Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

322results about How to "Short polymerization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing fatty group polycarbonate polylol

The invention discloses a manufacturing method for aliphatic series polycarbonate polyhydric alcohol that includes the following steps: putting catalyst, epoxide, molecular weight regulator, and solvent into high pressure reaction kettle after being fully dryied, adding CO2 to 0.5-6MPa, heating to 30-150 degree centigrade, polymerizing for 0.5-50 hours; and removing the unreacted epoxide, the product would be gained.

Owner:JIANGSU ZHONGKE JINLONG CHEM

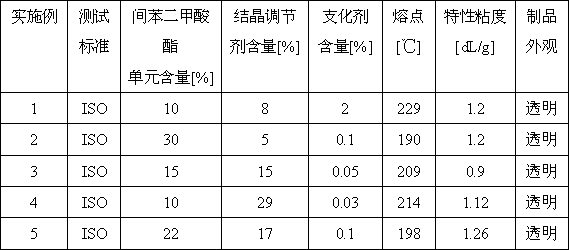

Low-melting point and transparent PET copolyester, its preparation method and application

ActiveCN103102473ASolve problems such as whiteningHigh transparencyMolten statePolyethylene terephthalate glycol

The invention discloses a low-melting point and transparent PET (polyethylene terephthalate) copolyester, its preparation method and application. The PET copolyester comprises, by mass: 60-84% of PET, 10%-30% of a unit derived from isophthalic acid, 5%-29% of a crystallization adjusting agent, and 0.03-2% of a branching agent. According to the preparation method, in a synthesis process of PET, based on p-phthalic acid (PTA) and ethylene glycol (EG), the unit derived from isophthalic acid, the crystallization adjusting agent and the branching agent are added to undergo a chemical reaction together, thus obtaining the low-melting point and transparent PET copolyester. The PET copolyester provided by the invention has an intrinsic viscosity greater than 0.9dL / g and a melting point lower than 230DEG C, can be solidified into an amorphous state from a molten state during injection molding, and has good transparency as well as further improved processing performance.

Owner:KINGFA SCI & TECH CO LTD +2

Stimuli-responsive textile fabric and method for preparing same

The invention relates to an environment-response intelligent weave fabric and relative preparation. Wherein, adding the fabric which is induced by argon microwave low-temperature plasma to generate free group on surface, into the dual monomer solution of 2-acrylamide-2-methanesulfonic acid and N-isopropyl acrylamide that contains N and N'-methylene dual acrylamide cross linker to process graft polymerization reaction, while the bath ratio is 1:40, to graft the dual intelligent gel on the fiber macromolecule of fabric, to attain said inventive product. When the invention is dry, it has no difference from general fabric, but when it is wet, the gel will adsorb water to expand and block the slits between fibers, to reduce the water and gas permeability of fabric, and avoid outer penetrating into the inner layer of fabric to stop heat emission. The invention can be used to produce army waterproof clothes, heat-accumulation temperature adjustable special clothes, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of cationic polyacrylamide

ActiveCN102603970AReduce dosageHigh puritySludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationUltraviolet lightsSewage treatment

The invention relates to a preparation method of cationic polyacrylamide. The cationic polyacrylamide is prepared by the following steps of: adding a certain amount of solubilizing agent and complexing agent into acrylamide (AM) and aqueous solution of two cationic monomers; regulating the pH value of a reaction system; then adding a certain amount of initiator; and performing the polymerization reaction under the ultraviolet light with a certain wavelength. The preparation method has the advantages that the polymerization reaction time is short; few types of auxiliaries are added; and the prepared product has high purity and is non-toxic and harmless. The cationic polyacrylamide obtained by the preparation method has multifunctionality, has the molecular weight of 1 million to 12 million, has ultralow concentration of a residual acrylamide monomer, is suitable for treatment of drinking water and sewage treatment and dehydration treatment of sludge and has excellent application prospect.

Owner:贾高锋 +1

Preparation method for hydrophobic-association cationic polyacrylamide

The invention relates to a preparation method for hydrophobic-association cationic polyacrylamide. The preparation method comprises the following steps of: firstly, adding distilled water, acrylyl oxyehtyl dimethyl benzyl ammonium chloride monomer and acrylamide monomer to a reaction device, uniformly stirring the mateirals until the materials are completely dissolved into a monomer aqueous solution; secondly, adding proper solubilizer, metal-chelator and initator to the monomer aqueous solution, uniformly stirring the materials and regulating the pH value of the mixture; ventilating high-pure nitrogen gas to the reaction device for removing the air in the reaction device; thirdly, sealing the reaction device and then putting the sealed reaction device to a ultraviolet-light reaction device for carrying out a polymerization reaction to prepare hydrophobic-association cationic polyacrylamide colloid; and finally, purifying, washing and refining the colloid, and drying the treated colloid in a vacuum drying box and grinding the dried colloid to obtain the finished product. The preparation method disclosed by the invention has the advantages that the two monomers can be directly polymerized by an aqueous solution without adding surfactant, so that the process is simple, and the polymerization reaction time is short; moreover, the reaction process is free of temperature control, the energy consumption is reduced, and the production cost is reduced.

Owner:JIANGSU HENGFENG FINE CHEM CO LTD

Method for preparing micro-sized monodisperse polyuria microspheres

The invention relates to a method for preparing micro-sized monodisperse polyuria microspheres. The method comprises the following steps of: adding a mixed solvent of water and acetone and a diisocyanate compound monomer to a reaction flask at room temperature, wherein the weight ratio of the water to the acetone is 2 / 8-6 / 4, and the diisocyanate compound monomer accounts for 0.5-10.0 percent of the total weight of a mixed system; hermetically shaking up; putting in a constant-temperature water-bath vibrator; performing a polymerization reaction under the conditions that the vibration frequency is 70-150 times per minute and the temperature is 20-80 DEG C; and performing centrifugal separation and drying on a product after polymerization is ended to obtain the micro-sized monodisperse polyuria microspheres. According to the method for preparing the micro-sized monodisperse polyuria microspheres, precipitation polymerization is performed under the vibration condition by using only one monomer, thereby, the process is simple, the raw materials are single, the consumed reaction time is short, the monomer can be completely converted, and the yield of the microspheres can reach at least86 percent. All the microspheres are clean in surface and contain a large amount of amido and can be used for the field of protein adsorption and separation, enzyme immobilization and chromatographicanalysis.

