Thin film solar cell of using ZnO as electrical isolation layer and impurity barrier layer, and preparation method

A technology for thin-film solar cells and electrical insulating layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as easy formation of pinholes, affecting resistivity improvement and blocking, and achieves improved performance, low preparation cost, and uniform film good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

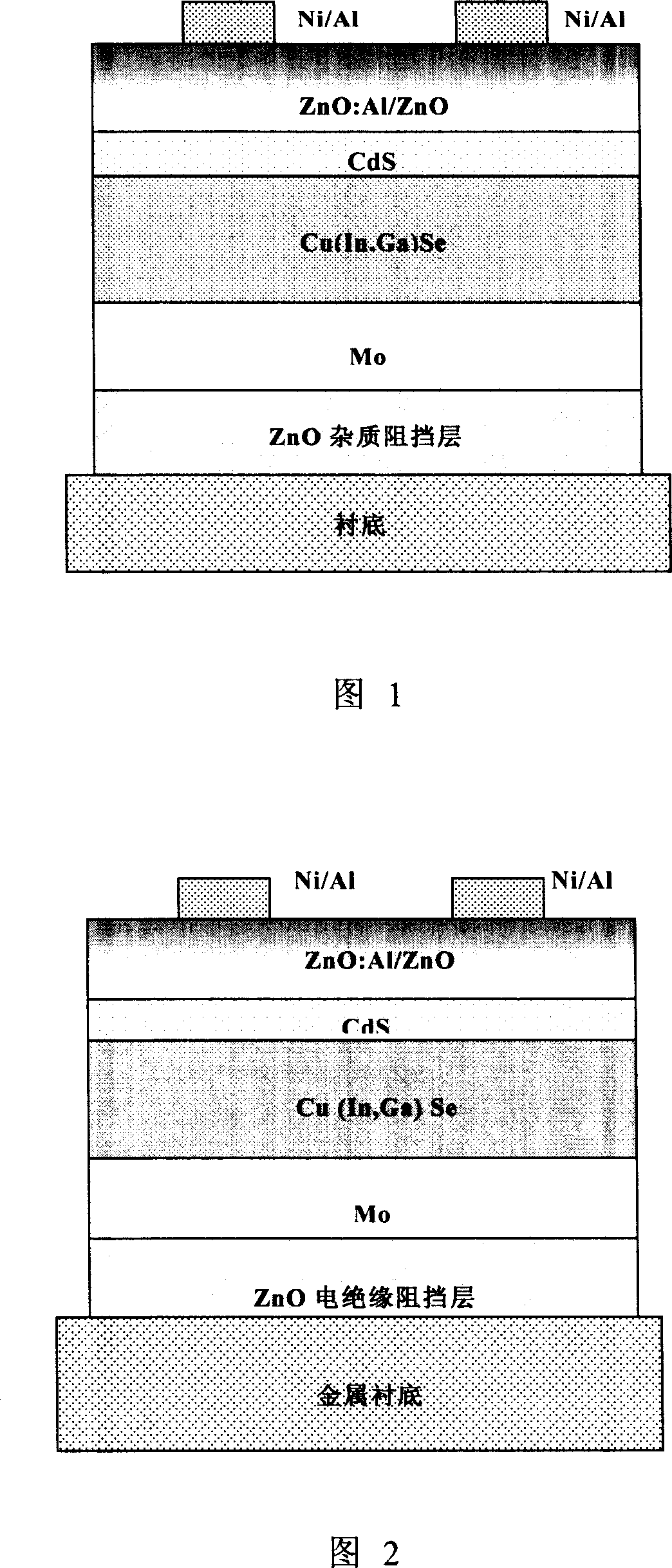

[0015] ZnO of the present invention is the thin-film solar cell of electrical insulation and impurity barrier layer, and its lightweight flexible substrate can be metal material substrate such as: stainless steel foil, Mo foil, Cu foil, Al foil or Ti foil etc., also can be polymer Material substrates such as: polyimide film and other insulating material substrates. On the substrate is a 0.8-4.0 μm ZnO electrical insulation and impurity blocking layer. The absorber layer is: CIGS, cadmium telluride, amorphous silicon, gallium arsenide, cadmium sulfide or dye TiO 2 and other photovoltaic materials.

[0016] The ZnO electrical insulation and impurity blocking layer can be a doped ZnO thin film or an intrinsic ZnO thin film. It can also be doped ZnO film or intrinsic ZnO film with Al 2 o 3 , SiO 2 Co-deposited or layer-deposited thin films. During the co-deposition, the three metal oxides are mixed in any proportion, and the thicknesses of the three metal oxides are respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com