Drug solution filling plastic ampoule and production method therefor

A manufacturing method and technology of liquid medicine, applied in the direction of medical containers, pharmaceutical packaging, packaged food, etc., can solve the problems of complicated manufacturing steps and rising manufacturing costs, and achieve the prevention of water vapor penetration, drug penetration, and drug absorption The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

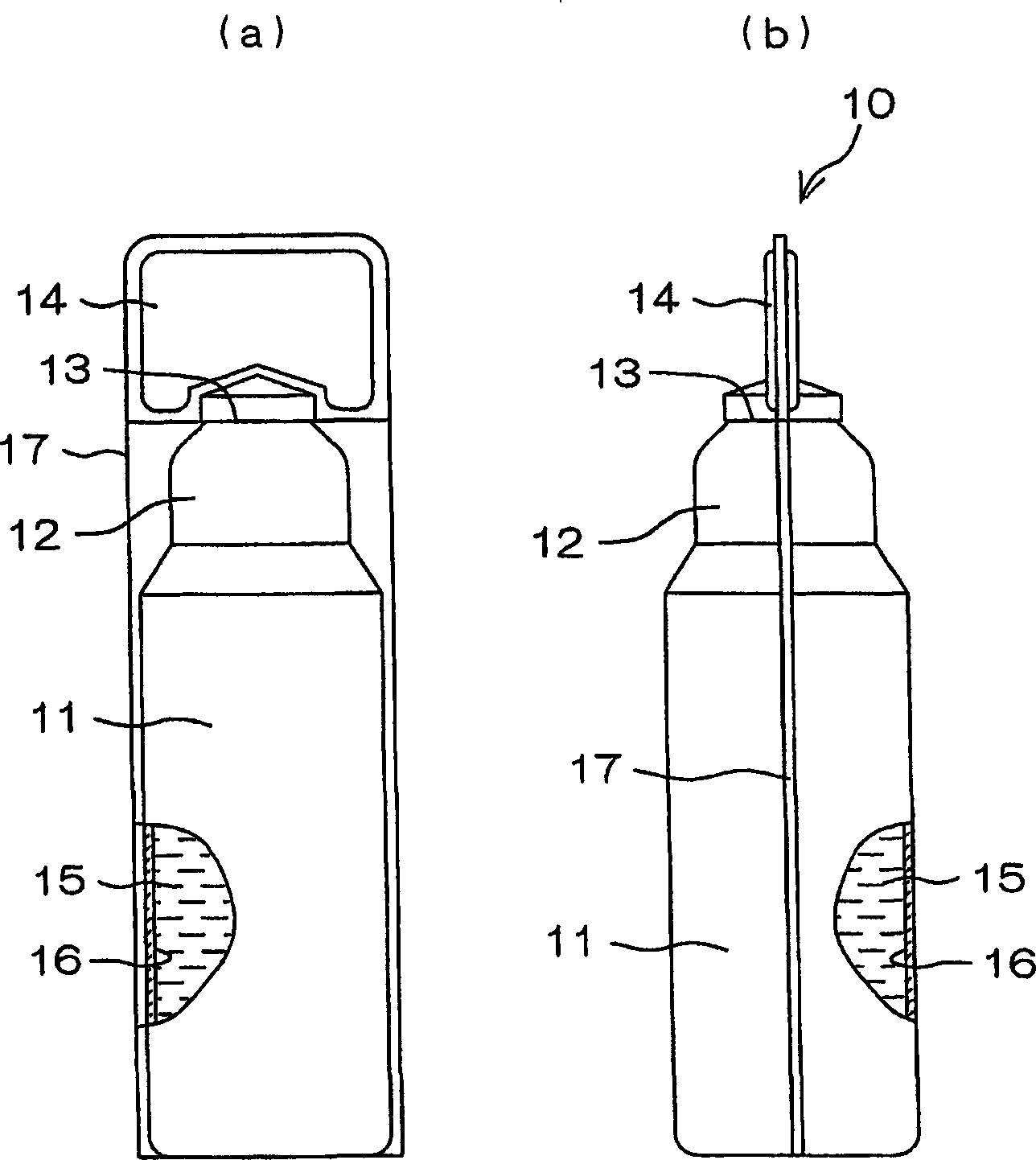

[0132] Using a blow-fill-seal machine with a 2-layer blow mold, the inner layer was prepared from COP1 (polycycloolefin), the outer layer was prepared from PE1 (polyolefin), and 10 mL of 0.005% aqueous solution of nitroglycerin was filled inside to produce A plastic ampoule (inner volume 10mL) with a 2-layer structure for filling liquid medicine. The ampoules of 10 have figure 1 In the shape shown, the wall thickness of the tube is 100 μm in the inner layer and 700 μm in the outer layer.

Embodiment 2

[0134] Using a blow-fill-seal machine with a 2-layer blow mould, the inner layer is prepared from a plastic blend of COP1 (polycycloolefin) and PE1 (polyolefin) in the ratio ) to prepare an outer layer, and fill the inside with 20 mL of 0.005% nitroglycerin aqueous solution to manufacture a plastic ampoule (inner volume: 20 mL) having a two-layer structure for filling the drug solution. The ampoules of 10 have figure 1 In the shape shown, the wall thickness of the tube is 100 μm in the inner layer and 700 μm in the outer layer.

Embodiment 3

[0136] Using a blow-fill-seal machine with 3-layer blow molding, the inner layer is made of PE1 (polyolefin), the middle layer is made of COP1 (polycycloolefin), the outer layer is made of PE1, and it is filled with 0.005% nitro Glycerin aqueous solution 10mL, and a plastic ampoule (inner volume: 10mL) with a 3-layer structure was manufactured. The ampoules of 10 have figure 1 For the shape shown, the tube wall thickness is 50 μm for the inner layer, 100 μm for the middle layer, and 700 μm for the outer layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com