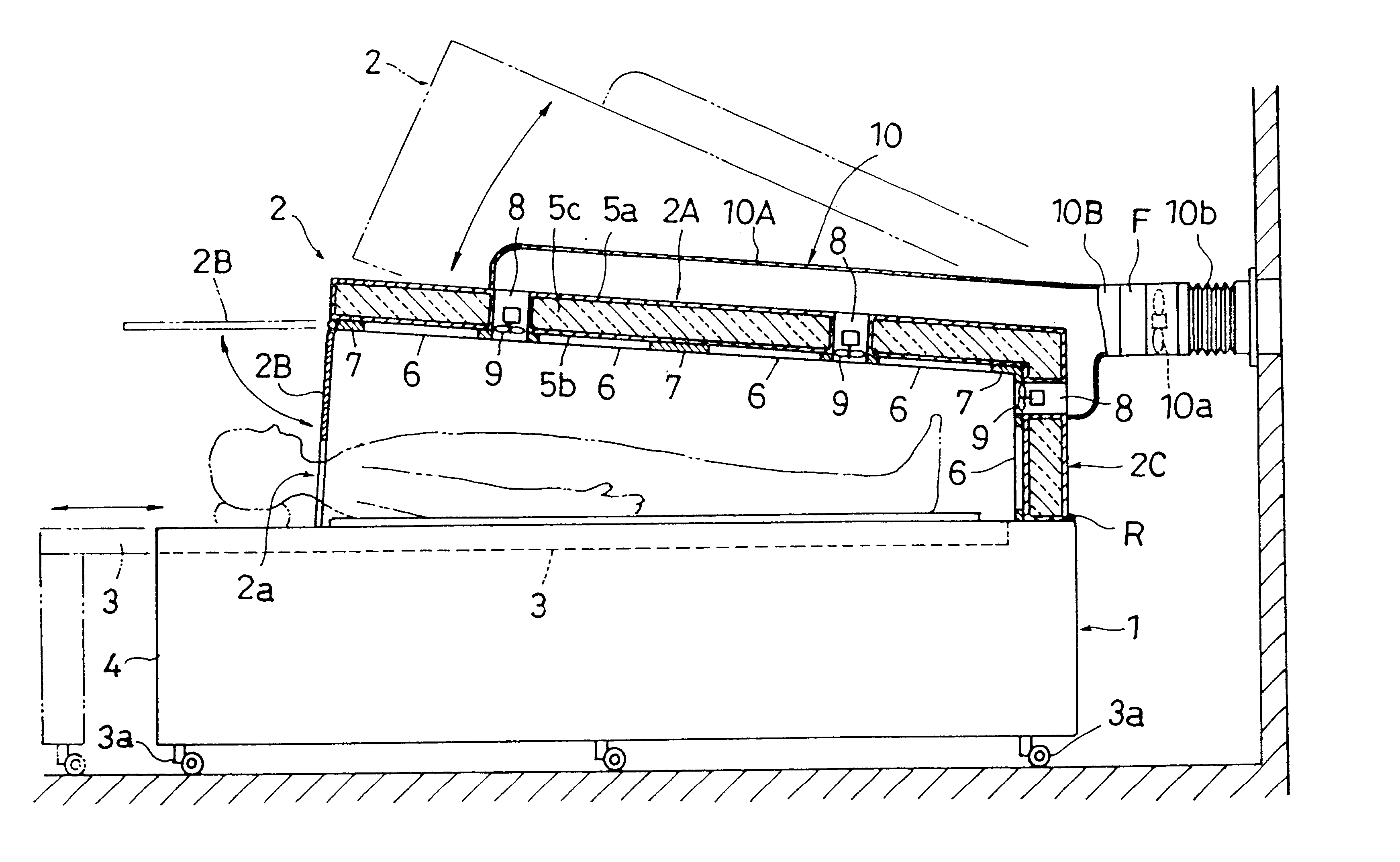

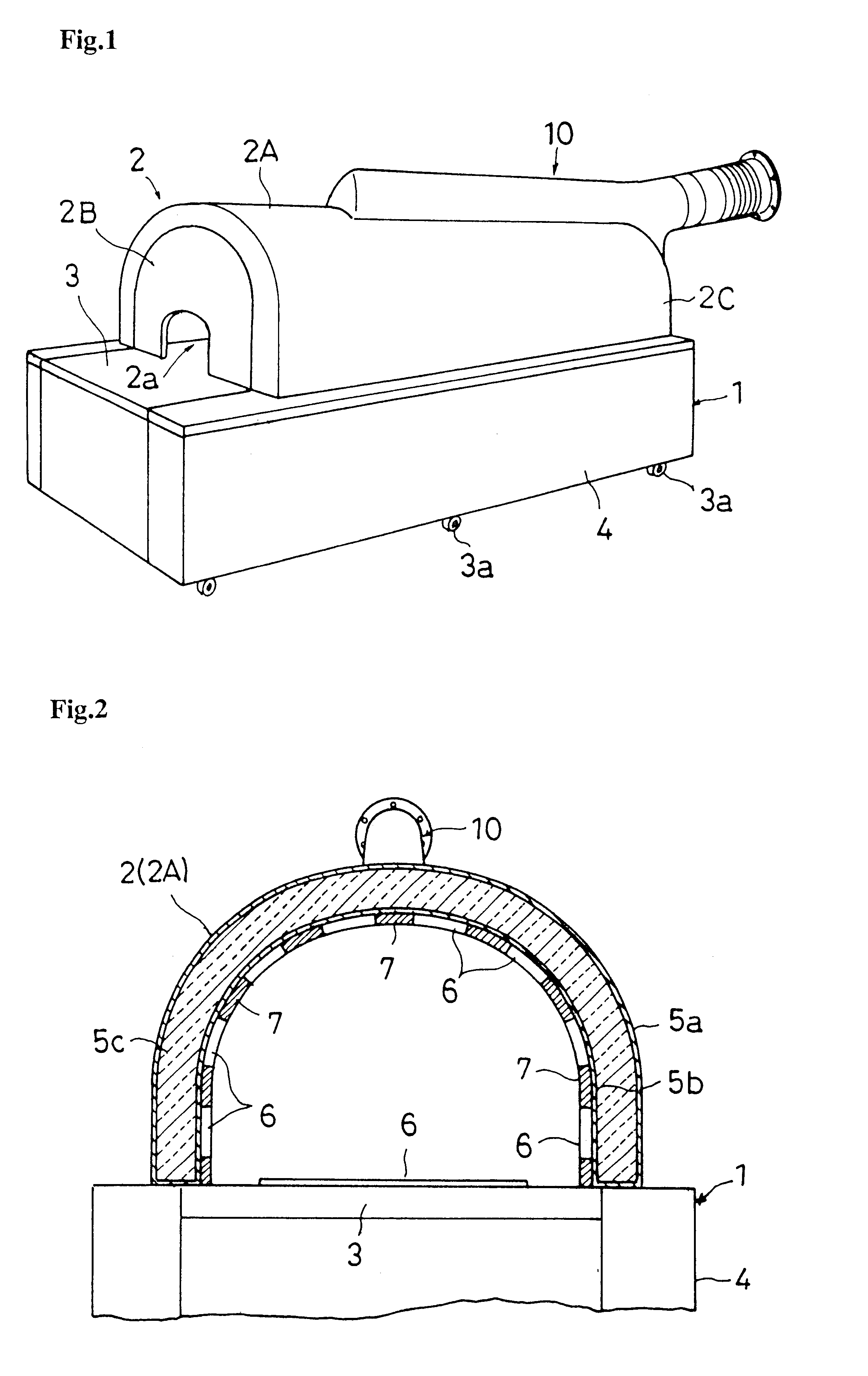

Whole body thermotherapy treatment apparatus

InactiveUS6613071B1Avoid environmentAvoid humidityElectrotherapyBathing devicesWhole bodyFar infrared

A thermotherapy treatment apparatus includes a human body mounting portion, a cover portion for covering a human body corresponding site on the human body mounting portion, a far infrared ray radiation source for radiating far infrared rays onto the human body corresponding site, a ventilation hole for ventilating the human body corresponding site, and a ventilation duct which is in communication with the ventilation hole.

Owner:SUN MEDICAL

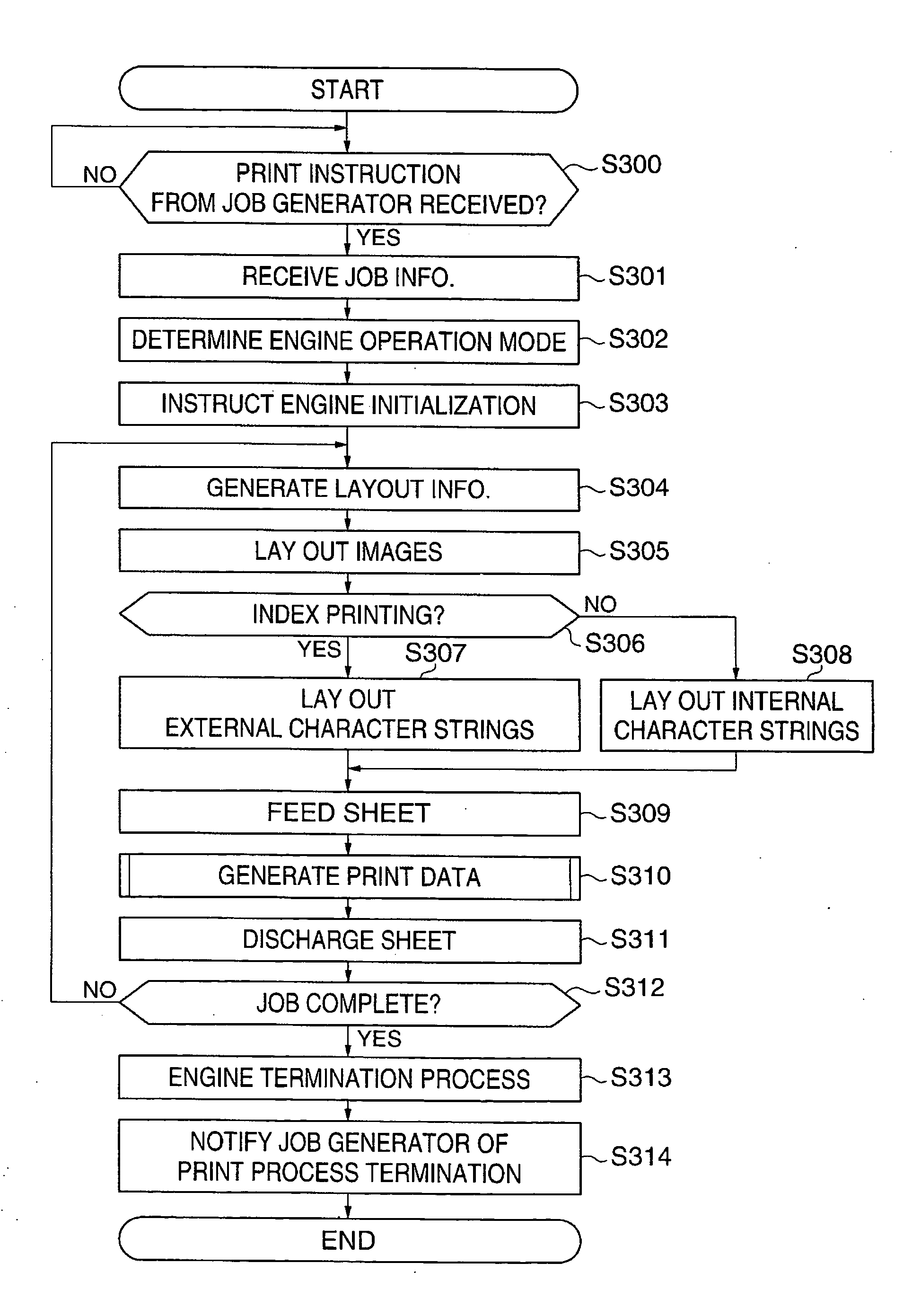

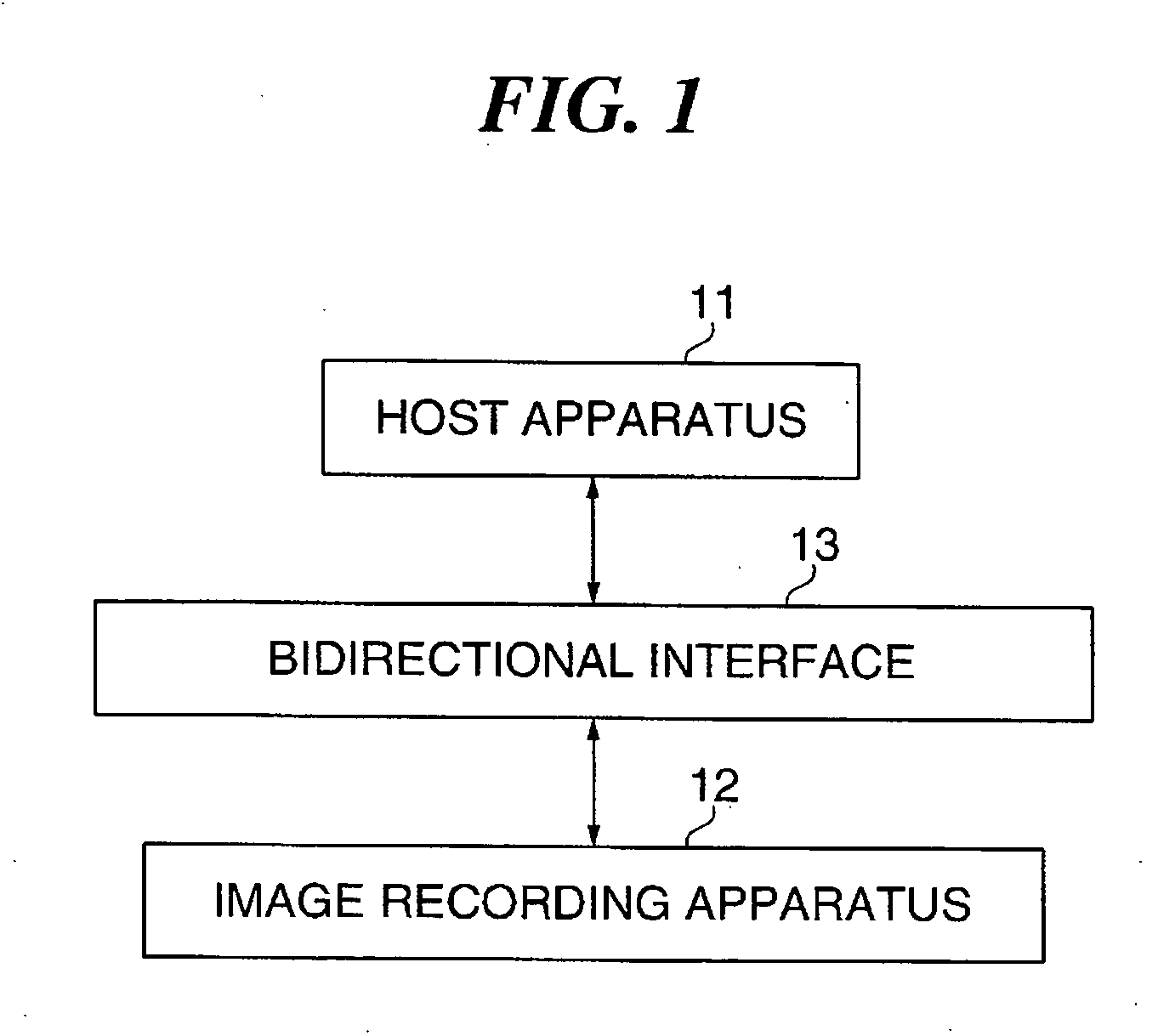

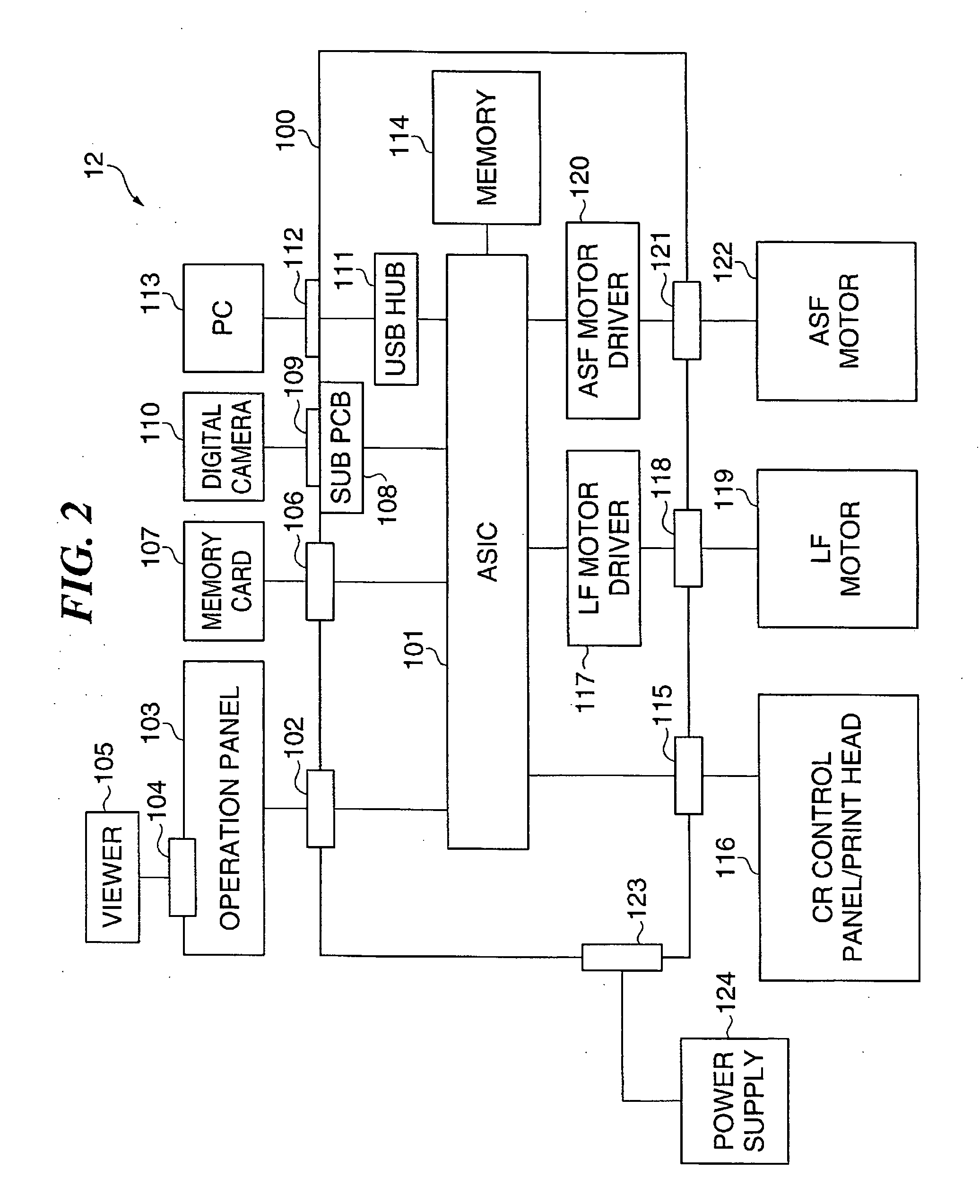

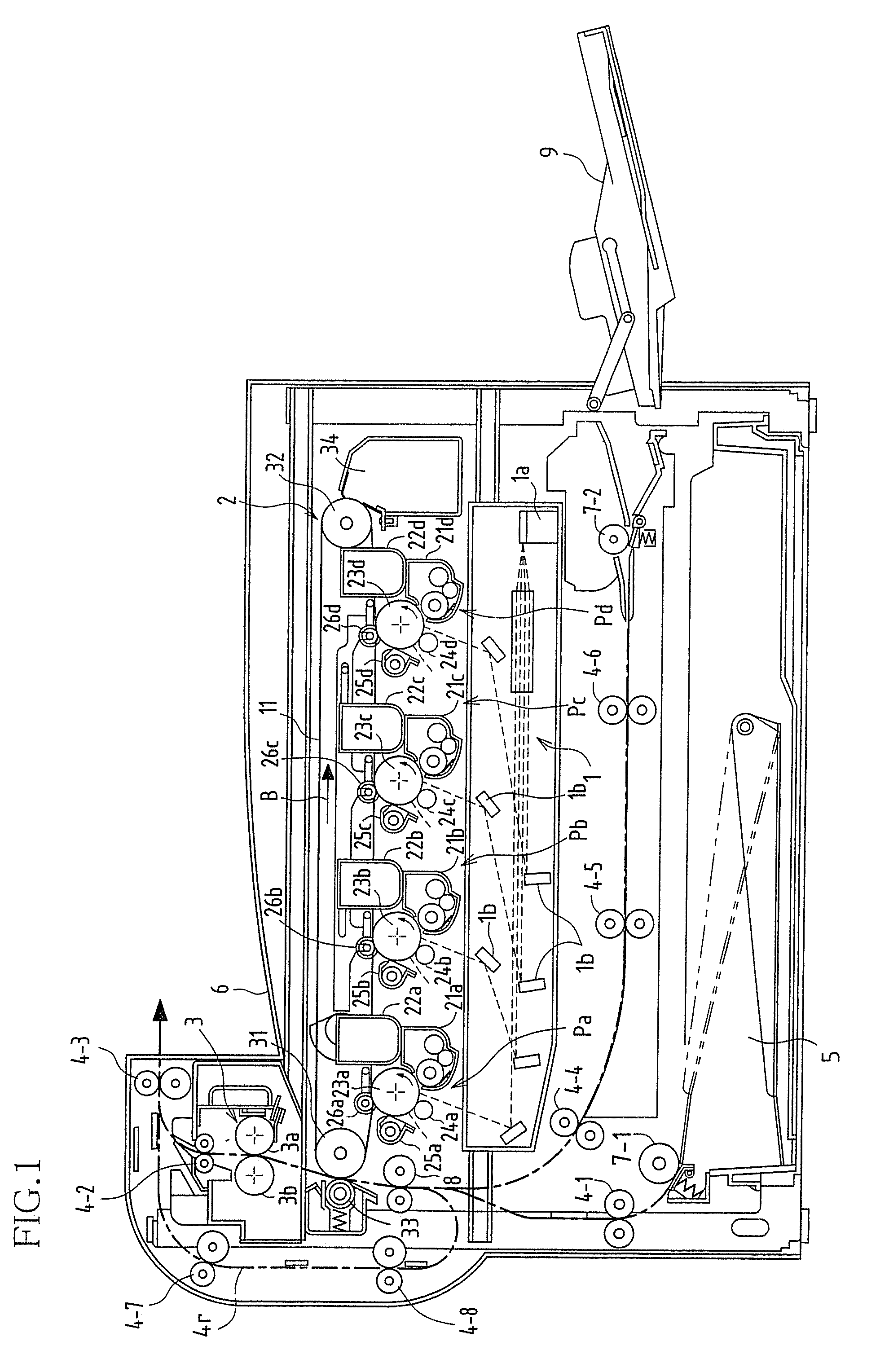

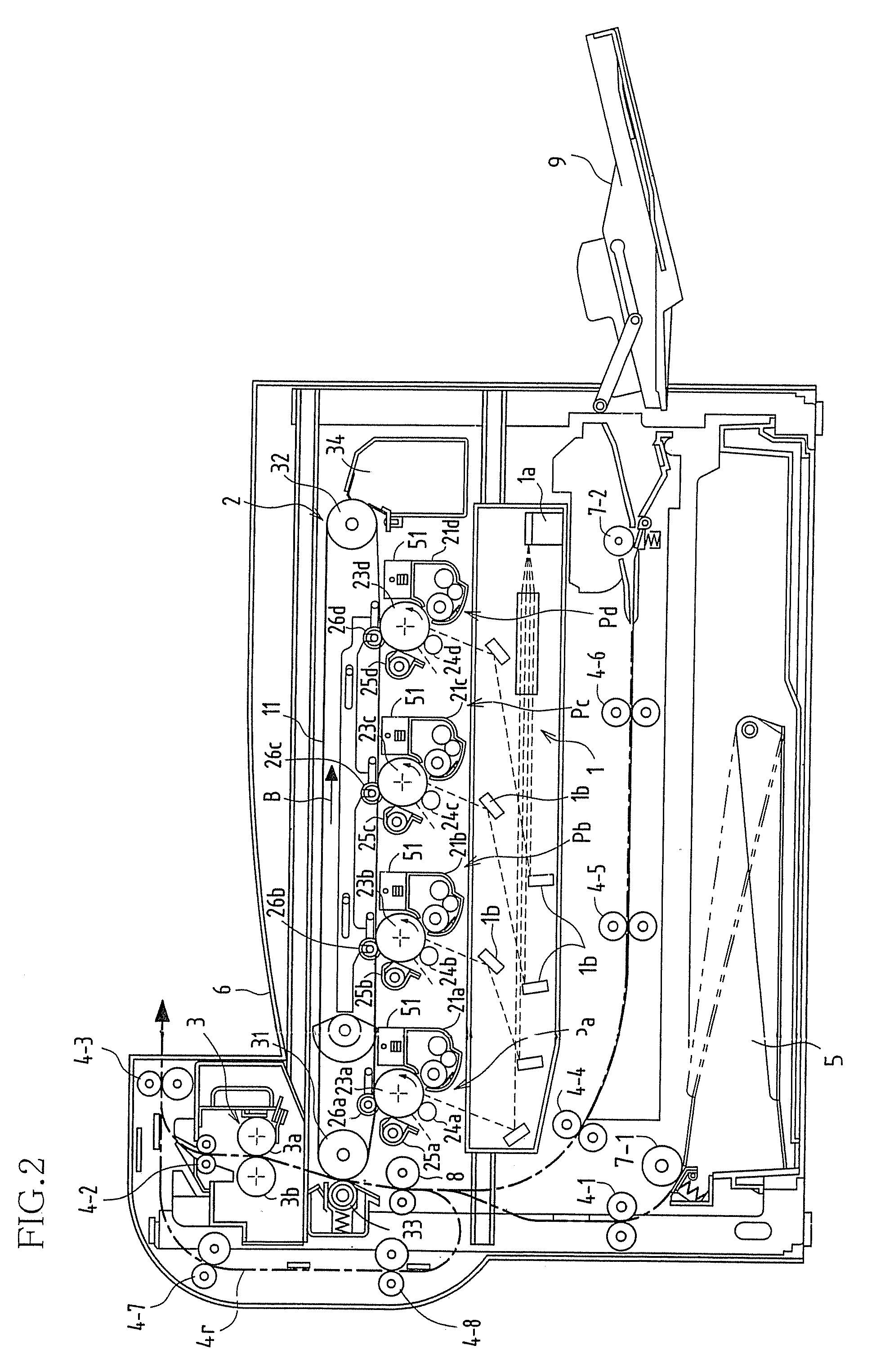

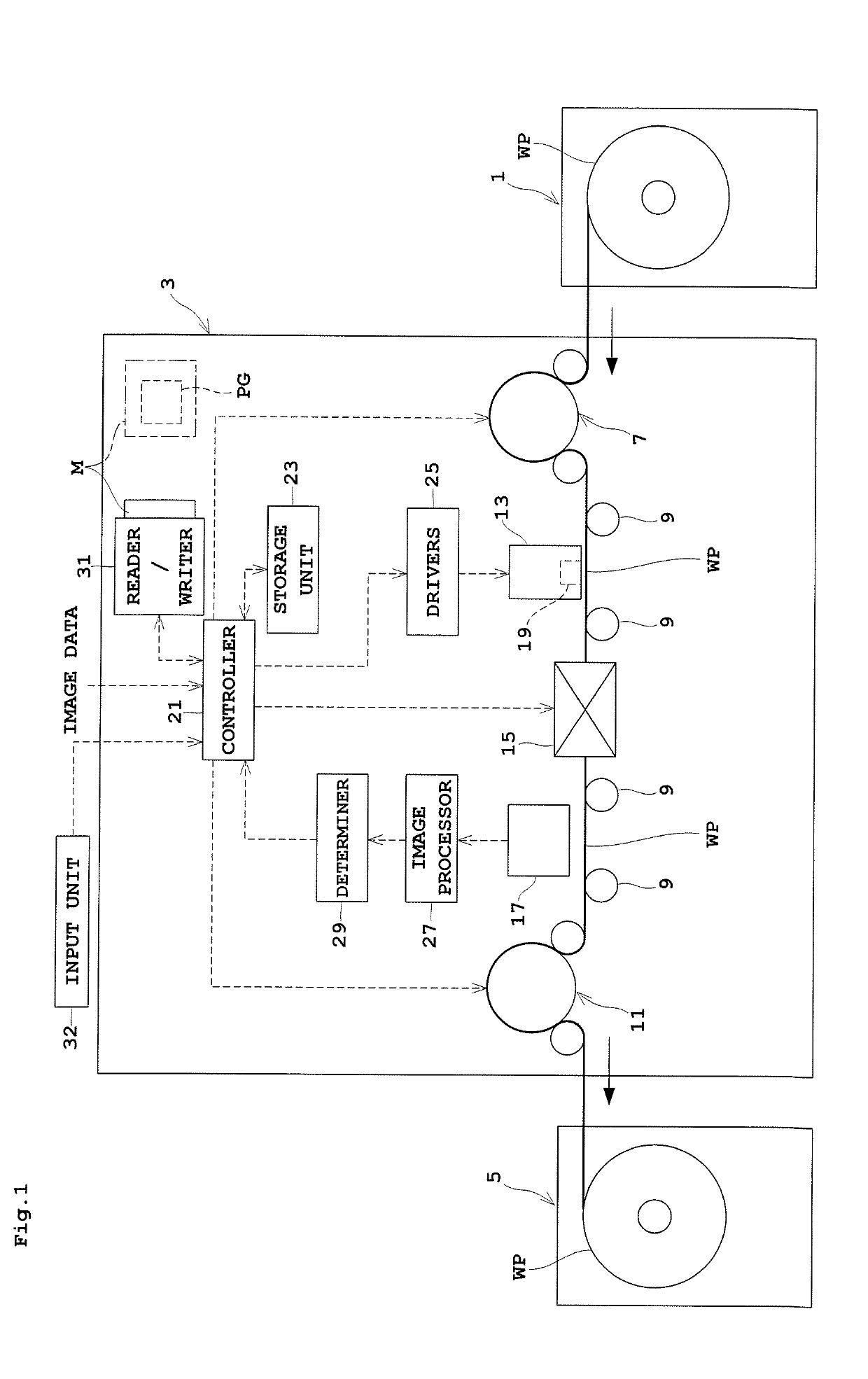

Image recording apparatus, method of generating print data for the same, and control program for implementing the method

InactiveUS20060126120A1Favorable print layoutLow costVisual presentationStill video camerasComputer graphics (images)Image recording

An image recording apparatus that is capable of realizing a favorable print layout where bottom orientations of image data are made uniform easily and at low cost. Rotation information of image data is obtained. A print layout type or pattern in accordance with the rotation information is selected. In accordance with the selected print layout type or pattern, print data for printing a print medium on which the image data is laid out is generated.