Owner:UNIV OF JINAN

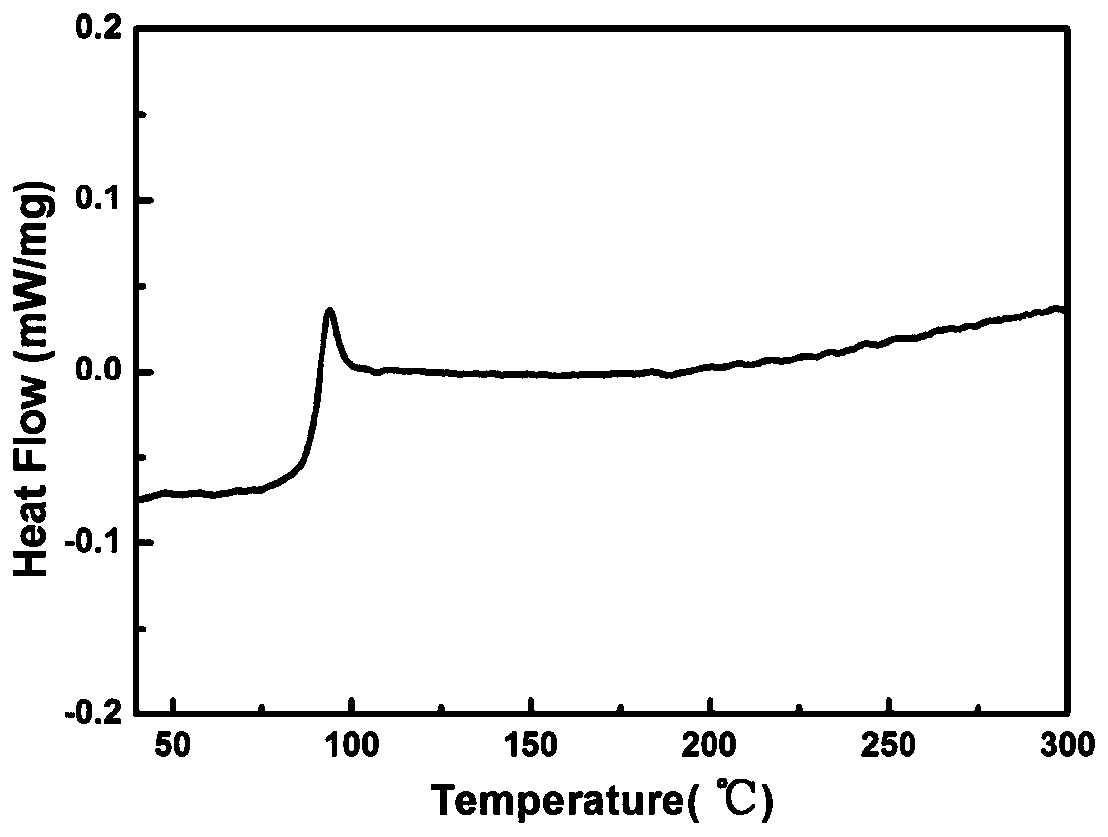

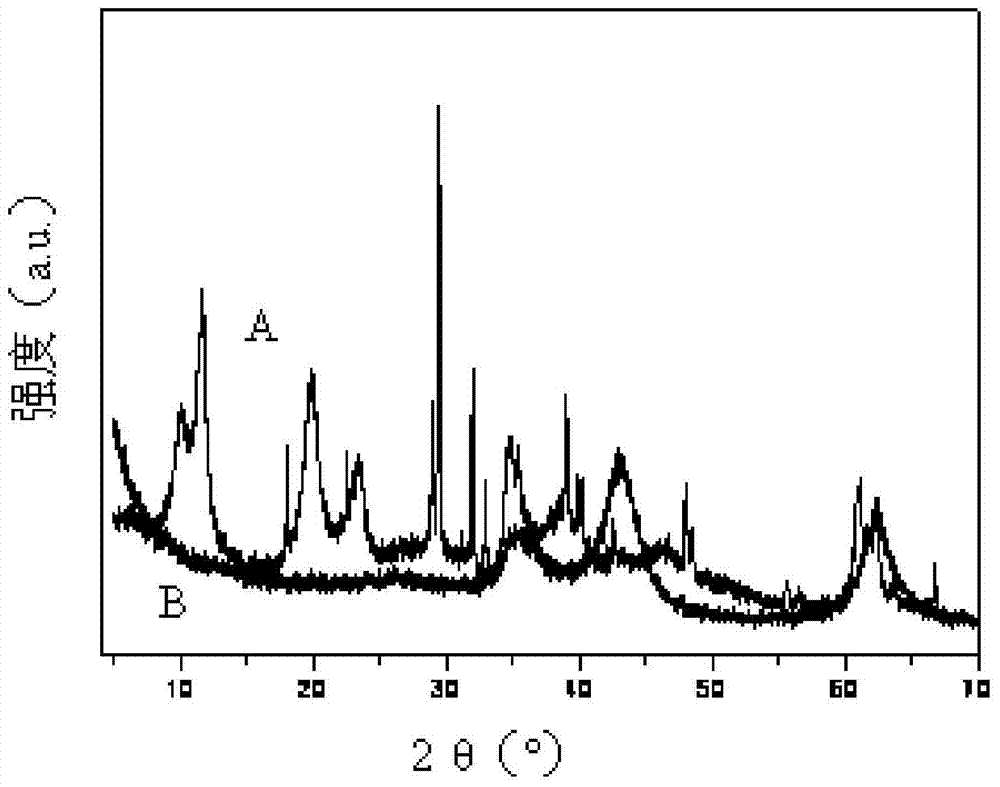

PLA (polylactic acid)/MMT (montmorillonite) degradation enhanced master batch blending modification PLA/PBAT (polyethylene terephthalate-adipic acid-butanediol copolyester) composite material and preparation method thereof

InactiveCN105199347AChange sizeReduce phase sizePolyethylene terephthalate glycolIn situ polymerization

The invention relates to a PLA (polylactic acid) / MMT (montmorillonite) degradation enhanced master batch blending modification PLA / PBAT (polyethylene terephthalate-adipic acid-butanediol copolyester) composite material and a preparation method thereof, belonging to the technical field of biodegradable materials. The method provided by the invention is characterized by taking PLA, PBAT and PLA / MMT degradation enhanced master batches as raw materials and uniformly mixing 10-90 parts of PLA, 10-90 parts of PBAT and 5-30 parts of PLA / MMT degradation enhanced master batches and then melting, blending and modifying PLA / PBAT to prepare the PLA / PBAT composite material with excellent performance, wherein the PLA / MMT degradation enhanced master batches are obtained by preparing organic MMT through ion exchange by using an intercalation agent and an intercalation assistant, increasing interlayer spacing among MMT and then intercalating monomer or polylactic acid molecular chains into the interlayer of MMT through melt in situ polymerization. The PLA / MMT degradation enhanced master batch blending modification PLA / PBAT composite material prepared by the method provided by the invention has excellent performance and can be used for production of daily supplies and packaging materials.

Owner:HUBEI UNIV OF TECH

Preparation method of modified non-halogen fire retardant

InactiveCN1990824AGood compatibilityImprove mechanical propertiesFireproof paintsHigh concentrationHalogen

The invention relates to a method for producing modified non- halogen flame retardant, it employs in-situ polymerization and comprises following steps: putting non- halogen flame retardant into kneader with high cottage at 25- 200 Deg. C, stirring thoroughly, feeding inclinly, adding polymeric monomer and initiator for thorough polymerization, and getting packed modified non- halogen flame retardant. The invention is characterized in that it uses no solvent, the polymerization time is short, and the productivity is high, suitable for industrial production, and the shell thickness and strength of microcapsule are easy to control. The modified flame retardant is characterized by large stacking density, sound flame retardance, high concentration, strong currency and good processing performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Synthesis method and application of water soluble chitosan-based flocculant

ActiveCN105622847ASpeed up homolysisThe polymerization reaction is fastWater/sewage treatment by flocculation/precipitationFunctional monomerAlcohol ethyl

The invention provides a synthesis method and application of a water soluble chitosan-based flocculant. The method comprises the steps of adding chitosan into acid solution, adding acylated monomer aqueous solution into the acid solution, uniformly stirring and mixing, performing vibration reaction for 1 to 10 h at 5 to 60 DEG C, performing precipitation and purification through ethyl alcohol and acetone, drying, and obtaining N-acylated chitosan; sequentially adding the N-acylated chitosan, deionized water, acrylamide and strong cation functional monomer into a reactor, uniformly stirring, leading nitrogen into homogenous solution to remove oxygen, adding a photoinitiator and a cosolvent, uniformly stirring and mixing, putting the raw materials into an ultraviolet light reaction device to perform polymerization reaction, drying, performing granulation and powder process, and obtaining the water soluble chitosan-based flocculant; the flocculant can be used for the removal treatment of alga in source water. The flocculant is good in solubility property, high in viscosity coefficient and short in synthesis time, does not need temperature reduction control, simplifies the production technology, reduces energy consumption, and reduces the production cost.

