Low-melting point and transparent PET copolyester, its preparation method and application

A copolyester, low melting point technology, applied in the field of modified PET copolyester, can solve the problems of poor transparency, poor dispersibility and high energy consumption of PET materials, shorten polymerization time, improve processing performance, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

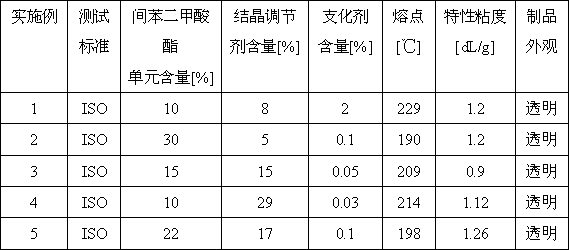

Examples

Embodiment 1

[0030] Put 3.74kg of terephthalic acid, 0.42kg of isophthalic acid, and 2.02kg of ethylene glycol into the esterification kettle, and carry out the esterification reaction at 0.2~0.4MPa and 260°C. When the distilled water generated by the esterification reaches After the target value, transfer it to the polycondensation tank, add catalyst, stabilizer, antioxidant and 332g polyethylene glycol 400 and 20.6g 1,2,3-propanetriol, normal compression polymerization for 45 minutes, in 45 minutes Gradually reduce the pressure in the reactor to 60Pa, and at the same time raise the temperature to 270°C, conduct high-vacuum polycondensation for 2 hours, when the intrinsic viscosity reaches the target value, fill with nitrogen, press the material into water under nitrogen pressure, and cool it with water , strands, and pelletized to obtain polycondensate slices; after drying the polycondensate slices, solid-state polycondensation under 20Pa and 190°C for 20 hours, when the intrinsic viscosi...

Embodiment 2

[0032] Put 2.91kg of terephthalic acid, 1.25kg of isophthalic acid, and 2.02kg of ethylene glycol into the esterification kettle, at 0.2~0.4MPa,

[0033] Carry out the esterification reaction at 260°C. When the distilled amount of water generated by the esterification reaches the target value, it is transferred to the polycondensation kettle, and a catalyst, a stabilizer, an antioxidant, 166g of polyethylene glycol 100 and 4.12g of three Methylol propane, polycondensation under normal pressure for 45 minutes, gradually reduce the pressure in the reactor to 60Pa within 45 minutes, and at the same time raise the temperature to 270°C, polycondensate under high vacuum for 2 hours, when the intrinsic viscosity reaches the target value, fill in Nitrogen, press the material into water under nitrogen pressure, and obtain polycondensate slices after water cooling, drawing, and pelletizing; after drying the polycondensate slices, carry out solid-state polycondensation under 20Pa and 160°...

Embodiment 3

[0035] 82.45g dimethyl terephthalate, 14.55g dimethyl isophthalate, 50g ethylene glycol, 9.3g neopentyl glycol,

[0036] Add catalyst, stabilizer, and antioxidant to a 500mL flask, esterify under a slight nitrogen flow at 190°C until methanol distillates to more than 95%, add 5mg of pentaerythritol, heat up to 250°C, vacuumize, and reduce the pressure within 45 minutes Gradually reduce to 60Pa, polycondensate under high vacuum for 3 hours to obtain polyester product; crush 20g of the product, put it into a 100mL round bottom flask after drying, and conduct solid phase polycondensation under high vacuum under 20Pa at 185°C for 15 hours, then cool to 60 The material is discharged below ℃, and the performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com