Owner:CANON KK

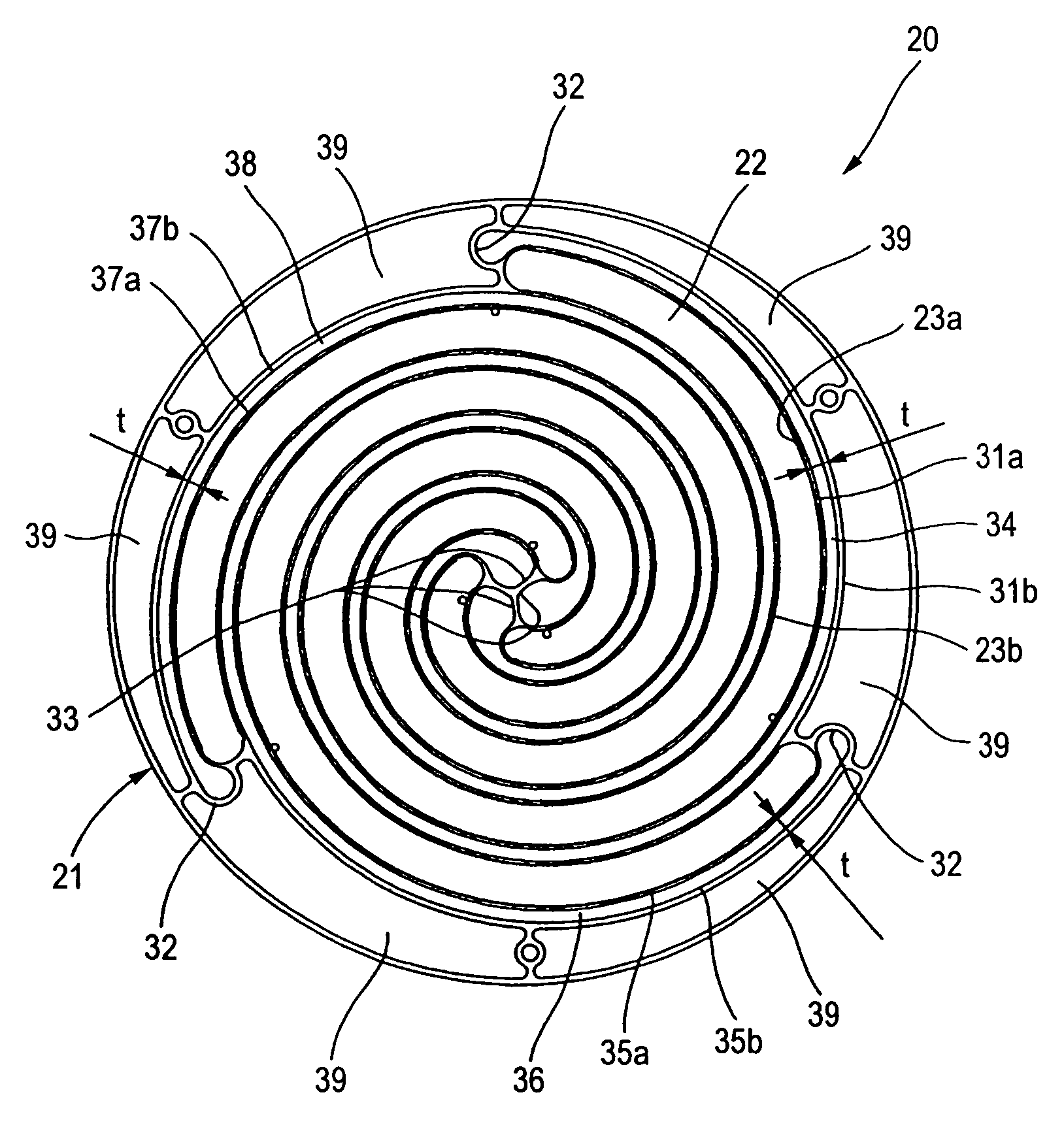

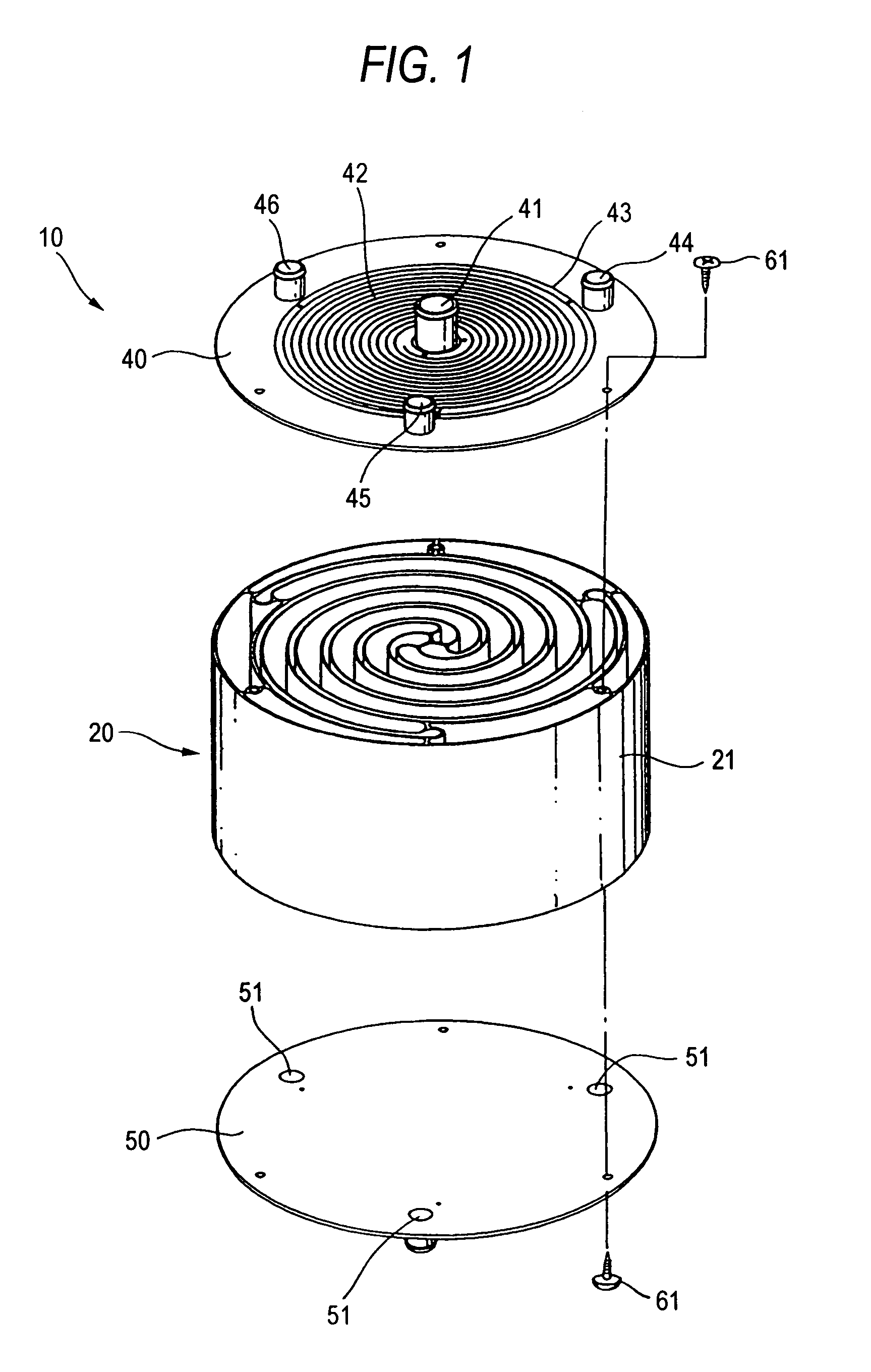

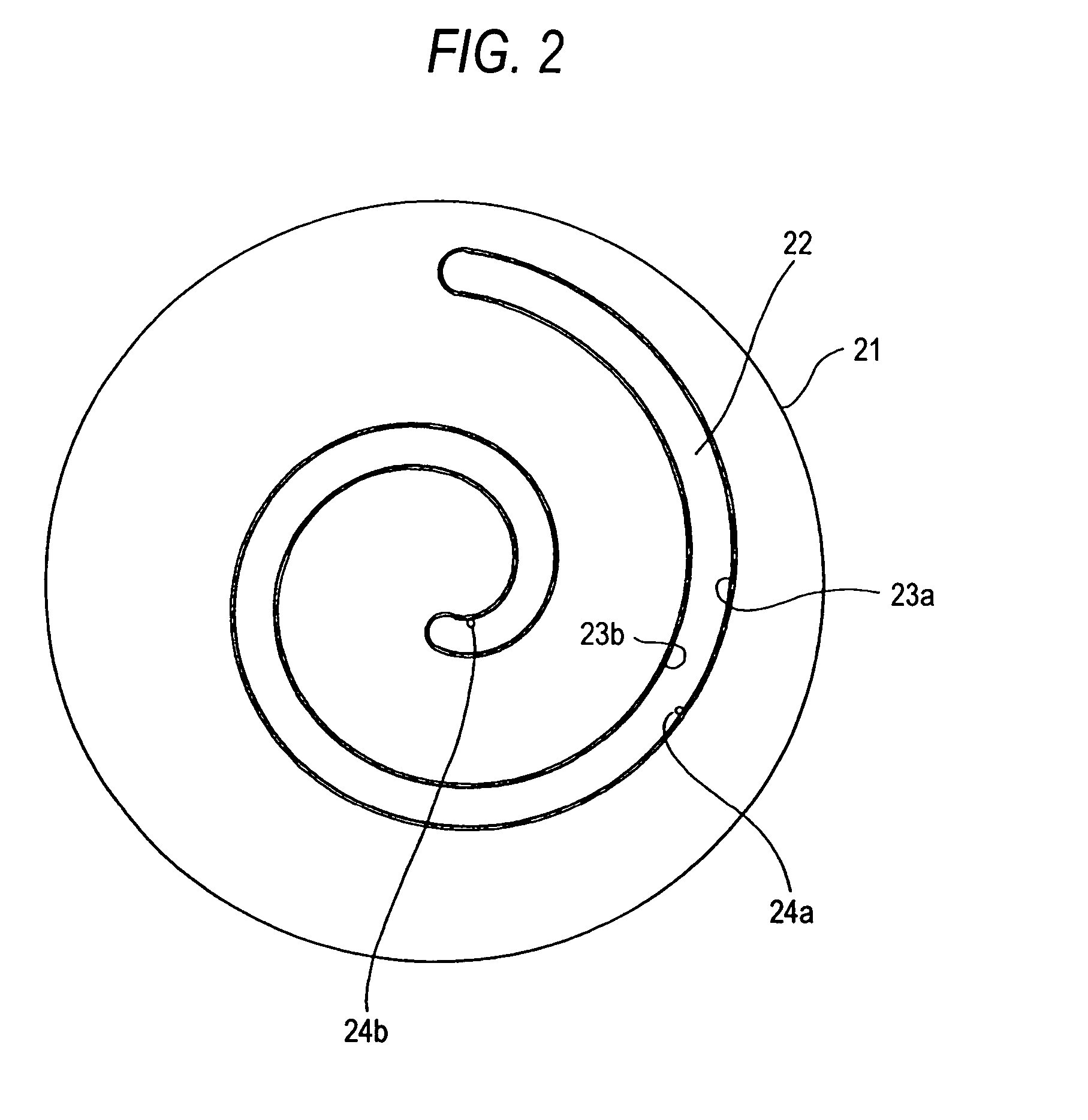

Heat storage apparatus with spiral electrically heated phase change material

A heat storage apparatus comprises a heat storage material accommodation cell for accommodating therein a heat storage material having an electricity conductive characteristic and configured to be electrically heated, and a fluid passageway for allowing a heat exchanging fluid to flow therethrough, the fluid passageway being adjacent to the heat storage material accommodation cell via a bulkhead. The heat storage material accommodation cell and the fluid passageway are put in a spiral configuration together with the bulkhead in a heat storage main body of the heat storage apparatus. Heat held in the heat storage material is transferred to the heat exchanging fluid so as to be taken out of the heat storage apparatus.

Owner:HONDA MOTOR CO LTD

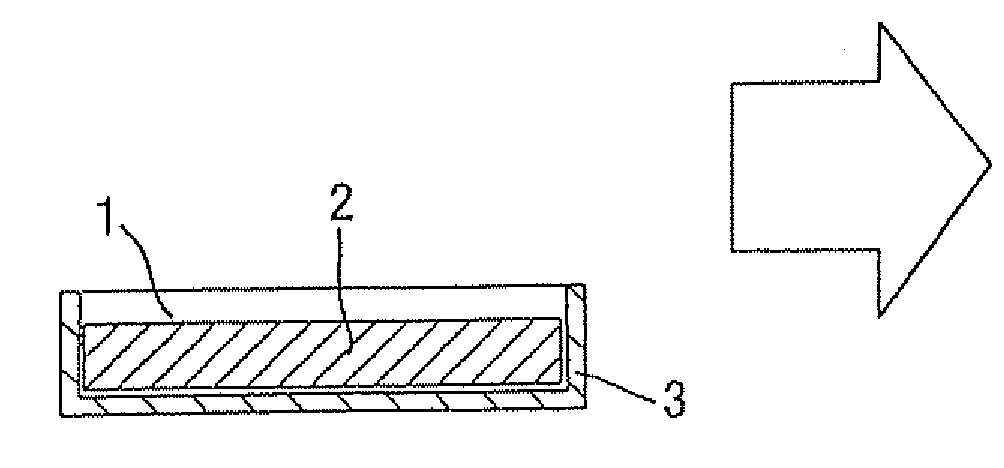

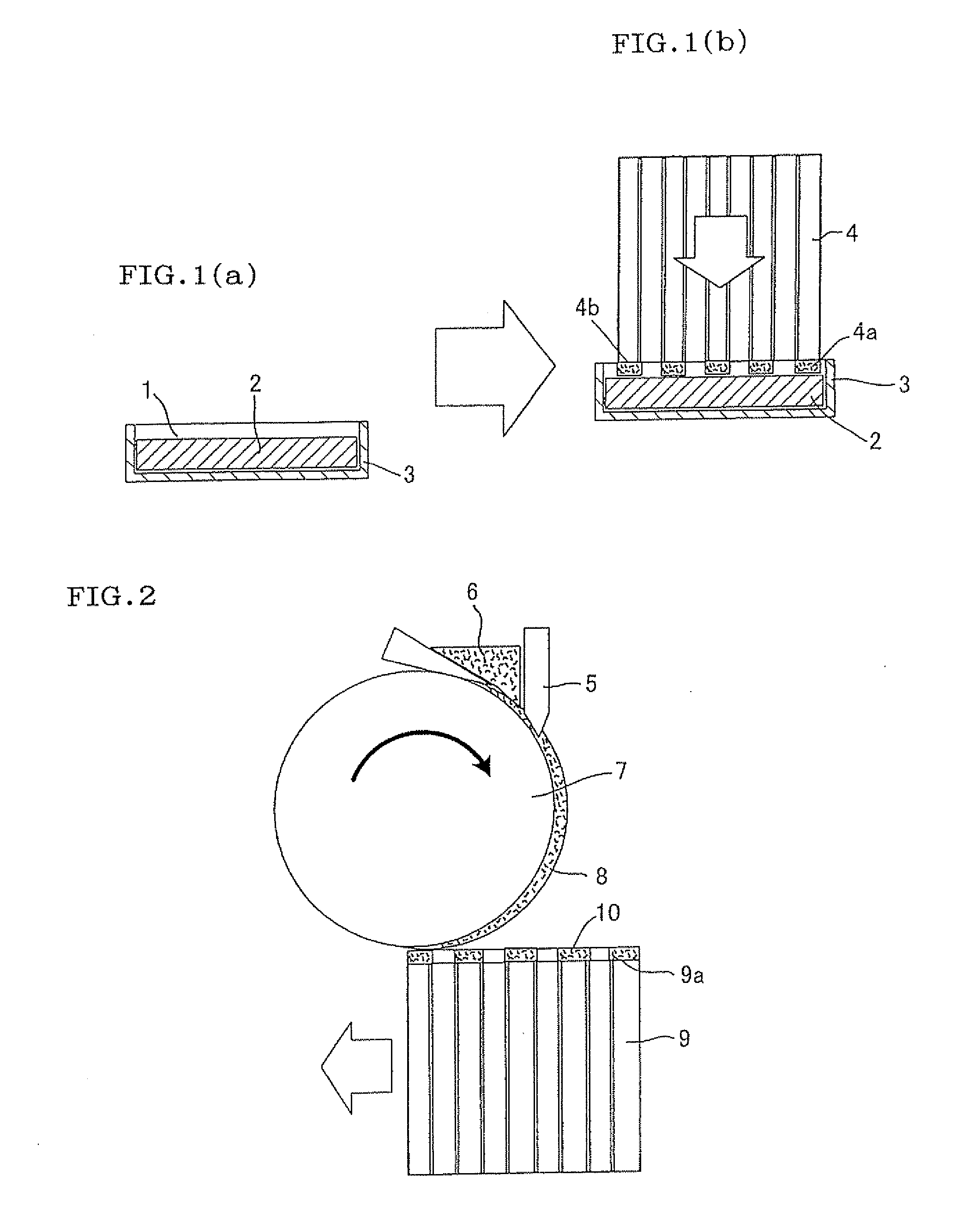

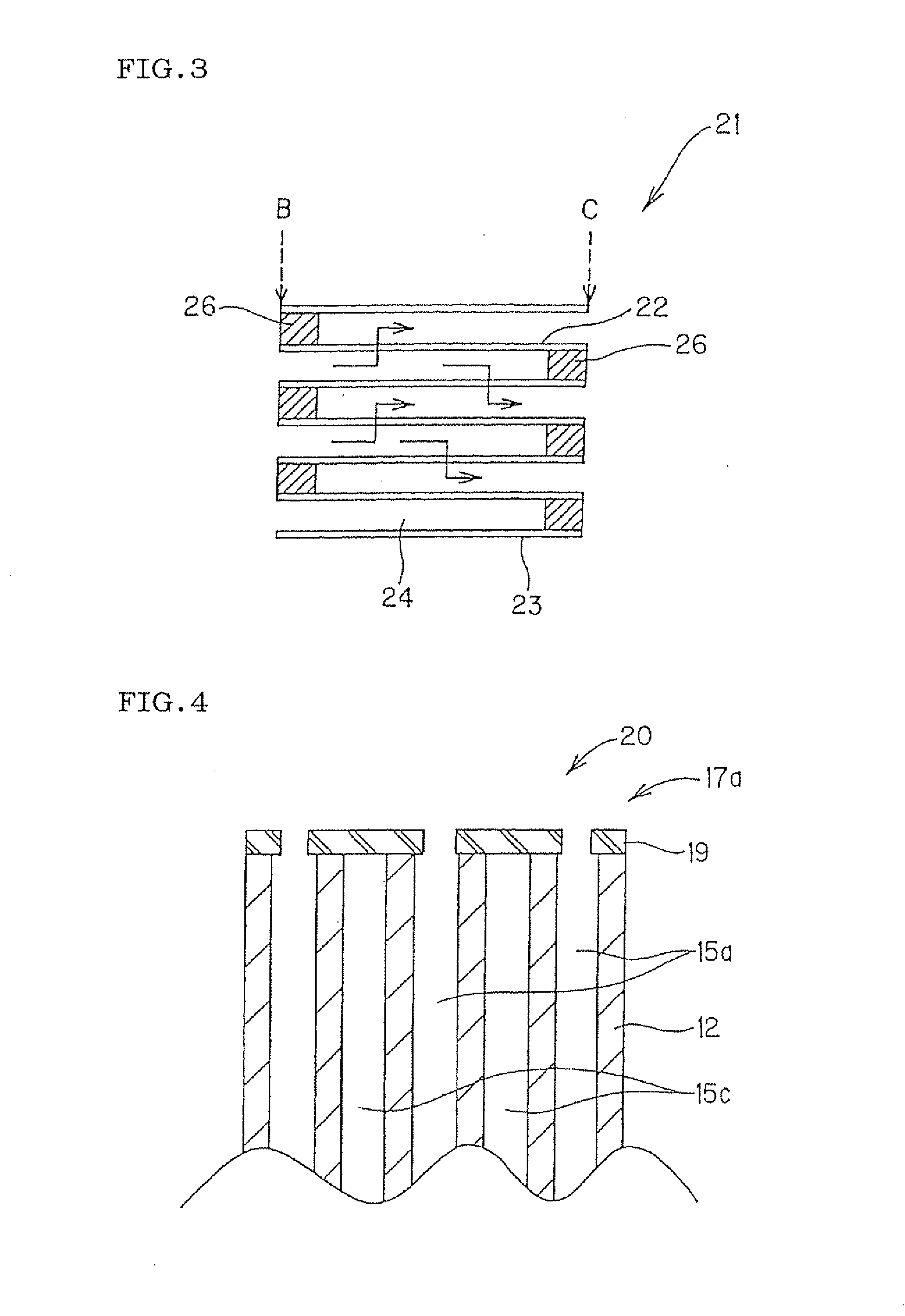

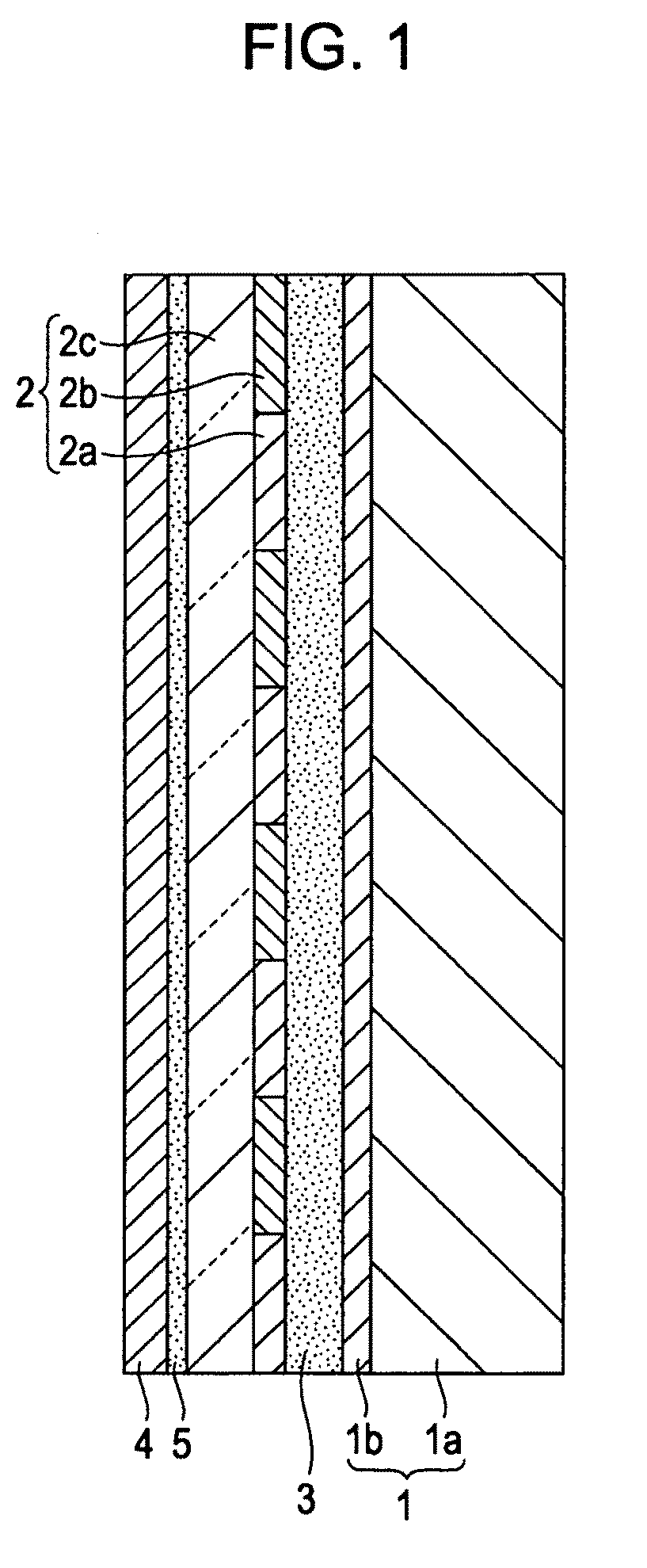

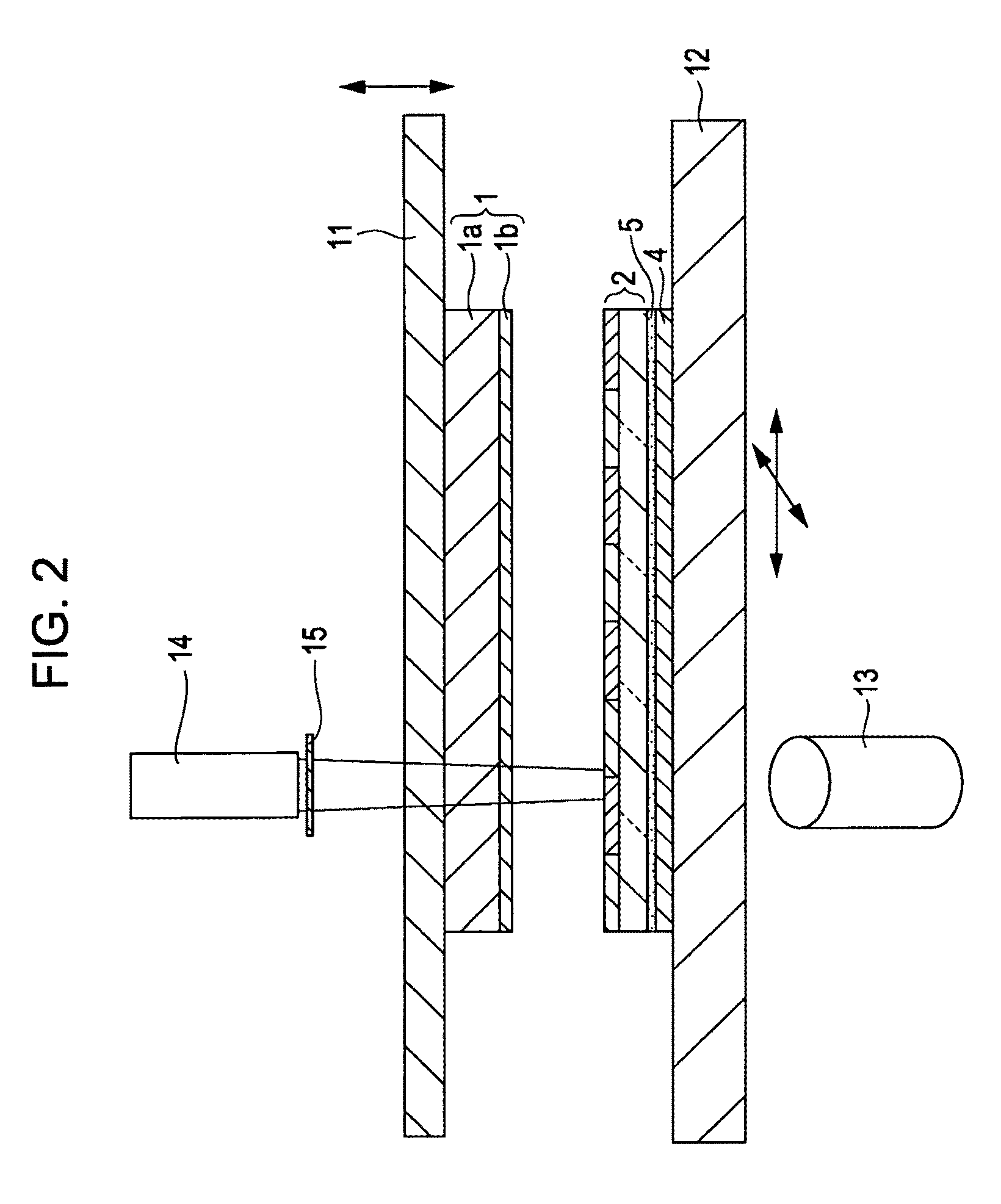

Production method of plugged honeycomb structure

InactiveUS20090011180A1Easy to uniformlyFluctuations of the plugging depth can be preventedDispersed particle filtrationLayered productsHoneycomb structureEngineering

There is disclosed a plugged honeycomb structure manufacturing method capable of easily manufacturing a plugged honeycomb structure for use in a filter or the like at low costs so that deposits disposed on an end surface of the structure are reduced, a uniform plugging depth is achieved and especially the plugging depth of a slurry-like plugging material at an outer peripheral portion of the honeycomb structure is easily made uniform. In the method of manufacturing the plugged honeycomb structure in which the plugging portion is formed in one opening end portion of each of predetermined cells of a cylindrical honeycomb structure including a plurality of cells divided by porous partition walls to form channels of a fluid in the form of a honeycomb, a flexible porous member 2 impregnated beforehand with a slurry-like plugging material 1 is pressed onto an end surface 4a of a honeycomb structure 4 to thereby fill cell passages of the honeycomb structure 4 with the slurry-like plugging material 1 contained in the flexible porous member 2 and form plugging portions 4b.

Owner:NGK INSULATORS LTD

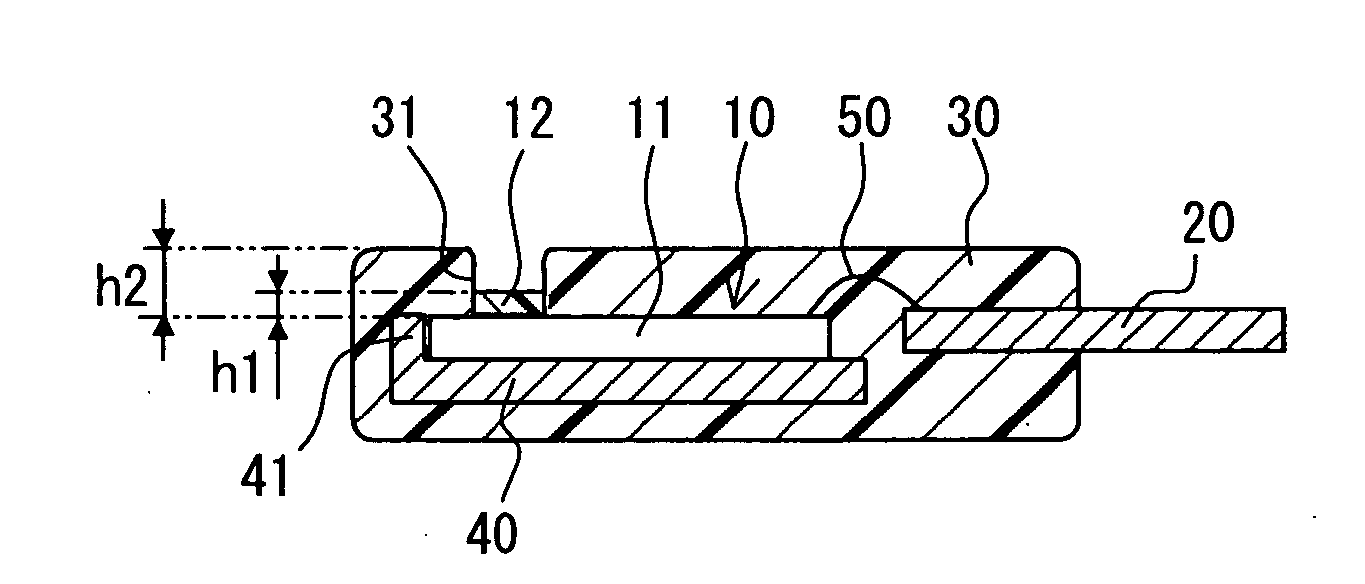

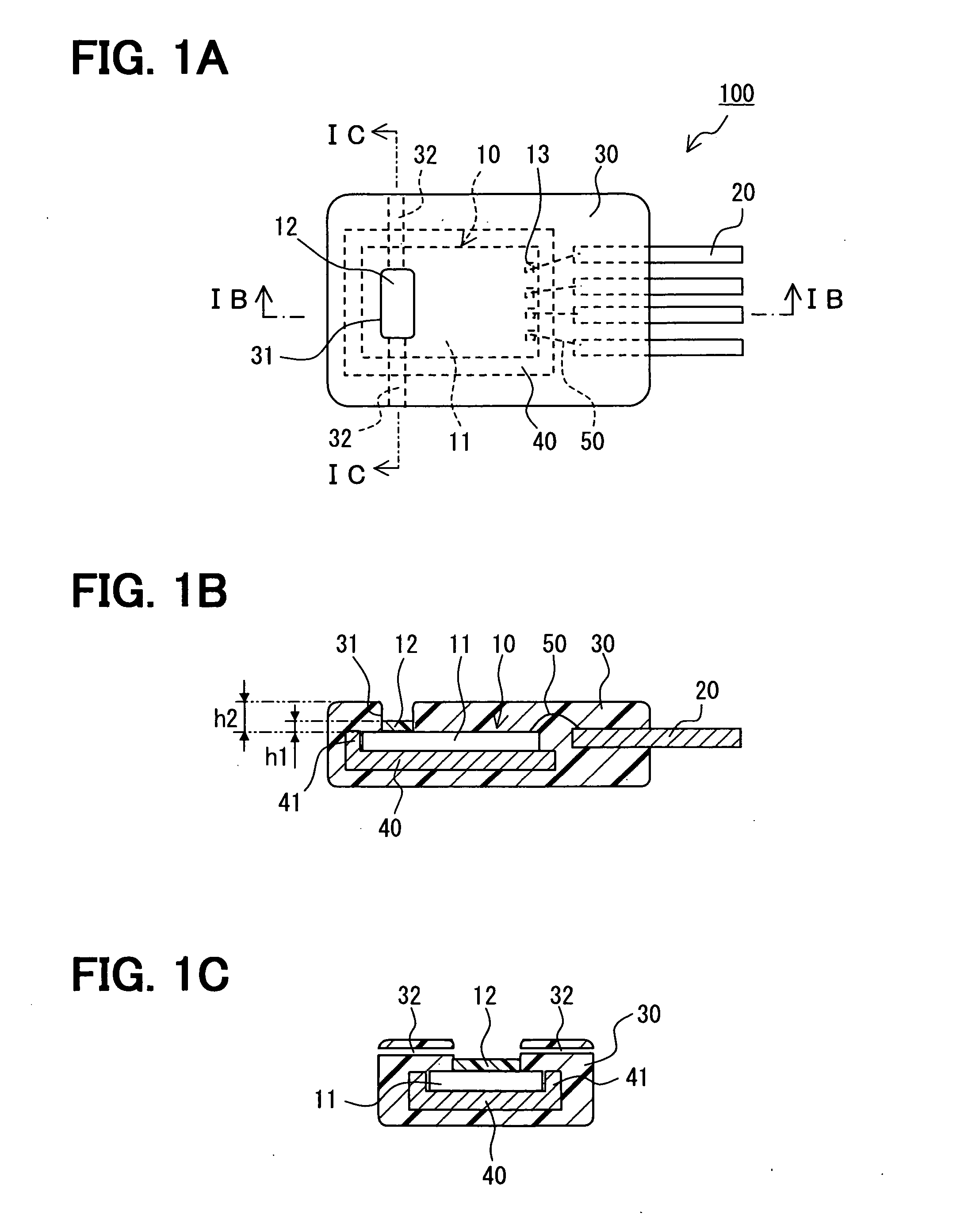

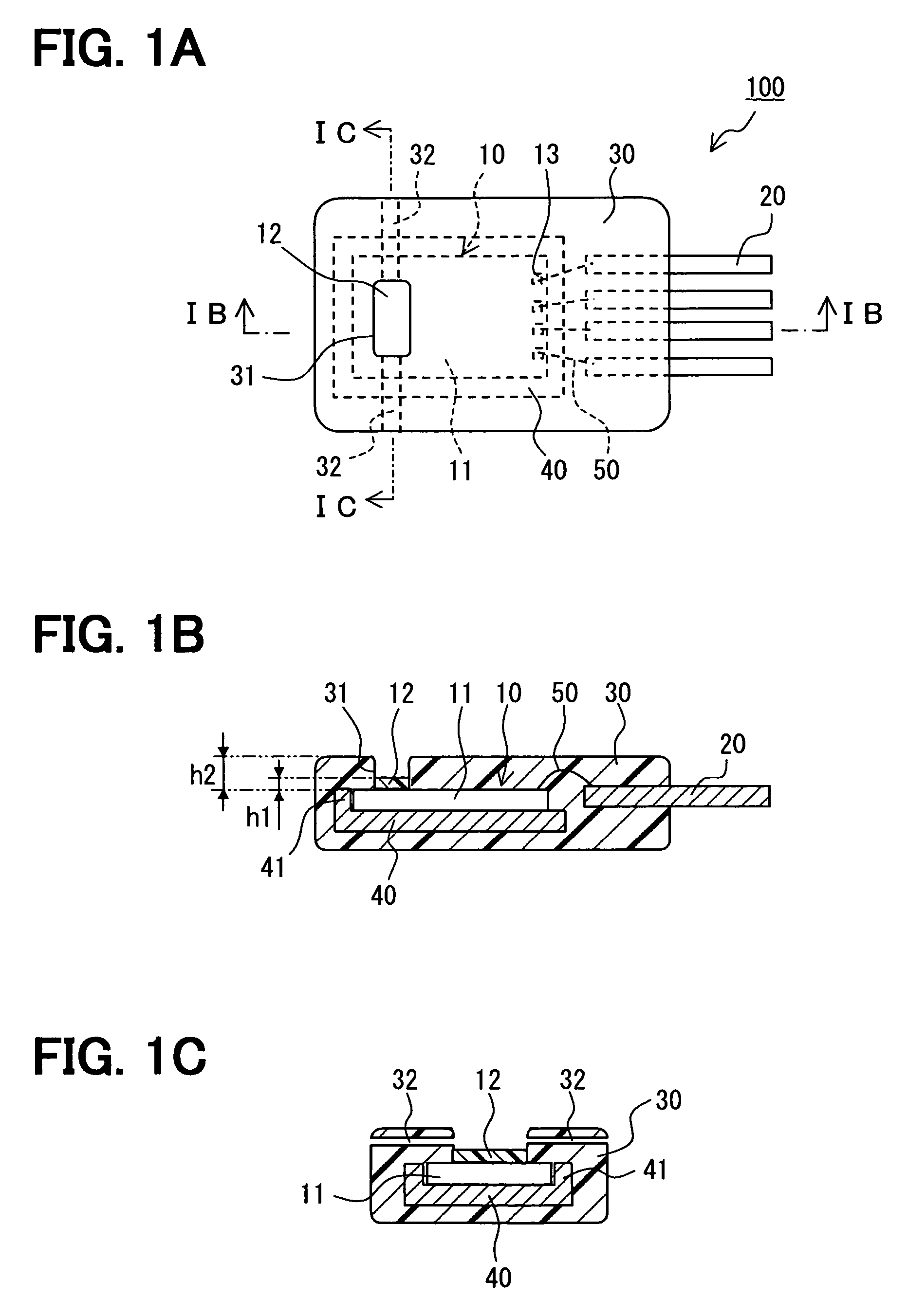

Humidity sensor having humidity sensitive film and method for manufacturing the same

InactiveUS20070113648A1Reduce variationReduce sensor costSolid-state devicesUsing mechanical meansMoisture sensorRelative permittivity

A humidity sensor includes: a sensor chip including a capacitive humidity sensor element and a connection electrode, wherein the capacitive humidity sensor element includes a humidity sensitive film having relative permittivity changeable in accordance with humidity, and wherein the connection electrode is electrically connected to the humidity sensor element; a lead plate electrically connected to the connection electrode; and a mold for covering a connection portion between the connection electrode and the lead plate. The mold is disposed on the sensor chip and includes a groove. The humidity sensitive film is disposed in the groove. The humidity sensitive film has a height in the groove, the height equal to or lower than a surface of the mold. The height of the humidity sensitive film in the groove is homogeneous.