Owner:NANJING UNIV OF TECH

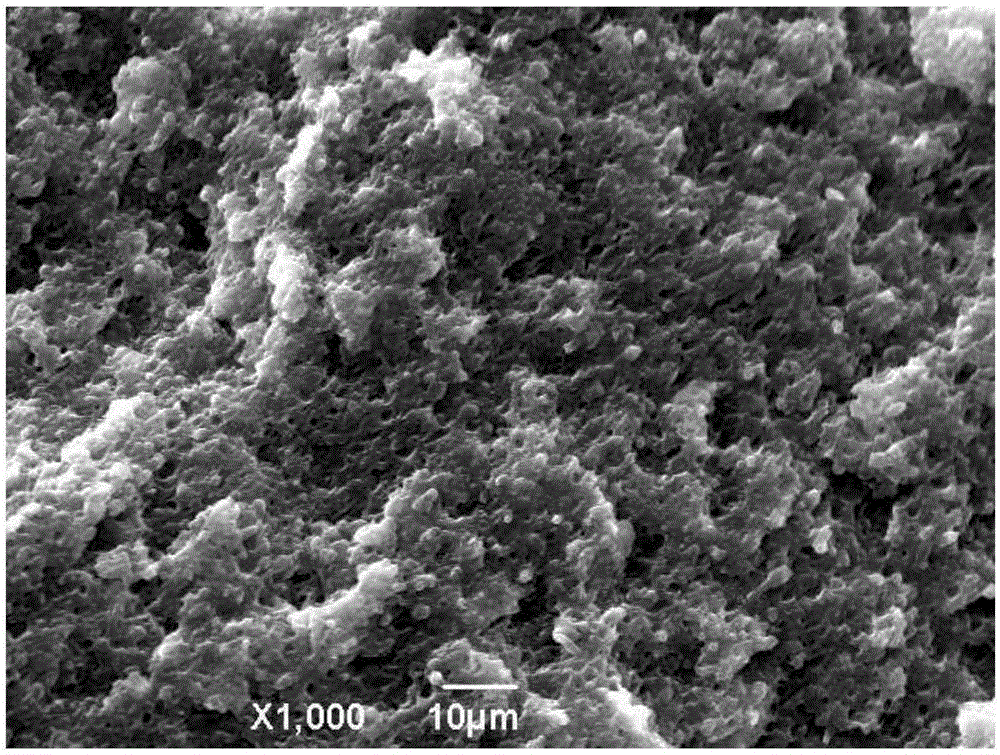

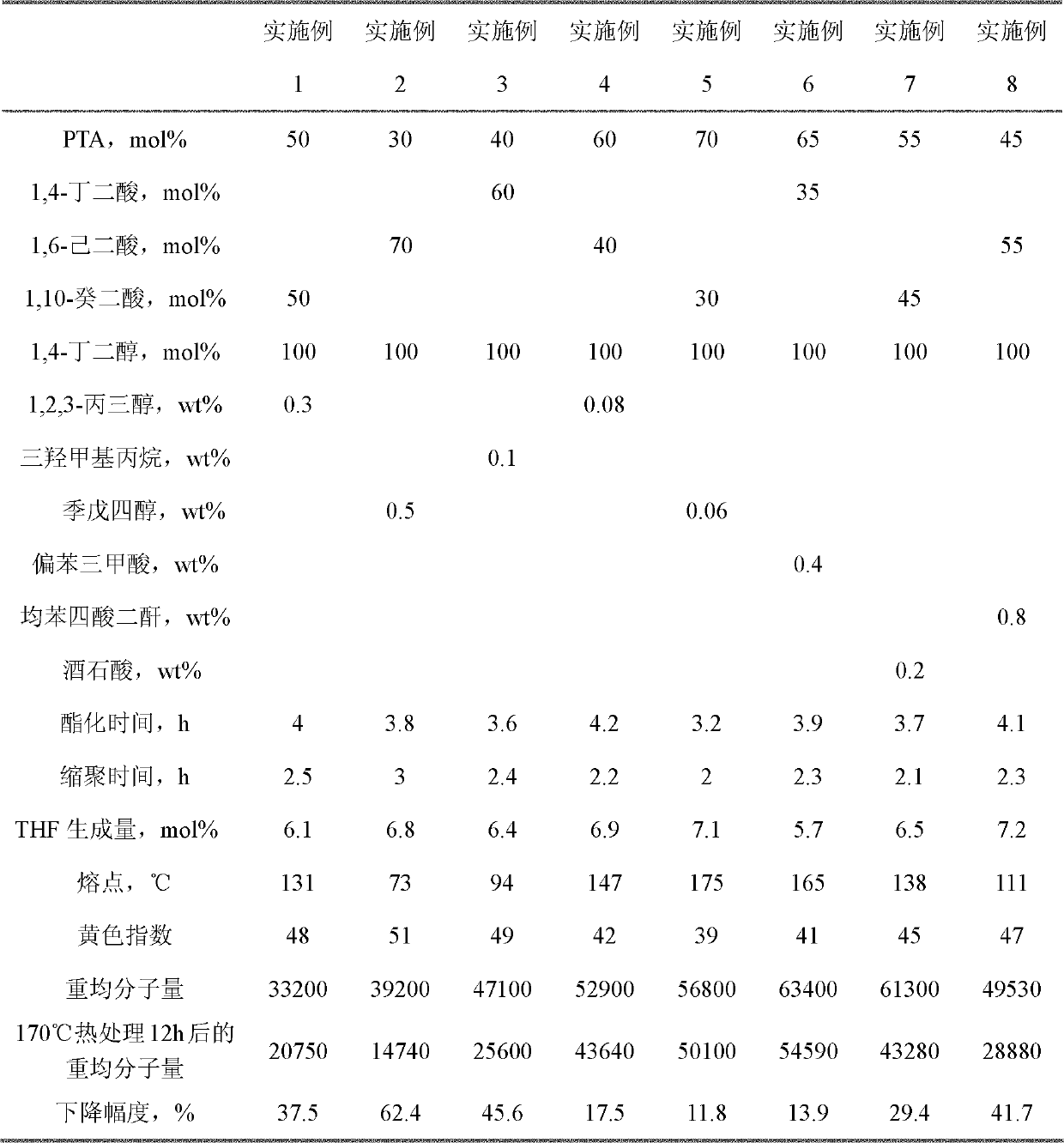

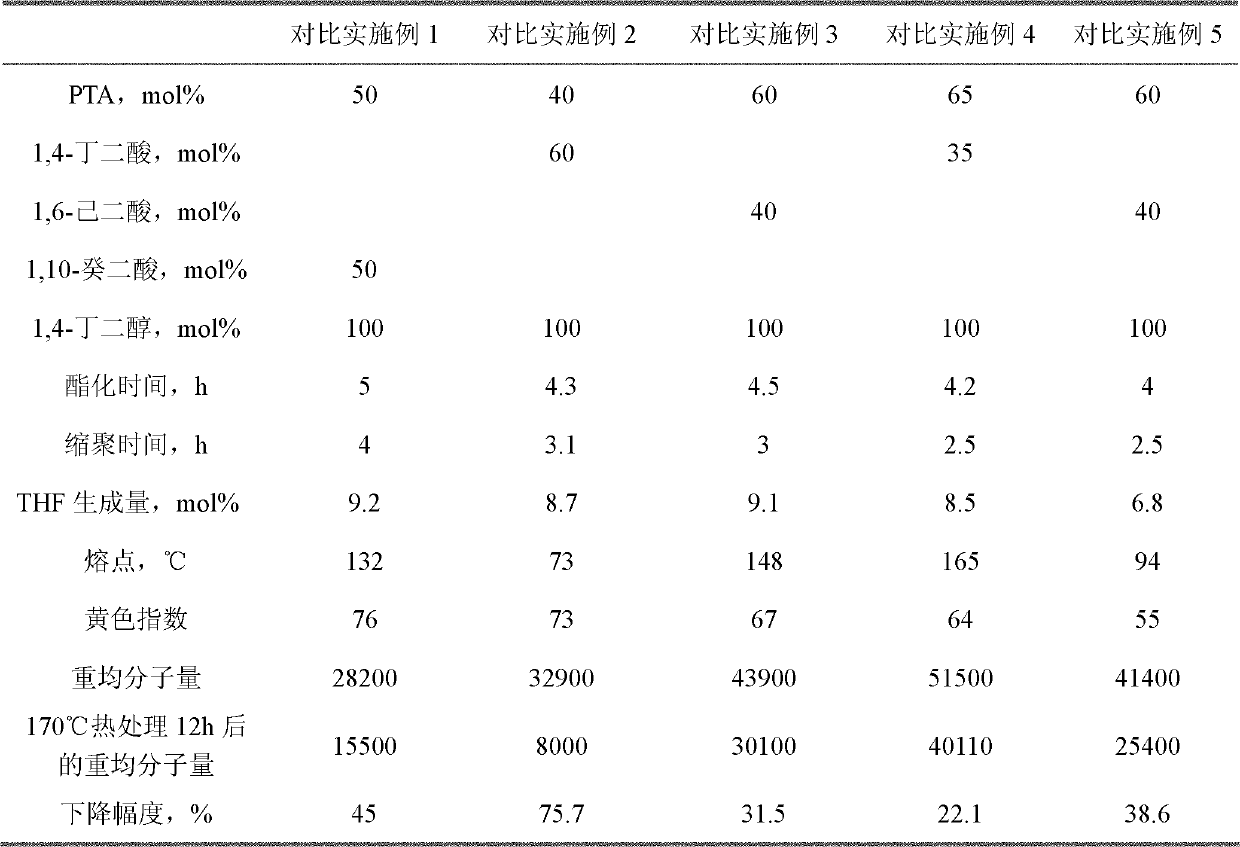

Aromatic-aliphatic copolyester and synthetic method thereof

InactiveCN102558519AShort polymerization timeLess by-products are producedAdhesivesSide productComposite material

The invention provides a new aromatic-aliphatic copolyester and a synthetic method thereof. The synthetic method comprises the following steps of: performing esterification and condensation polymerization reaction on C6-C10 aromatic dicarboxylic acids, C4-C12 aliphatic dicarboxylic acids and C2-C6 aliphatic diols in the presence of a catalyst, and adding 0.01 to 2 weight percent of polyol containing three or more hydroxyls, polybasic acid containing three or more carboxyls, compound containing two or more carboxyls and more than one hydroxyl or compound containing two or more hydroxyls and more than one carboxyl based on the total weight of the aromatic-aliphatic copolyester. By the method, the polymerization reaction time is short, a few byproducts are generated, and the product is white, has good thermal stability and is particularly suitable to be used as hot melt adhesive.

