Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

An olefin polymerization, non-metallocene technology, applied in the field of heterogeneous catalysts, can solve the problems of low catalyst polymerization activity, uneconomical industrial production and high ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

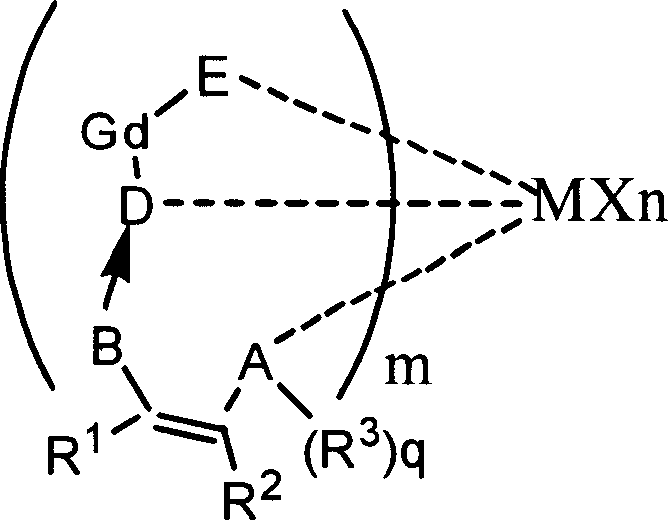

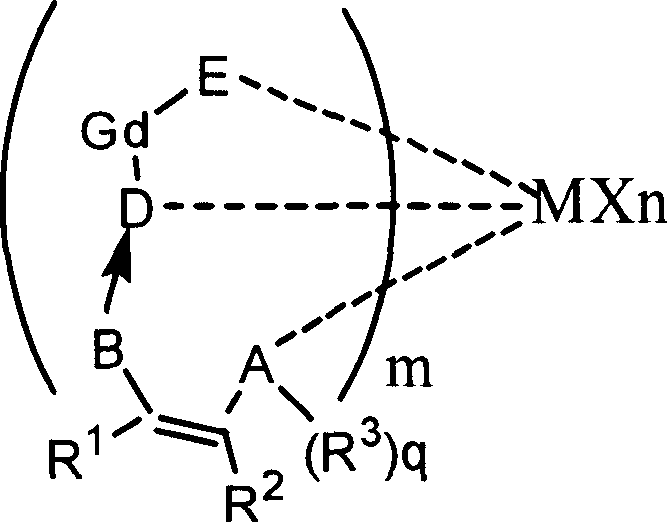

AI Technical Summary

Problems solved by technology

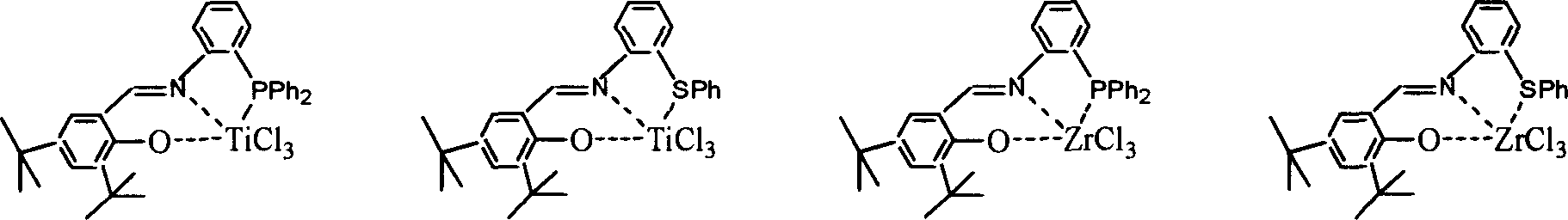

Method used

Image

Examples

Embodiment 1

[0134] The carrier adopts porous silica, the model is ES757 (product of Ineos Company), and the silica is heated at 600 ° C under N 2 Continuous roasting under atmosphere for 4h, and then stored under nitrogen.

[0135] 0.75g will have the formula The non-metallocene olefin polymerization catalyst is dissolved in 7.75ml tetrahydrofuran solvent, and 5g of silicon dioxide after adding activation (the pore volume is 1.55ml / g, and the solvent consumption is 100% of the carrier pore volume), after stirring under airtight normal temperature conditions Drain directly to obtain a supported non-metallocene olefin polymerization catalyst. The catalyst is designated CAT-1.

[0136] The Ti content in the supported non-metallocene olefin polymerization catalyst is 1.04%.

Embodiment 1-A

[0138] Ethylene homopolymerization: 27.4mg CAT-1, 2.7ml cocatalyst triethylaluminum (TEAL) hexane solution (concentration: 0.88mol / L) and 1L solvent hexane were added simultaneously in a 2L autoclave, and the stirring speed was 250rpm, feed ethylene until the total polymerization pressure is 0.8MPa, carry out homopolymerization of ethylene at 80°C, the reaction time is 2 hours, stop feeding ethylene after 2 hours, vent the pressure in the reactor, stop stirring, and then cool down to 25°C to obtain Polymerization product.

[0139] The concentration of CAT-1 in the catalytic system is 0.0274 g / liter of solvent, and the concentration of cocatalyst is 0.27 g / liter of solvent.

Embodiment 1-B

[0141] Homopolymerization of ethylene in the presence of hydrogen:

[0142] Essentially the same as Example 1-A, but with the following changes:

[0143] Before feeding ethylene, first feed hydrogen to the reactor to 0.2MPa, and then feed ethylene until the total pressure of the reactor is 0.8MPa.

[0144] The concentration of CAT-1 in the catalytic system is 0.030 g / liter of solvent, and the concentration of cocatalyst is 0.29 g / liter of solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com