Owner:DENSO CORP

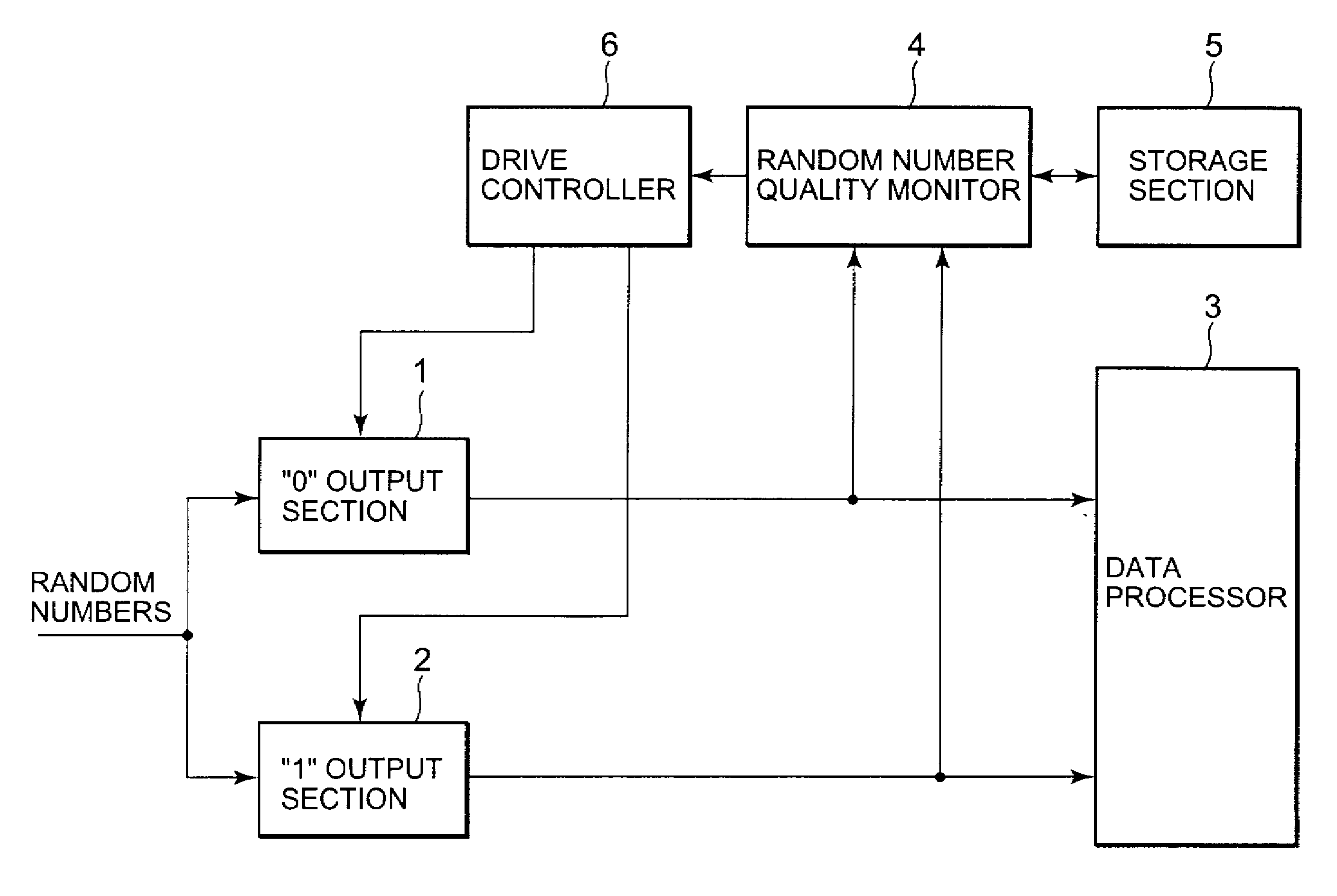

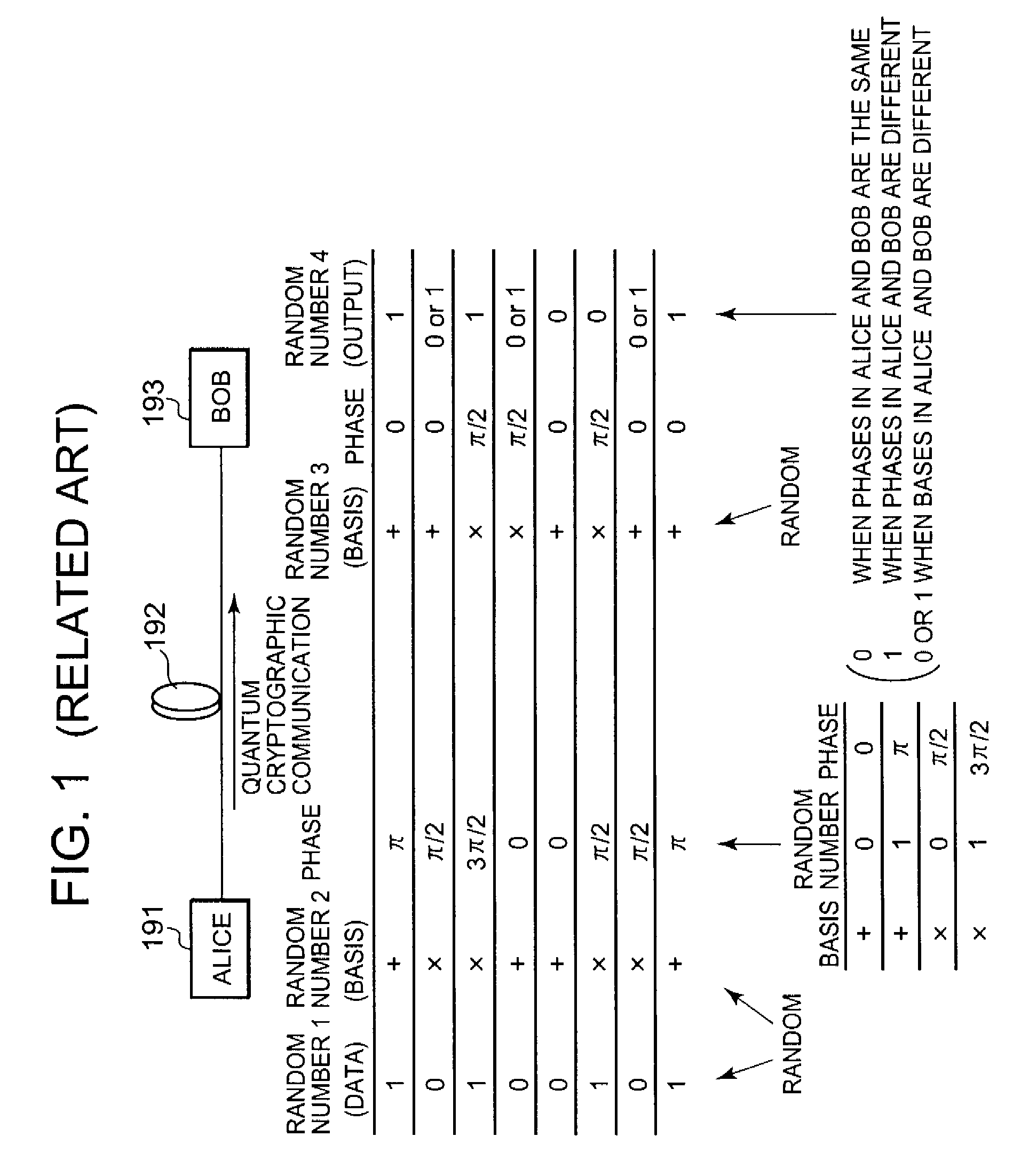

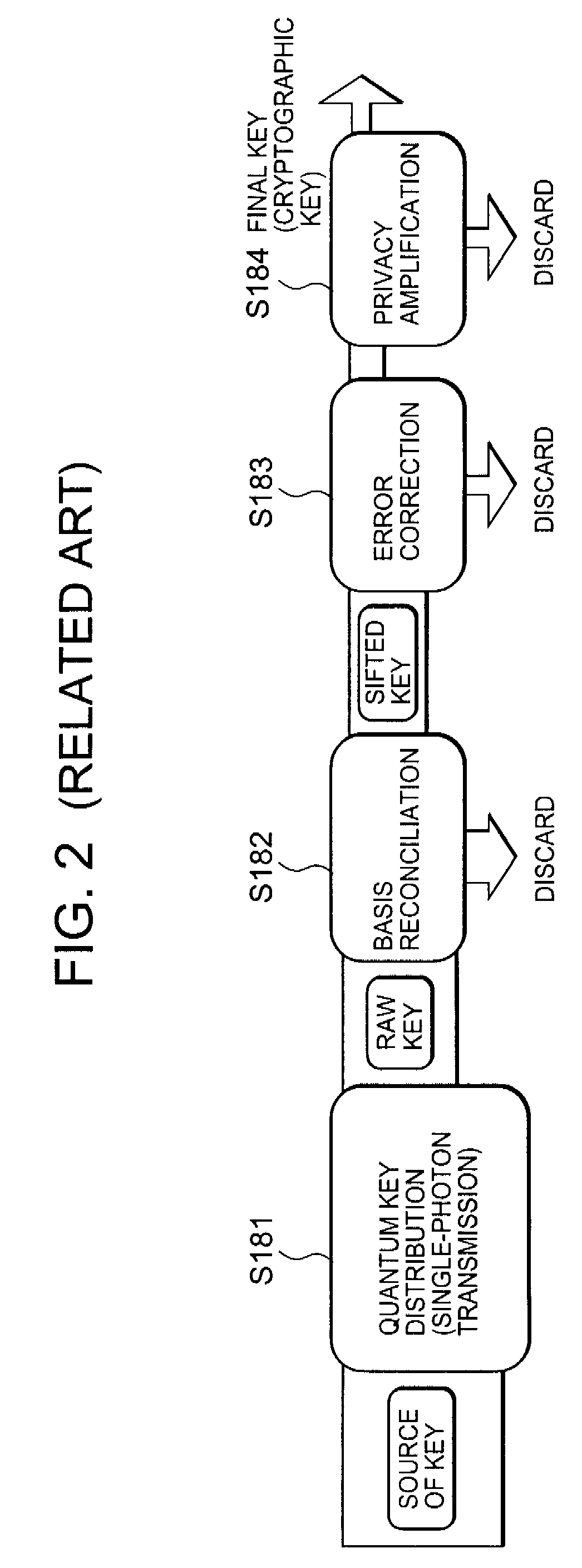

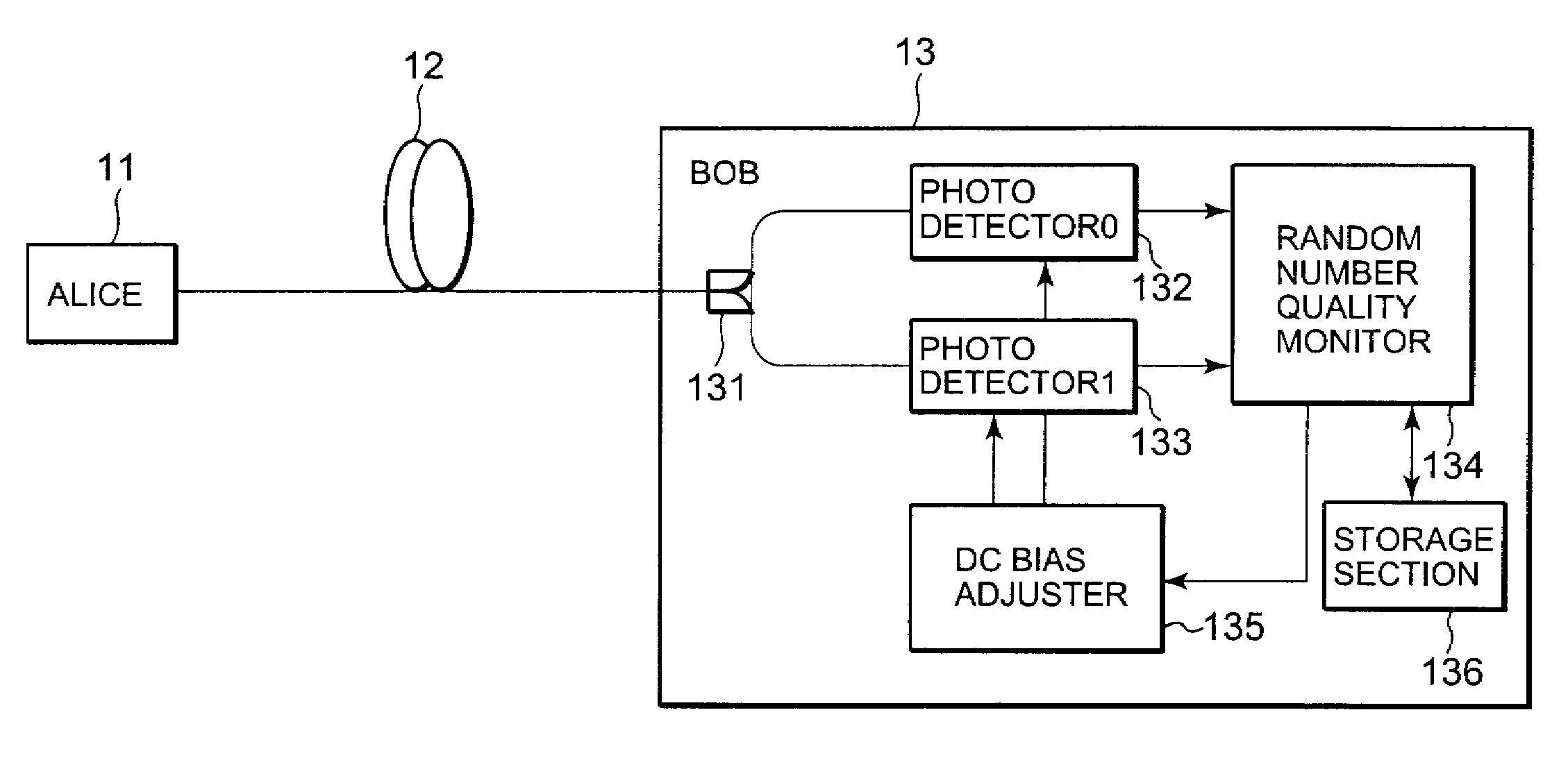

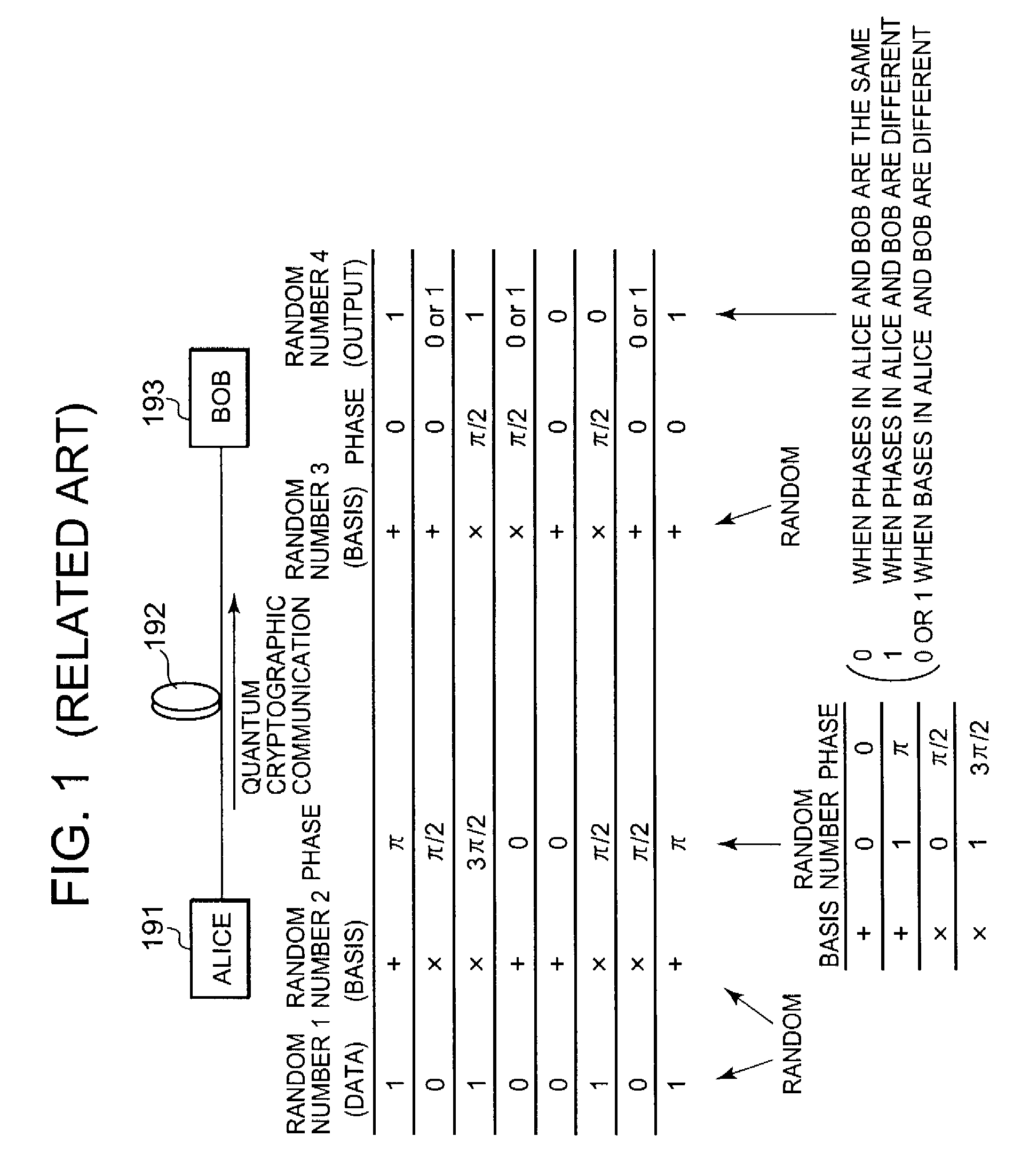

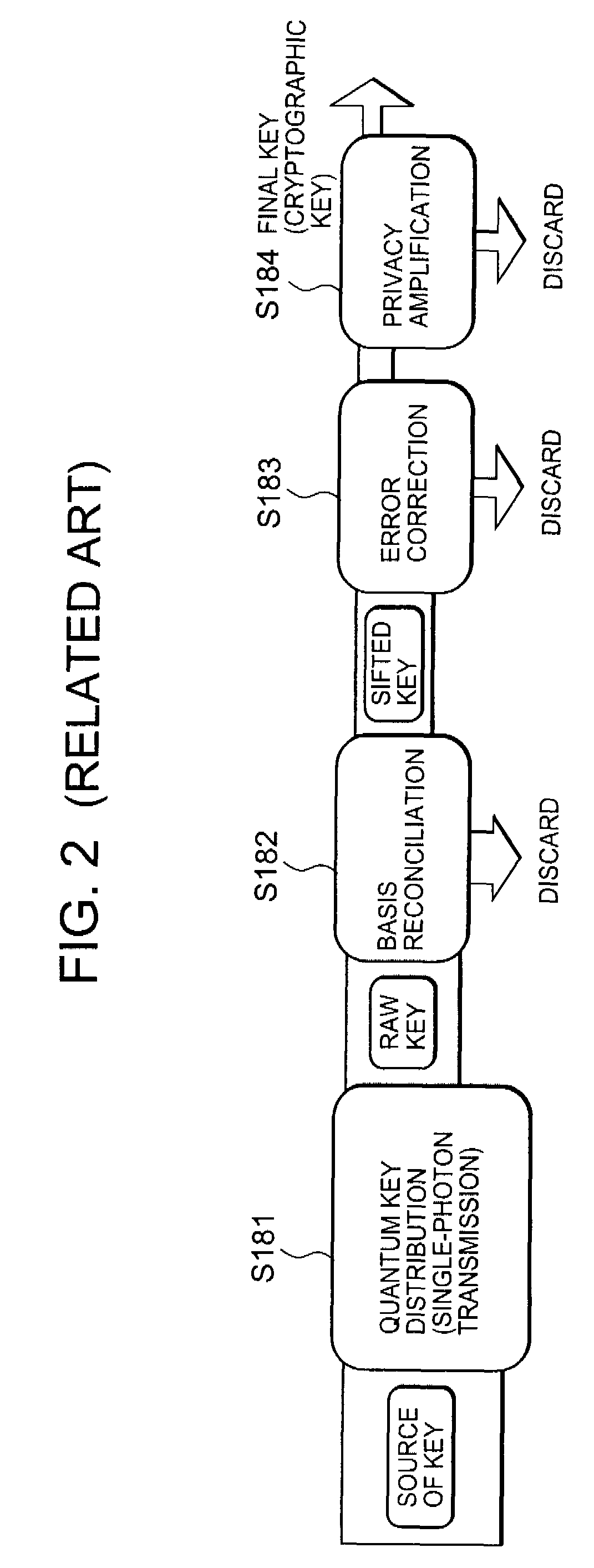

Circuit and method for controlling quality of random numbers

ActiveUS20080052577A1Reduce the amount of informationReduce the amount requiredRandom number generatorsElectronic circuit testingQuality controlQuality level

A random number quality control circuit capable of fast control of the level of random number quality is present. When a “0” output section and a “1” output section generate random numbers by individually receiving a random number signal, a random number quality monitor monitors an unbalance between the numbers of “0”s and “1”s. If a deviation from a desired ratio is found, a drive controller controls the reception characteristics of the “0” output section and “1” output section individually so that the deviation will be compensated for. The amount of information intercepted between a sender and a receiver can be reduced by maintaining the mark ratio of shared random numbers at 50%.

Owner:NEC CORP

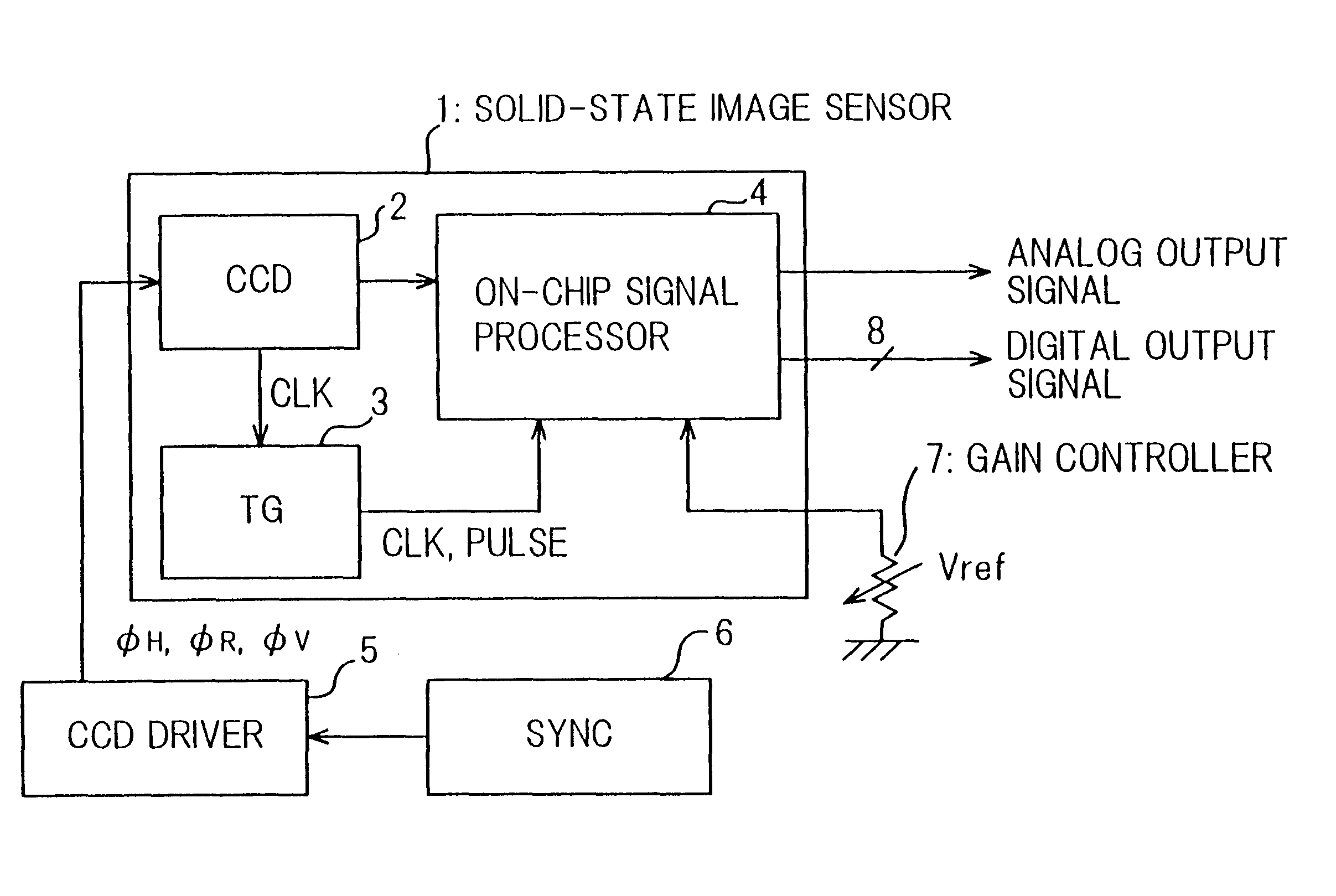

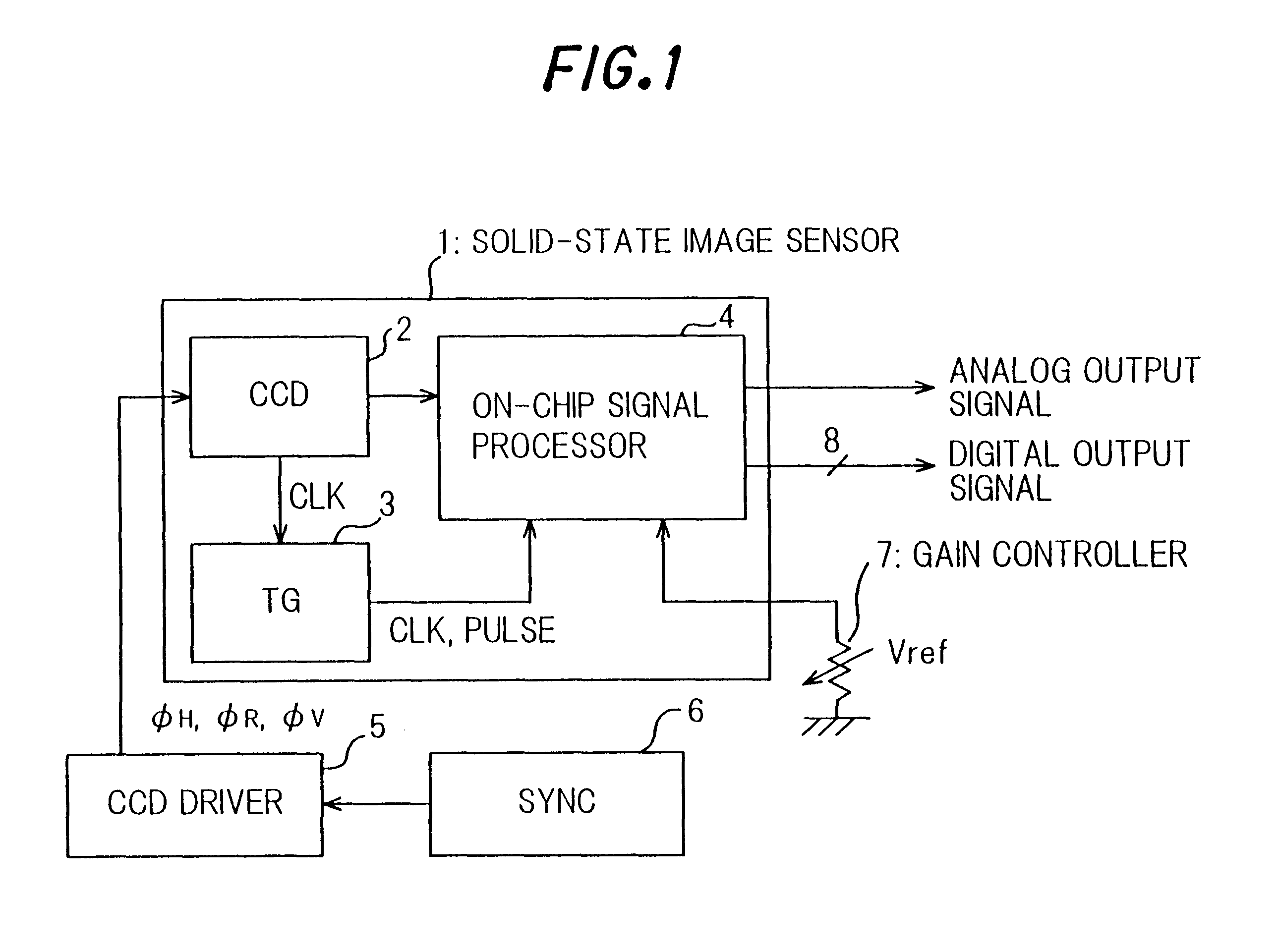

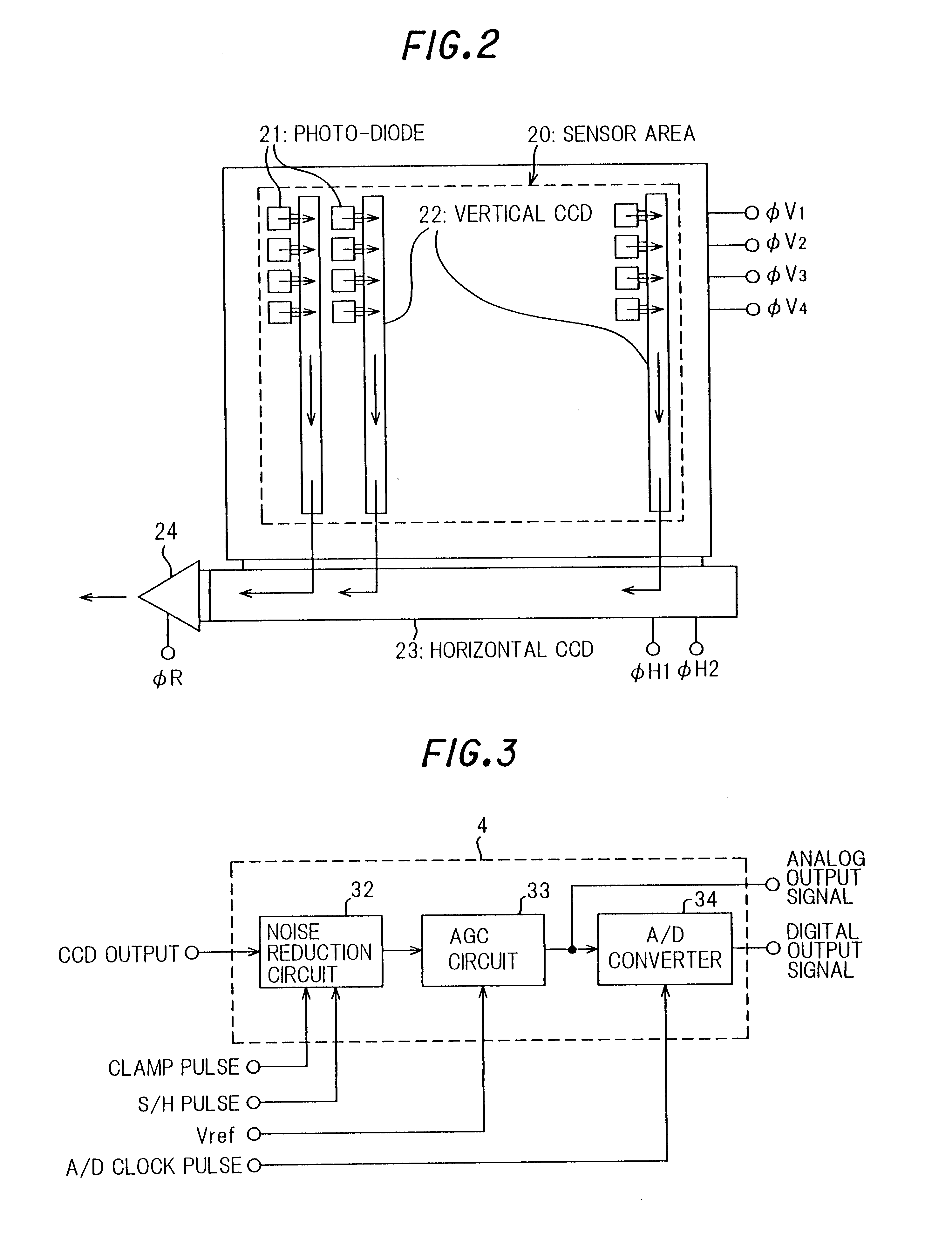

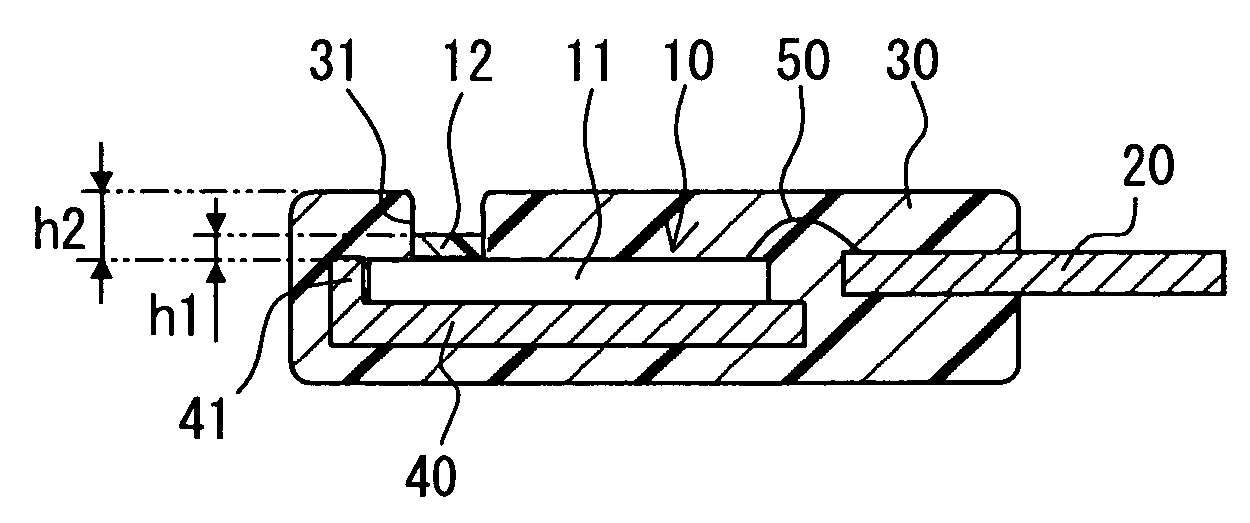

Solid-state camera including a charge coupled device

InactiveUS6940553B1Simple and miniaturized and economical configurationImprove performanceTelevision system detailsTelevision system scanning detailsSemiconductor chipEngineering

To provide a solid-state image sensor, wherein no field adjustment of timing pulse phases used in the signal processor or of signal balances is needed, and noise performance is more improved, with a simple, miniaturized and economical configuration, a solid-state image sensor (1) of the invention comprises: a CCD (2) configured on a semiconductor chip for generating a CCD signal according to an optical image focused on a sensor area thereof; an on-chip signal processor (4) configured on the semiconductor chip by way of the same fabrication process with the CCD including a noise reduction circuit for eliminating noises from the CCD signal, an AGC circuit for amplifying output of of the noise reduction circuit; and a timing pulse generator (3) configured on the semiconductor chip by way of the same fabrication process with the CCD (2) for generating timing pulses used the on-chip signal processor. The on-chip signal processor (4) of the solid-state image sensor (1) may further comprise an A / D converter for converting output of the AGC circuit into a digital signal.

Owner:NEC CORP

Humidity sensor having humidity sensitive film and method for manufacturing the same

InactiveUS7644615B2Reduce variationReduce sensor costSolid-state devicesUsing mechanical meansMoisture sensorRelative permittivity

A humidity sensor includes: a sensor chip including a capacitive humidity sensor element and a connection electrode, wherein the capacitive humidity sensor element includes a humidity sensitive film having relative permittivity changeable in accordance with humidity, and wherein the connection electrode is electrically connected to the humidity sensor element; a lead plate electrically connected to the connection electrode; and a mold for covering a connection portion between the connection electrode and the lead plate. The mold is disposed on the sensor chip and includes a groove. The humidity sensitive film is disposed in the groove. The humidity sensitive film has a height in the groove, the height equal to or lower than a surface of the mold. The height of the humidity sensitive film in the groove is homogeneous.

