Perforated non-woven fabric

A non-woven, open-porosity technology, used in medical science, bandages, layered products, etc., can solve problems such as poor dry performance, sticky skin, and moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

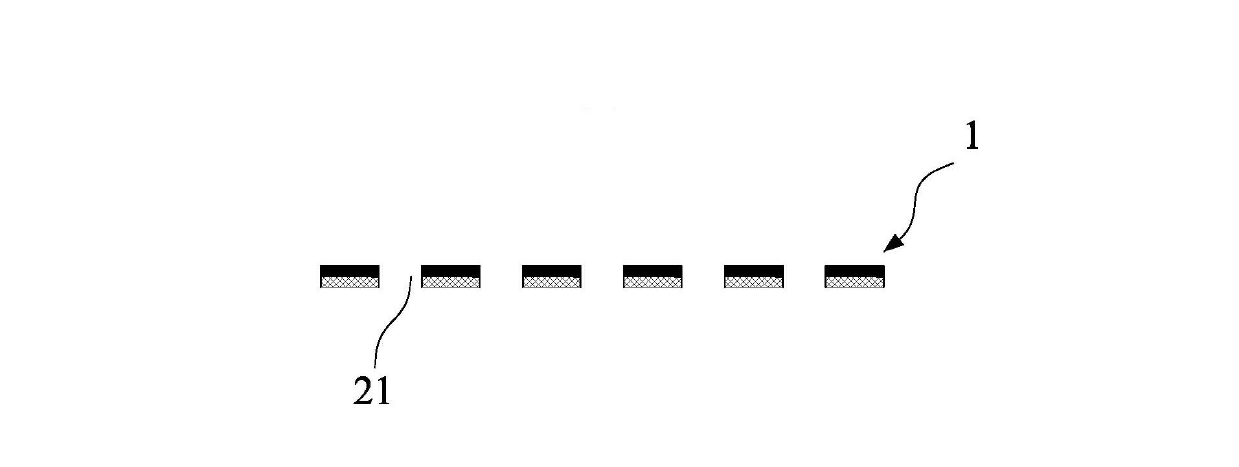

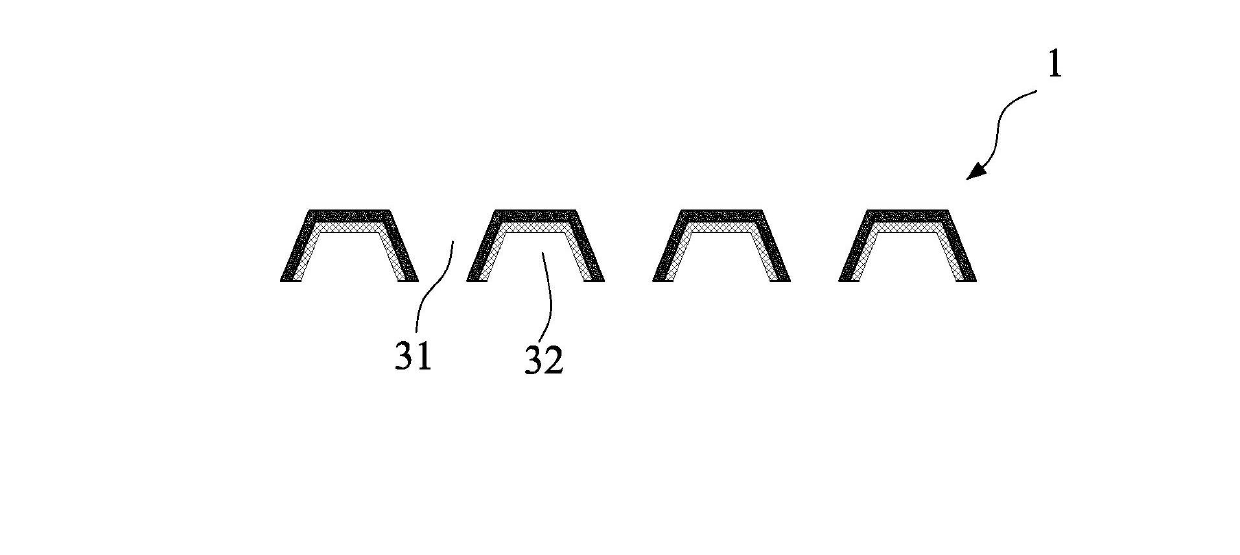

[0024] Such as Figure 1 to Figure 5 As shown, the present invention discloses a perforated non-woven fabric, which is one of hot-air non-woven fabric, spunbonded non-woven fabric, hot-rolled non-woven fabric or spunlace non-woven fabric; The perforated non-woven fabric has a grammage of 6 grams / square meter to 60 grams / square meter, especially 12 grams / square meter to 50 grams / square meter.