Owner:SHANGHAI LIGHT IND RES INST

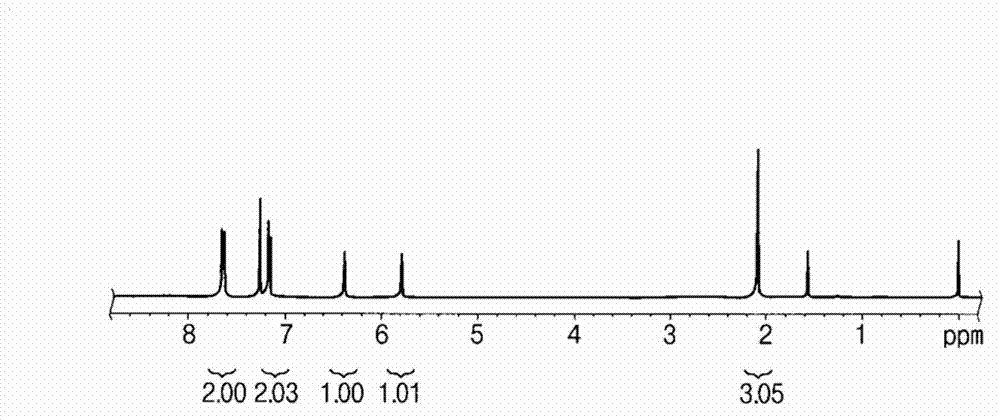

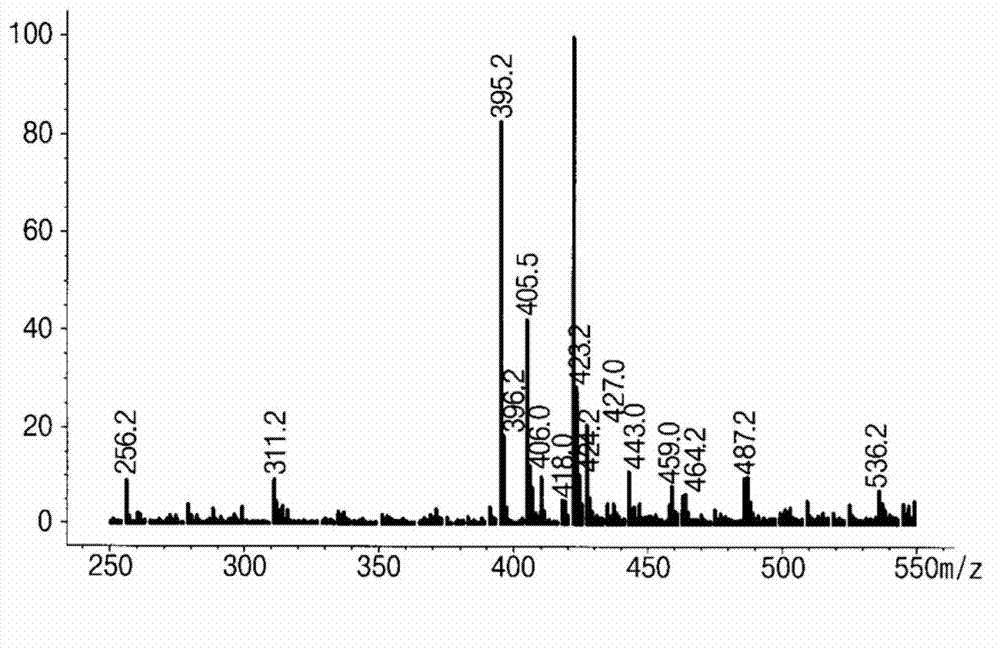

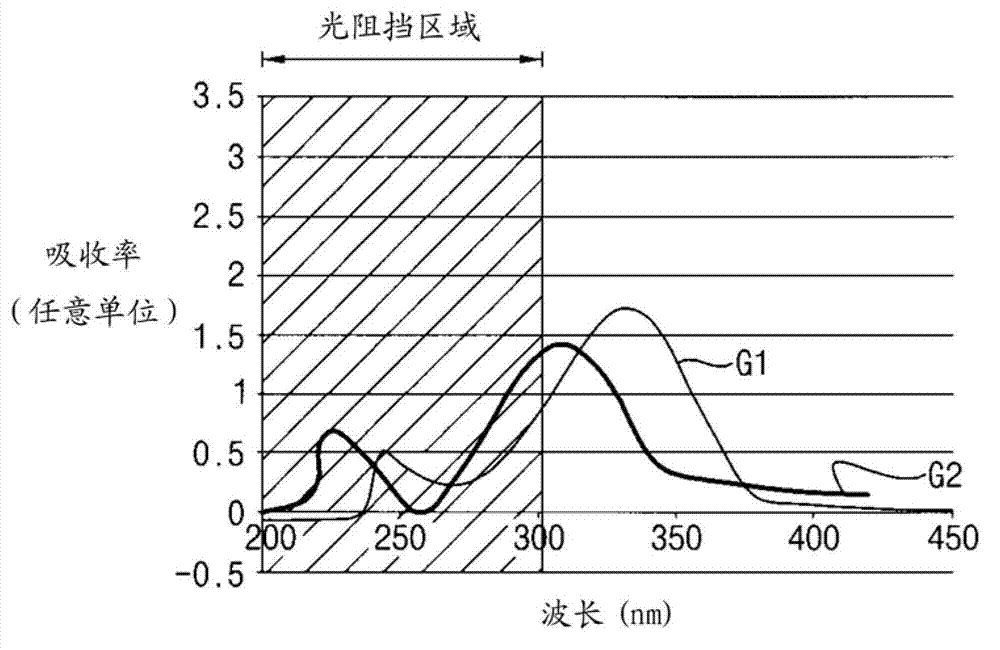

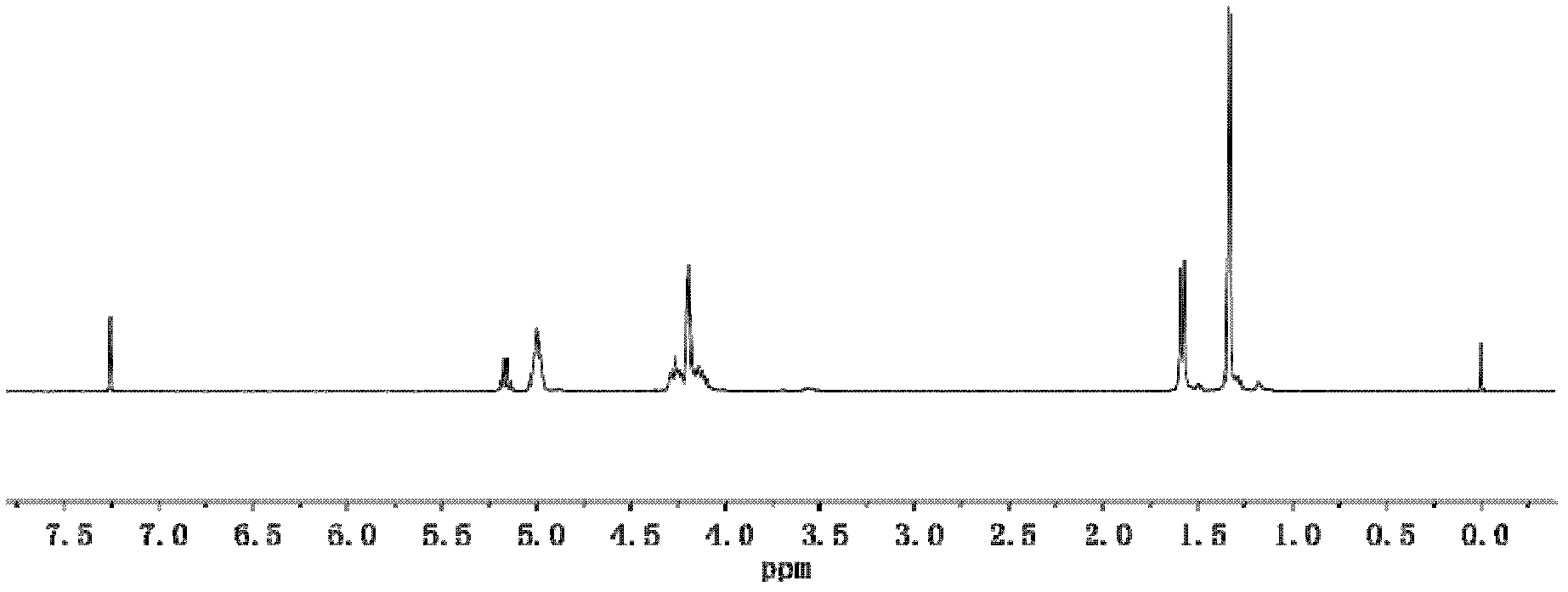

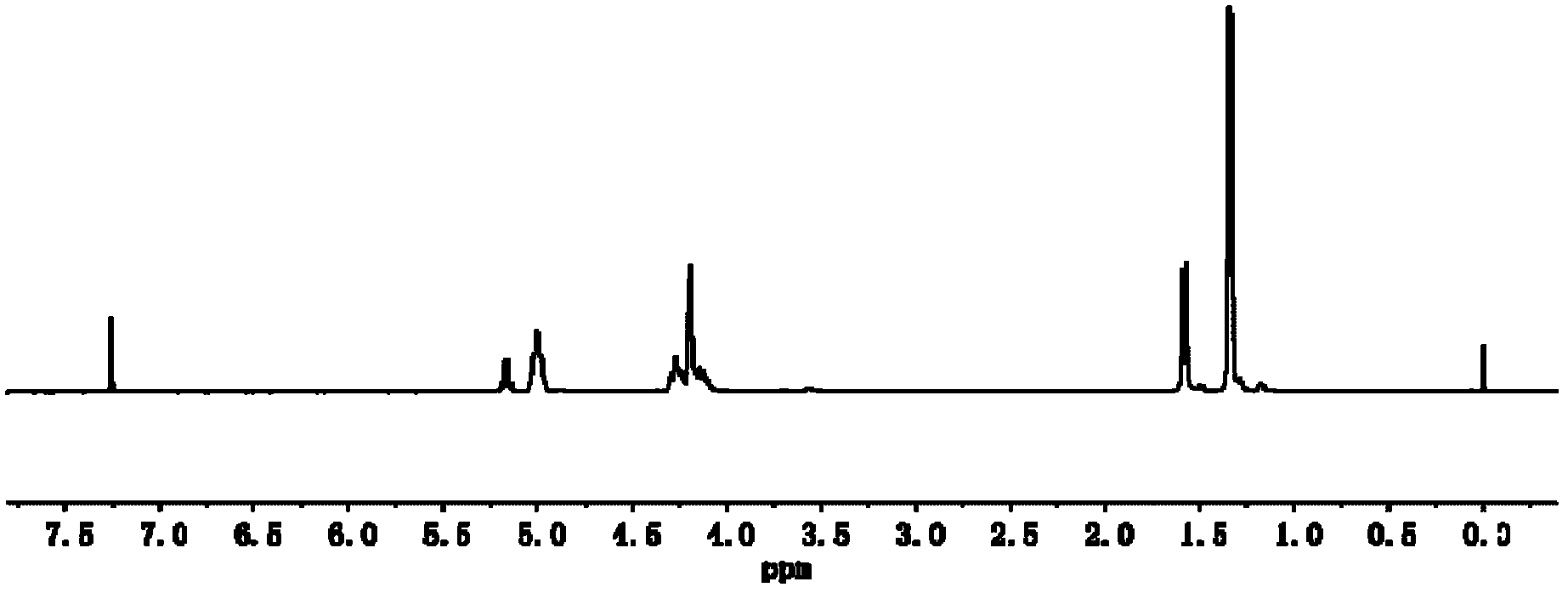

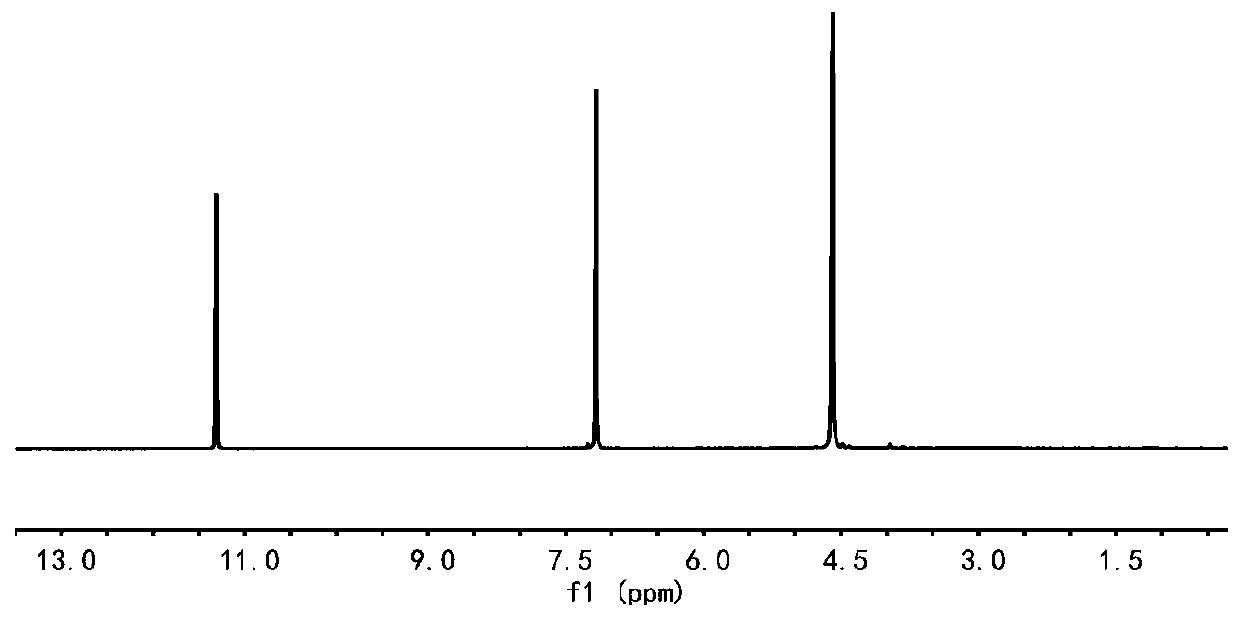

Reactive mesogen compound, liquid crystal composition, display panel, and preparation method thereof

ActiveCN103242288AImproved photoreaction efficiencyShort polymerization timeLiquid crystal compositionsOrganic chemistryMethacrylateHydrogen atom

A reactive mesogen compound, a liquid crystal composition including the reactive mesogen compound, a method of manufacturing a display panel, and a display panel are disclosed. The reactive mesogen compound is represented by Chemical Formula 1-1. In Chemical Formula 1-1, each of A1 and A2 independently represents or a single bond, each of "n" and "m" independently represents an integer in a range of 0 to about 3 ("m" and "n" do not simultaneously represent 0), each of B1 and B2 independently represents a single bond or -(CH2)k- ("k" represents an integer in a range of 0 to 6), at least one -(CH2)- in each of B1 and B2 is replaceable with -O-, -COO-, -OCO- or -CO-, each of D1 and D2 independently represents methacrylate or acrylate, and at least one hydrogen atom of each of A1, A2 and 2,5-thiophene is replaceable with F, Cl, OCH3 or an alkyl group having 1 to about 6 carbon atoms.