Owner:DENSO CORP

Circuit and method for controlling quality of random numbers

ActiveUS8949300B2Control the level of qualityQuality improvementKey distribution for secure communicationRandom number generatorsQuality levelQuality control

A random number quality control circuit capable of fast control of the level of random number quality is present. When a “0” output section and a “1” output section generate random numbers by individually receiving a random number signal, a random number quality monitor monitors an unbalance between the numbers of “0”s and “1”s. If a deviation from a desired ratio is found, a drive controller controls the reception characteristics of the “0” output section and “1” output section individually so that the deviation will be compensated for. The amount of information intercepted between a sender and a receiver can be reduced by maintaining the mark ratio of shared random numbers at 50%.

Owner:NEC CORP

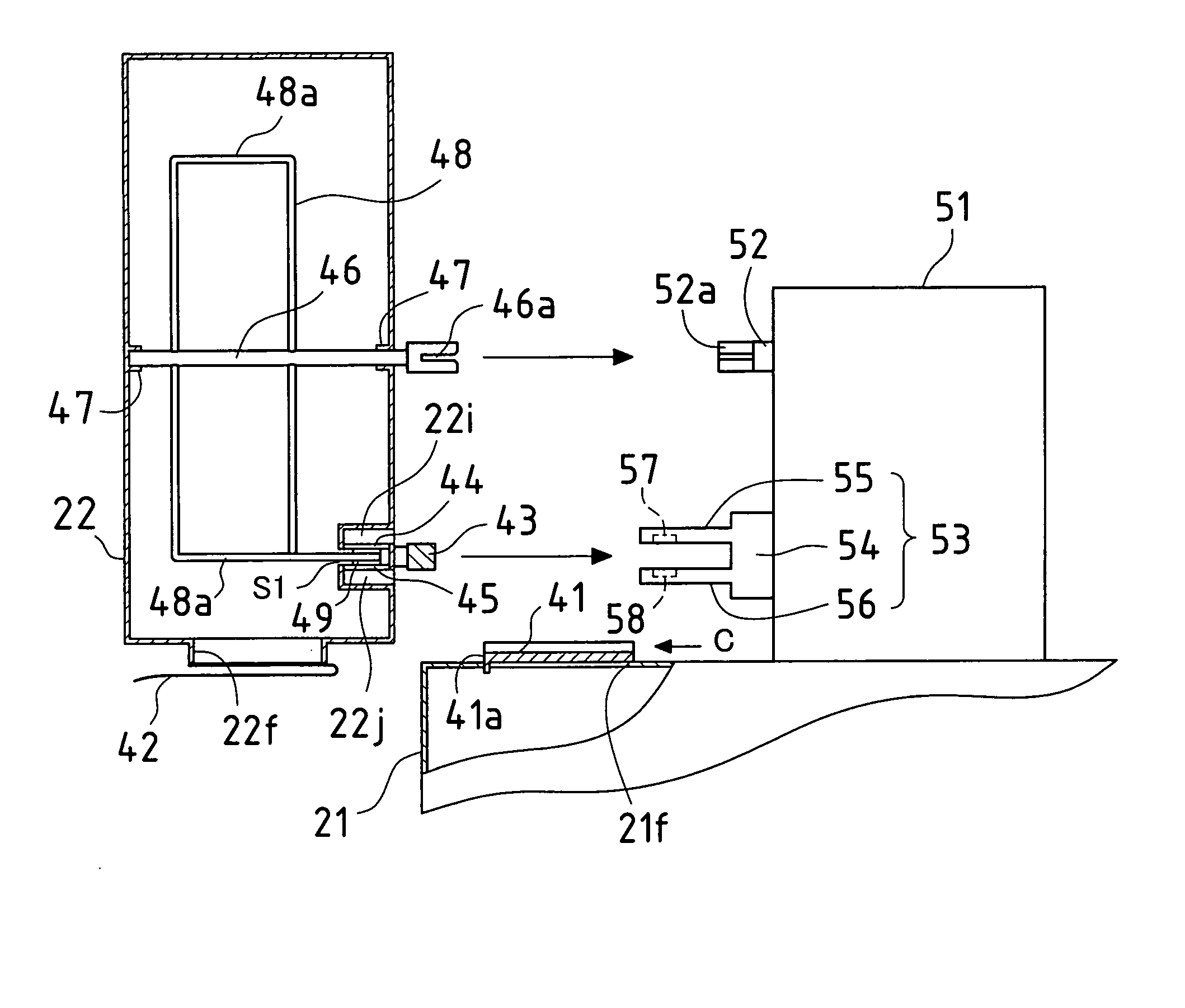

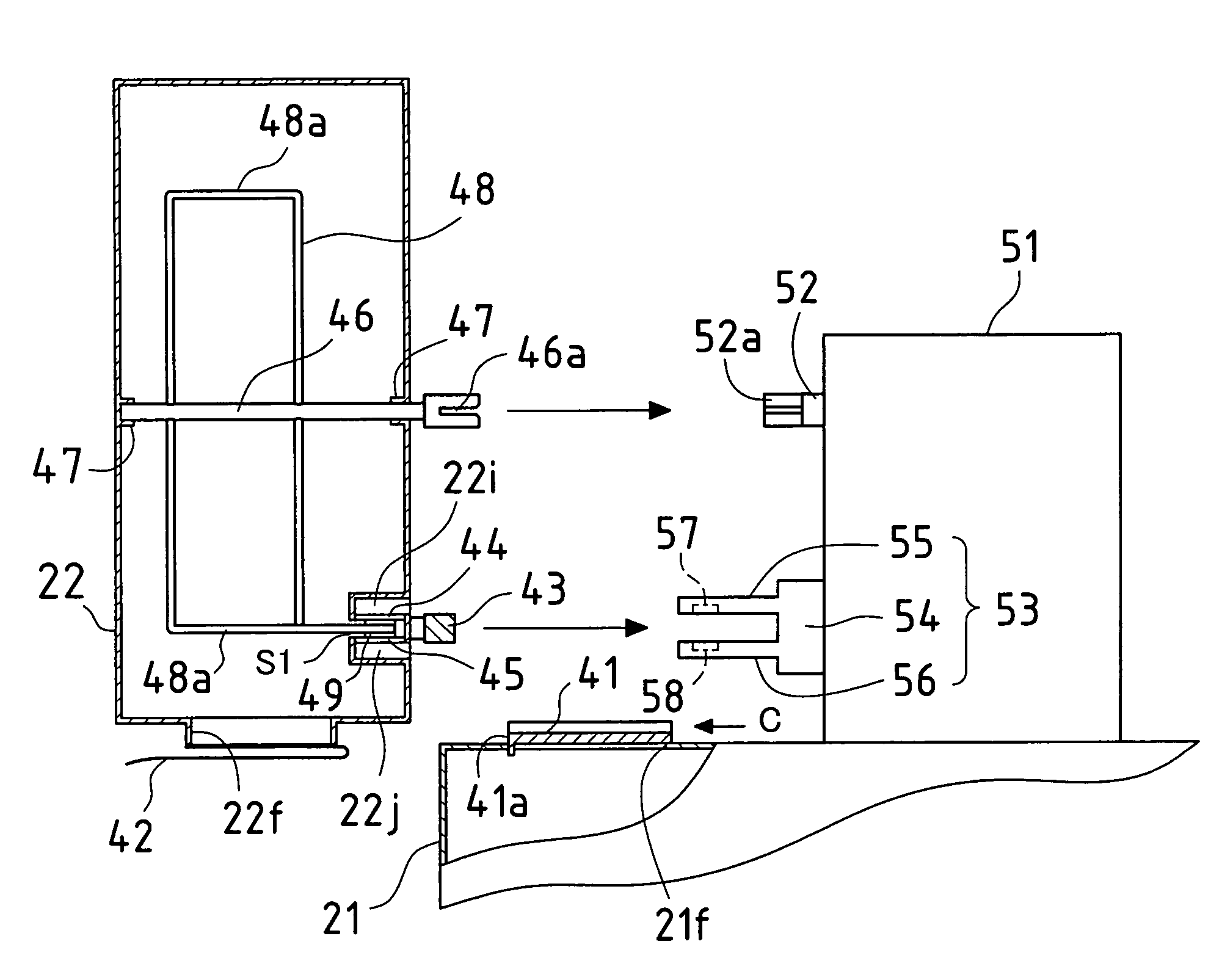

Remaining toner detection apparatus and image forming apparatus provided with same

ActiveUS20050117921A1Accurately determinedAccurate measurementElectrographic process apparatusLevel indicators by physical variable measurementImage formationEngineering

A pair of indentations is formed with a vertical spacing on a side wall of a toner cartridge, respective translucent windows are arranged on opposing upper and lower surfaces of the indentations protruding into the toner cartridge, and a light-emitting element and a light-receiving element of a remaining toner sensor are inserted to the indentations such that the light-emitting element and the light-receiving element of the remaining toner sensor face each other via the translucent windows of the indentations. When there is sufficient toner remaining in the toner cartridge, there is toner in the space between the transparent plates, and the space between a light-emitting diode and a phototransistor is blocked such that light is not incident on the phototransistor, whereas when there is little toner remaining in the toner cartridge, there is no toner in the space between the transparent plates, and the light is incident on the phototransistor via the space between the light-emitting diode and the photoresistor.

Owner:SHARP KK

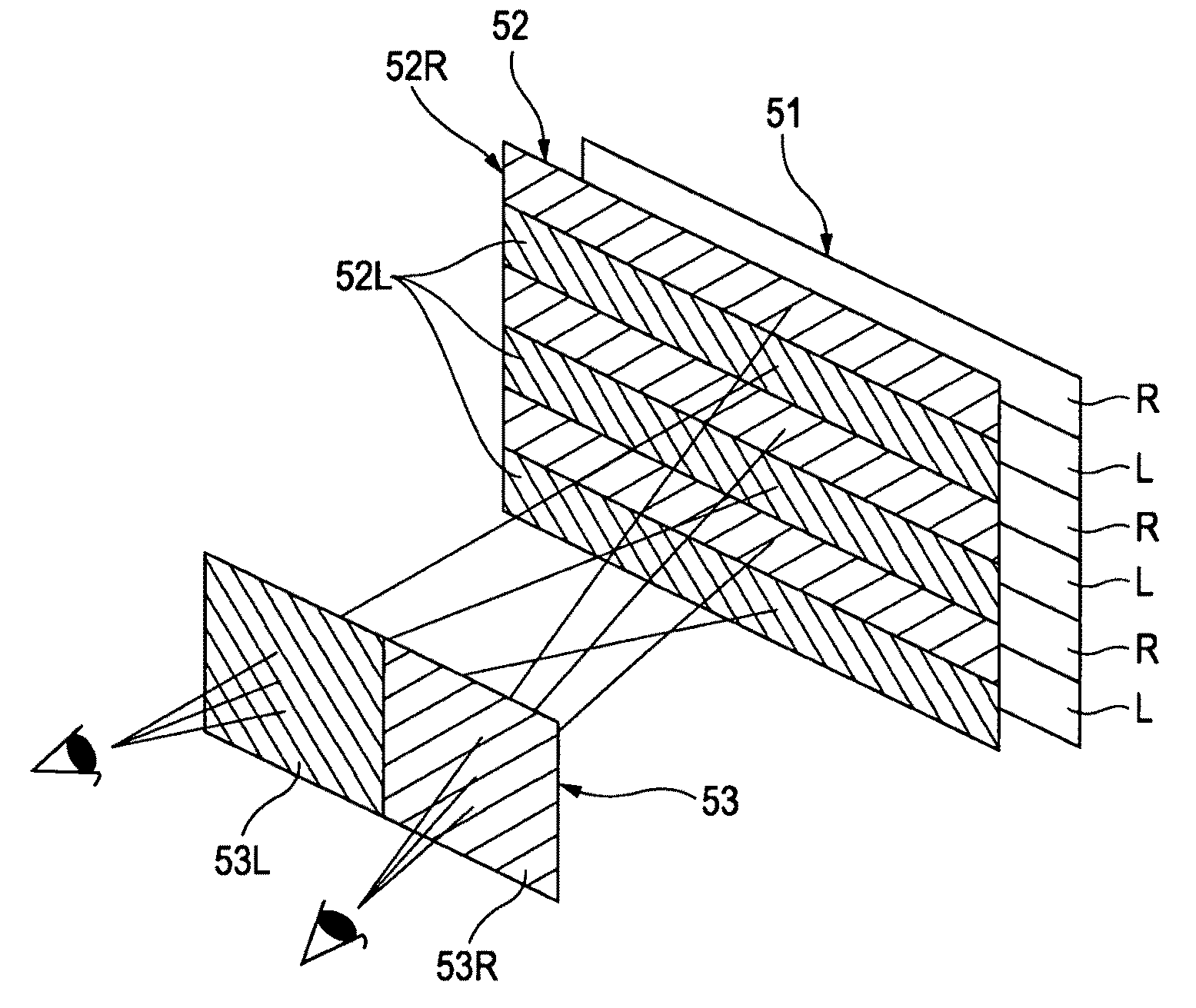

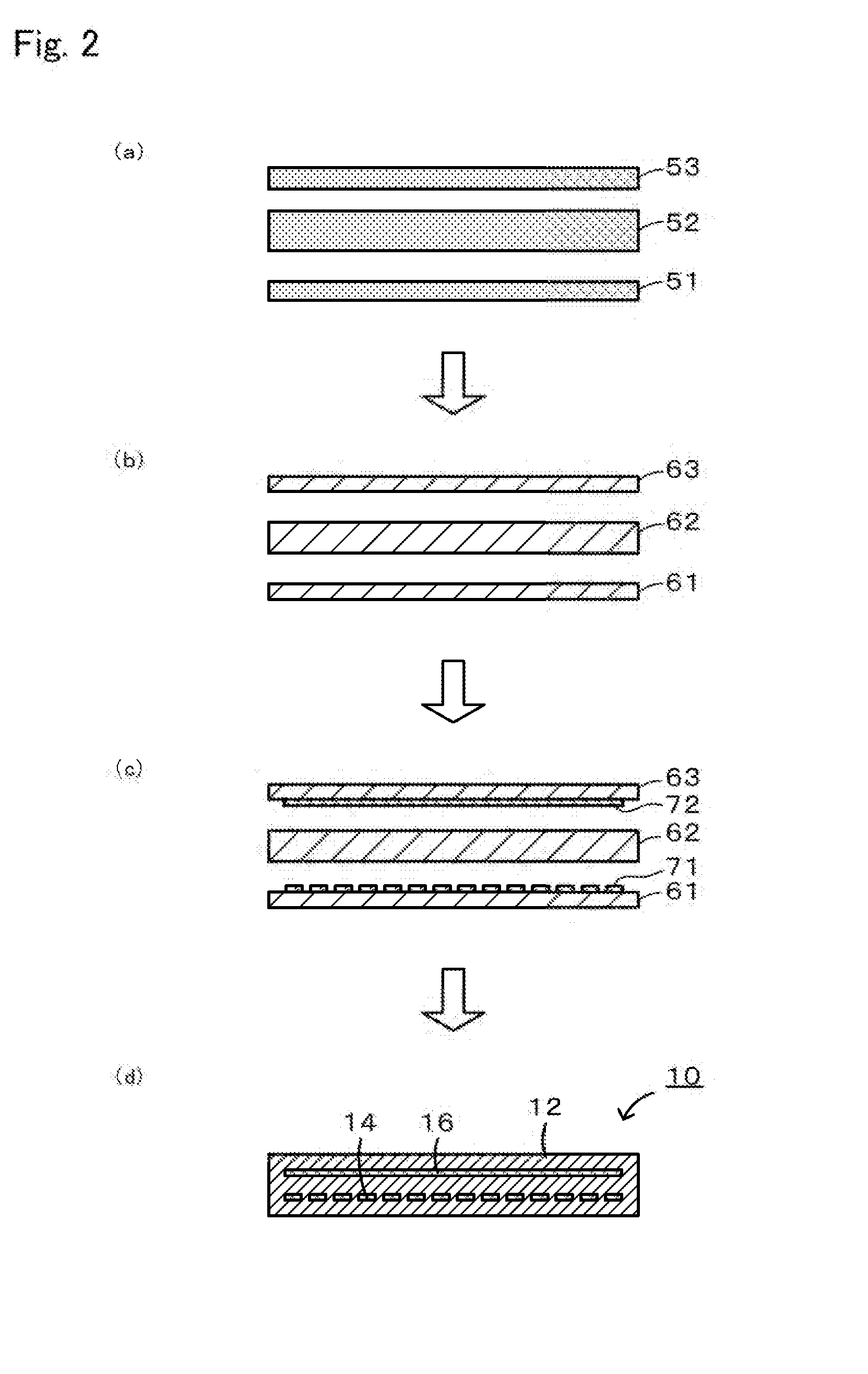

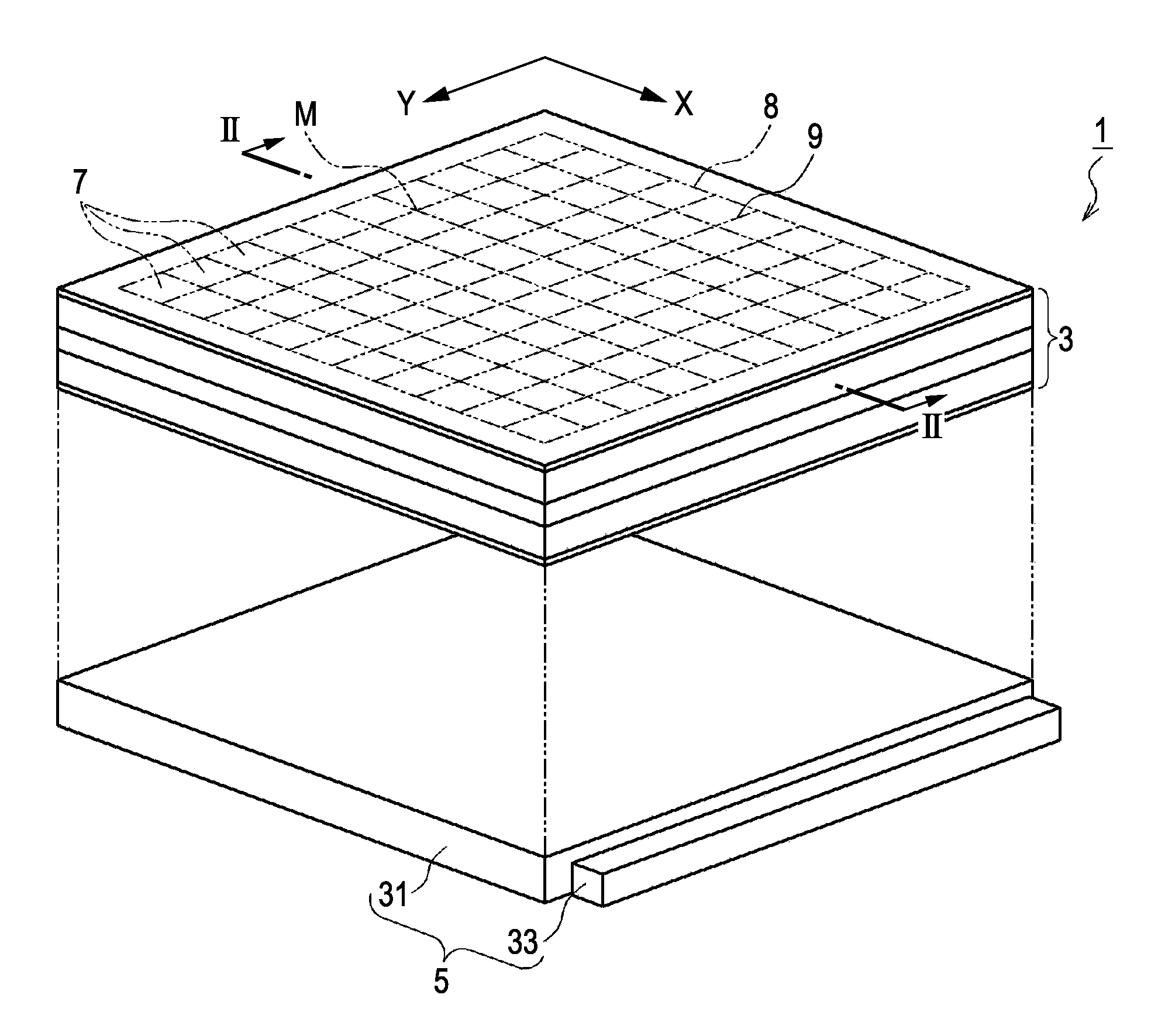

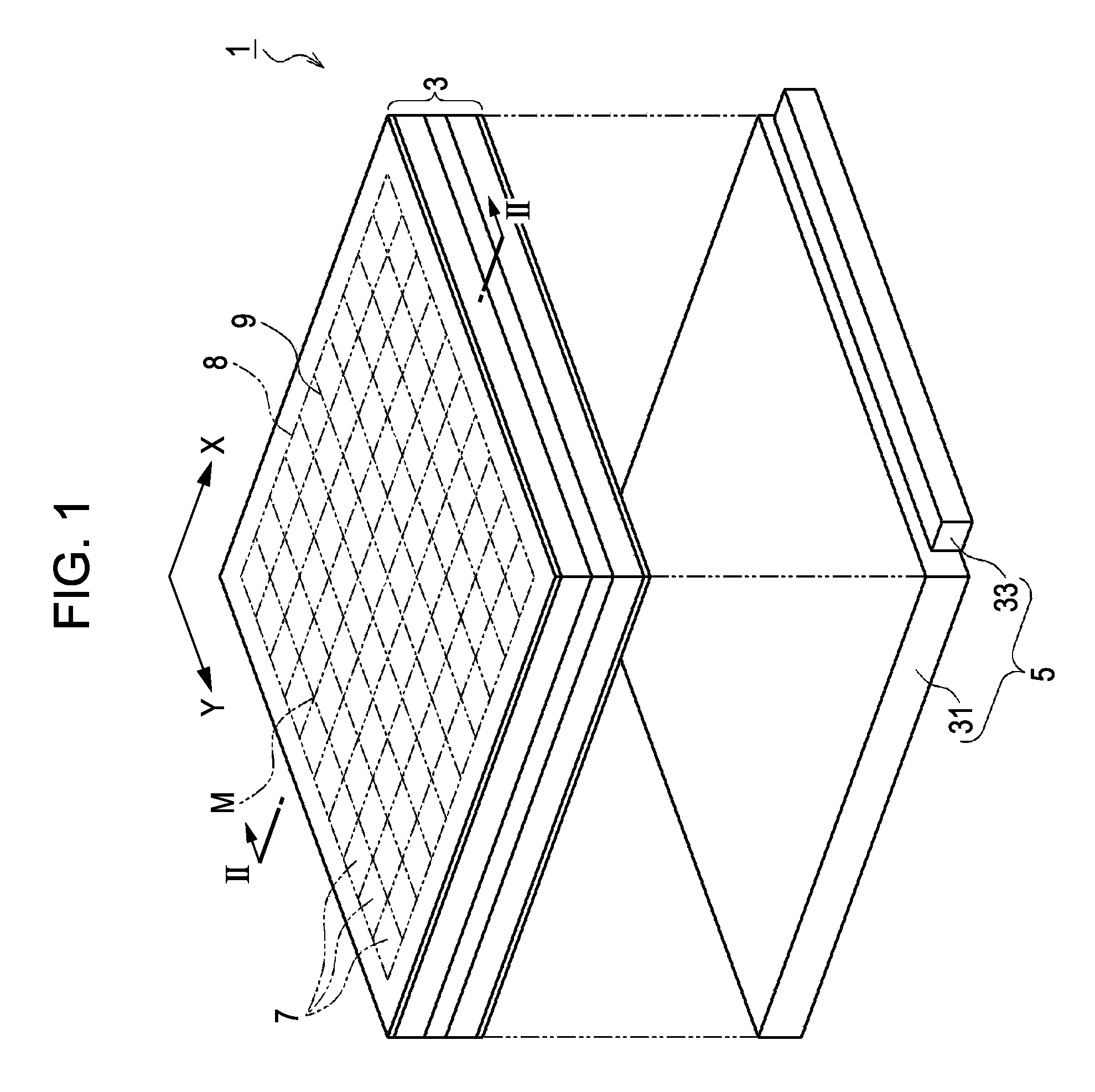

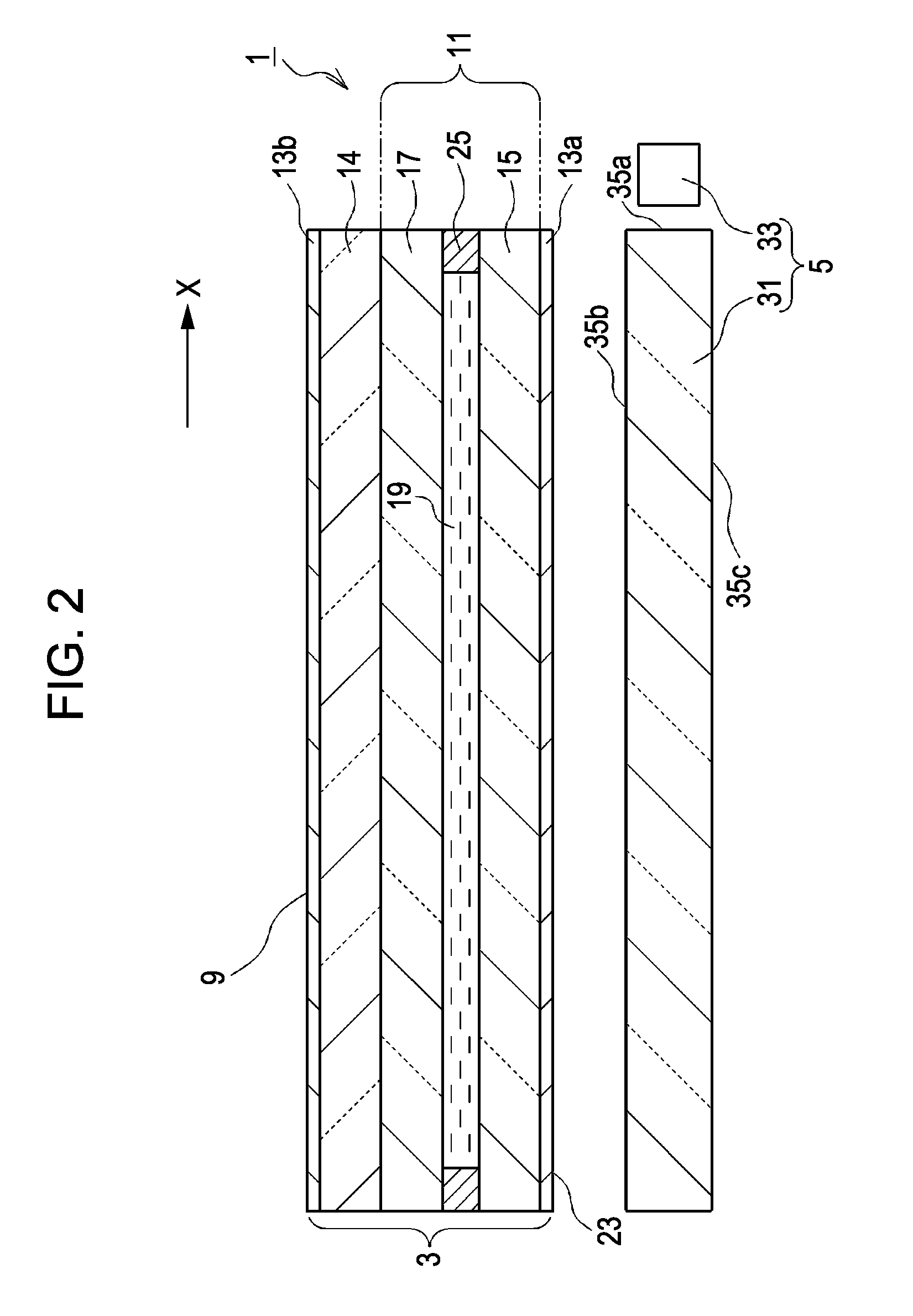

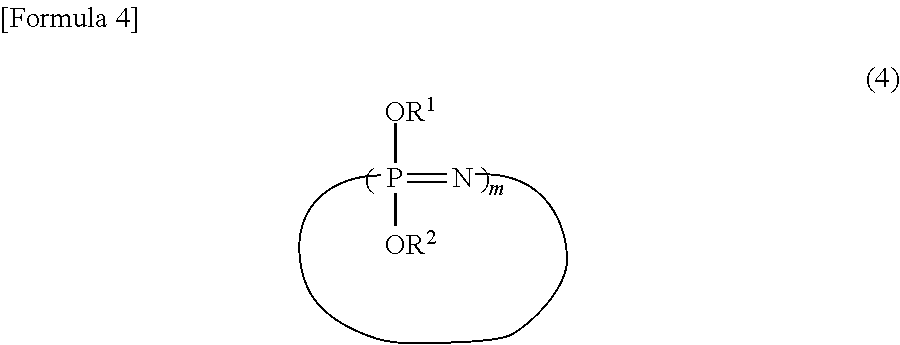

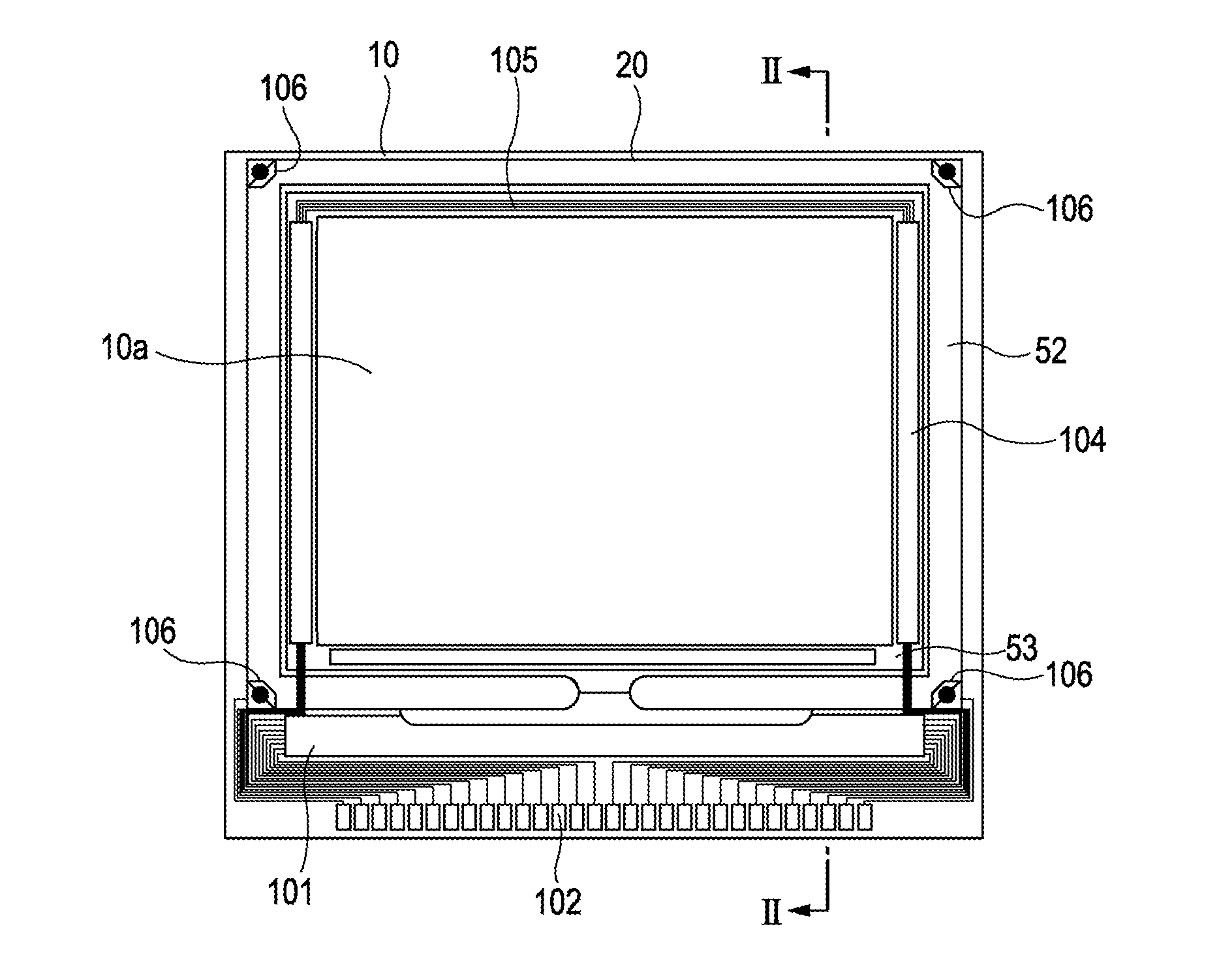

Method for manufacturing stereoscopic image display apparatus and stereoscopic image display apparatus

InactiveUS20100026792A1Easy to uniformlyAvoid mixingSemiconductor/solid-state device manufacturingColor television detailsRegular patternPhase difference

A method for manufacturing a stereoscopic image display apparatus includes a bonding step of bonding an image display panel and a phase difference element by disposing an adhesive layer between the entire surfaces thereof, the image display panel displaying a right-eye image and a left-eye image by regularly mixing them in a plane, the phase difference element including a right-eye image display section corresponding to the right-eye image and a left-eye image display section corresponding to the left-eye image, the phase difference element achieving different polarizations between the right-eye image display section and the left-eye image display section, the adhesive layer being composed of a transparent gel acrylic adhesive with a thickness of 25 to 100 μm, hardness of the adhesive being more than 0 and 350000 μN or less, holding strength of the adhesive at 40° C. after bonding being 8 to 20 N / 20 mm.