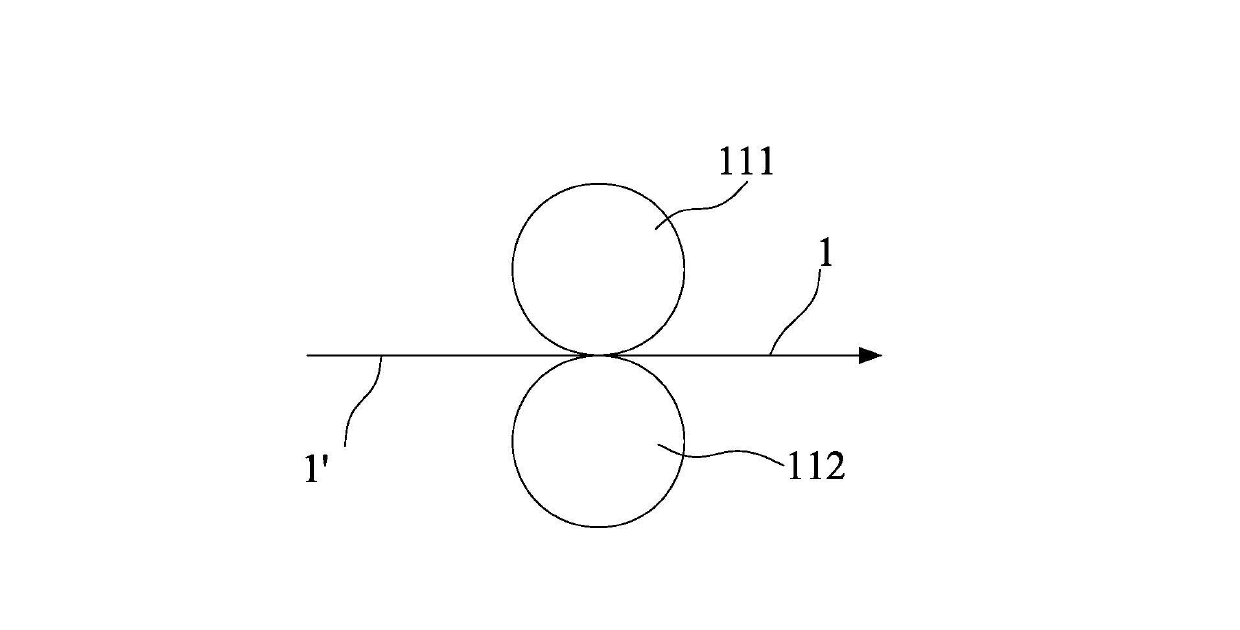

[0025] The perforated non-woven fabric 1 is made by passing the non-woven fabric 1' through the punching devices 111 and 112 to form holes on the surface from the surface layer to the bottom layer, and the opening rate is 5-50%, especially 10-40%; three-dimensional The thickness is 0.1-1.5 mm; especially 0.4-1.0 mm. Wherein, the surface layer of the non-woven fabric 1′ is composed of a fiber layer with a water contact angle greater than 70°, especially greater than 90°, and the bottom layer is made of a fiber layer with a water contact angle less than 90°, especially less than 70°.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com