Owner:SAMSUNG ELECTRONICS CO LTD

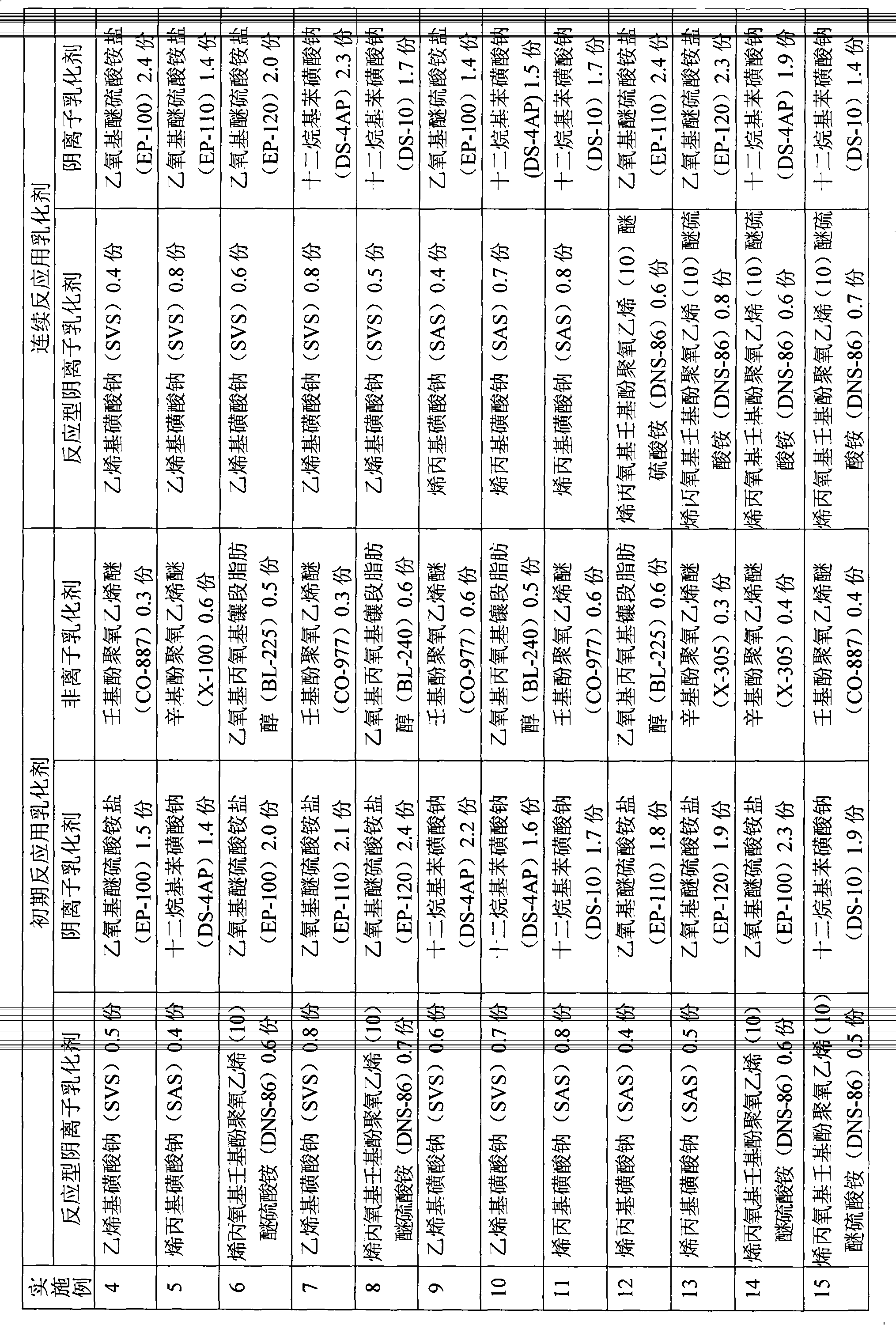

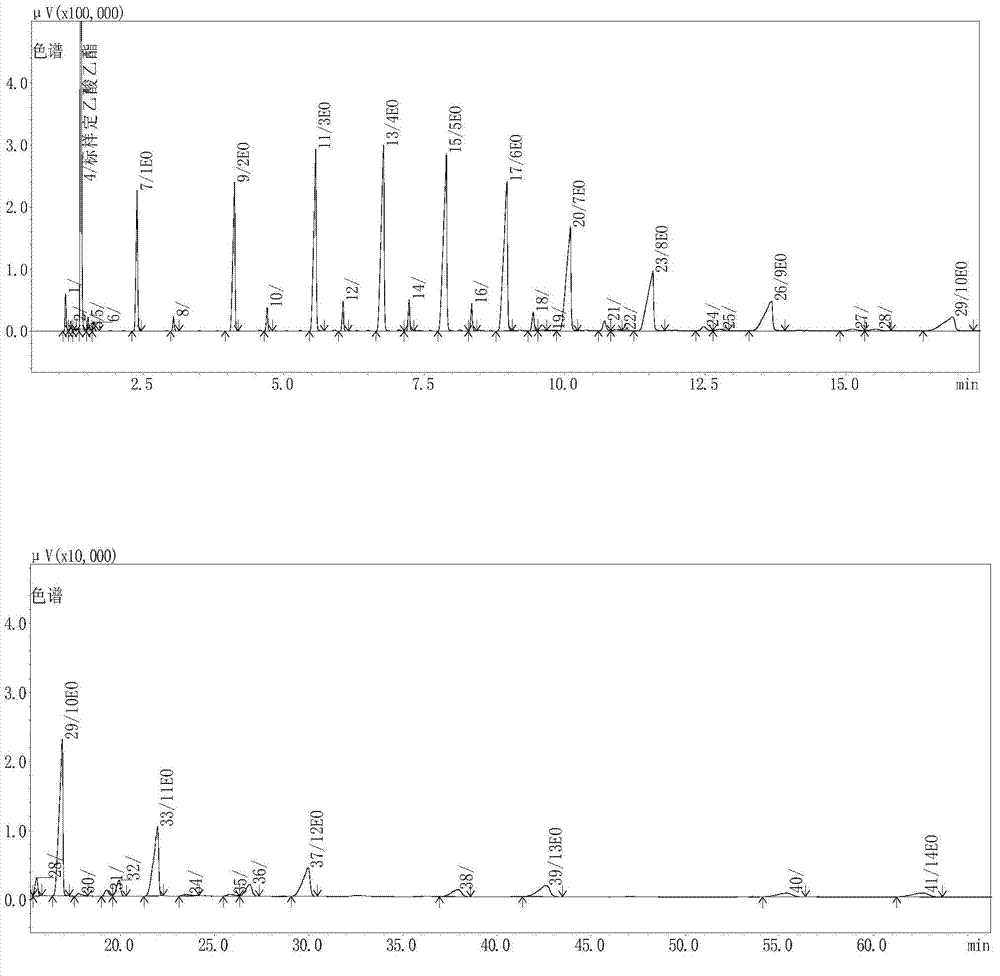

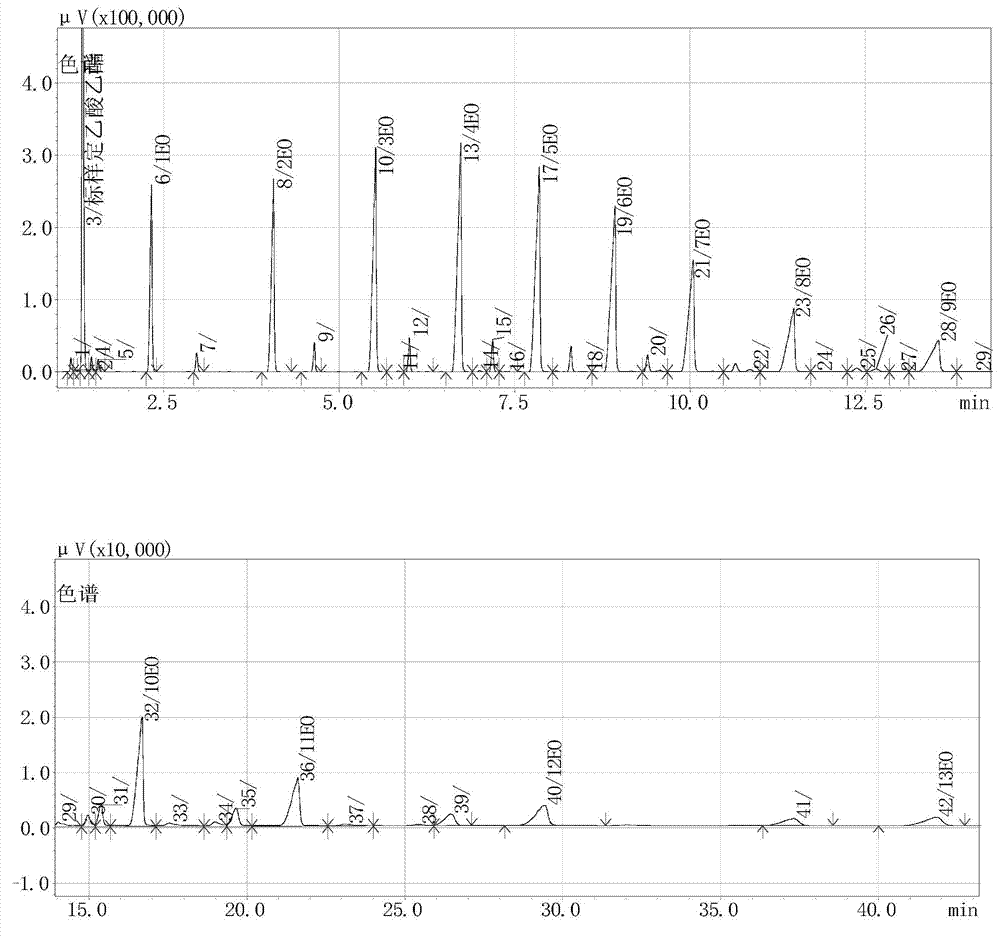

Vinyl acetate-ethylene copolymer emulsion (VAE emulsion) and synthesis method thereof

The invention relates to vinyl acetate-ethylene copolymer emulsion (VAE emulsion) and a synthesis method thereof. The synthesis method comprises the processes of pre-emulsification, emulsion polymerization reaction, finishing and defoaming. The invention is characterized in that complex emulsifying agents added into a reaction system include a non-ion emulsifying agent, an anion emulsifying agent and a reactive type emulsifying agent. In the synthesis method, the complex emulsifying agents are adopted mainly, the solid content of the produced VAE emulsion is more than or equal to 54.5%, the number average particle size can be less than 0.3mu m, the stability is good and the viscosity is low; the polymerization reaction time is short, the speed is fast, the conversion rate is high, the technique is simple and the industrialization is easy to realize; and the obtained fine-particle-size VAE emulsion is white in color, can be used for industries such as high-end building coatings, paper and textiles, and has wide market.

Owner:CHINA PETROCHEMICAL CORP +2

Poly(m-phenylene isophthalamide) resin liquid, preparation method thereof, poly(m-phenylene isophthalamide) resin and poly(m-phenylene isophthalamide) fibrid

InactiveCN107522858AGood dispersionImprove liquidityMonocomponent polyamides artificial filamentBreaking strengthMoisture absorption

The invention discloses a poly(m-phenylene isophthalamide) resin liquid, a preparation method thereof, a poly(m-phenylene isophthalamide) resin and a poly(m-phenylene isophthalamide) fibrid. The preparation method of the poly(m-phenylene isophthalamide) resin liquid comprises (1) preparing m-phenylenediamine solution and m-phthaloyl dichloride organic solution; (2) mixing the m-phenylenediamine solution and a part of the m-phthaloyl dichloride organic solution for pre-polymerization; (3) mixing pre-polymerized mixture solution with the rest part of the m-phthaloyl dichloride for polymerization to obtain the poly(m-phenylene isophthalamide) resin liquid. The poly(m-phenylene isophthalamide) resin and the poly(m-phenylene isophthalamide) fibrid are both prepared through precipitation of the poly(m-phenylene isophthalamide) resin liquid. The preparation method of the poly(m-phenylene isophthalamide) resin liquid has the advantages of being controllable in reaction heat, small in influence of by-products, free from of neutralization of acid-binding agent, capable of avoiding moisture absorption of m-phthaloyl dichloride and formation of intermediates, and low in content of low-molecular polymers during reaction. Therefore, the prepared poly(m-phenylene isophthalamide) resin is high and stable in logarithmic viscosity number, and the prepared poly(m-phenylene isophthalamide) fibrid is uniform in fiber structure and high in tensile breaking strength.

Owner:HUNAN CHEM RES INST +1

Method for preparing inorganic mineral polymers through lead and zinc mine tailings

InactiveCN104003632AGood heat insulation at high temperatureIncreased durabilityCement productionMining engineeringMetakaolin