Owner:SONY CORP

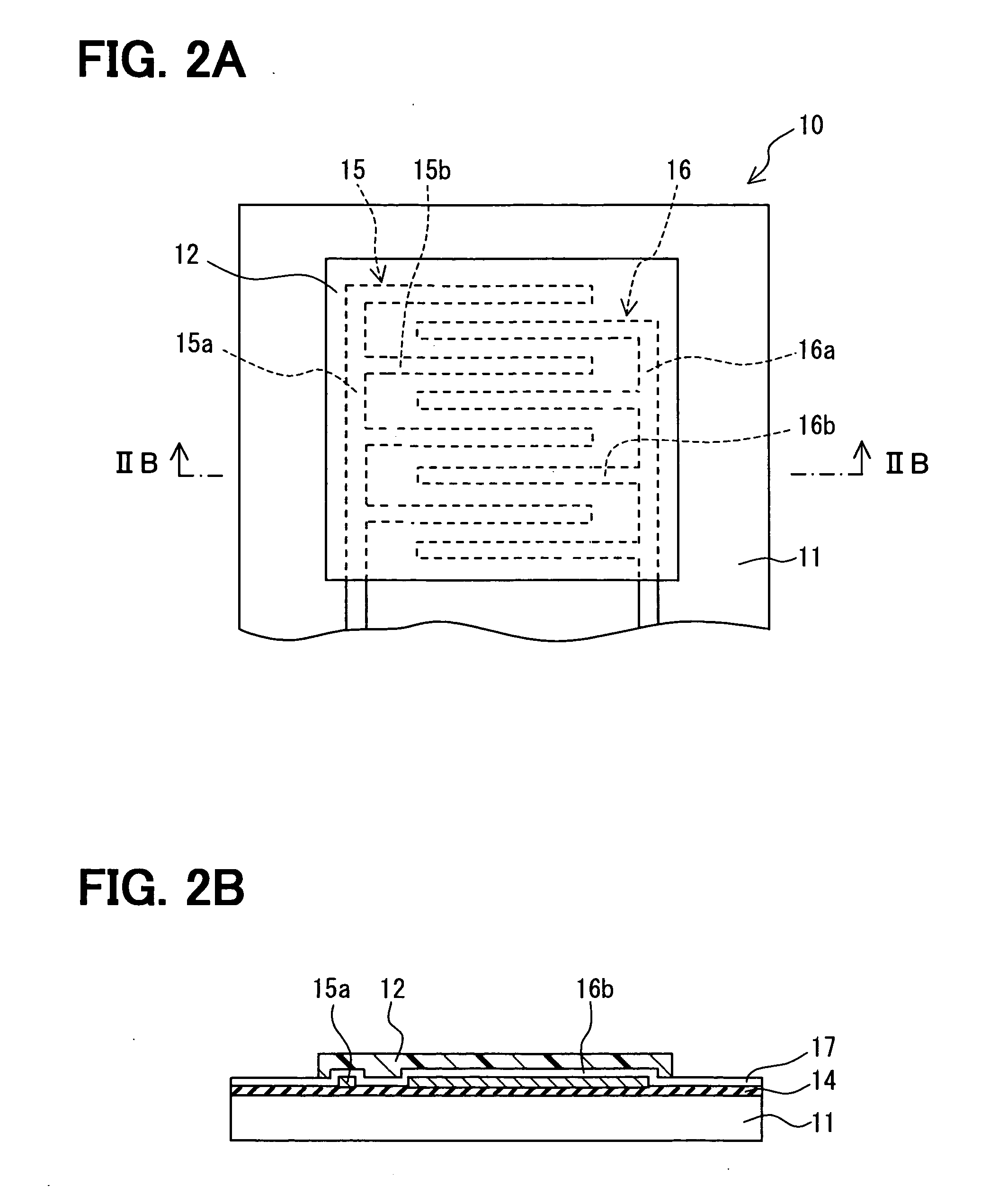

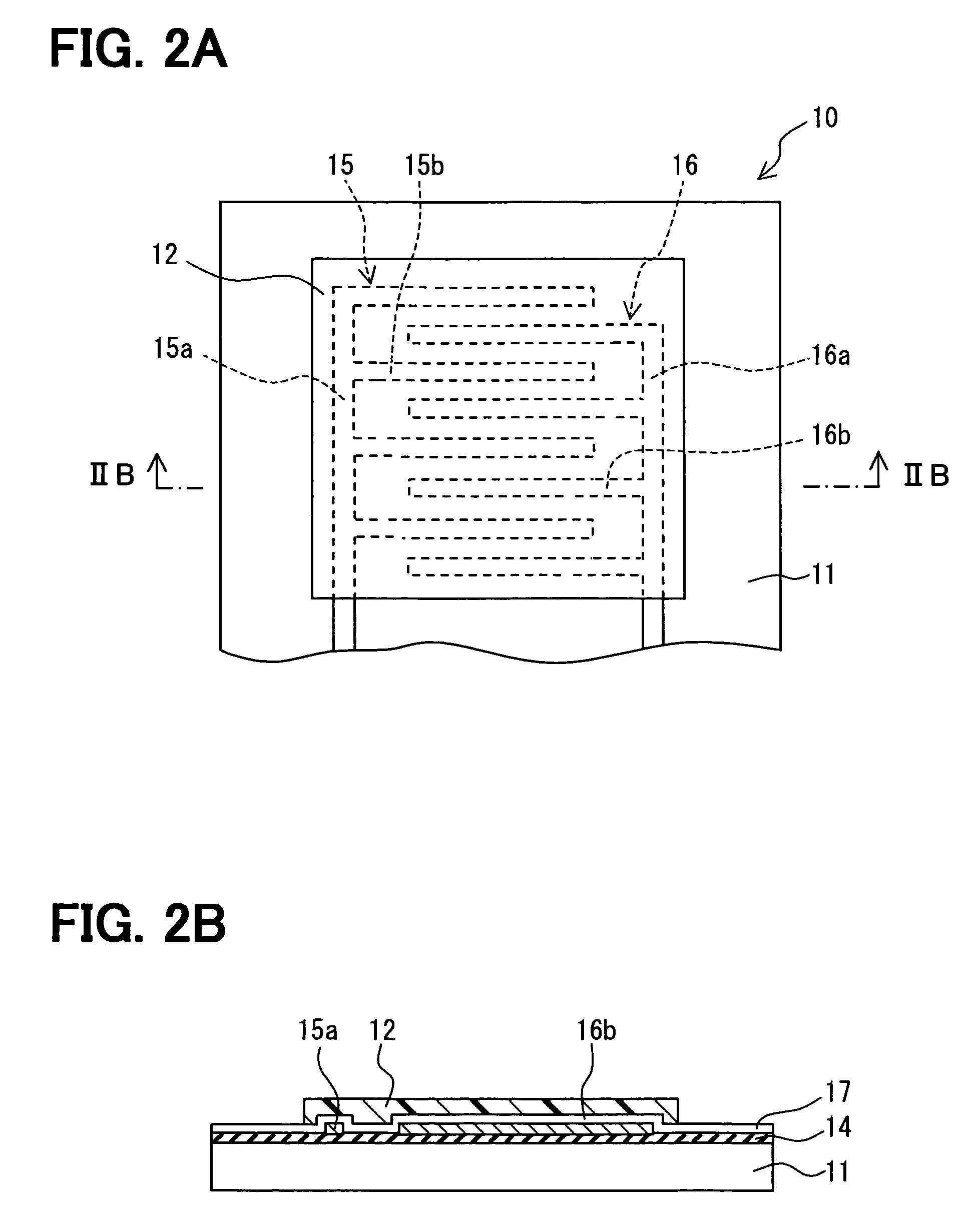

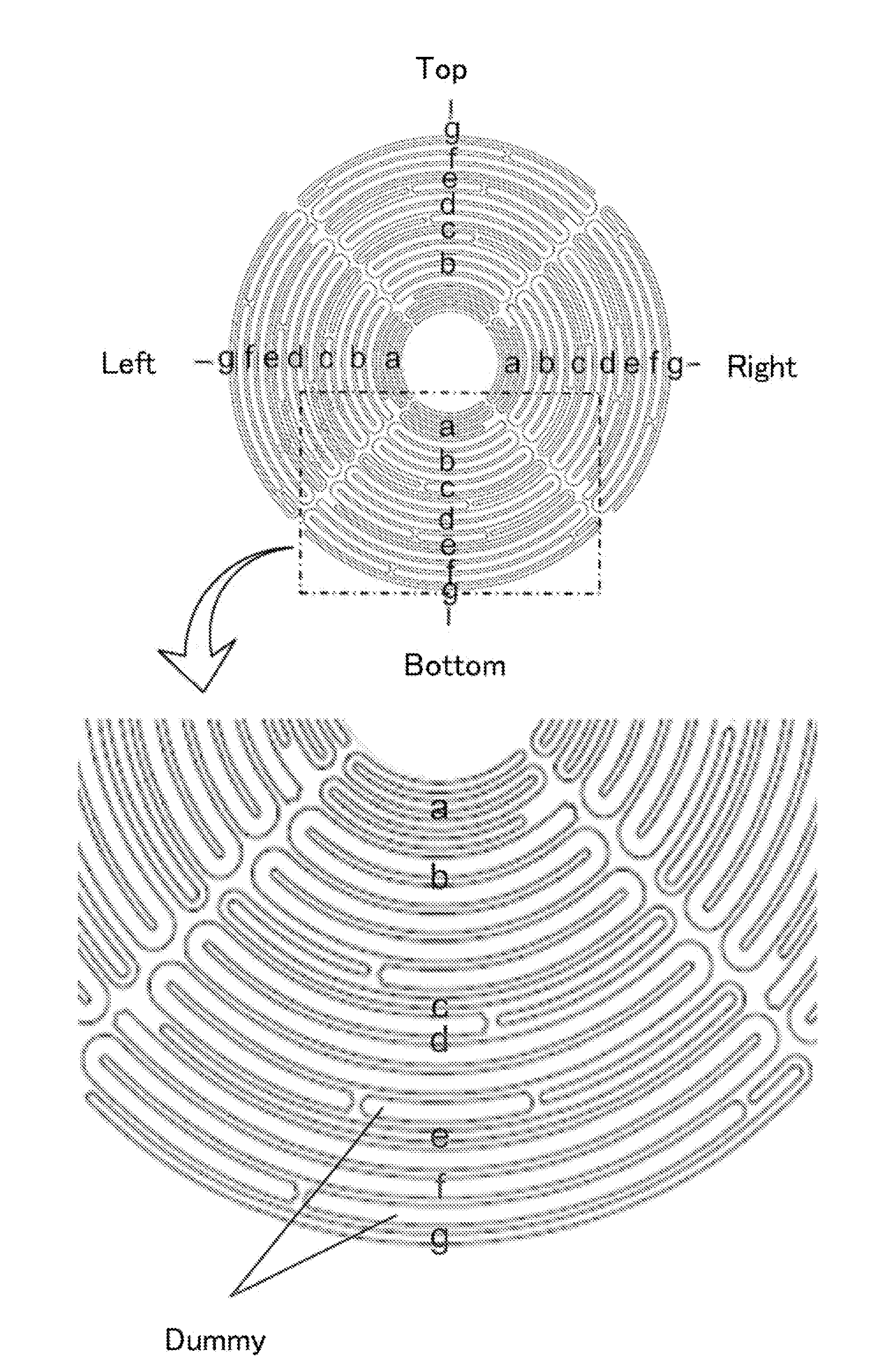

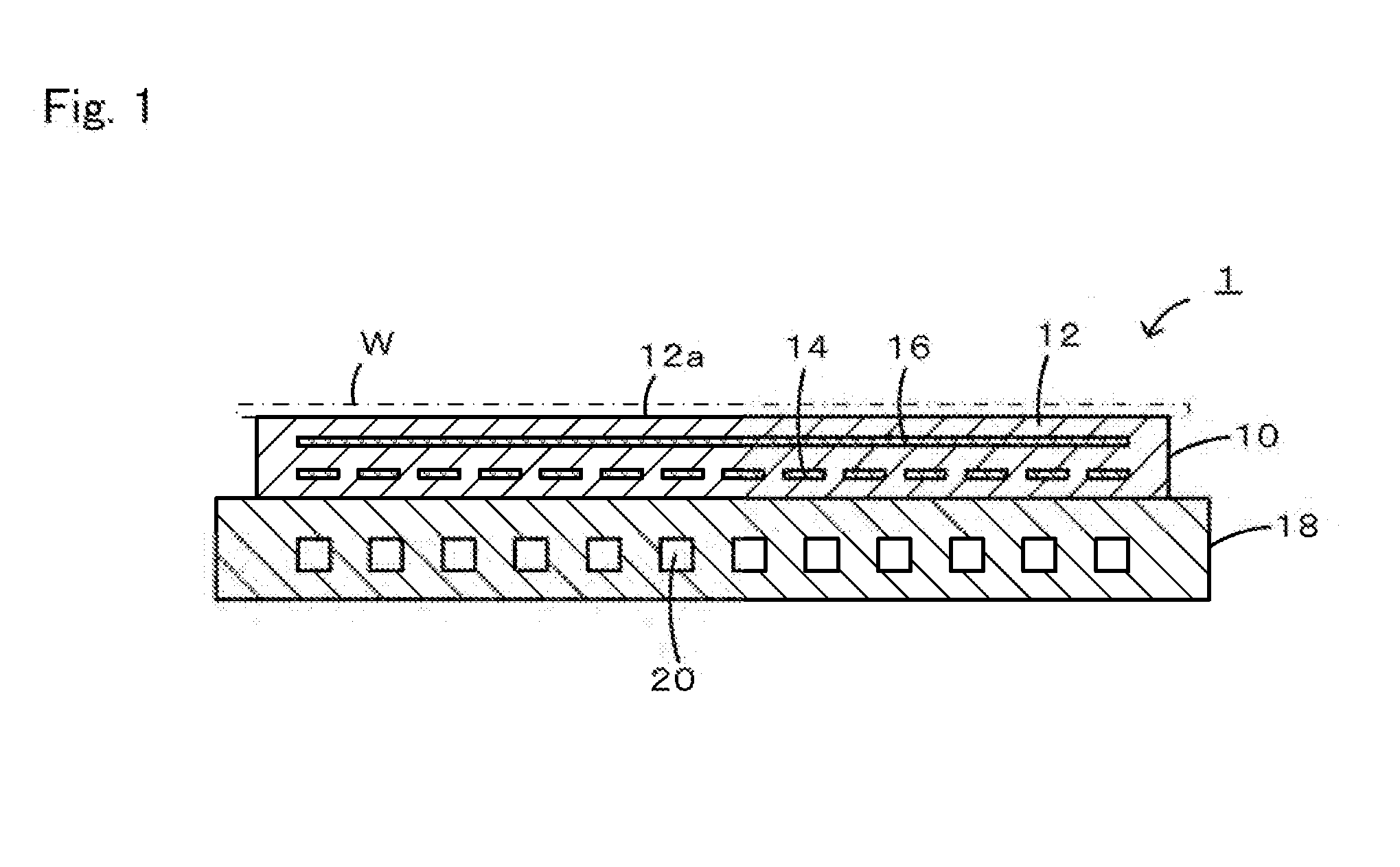

Ceramic heater and method for producing the same

ActiveUS20140284320A1Suppress in-plane variationReversal phenomenon is suppressedOhmic-resistance electrodesSemiconductor/solid-state device manufacturingBrush strokeMetallurgy

An electrostatic chuck 10 includes a disc-shaped alumina ceramic base 12, and a heater electrode 14 and an electrostatic electrode 16 that are embedded in the alumina ceramic base 12. An upper surface of the alumina ceramic base 12 functions as a wafer-receiving surface 12a. The heater electrode 14 is formed in a pattern shape, for example, in the manner of a single brush stroke so as to be arranged over the entire surface of the alumina ceramic base 12. When a voltage is applied to the heater electrode 14, the heater electrode 14 generates heat, and heats a wafer W. This heater electrode 14 contains TiSi2 as a main component.

Owner:NGK INSULATORS LTD

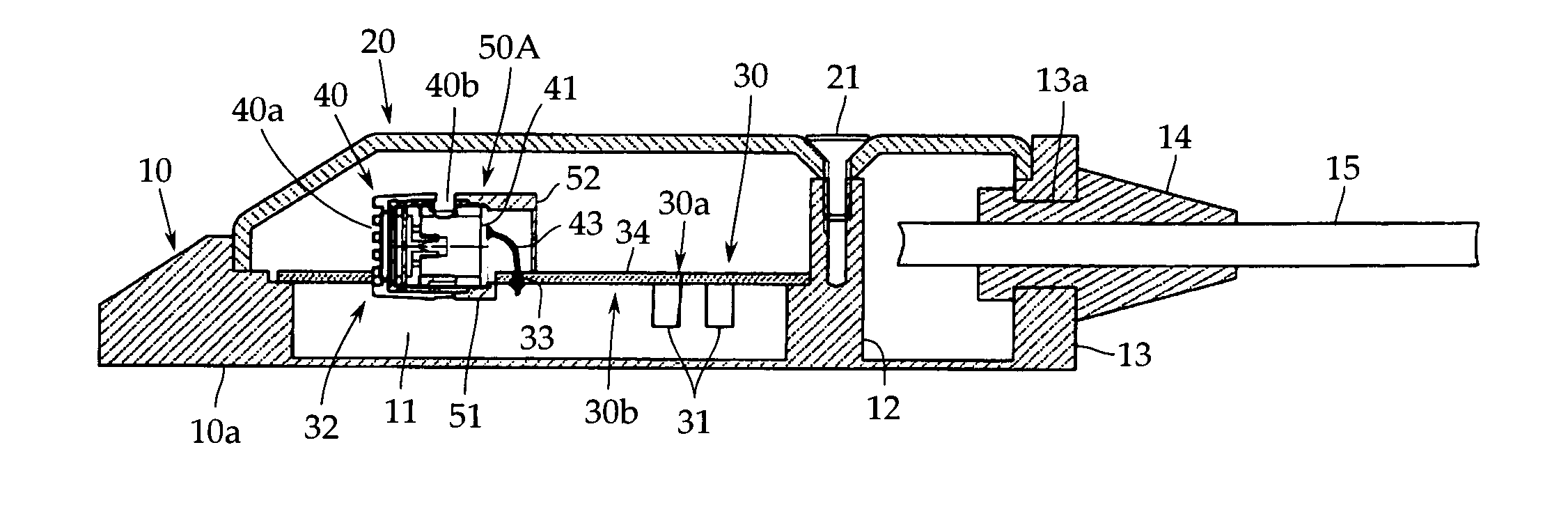

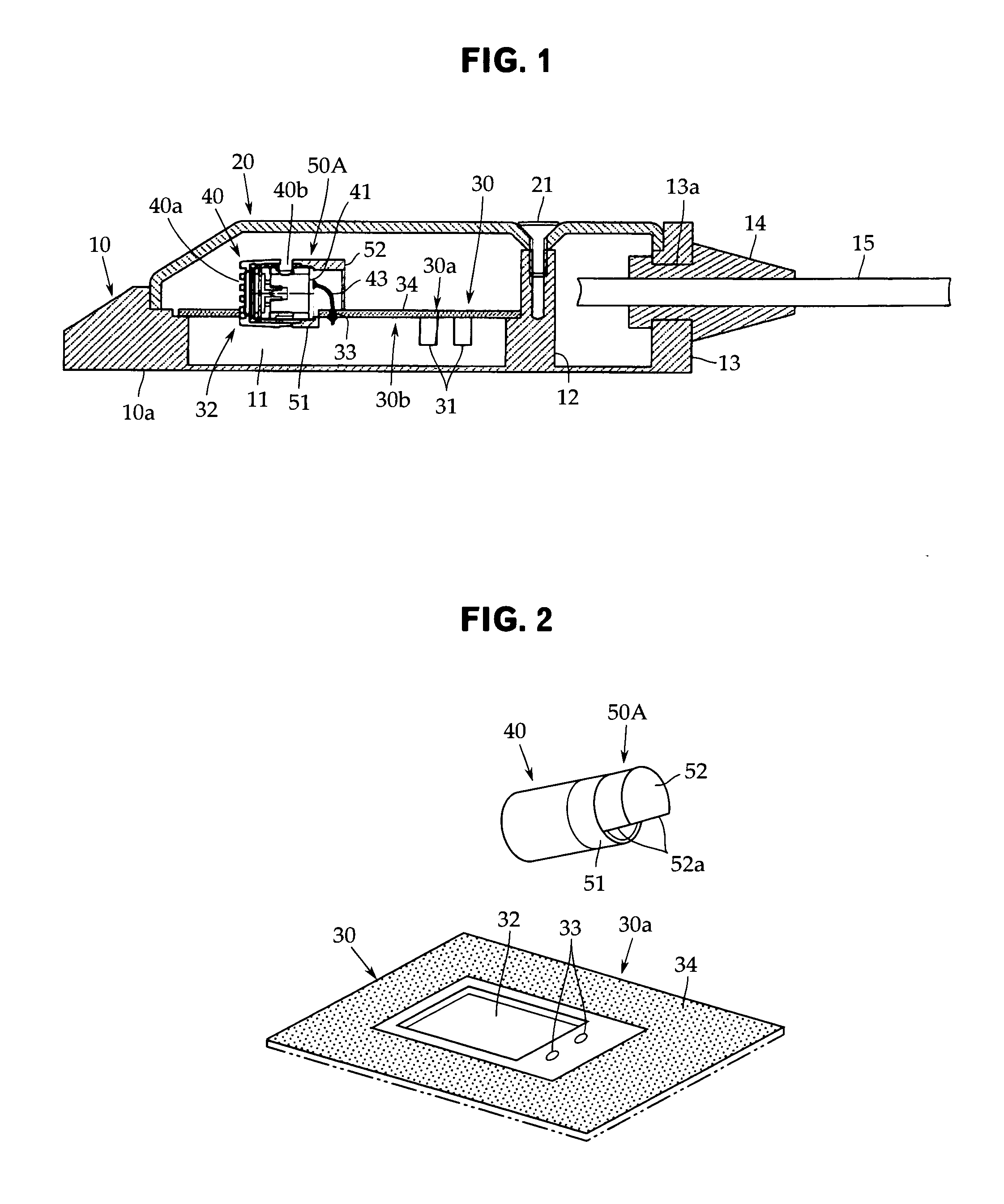

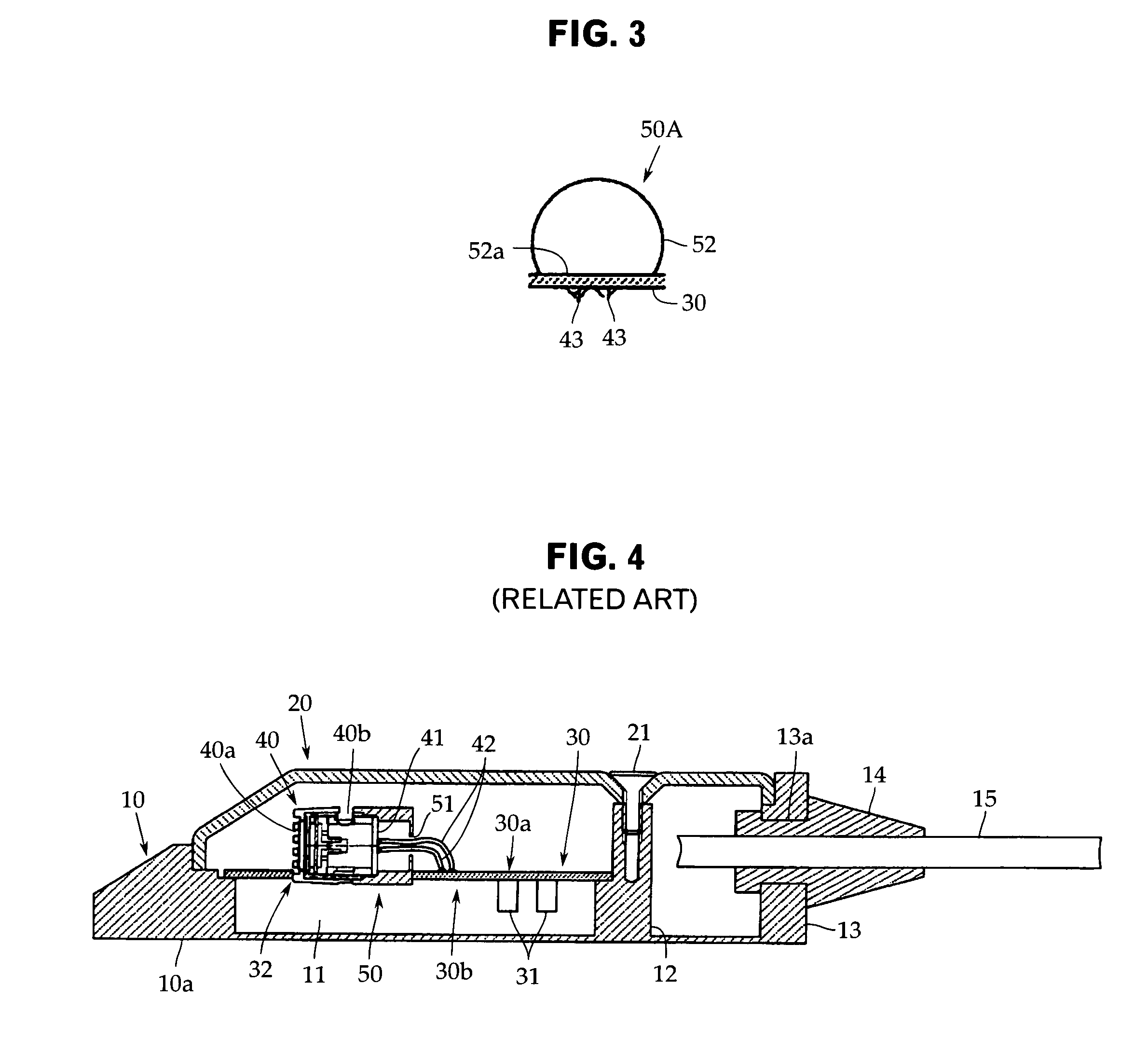

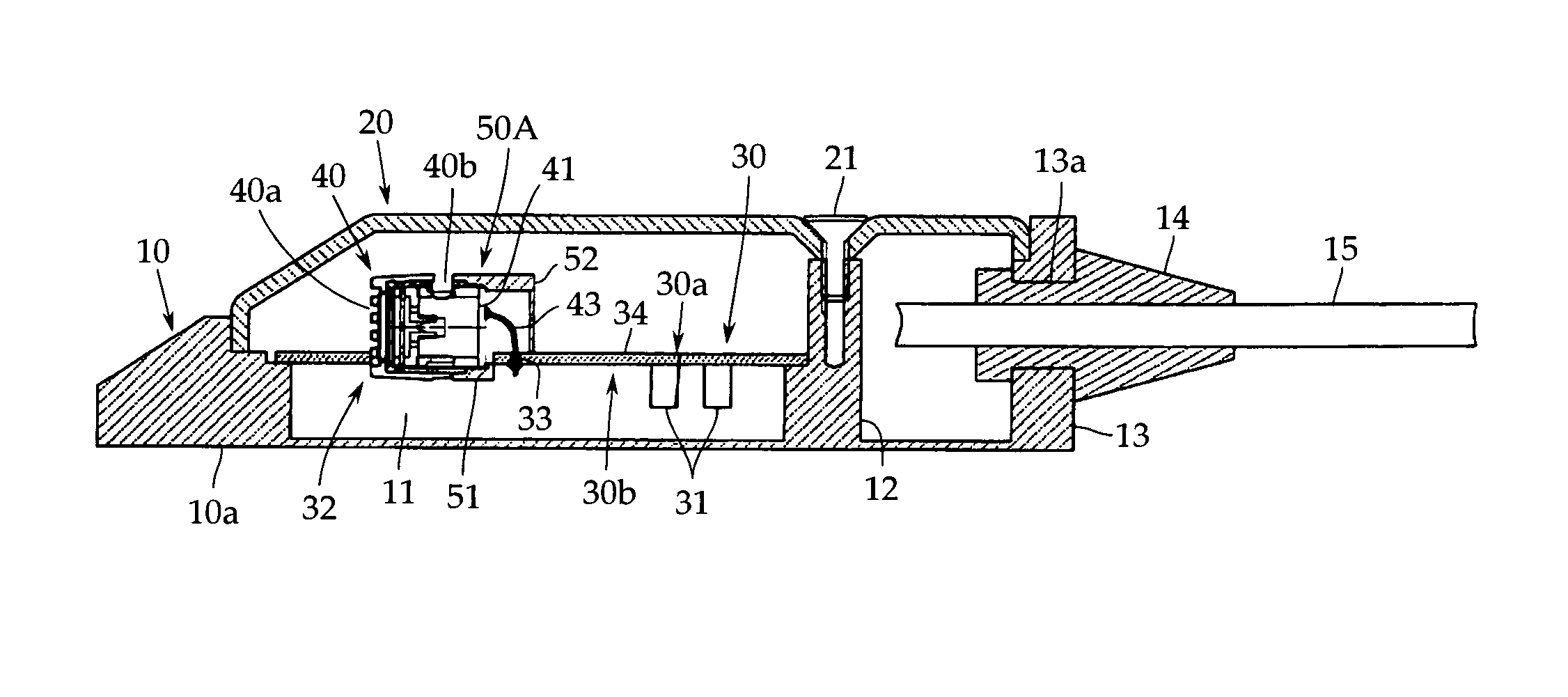

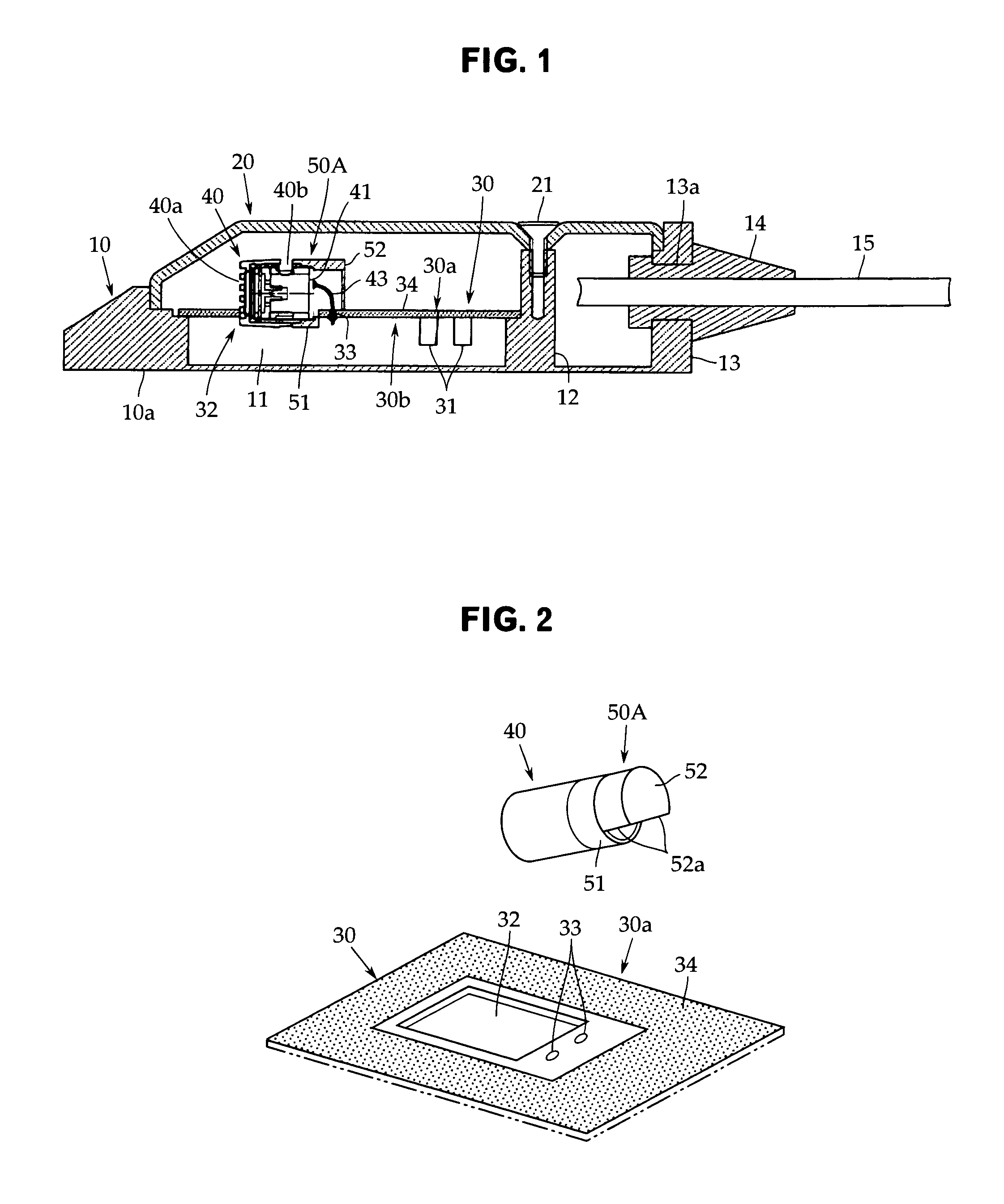

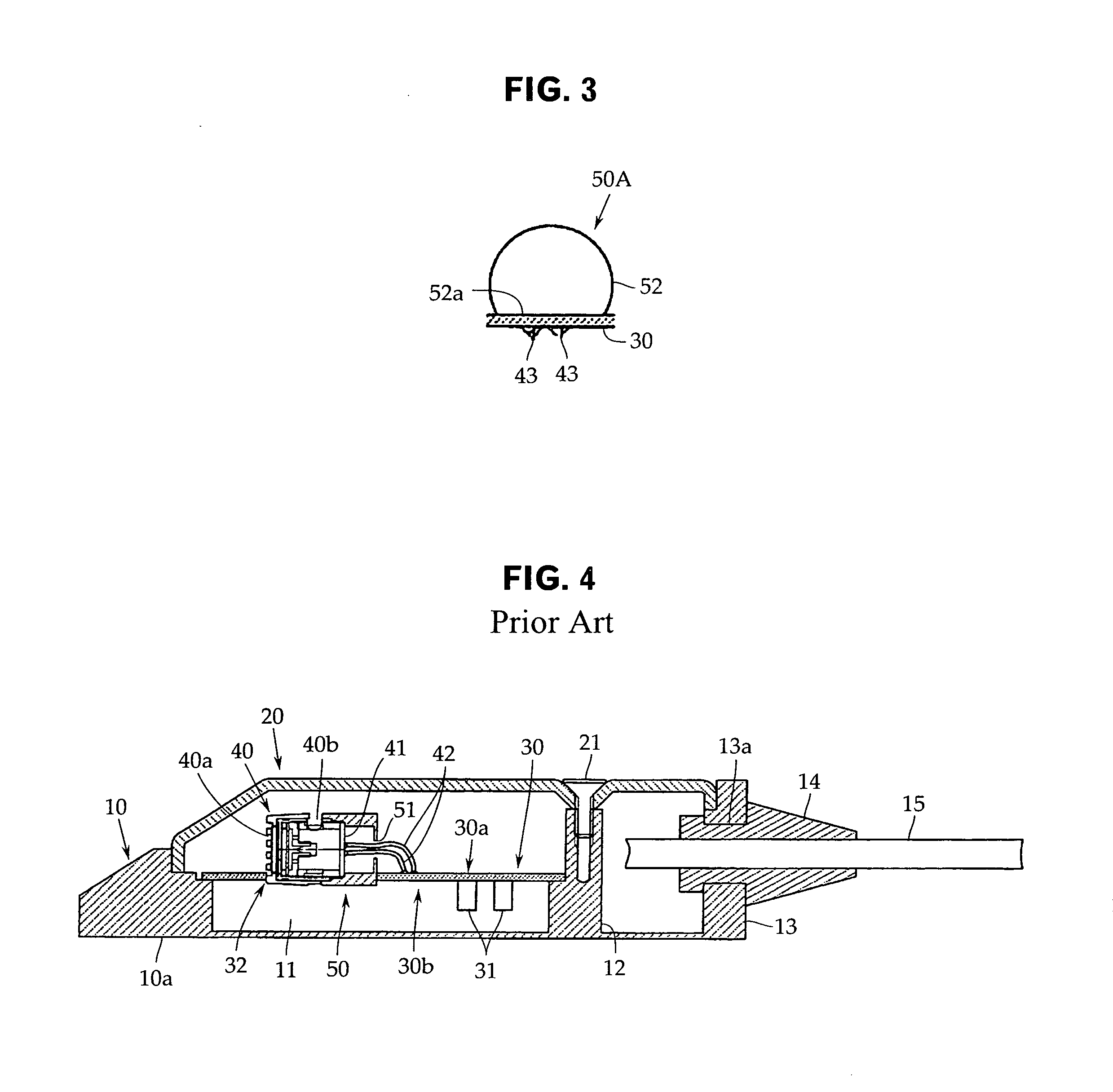

Boundary microphone

InactiveUS20120099752A1Effective noiseEasy to uniformlyPiezoelectric/electrostrictive microphonesMagnetic/electric field screeningMicrophone

A boundary microphone is provided to effectively reduce noises caused by external electromagnetic waves by providing electrostatic shielding, including on the portion of lead wires from a microphone unit to a circuit board. The boundary microphone has a base plate, a cover, a circuit board, and a microphone unit mounted in the opening with a metallic holder. A shield pattern for electrostatically shielding inside of the recess with the base plate is formed on the circuit board. The holder is configured to include a cylindrical section into which a rear end side of the microphone unit is fitted, and a D-cut section in which a part of a circumferential surface and a base surface of a cylinder with a base integral with the cylindrical section are cut away in parallel to a board surface of the circuit board, and the lead wire is routed within the D-cut section.

Owner:AUDIO-TECHNICA

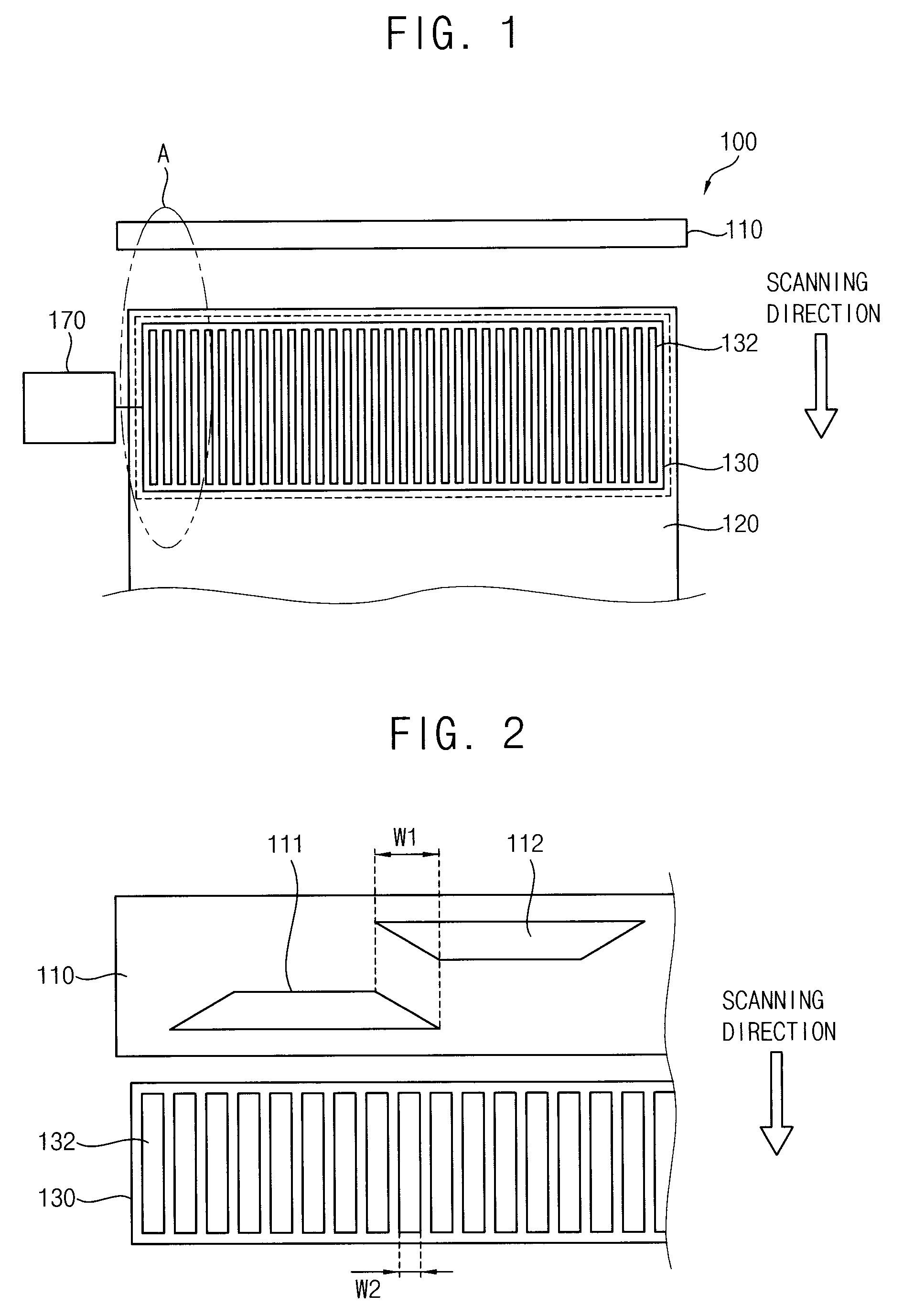

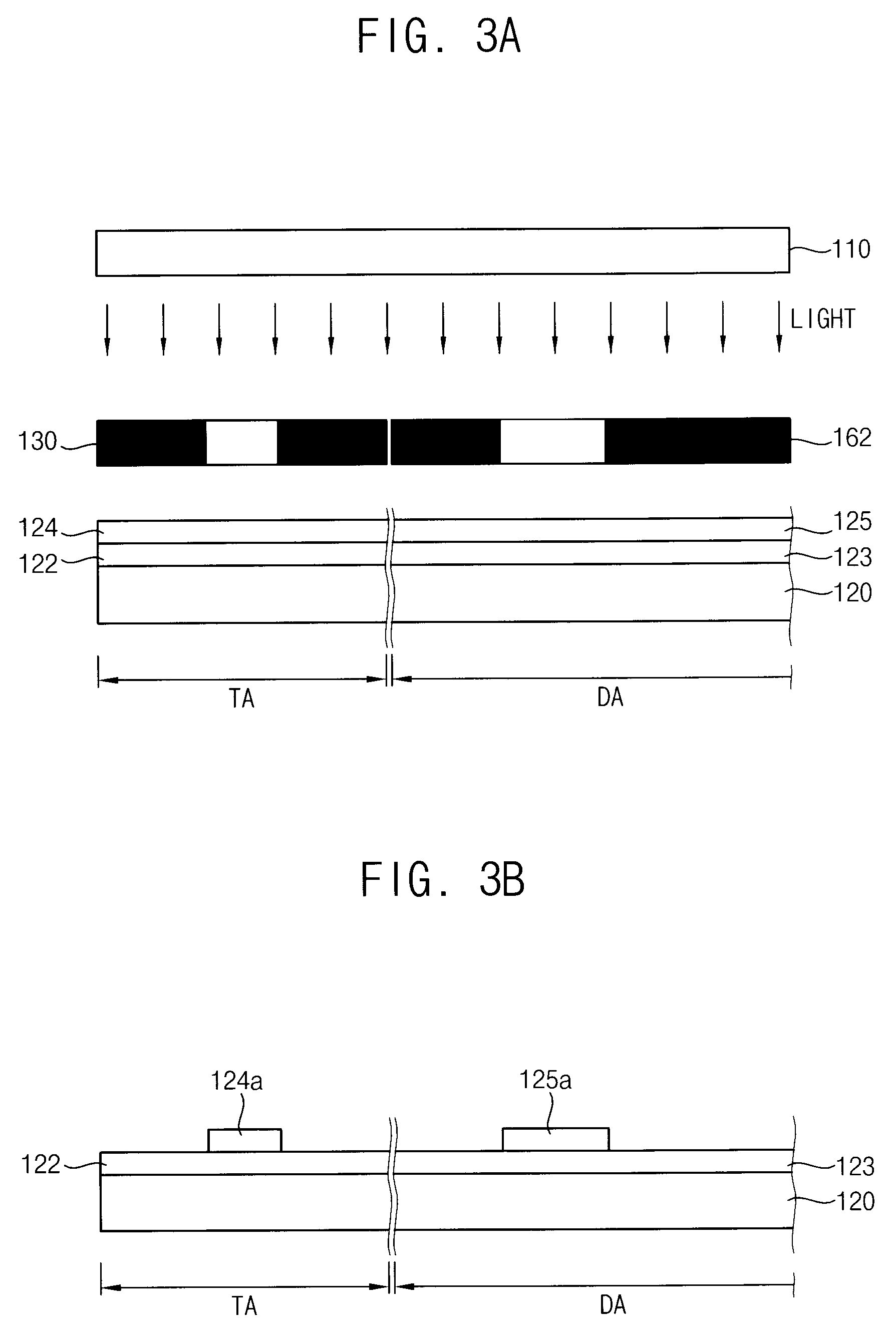

Electro-optic device and electronic apparatus

ActiveUS20090116094A1Uniform brightness of imageEasy to uniformlySteroscopic systemsNon-linear opticsComputer visionElectron

Owner:BOE TECH GRP CO LTD

Boundary microphone

InactiveUS8520880B2Effective noiseEasy to uniformlyPiezoelectric/electrostrictive microphonesInterconnection arrangementsEngineeringMicrophone

A boundary microphone is provided to effectively reduce noises caused by external electromagnetic waves by providing electrostatic shielding, including on the portion of lead wires from a microphone unit to a circuit board. The boundary microphone has a base plate, a cover, a circuit board, and a microphone unit mounted in the opening with a metallic holder. A shield pattern for electrostatically shielding inside of the recess with the base plate is formed on the circuit board. The holder is configured to include a cylindrical section into which a rear end side of the microphone unit is fitted, and a D-cut section in which a part of a circumferential surface and a base surface of a cylinder with a base integral with the cylindrical section are cut away in parallel to a board surface of the circuit board, and the lead wire is routed within the D-cut section.

Owner:AUDIO-TECHNICA

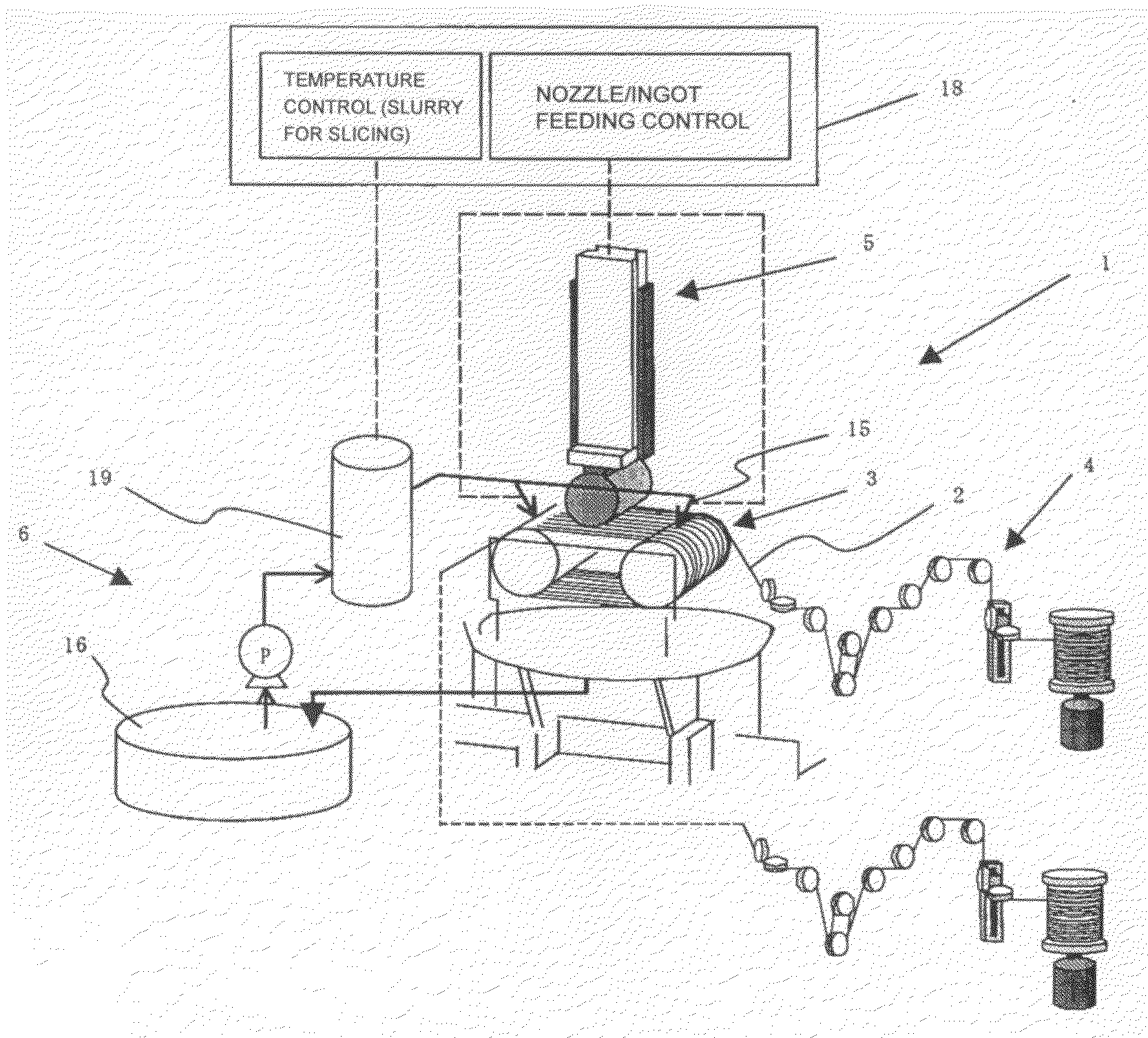

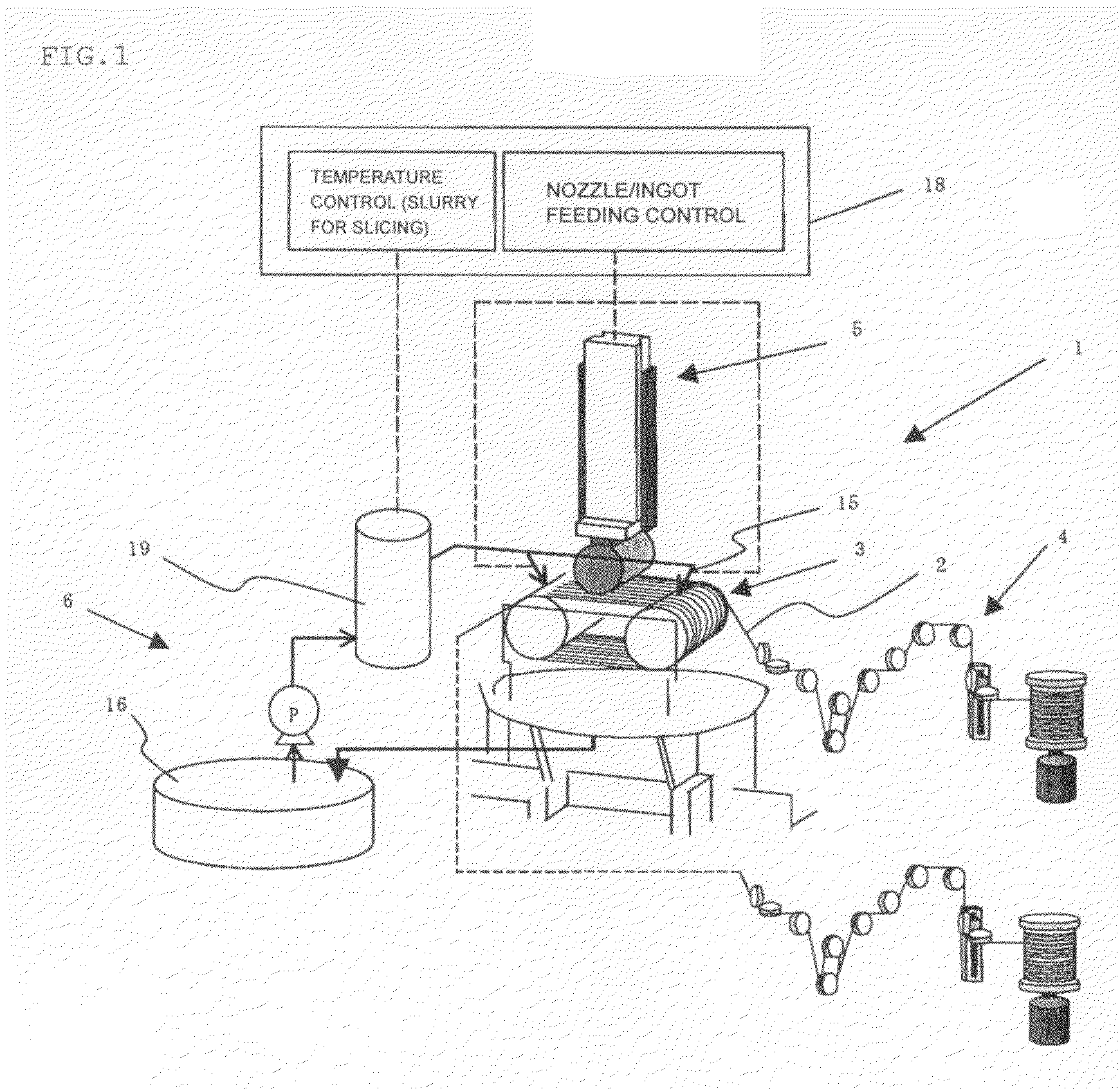

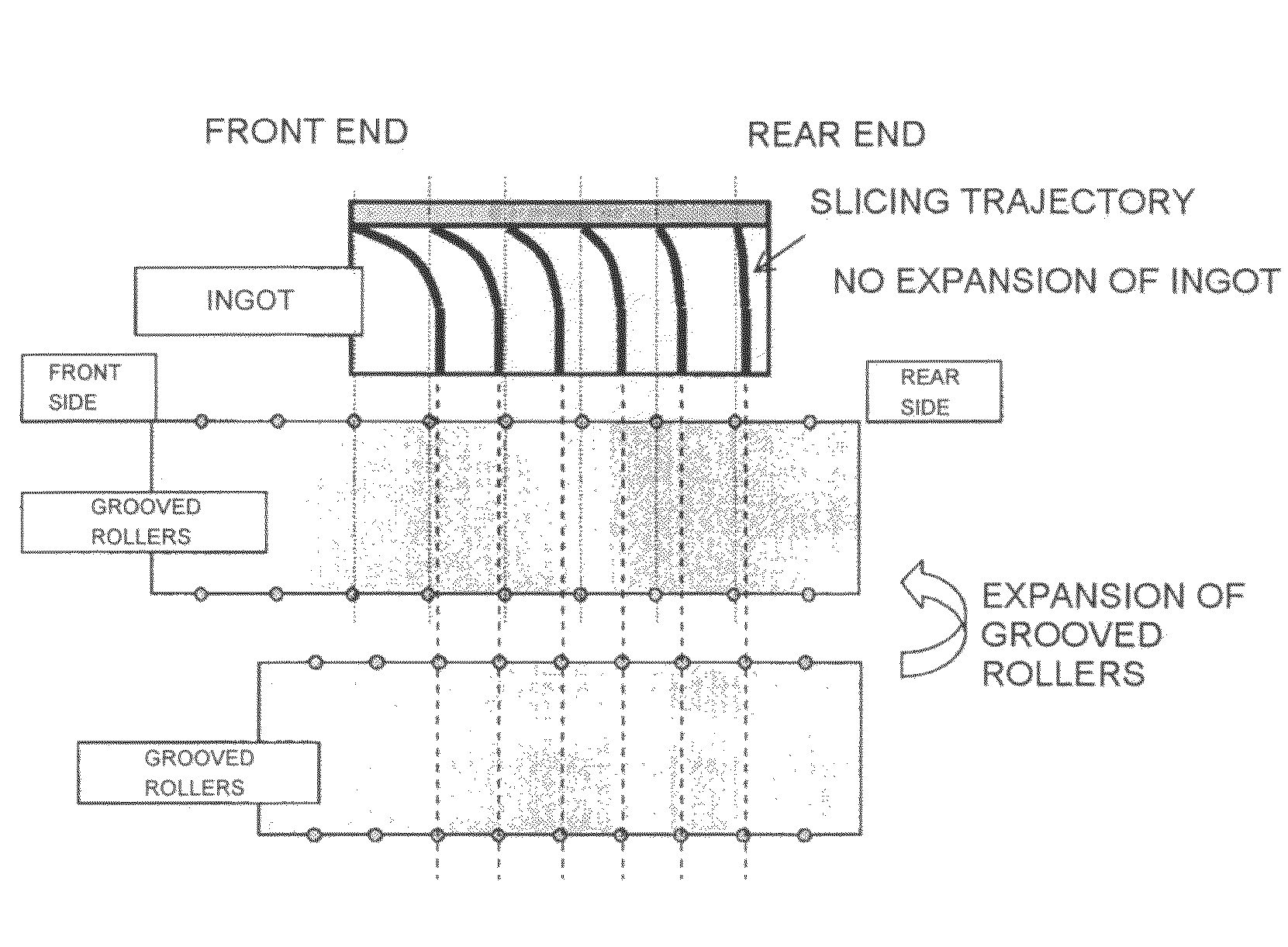

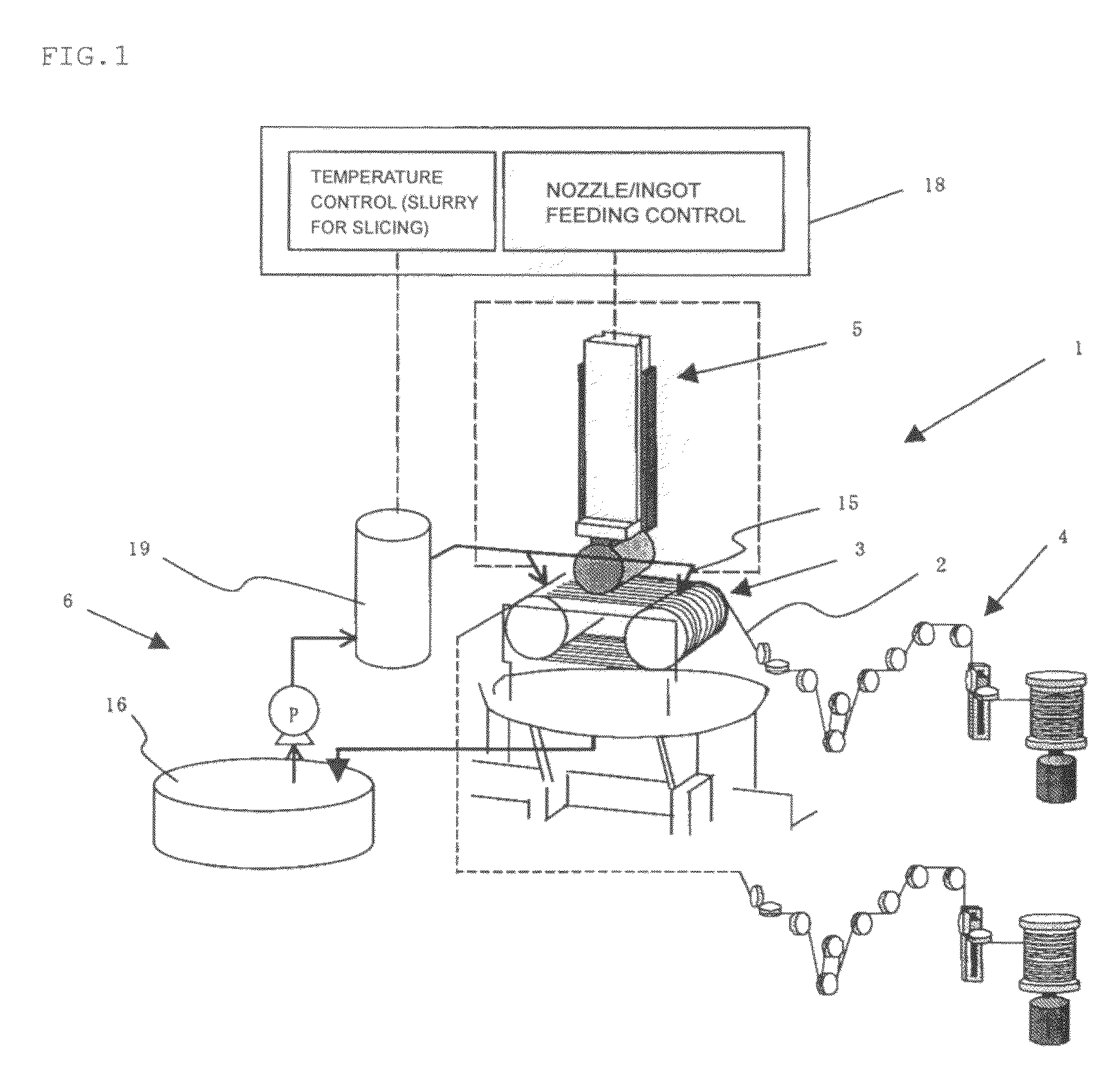

Slicing method and method for manufacturing epitaxial wafer

ActiveUS20090288530A1Improve work efficiencyEasy to implementFrom normal temperature solutionsBy zone-melting liquidsAxial displacementIngot

There is provided a slicing method including winding a wire around a plurality of grooved rollers and pressing the wire against an ingot to be sliced into wafers while supplying a slurry for slicing to the grooved rollers and causing the wire to travel, in which a test of slicing the ingot while supplying the slurry for slicing to the grooved rollers and controlling a supply temperature thereof is previously conducted to examine a relationship between an axial displacement of the grooved rollers and a supply temperature of the slurry for slicing, a supply temperature profile of the slurry for slicing is set based on the relationship between an axial displacement of the grooved rollers and a supply temperature of the slurry for slicing, and the slurry for slicing is supplied based on the supply temperature profile to slice the ingot while controlling an axial displacement of the grooved rollers and to uniform Sori of all wafers to be sliced out in one direction. As a result, the slicing method that can easily perform slicing with excellent reproducibility while uniforming Sori of all wafers in one direction at the time of slicing an ingot by using a wire saw is provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

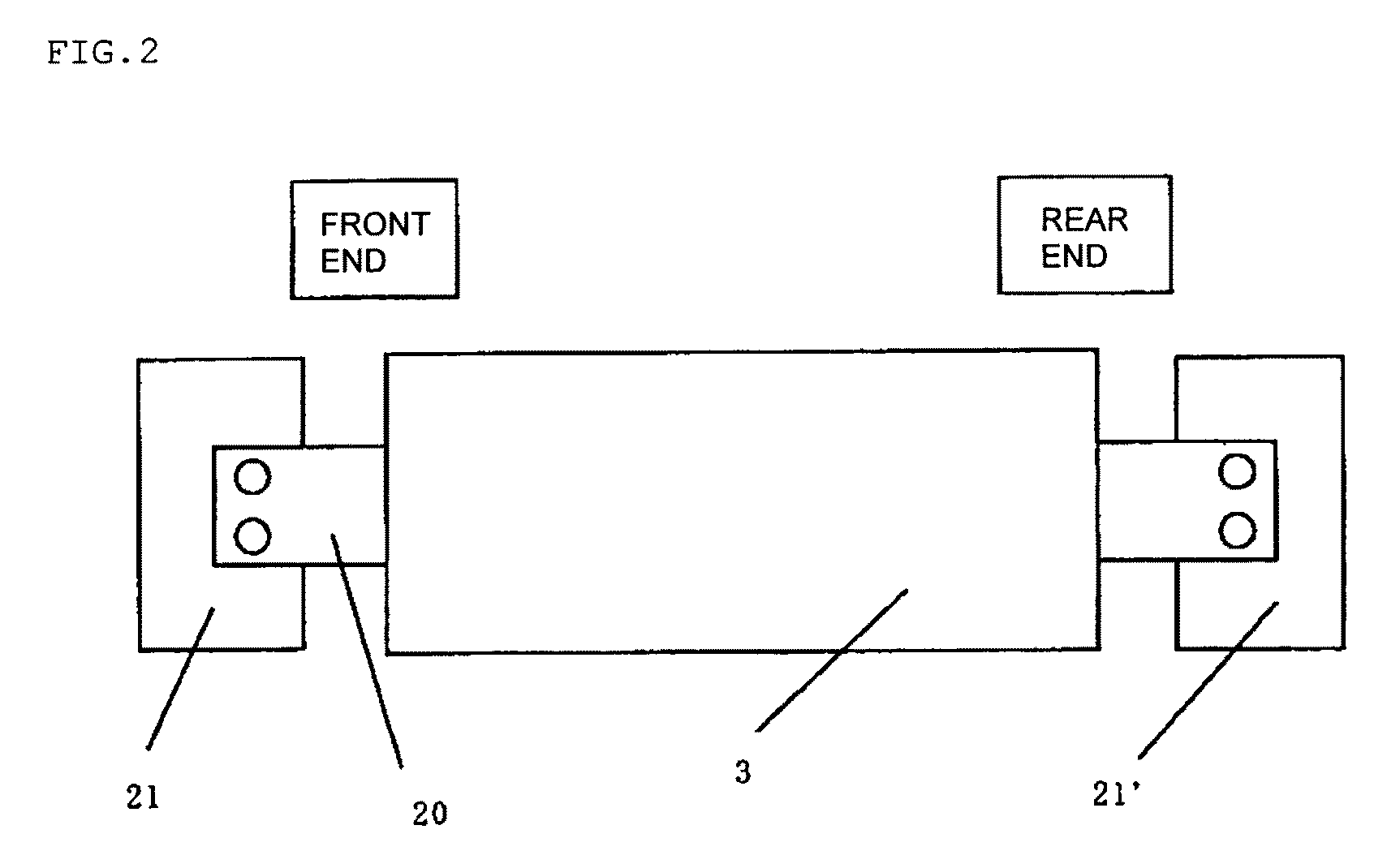

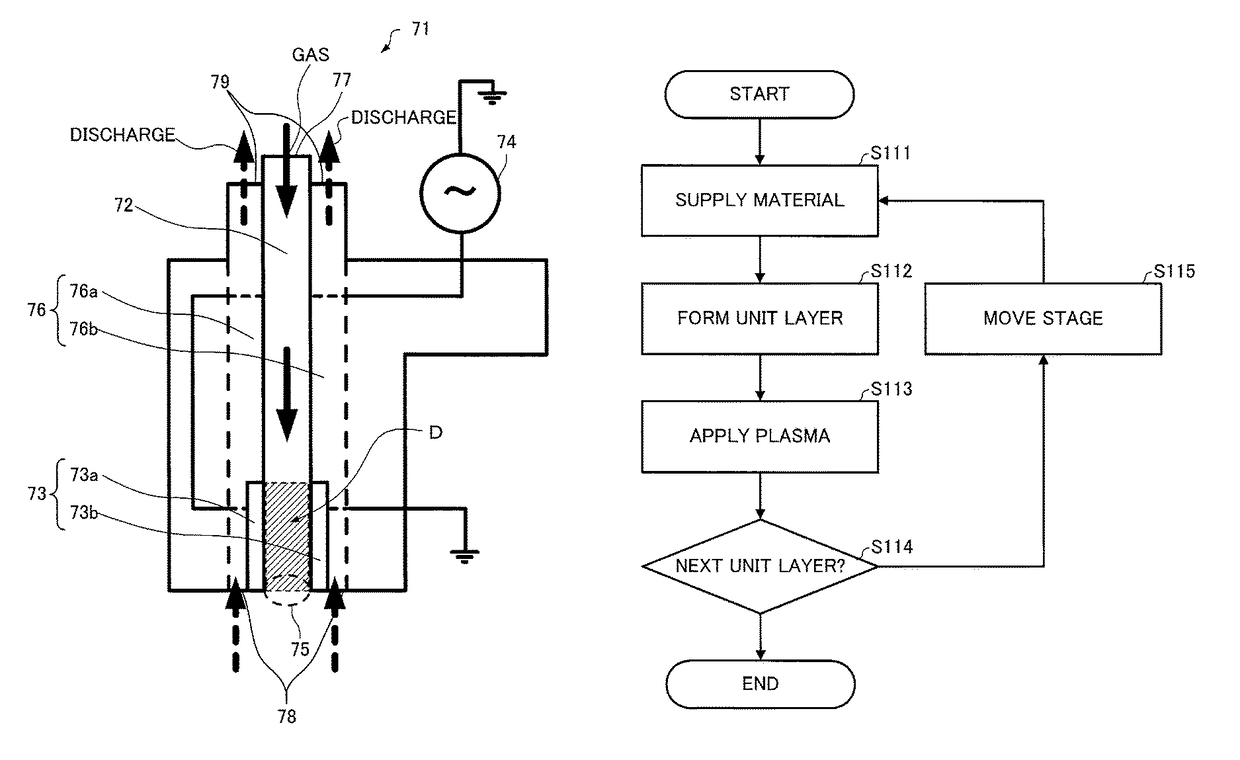

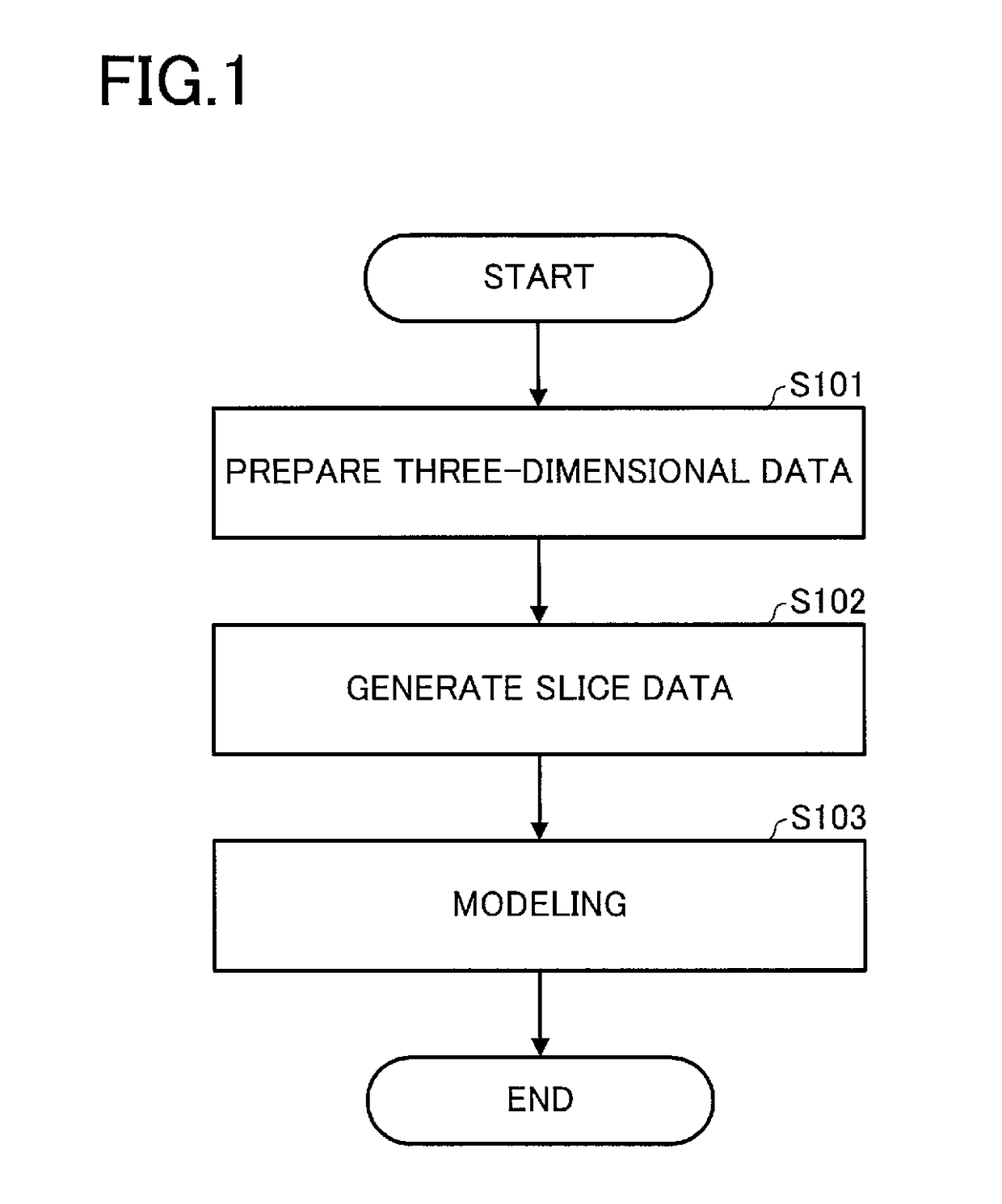

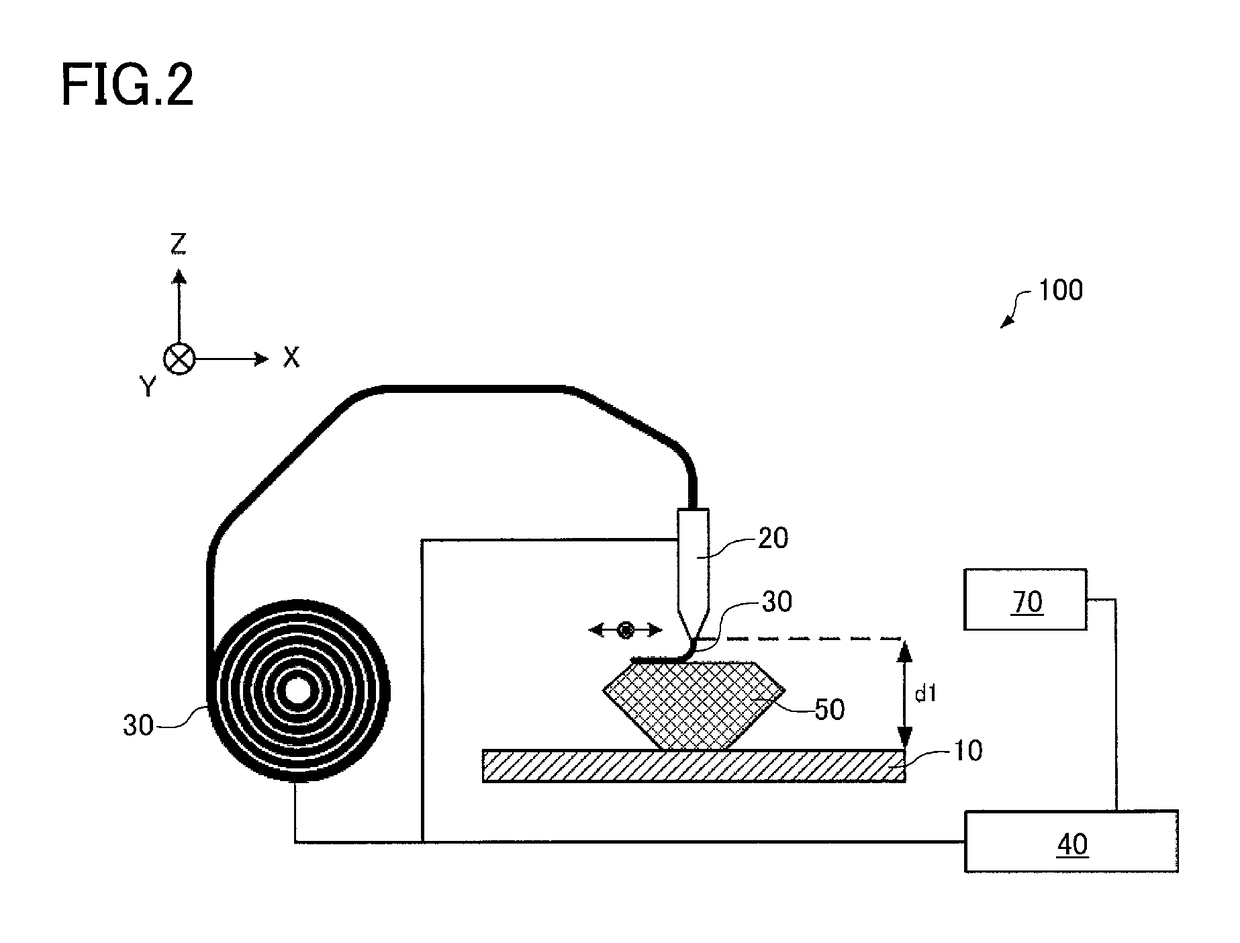

Method for producing object

ActiveUS9802363B2Improve accuracyHigh strengthManufacturing heating elementsManufacturing environment conditioningOptoelectronicsMaterials science

A method for producing an object includes forming and laying N unit layers into which an object is divided, sequentially from a first layer to an Nth layer, using a resin material as a material, or using a resin material for implementing a step, to form the object, the method including performing a discharge treatment at either or both of a timing while forming a unit layer among the N unit layers, and a timing after forming the unit layer, but before starting forming a next unit layer among the N unit layers.