The invention discloses a method for preparing inorganic mineral polymers through lead and zinc mine tailings. The method includes the steps that activating treatment is carried out on the lead and zinc mine tailings through the wet-process alkalize calcination, alkali-activator is added for inorganic polymerization reaction after metakaolin and sand are added and stirred, the inorganic mineral polymers of a net structure are formed, and a foaming agent and a foam stabilizer can be added into the obtained inorganic mineral polymers to be further prepared into foamed inorganic mineral polymers. The obtained finished inorganic mineral polymers are good in durability, have good high temperature heat insulating property, will not release poisonous substances even when exposed in flame, and can be used for backfill and sealing after a mine is mined, building materials and other aspects. Not only can the stacking problem of the lead and zinc mine tailings be effectively solved and environmental pollution be reduced, but also a new path is developed for developing and utilizing waste lead and zinc mine tailings in China, a new exploration direction is provided for relevant research on recycling of tailings, and the method has a great significance to energy conservation, emission reduction, environmental protection, waste utilization and creation of the environment-friendly society.

Owner:FUZHOU UNIV

Preparation method of biodegradable polybutylene succinate

The invention provides a preparation method of biodegradable polybutylene succinate (PBS). The preparation method of the biodegradable polybutylene succinate takes a succinate compound and 1, 4-butanediol as polymerizing monomers, adopts an efficient compound catalyst system and comprises the following steps: performing transesterification reaction to obtain a PBS (polybutylene succinate) oligomer first and then performing melting polycondensation reaction to obtain a PBS polymer with a high molecular weight and good color and luster. By the preparation method, PBS degradable plastic with excellent color and luster and a high molecular weight can be prepared without using a chain extender, and meanwhile industrial production can be realized.

Owner:沧州旭阳化工有限公司

Method for synthesizing high-molecular-weight poly(lactic acid) through melt polycondensation of lactic acid under catalysis of three-way composite catalyst

The invention provides a method for synthesizing high-molecular-weight poly(lactic acid) through melt polycondensation of lactic acid under catalysis of a three-way composite catalyst, which belongs to the field of poly(lactic acid). The method is as follows: lactic acid oligomer is synthesized at first and is then subjected to melt polycondensation under catalysis of the three-way composite catalyst so as to obtain high-molecular-weight poly(lactic acid) in a short time, wherein the three-way composite catalyst is a compound of a metallic compound, protonic acid and dihydroxycarboxylic acid.The method provided in the invention has the advantages of a simple process, low cost, few side reactions, a short polymerization time and high yield; prepared poly(lactic acid) has a molecular weight in a range of 40, 000 to 210, 000 and can be used in the medical domain with high additional values and the field of environment-friendly materials for general purposes.