Owner:SEIKO EPSON CORP

Remaining toner detection apparatus and image forming apparatus provided with same

ActiveUS7283755B2Accurately determinedAccurate measurementElectrographic process apparatusLevel indicators by physical variable measurementImage formationEngineering

A pair of indentations is formed with a vertical spacing on a side wall of a toner cartridge, respective translucent windows are arranged on opposing upper and lower surfaces of the indentations protruding into the toner cartridge, and a light-emitting element and a light-receiving element of a remaining toner sensor are inserted to the indentations such that the light-emitting element and the light-receiving element of the remaining toner sensor face each other via the translucent windows of the indentations. When there is sufficient toner remaining in the toner cartridge, there is toner in the space between the transparent plates, and the space between a light-emitting diode and a phototransistor is blocked such that light is not incident on the phototransistor, whereas when there is little toner remaining in the toner cartridge, there is no toner in the space between the transparent plates, and the light is incident on the phototransistor via the space between the light-emitting diode and the photoresistor.

Owner:SHARP KK

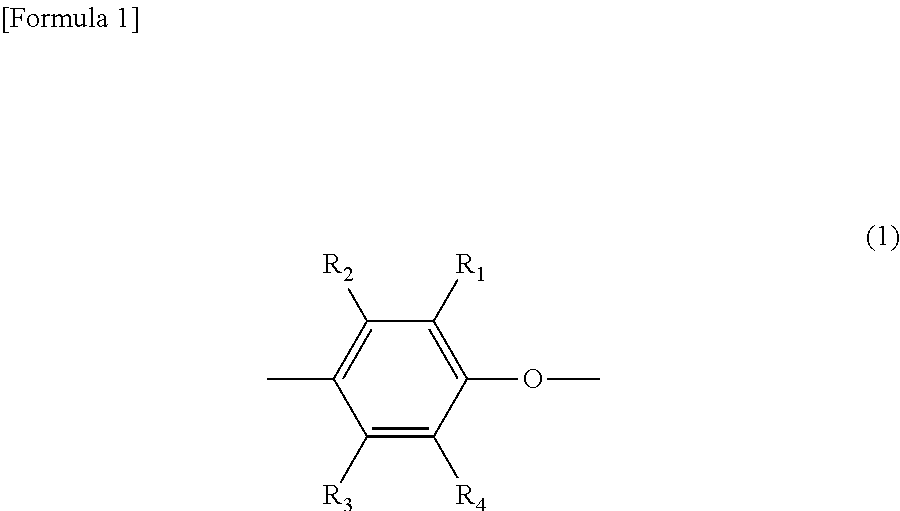

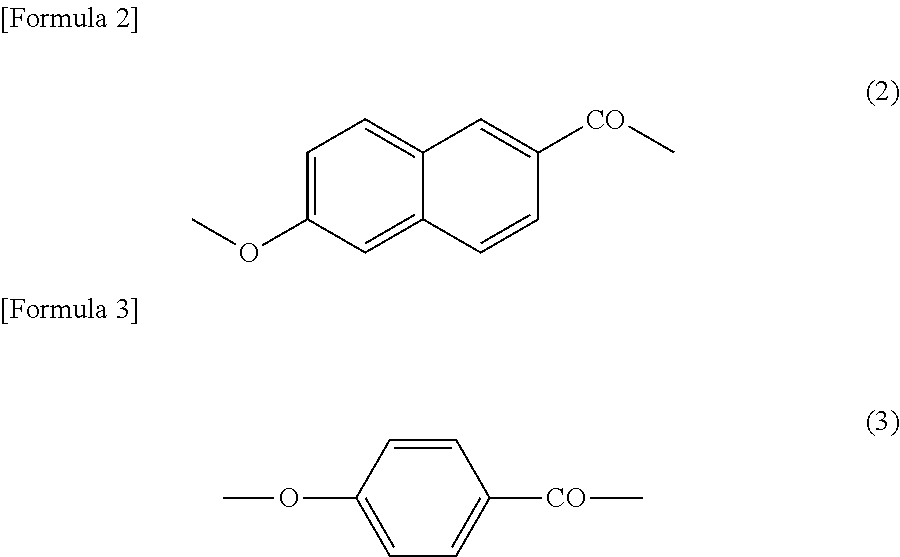

Small-Animal Controlling Resin Composition

InactiveUS20180116211A1Easy to optimizeEasy to uniformlyBiocideAnimal repellantsSmall animalBoiling point

An small-animal-controlling resin composition includes at least a base resin, a small-animal-controlling agent, a sustained release auxiliary for the small-animal-controlling agent, an organic weatherproofing agent, and metal oxide fine particles as an inorganic weatherproofing agent. Surfaces of the metal oxide fine particles are subjected to a surface treatment using a surface treatment agent comprising an organic material. A low volatility carboxylic acid ester derivative having a boiling point of no less than 200° C. is used as the sustained release auxiliary for the small-animal-controlling agent.

Owner:NIX INC

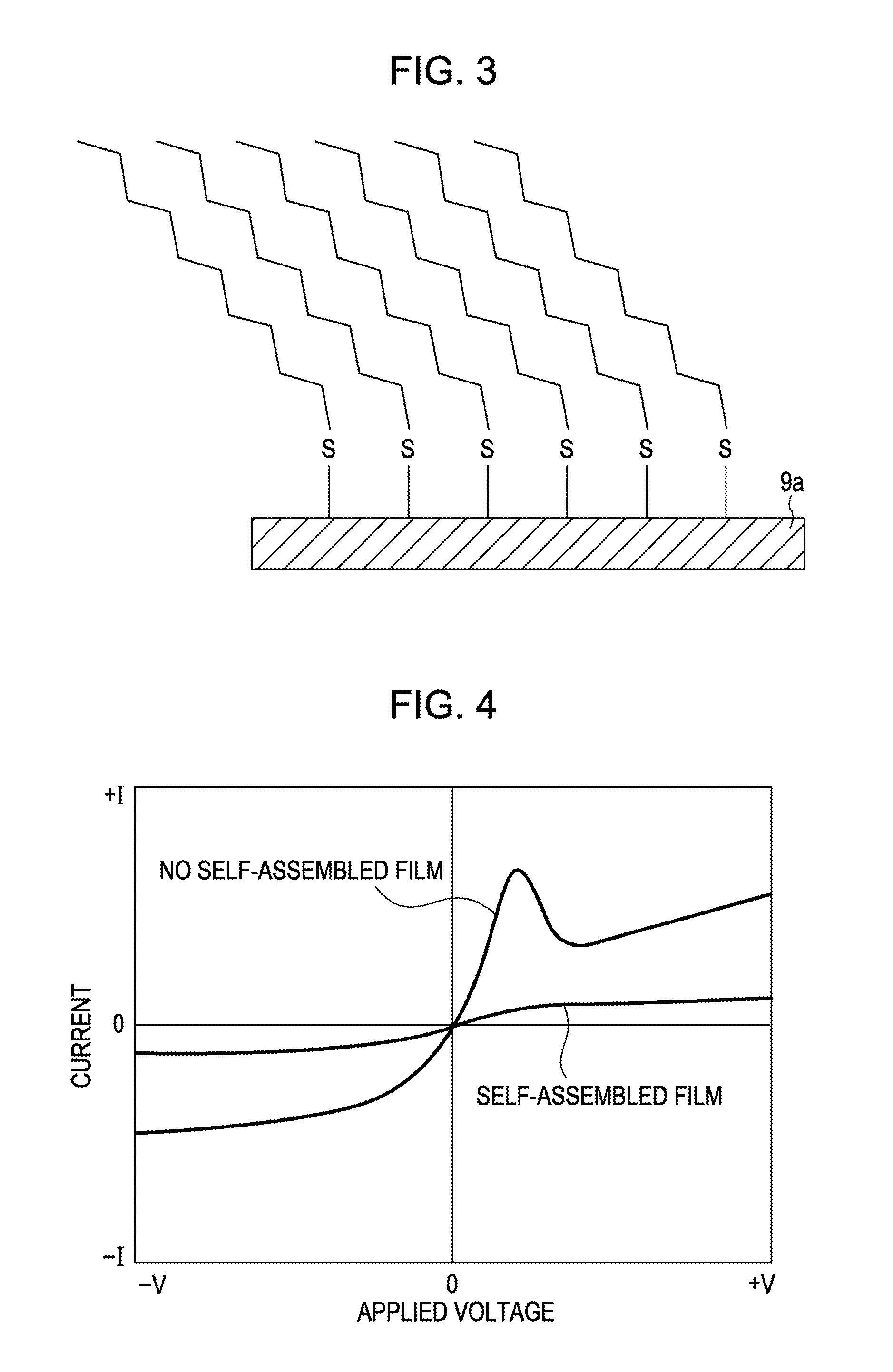

Liquid crystal device, method of manufacturing the same, and electronic apparatus

InactiveUS20110090440A1Easily and reliably preventing charge occurringAvoid chargingColor television detailsNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal device includes: a liquid crystal layer being interposed between a pair of substrates; an electrode disposed on surfaces of at least one of the pair of substrates facing the liquid crystal layer; a self-assembled film disposed to cover the electrode on the side of the liquid crystal layer; and an inorganic alignment film disposed between the self-assembled film and the liquid crystal layer.

Owner:SEIKO EPSON CORP

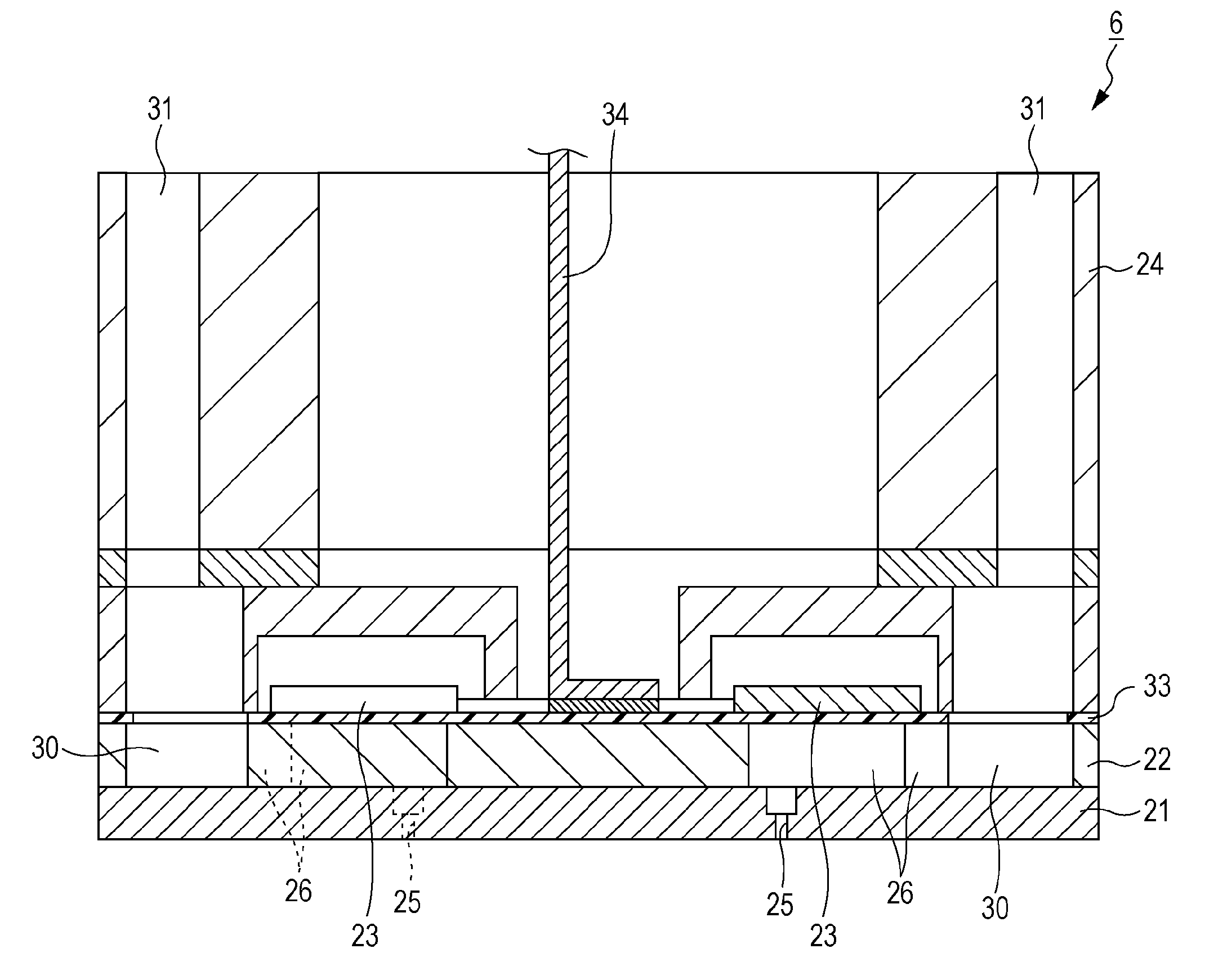

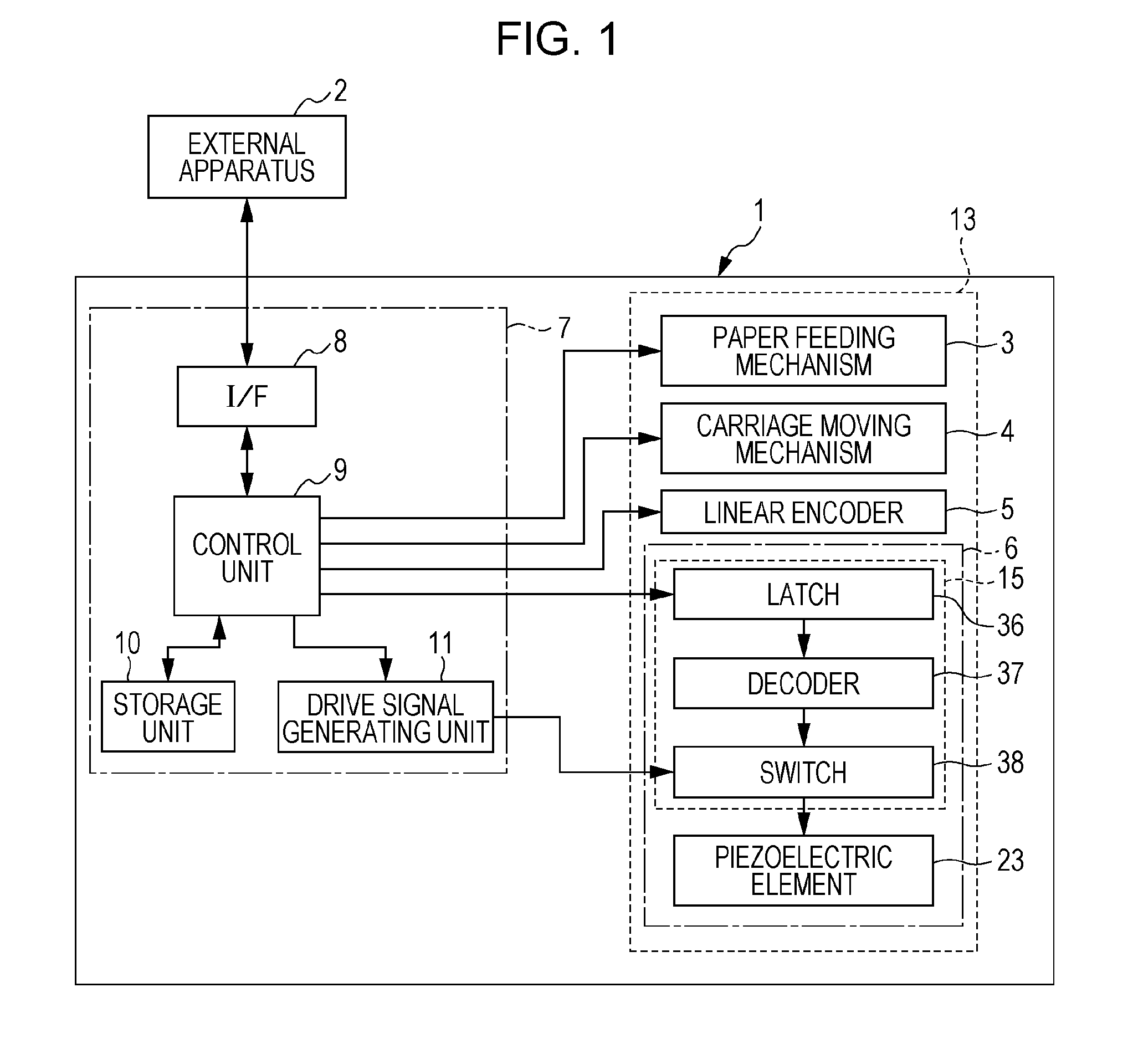

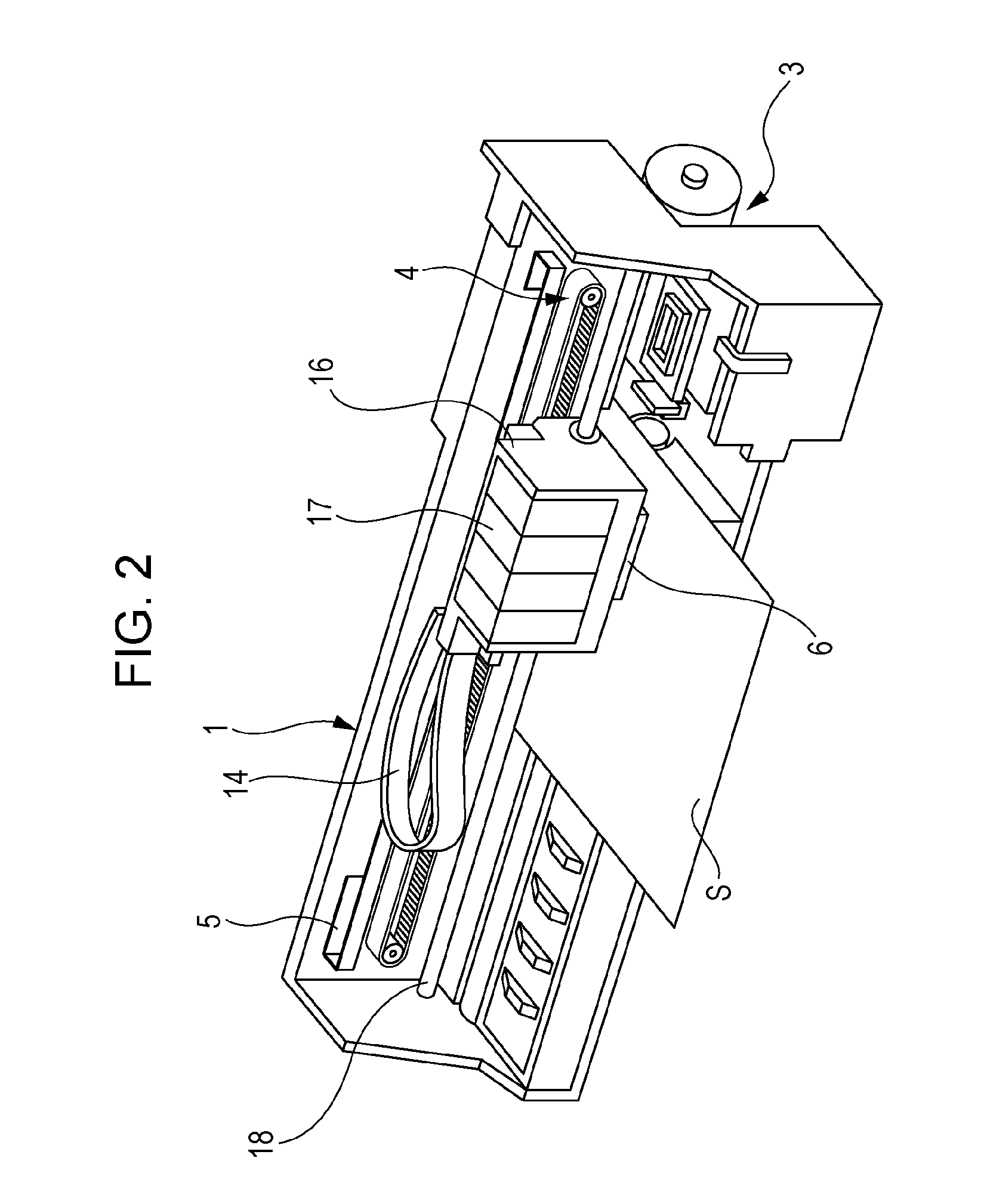

Liquid ejecting apparatus and method of controlling liquid ejecting apparatus

A pressure chamber array includes one or more dummy pressure chambers in which ejection of ink is not performed, the dummy pressure chamber includes a piezoelectric element, and a drive potential generator continues to apply a drive potential to the piezoelectric element corresponding to the dummy pressure chamber, while the ejection of the ink from a nozzle of at least a pressure chamber adjacent to the dummy pressure chamber is performed.

Owner:SEIKO EPSON CORP

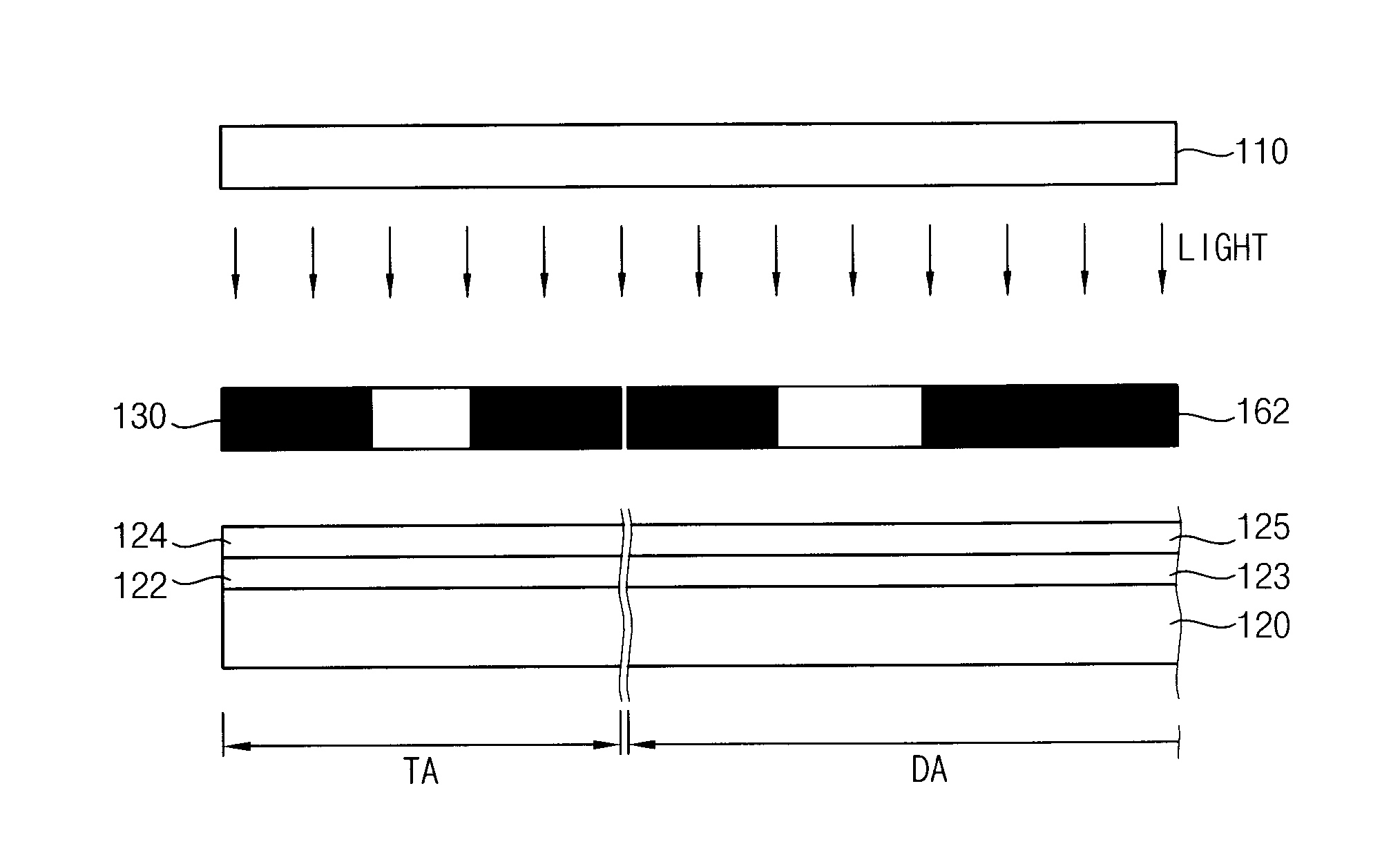

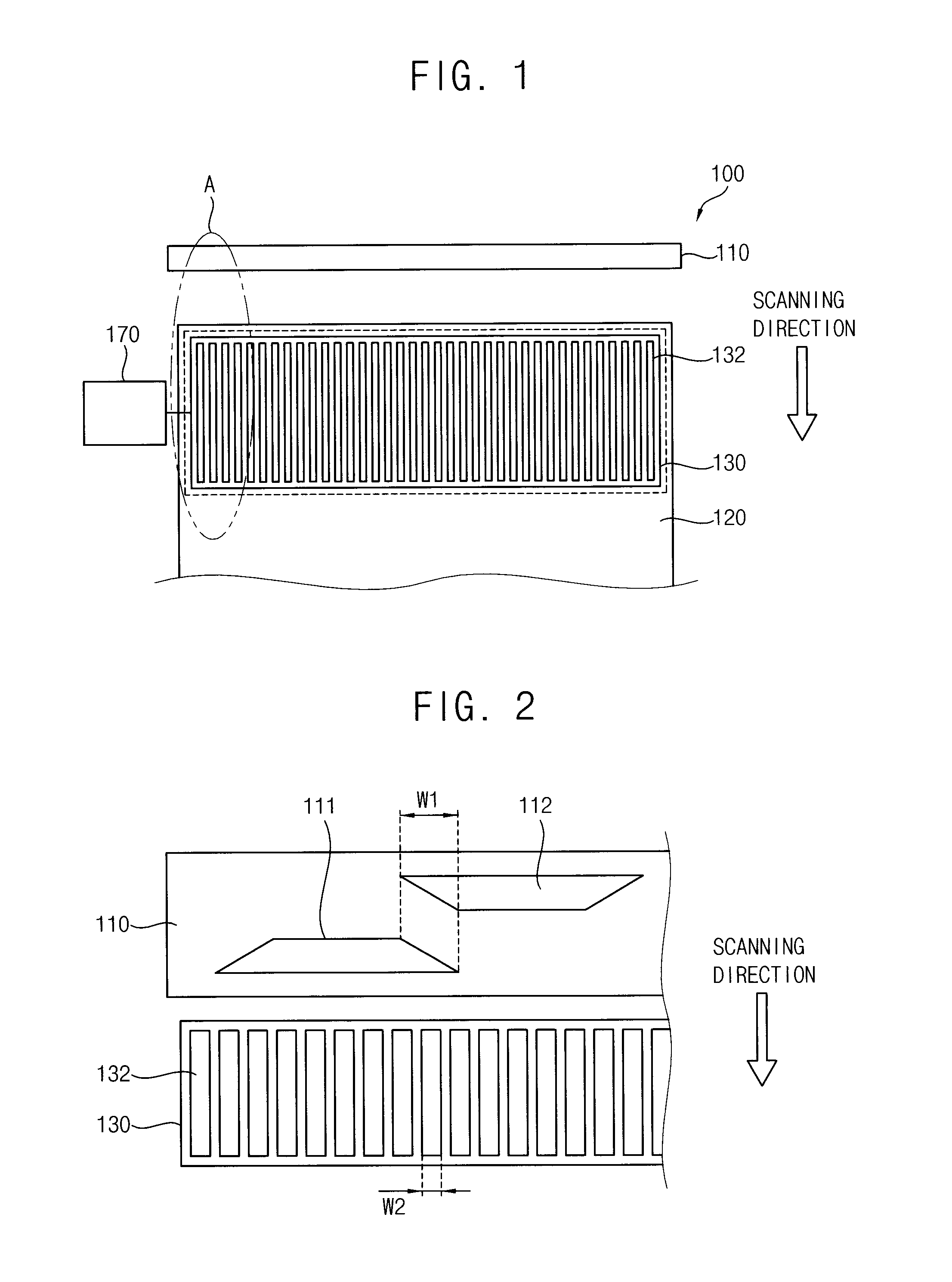

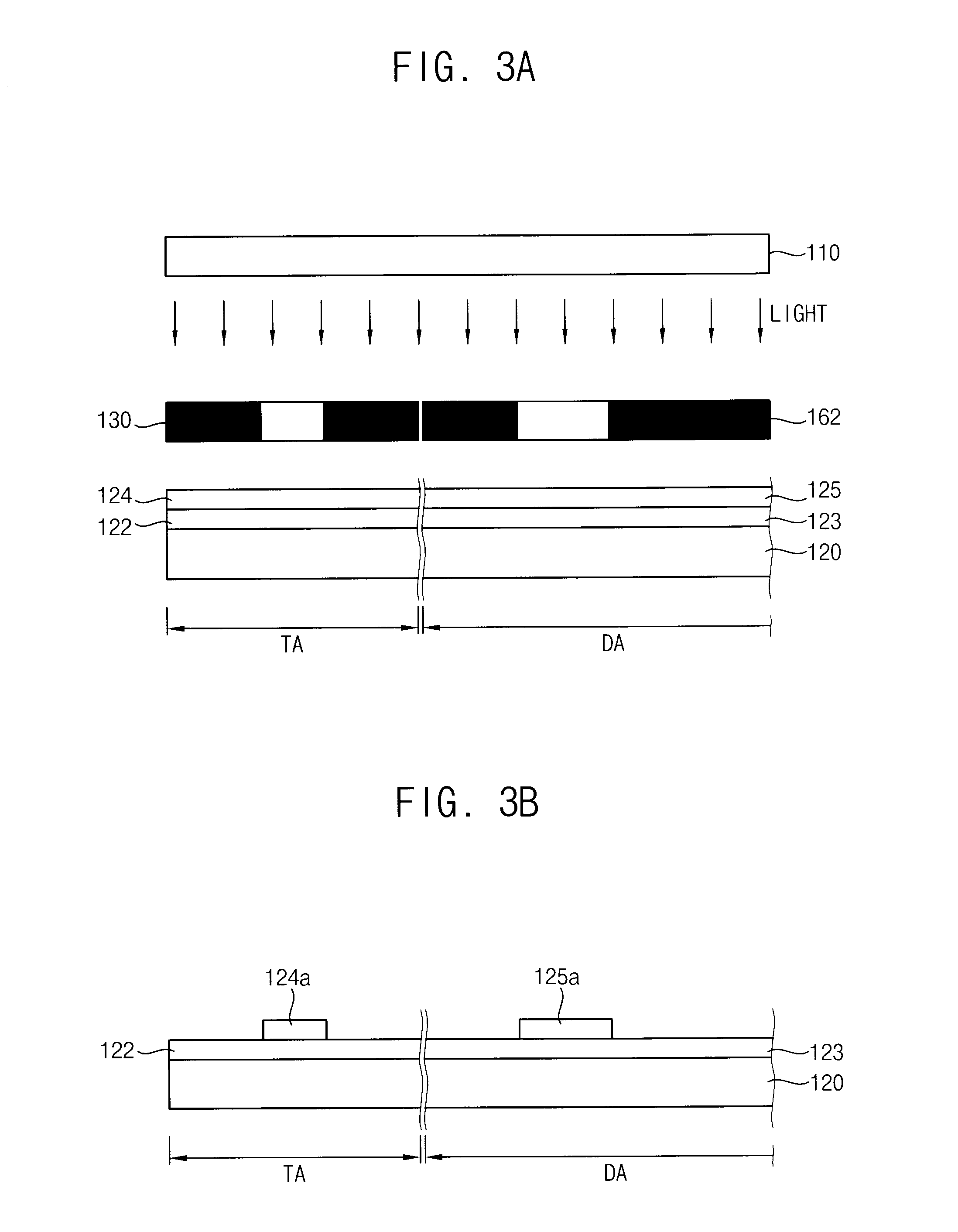

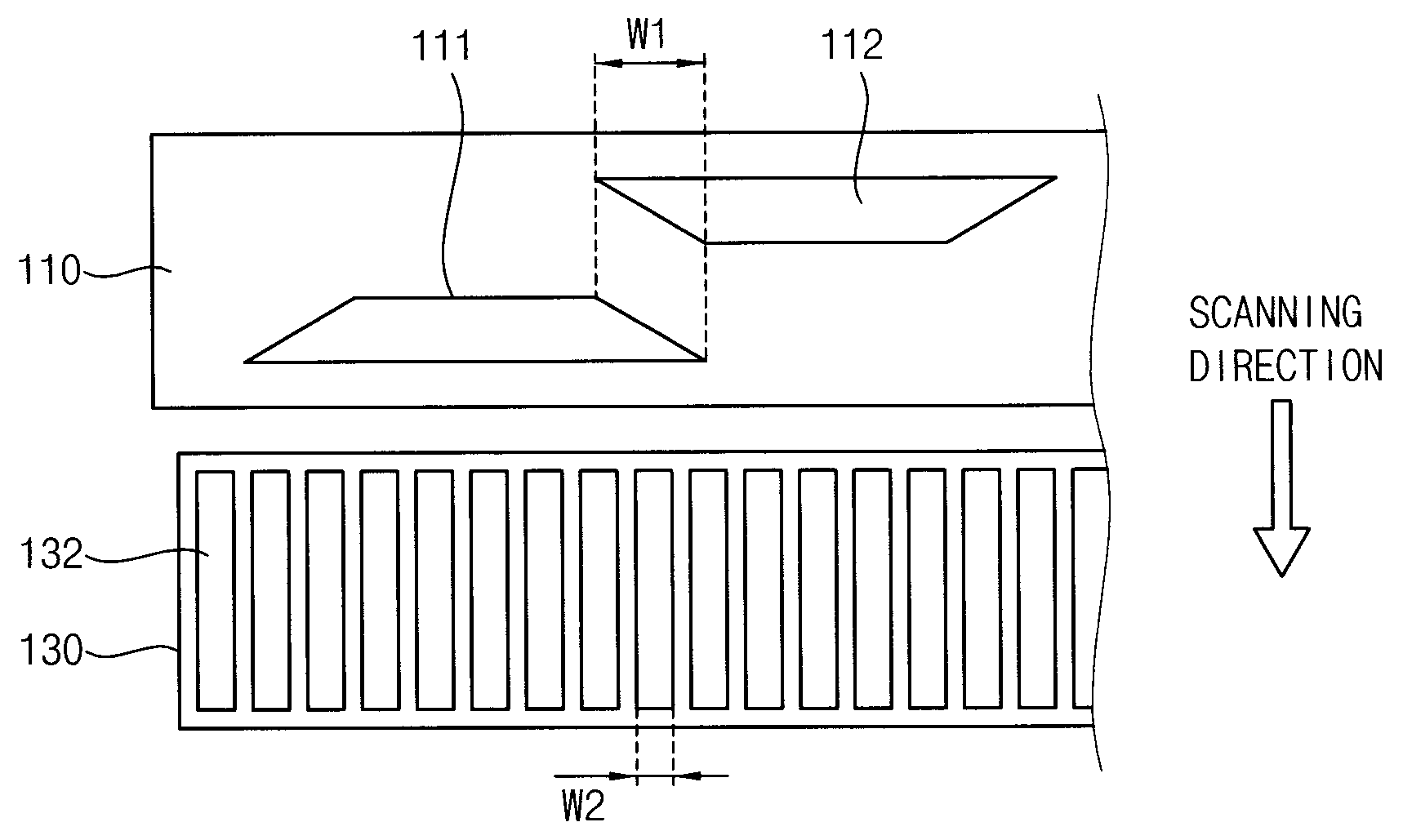

Method of measuring uniformity of exposing light and exposure system for performing the same

ActiveUS20130141714A1Easy to uniformlyReduce defective ratePhotometryPhotomechanical exposure apparatusOpticsMeasurement testing

An exposure system includes an exposure apparatus, a mask, a test pattern portion and a uniformity measuring part. The exposure apparatus includes a first module and a second module. The first and second modules each emit light and are overlapped in an overlapping area. The mask includes a plurality of transmission portions which are spaced apart from each other. Each of the transmission portions has a width less than a width of the overlapping area. The test pattern portion includes a plurality of test patterns which are patterned by using the light transmitted through the transmission portions of the mask. The uniformity measuring part measures a uniformity of the test patterns.

Owner:SAMSUNG DISPLAY CO LTD

Method of measuring uniformity of exposing light and exposure system for performing the same

ActiveUS8902414B2Easy to uniformlyEasy to detectPhotometryPhotomechanical exposure apparatusMeasurement testOptics

An exposure system includes an exposure apparatus, a mask, a test pattern portion and a uniformity measuring part. The exposure apparatus includes a first module and a second module. The first and second modules each emit light and are overlapped in an overlapping area. The mask includes a plurality of transmission portions which are spaced apart from each other. Each of the transmission portions has a width less than a width of the overlapping area. The test pattern portion includes a plurality of test patterns which are patterned by using the light transmitted through the transmission portions of the mask. The uniformity measuring part measures a uniformity of the test patterns.

Owner:SAMSUNG DISPLAY CO LTD

Slicing method and method for manufacturing epitaxial wafer

ActiveUS8210906B2Easy to implementGood reproducibilityFrom normal temperature solutionsBy zone-melting liquidsAxial displacementEngineering

A wafer slicing method includes winding a wire around rollers and pressing the wire against an ingot while supplying slurry to the rollers. A previously conducted experiment provides a supply temperature profile of the slurry during the slicing process and the relationship to the axial displacement of the rollers. This relationship is used to implement slurry delivery during the slicing process. The resultant wafers are bowed in a uniform direction. This slicing method provides excellent reproducibility in addition to producing wafers that are bowed in a uniform direction.

Owner:SHIN-ETSU HANDOTAI CO LTD

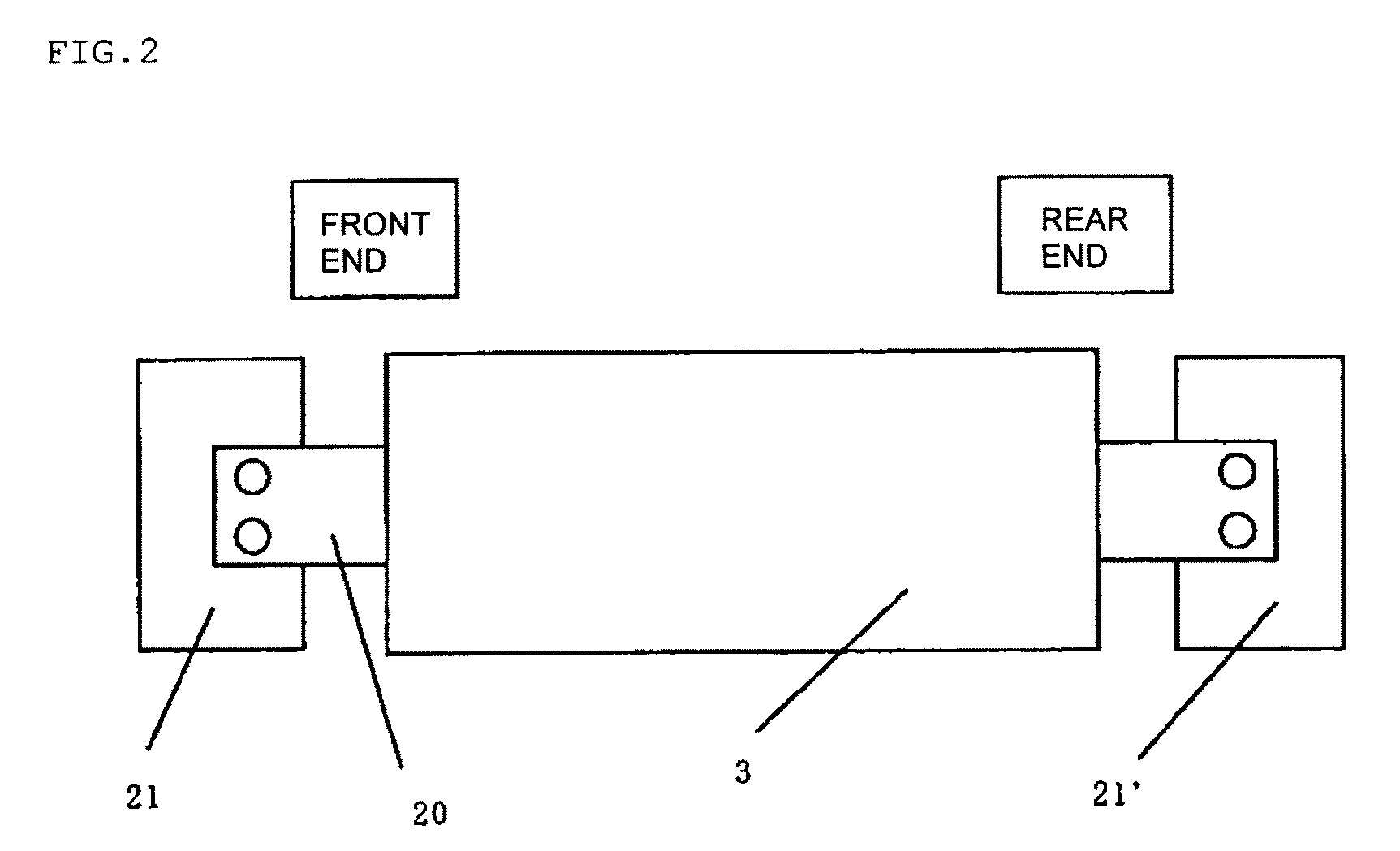

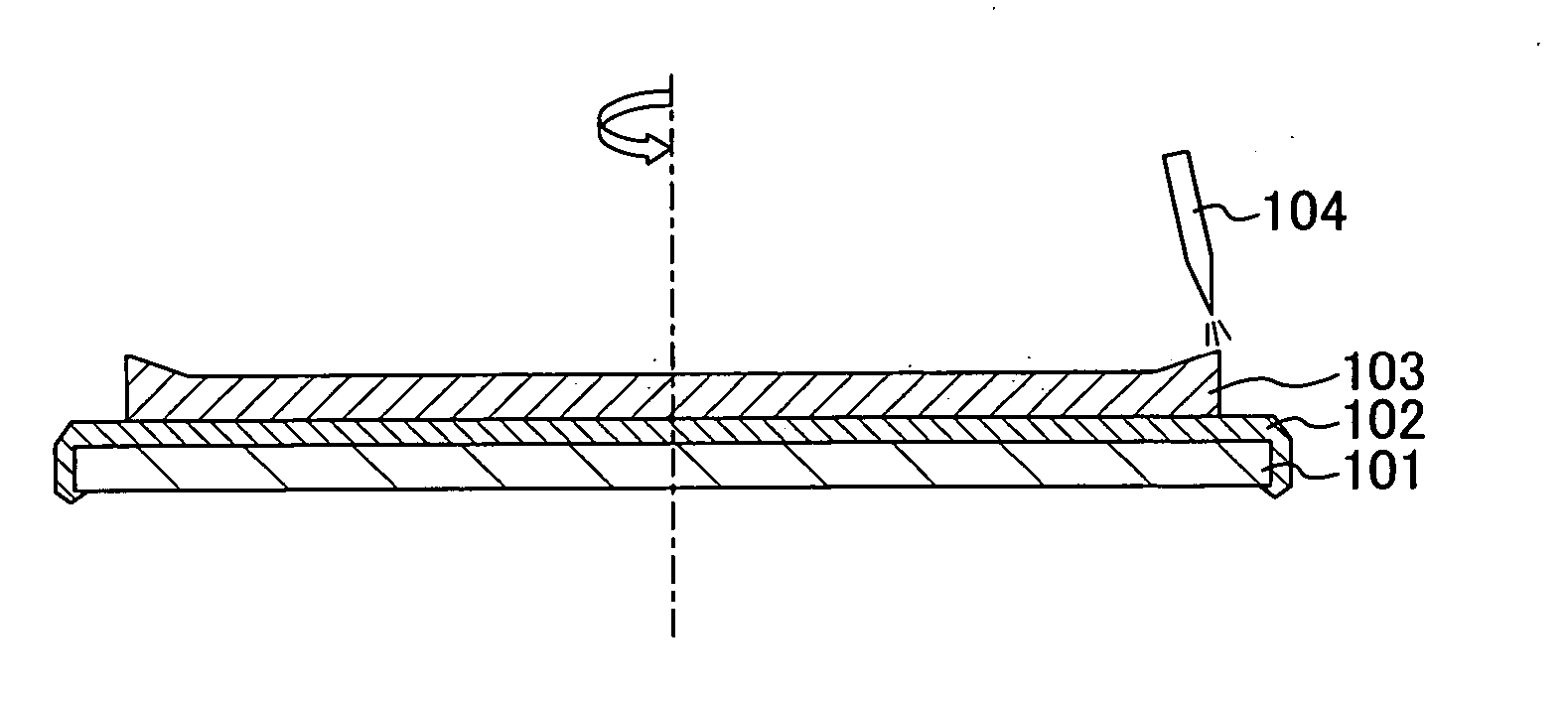

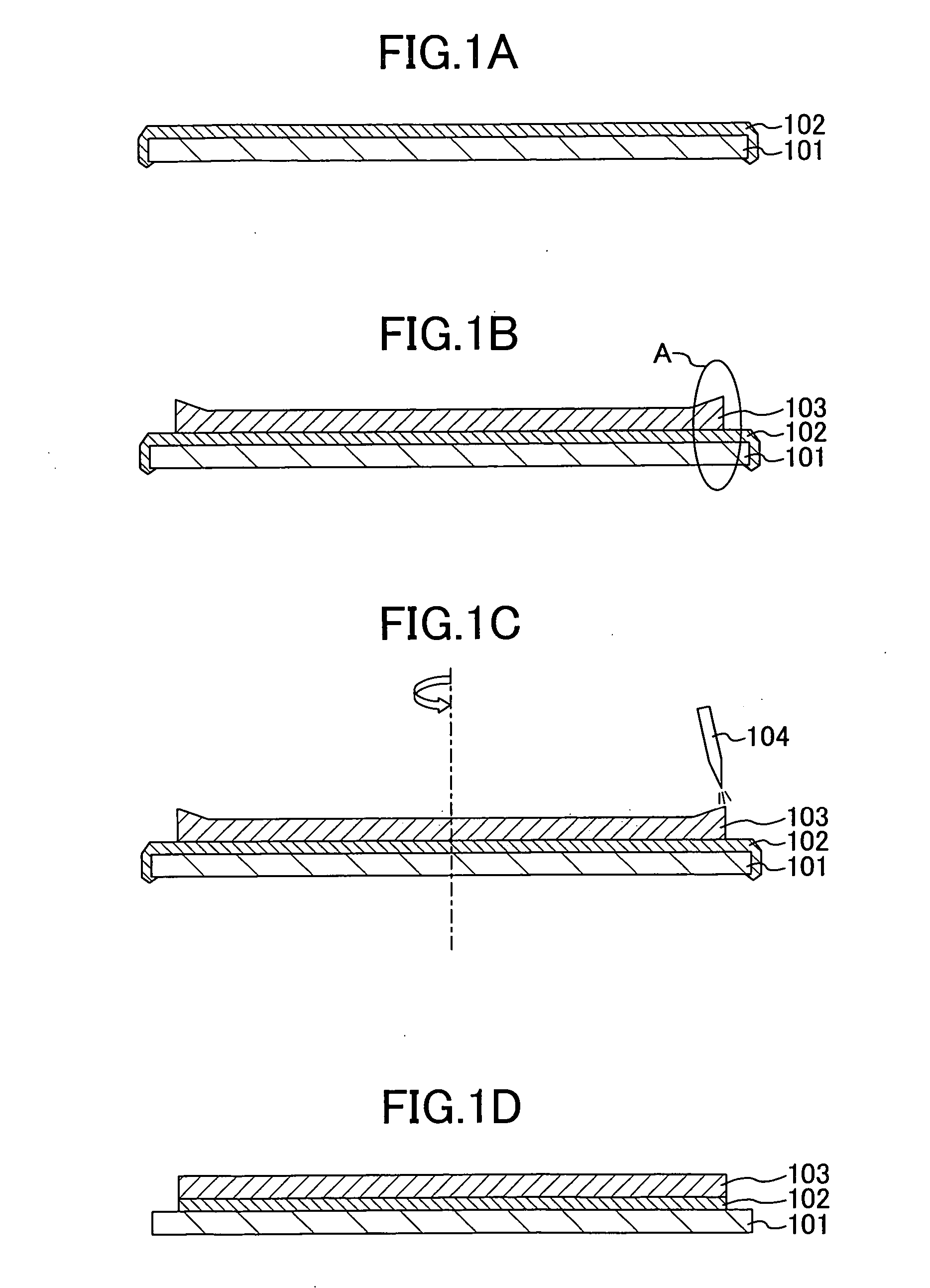

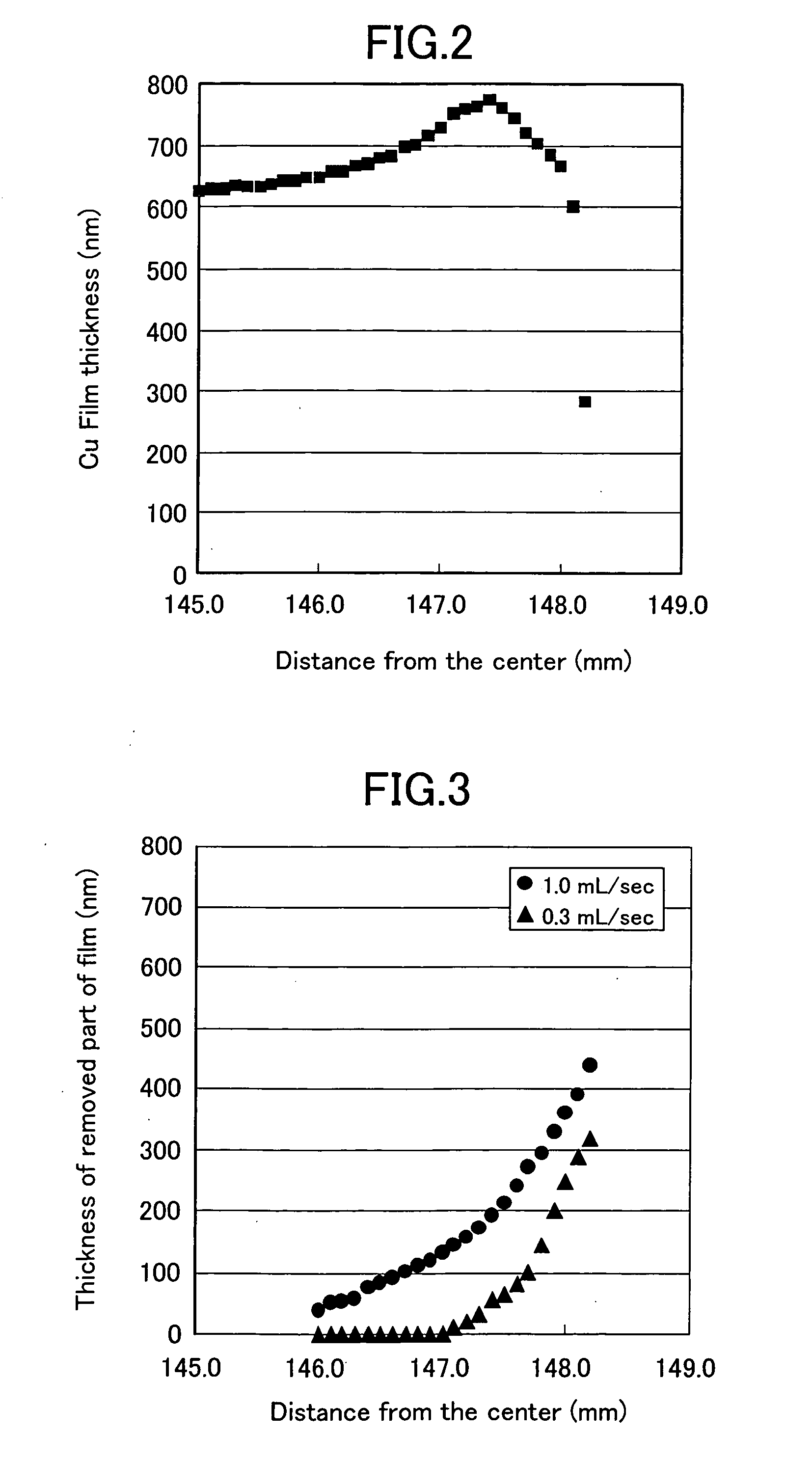

Etching method and etching apparatus

InactiveUS20070134929A1Uniform thicknessMake the thickness of the metal film uniformSemiconductor/solid-state device manufacturingElectroplatingSemiconductor

While a semiconductor substrate having a metal film formed thereover by electrolytic plating is rotated, an etching solution for the metal film is supplied to the peripheral portion of the metal film at a first flow rate and then the etching solution is continuously supplied at a second flow rate, which is lower than the first flow rate.

Owner:PANASONIC CORP

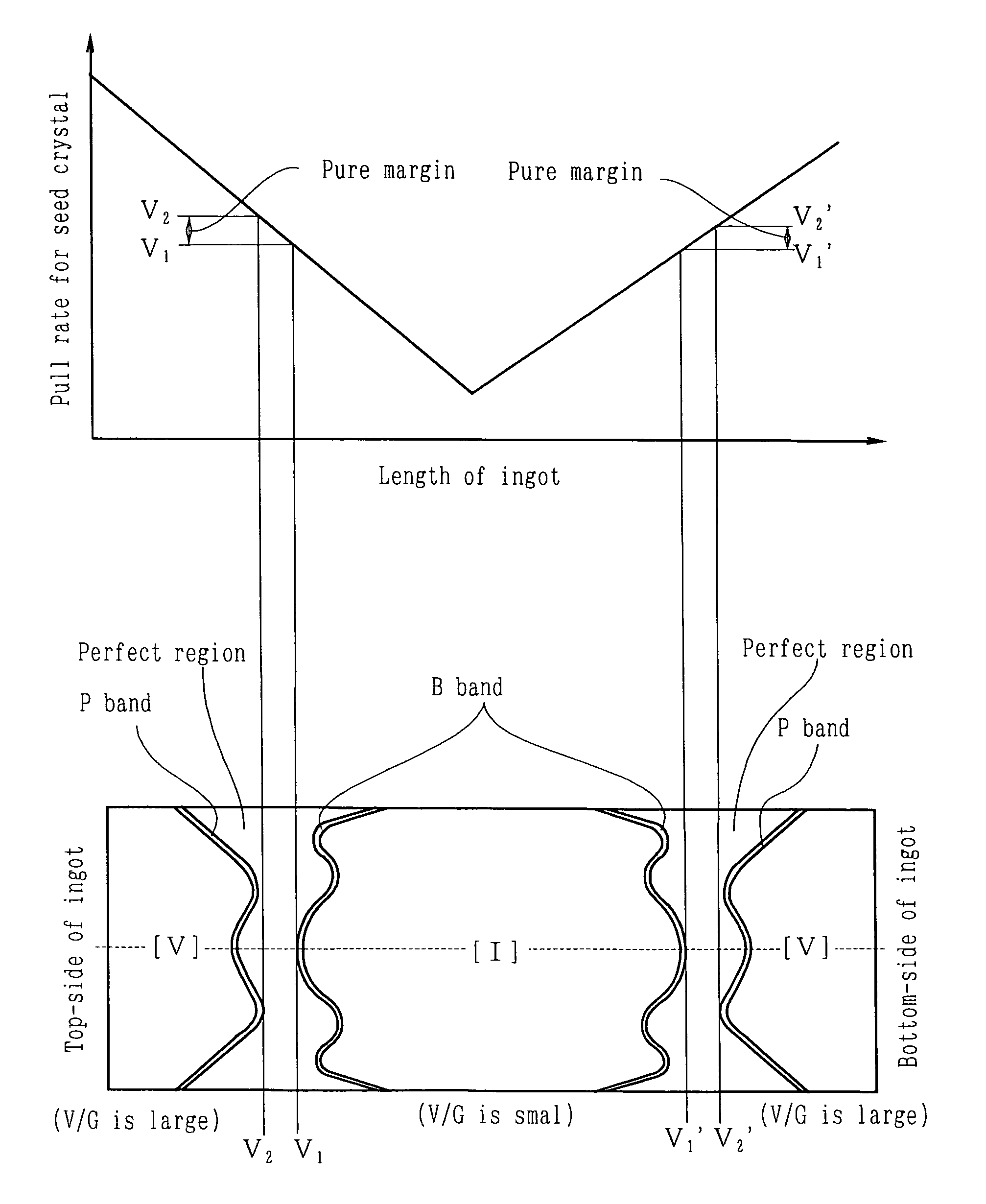

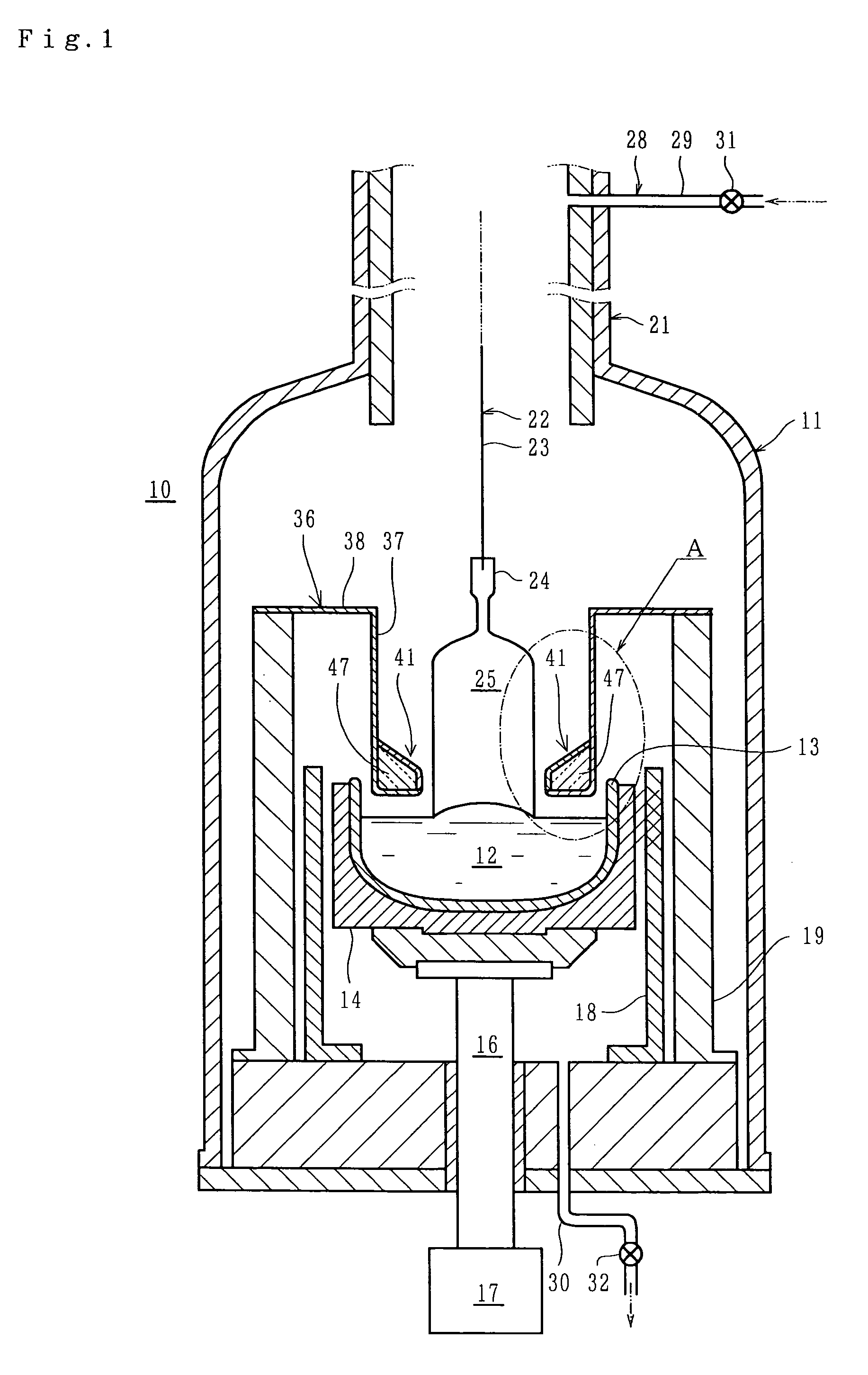

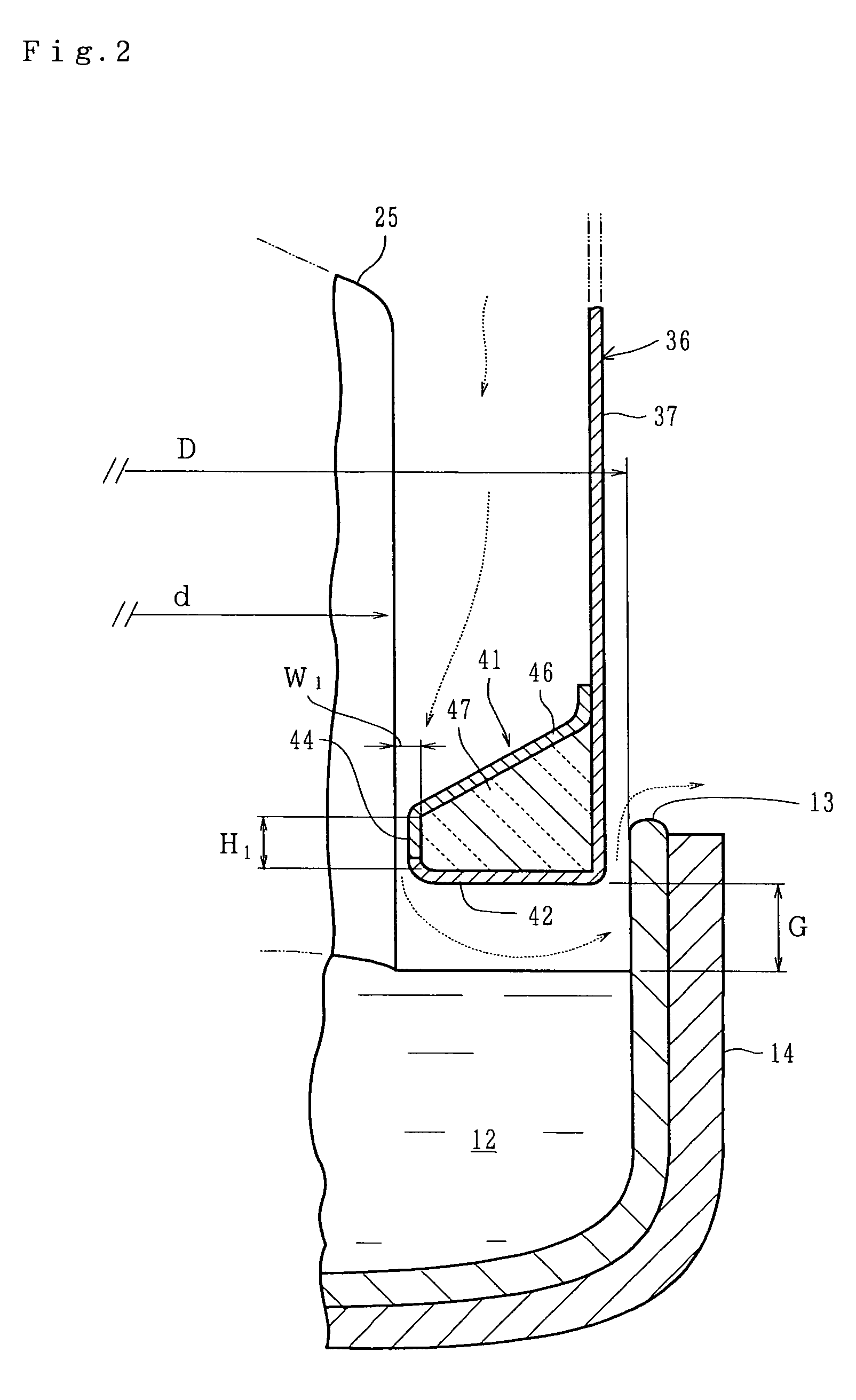

Method of manufacturing silicon single crystal and silicon single crystal manufactured by the method

ActiveUS7208042B2Easy to uniformlyPolycrystalline material growthBy pulling from meltIngotQuartz crucible

Owner:SUMITOMO MITSUBISHI SILICON CORP

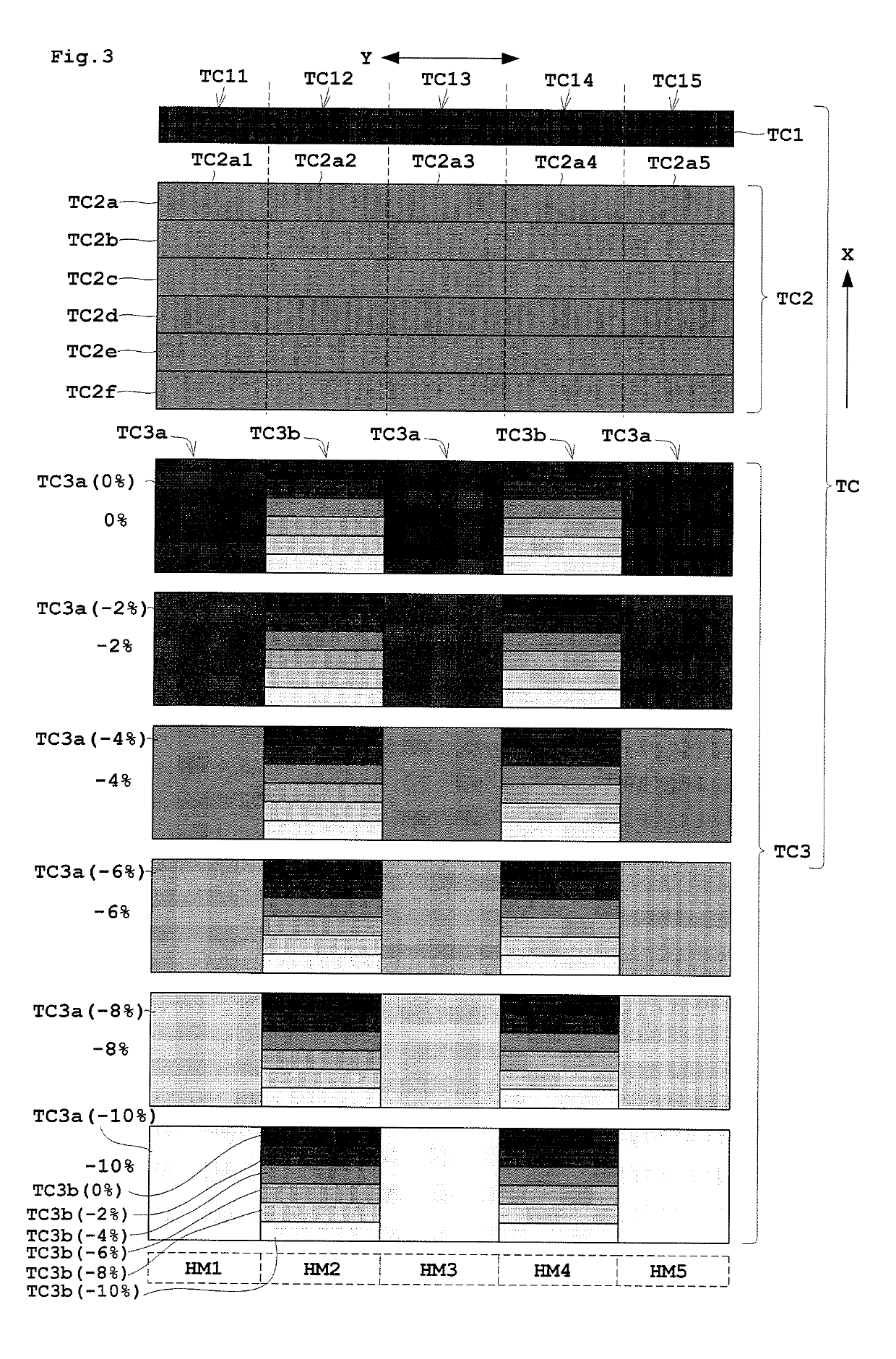

Head voltage correcting method for inkjet printing apparatus, an apparatus using same, and a program thereof

ActiveUS20190168513A1Easy to uniformlyInhibit deteriorationVisual presentationOther printing apparatusEngineeringVoltage reference

A head voltage correcting method for inkjet printing apparatus which perform printing with a head having a plurality of head modules includes the following steps: a testing chart printing step for printing testing charts which includes a lowest density head module check pattern, satellite check patterns, band-by-band density variable patterns, and in-band density variable patterns; a lowest density head module determining step for determining a lowest density head module; a satellite-free drive voltage determining step; and a new reference voltage determining step for determining a drive voltage of the band-by-band density variable patterns of the adjacent head module to be a new reference voltage for the adjacent head module.

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com