Owner:BEIJING UNIV OF CHEM TECH

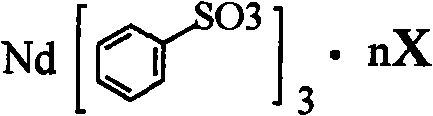

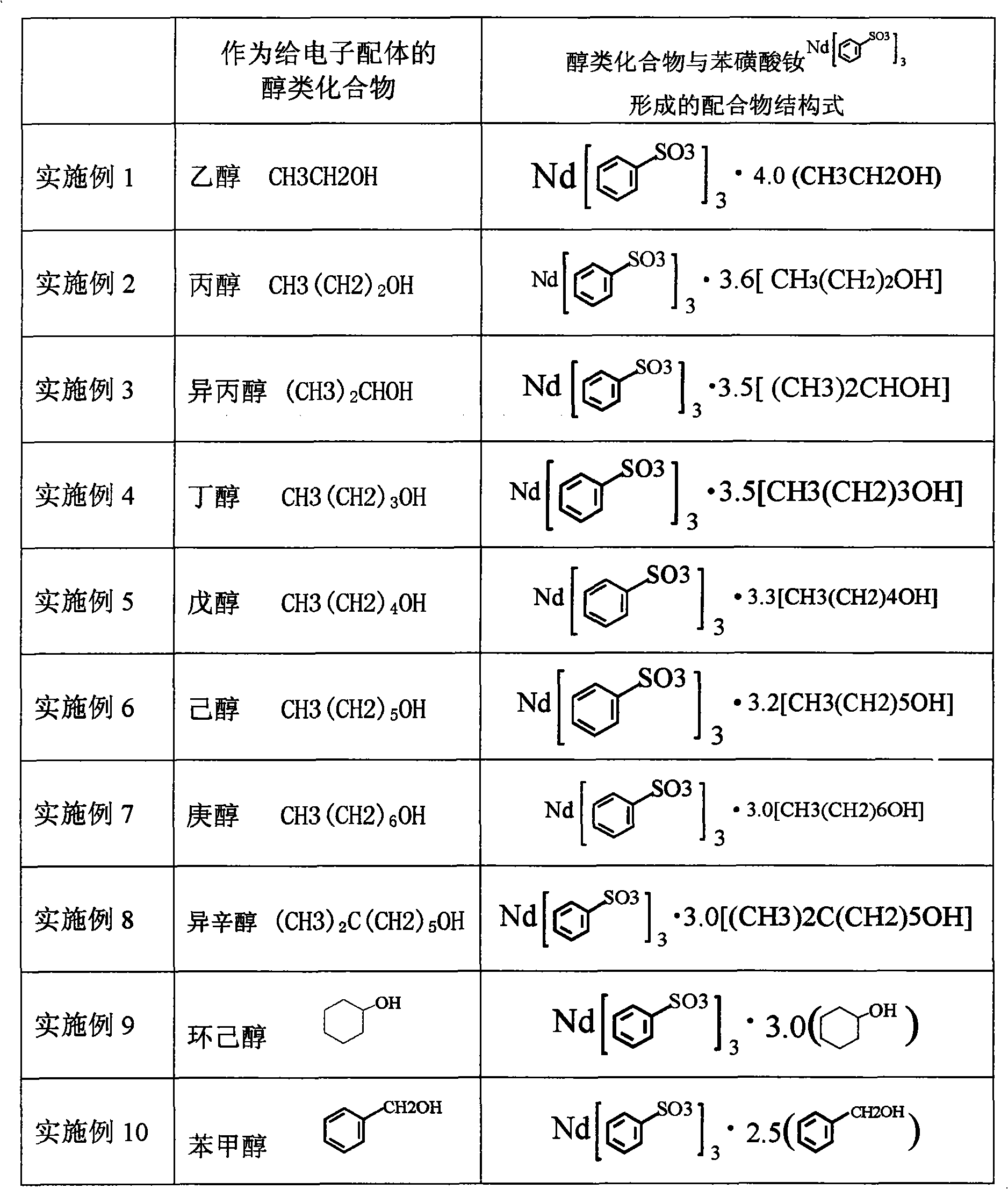

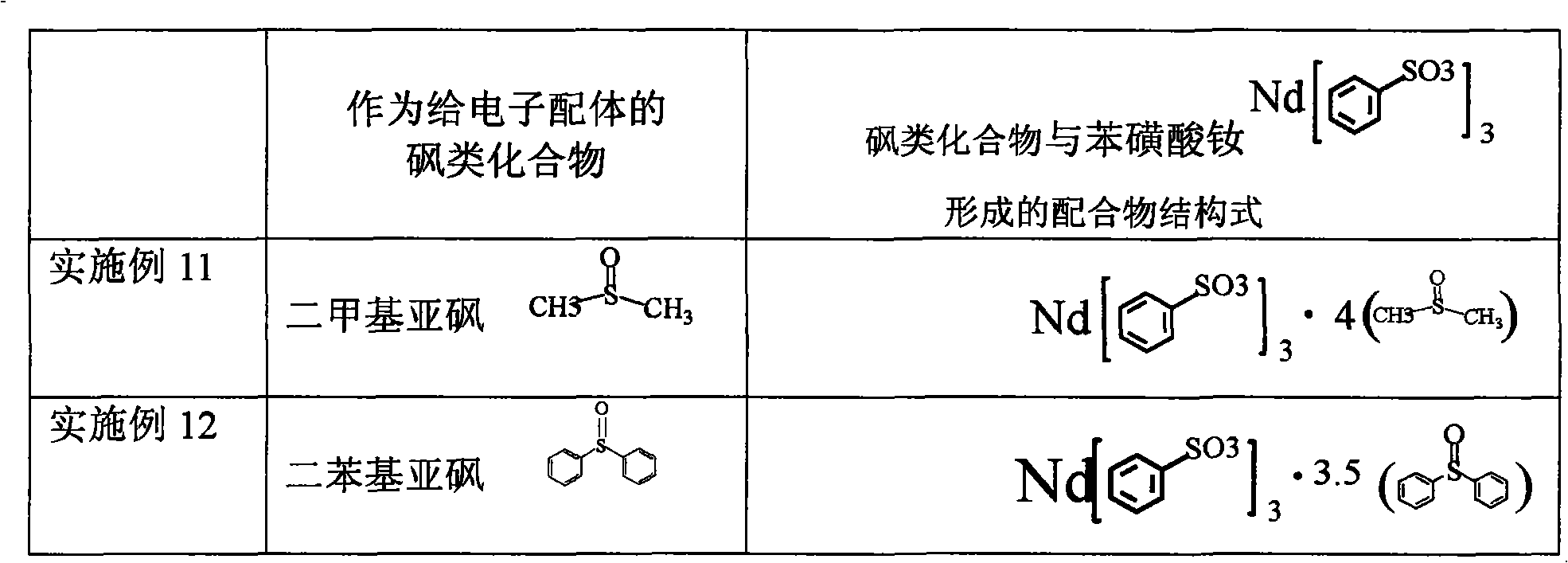

Sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and preparation method thereof

The invention relates to a sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and a preparation method thereof. The catalyst comprises benzenesulfonic acid neodymium rare earth complex and alkyl aluminum; the molar ratio of the alkyl aluminum to the rare earth neodymium in the benzenesulfonic acid neodymium rare earth complex is 15 to 40:1, wherein the benzenesulfonic acid neodymium rare earth complex comprises benzenesulfonic acid neodymium alcohol complex, benzenesulfonic acid neodymium sulphoxide complex, benzenesulfonic acid neodymium furan complex, benzenesulfonic acid neodymium amine complex, benzenesulfonic acid neodymium ether complex and benzenesulfonic acid neodymium ester complex; ligand comprises: alcohol compound, sulfoxide compound, furan compound, amine compound, ether compound and ester compound; and the alkyl aluminum comprises: 3-isobutyl aluminum, triethyl aluminum, diisobutyl aluminum hydride, or diethyl aluminum hydride. The sulfoacid rare earth complex catalyst is used for polymerizing isoprene, and can obtain the high-cis rare earth polyisoprene rubber with the cis 1,4 structure content more than 96.0 percent and the weight-average molecular weight more than 2.2 million.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Polyhedral oligomeric silsesquioxane-polyethylene glycol polymer solid electrolyte material and preparation method thereof

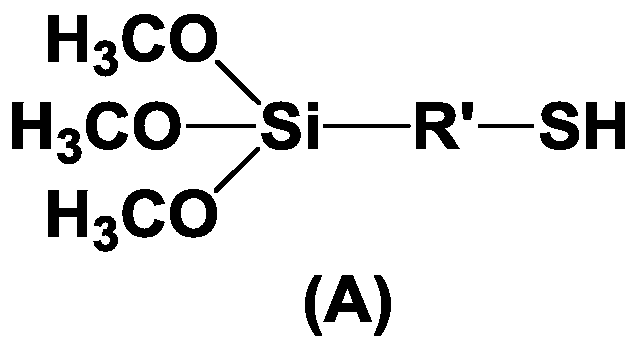

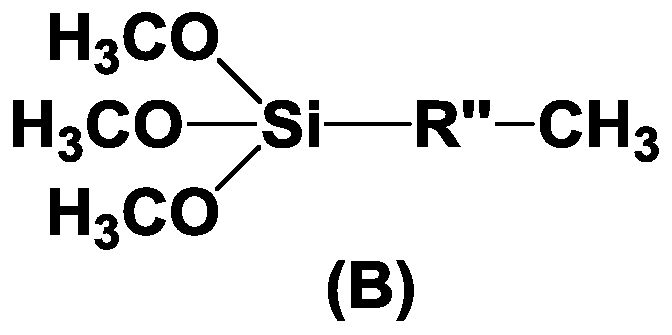

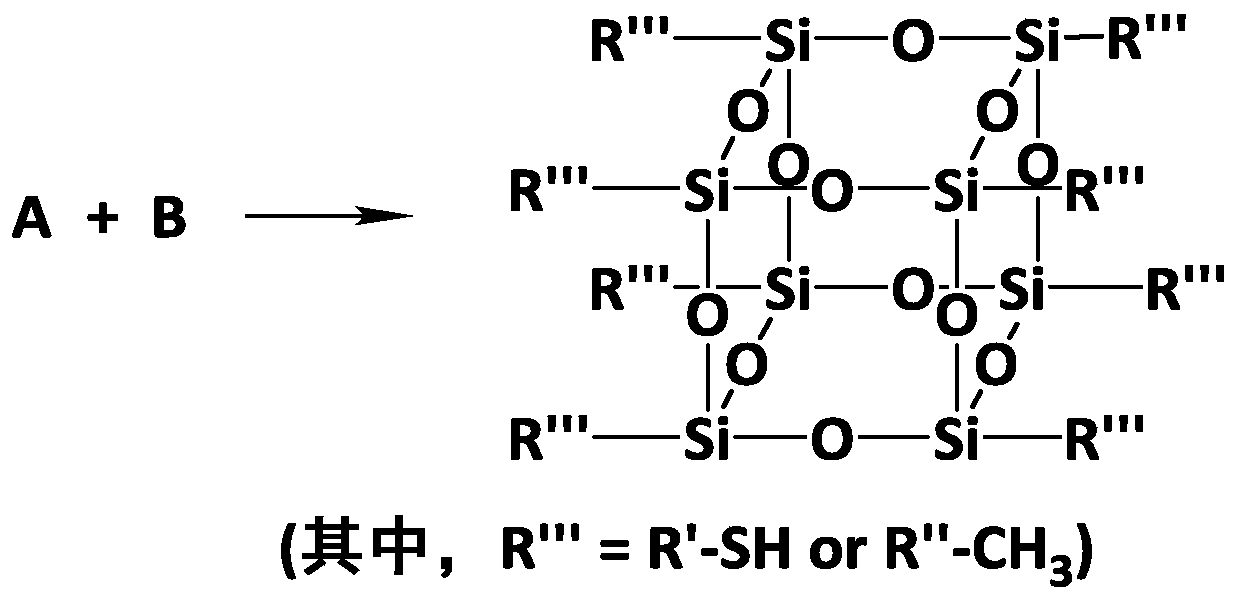

ActiveCN110156998AInhibit crystal growthMultiple amorphous regionsSolid electrolytesSecondary cellsCross-linkSolid state electrolyte

The invention discloses a polyhedral oligomeric silsesquioxane-polyethylene glycol polymer solid electrolyte material and a preparation method thereof. The preparation method comprises the following steps: dissolving trimethoxy silane and concentrated hydrochloric acid in an organic solvent with polarity of 5-7, conducting stirring and polymerizing at a controlled temperature to obtain polyhedraloligomeric silsesquioxane with a surface grafted with sulfydryl, further conducting process to obtain pure polyhedral oligomeric silsesquioxane with a surface grafted with sulfydryl, blending the purepolyhedral oligomeric silsesquioxane with a surface grafted with sulfydryl and polyethylene glycol with a single-side double-bond end-capped, adding a photoinitiator and lithium salt into the blend,and performing cross-linking polymerization by ultraviolet irradiation to obtain the polymer solid electrolyte material. According to the invention, the whole process flow of the key preparation process, the reaction conditions of each step and the like are optimized to form an organic block polymer solid electrolyte material; compared with the prior art, the ionic conductivity and the mechanicalproperty of the electrolyte material are improved; the preparation process is simple and easy to implement; and no pollution is generated by ultraviolet polymerization.

Owner:LUOYANG INST OF SCI & TECH

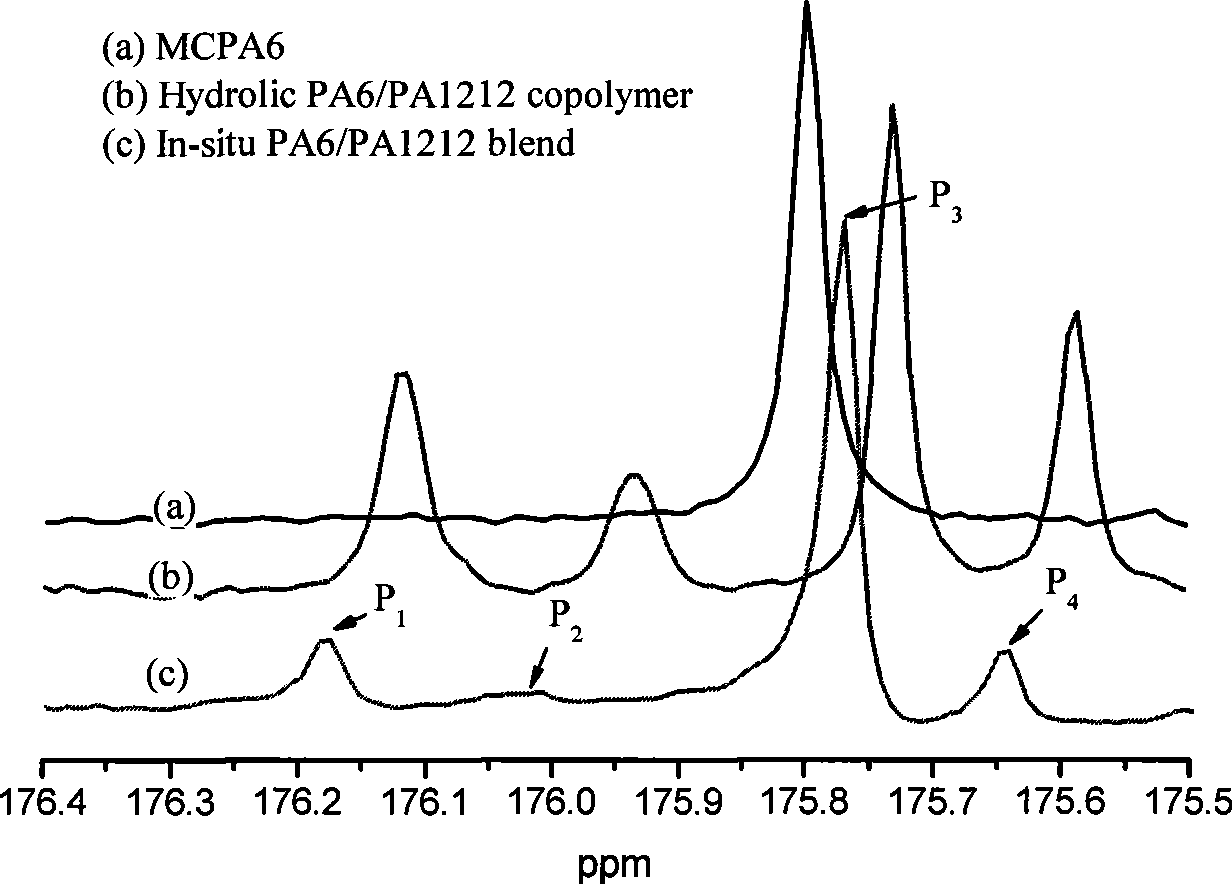

Copolymerization nylon composition and preparation thereof

The invention relates to a copolymeric nylon composition and a method for preparing the same. In the composition, 1 to 100 weight portions of nylon and 0 to 100 weight portions of filler are dissolved in 100 weight portions of lactam to obtain a mixture of the nylon, the filler and the lactam; and the mixture is added with 0.01 to 10 weight portions of anion polymerization initiator and 0.01 to 50 weight portions of activating agent and has polymerization reaction for 5 to 120 minutes at a temperature of between 100 and 250 DEG C to generate the copolymeric nylon. Compared with the prior art, the method has the characteristics of low reaction temperature, simple equipment requirement and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method of powdered acrylonitrile-butadiene rubber with high performance

A preparation method of a powdered acrylonitrile-butadiene rubber with high performance comprises steps of: dispersing of carbon nanotubes: adding carbon nanotubes and water in a high-speed disperser, and stirring to evenly disperse the carbon nanotubes; preparation of a rapid polymerization latex: adding water, acrylonitrile and an emulsifier into a polymerization kettle, after confirmation of no leakage, adding butadiene, a crosslinking agent, an initiator and a molecular weight regulator for polymerization; and when the conversion rate reaches a certain level, adding a terminator to obtain a fast polymerization acrylonitrile-butadiene latex; and condensation into a powder: adding the acrylonitrile-butadiene latex, water, carbon nanotubes, a separant, a flocculant and a coagulant into a coagulation tank; curing, washing, dehydrating and drying to obtain the powdered acrylonitrile-butadiene rubber. The prepared acrylonitrile-butadiene rubber slurry has the following properties: pH of 7-10, Mooney viscosity of ML (1+4) 100 DEG C 60-110, structure gel of 75%-85%, and acrylonitrile-butadiene rubber mechanical stability of less than 1.0%; and the powdered acrylonitrile-butadiene rubber has the following properties: powder particle size of 0.6-1.0 mm, acrylonitrile content of 40%-55%, ash content no more than 1.0, volatile matter no more than 1.0, and powdered ratio no less than 95%.

Owner:PETROCHINA CO LTD

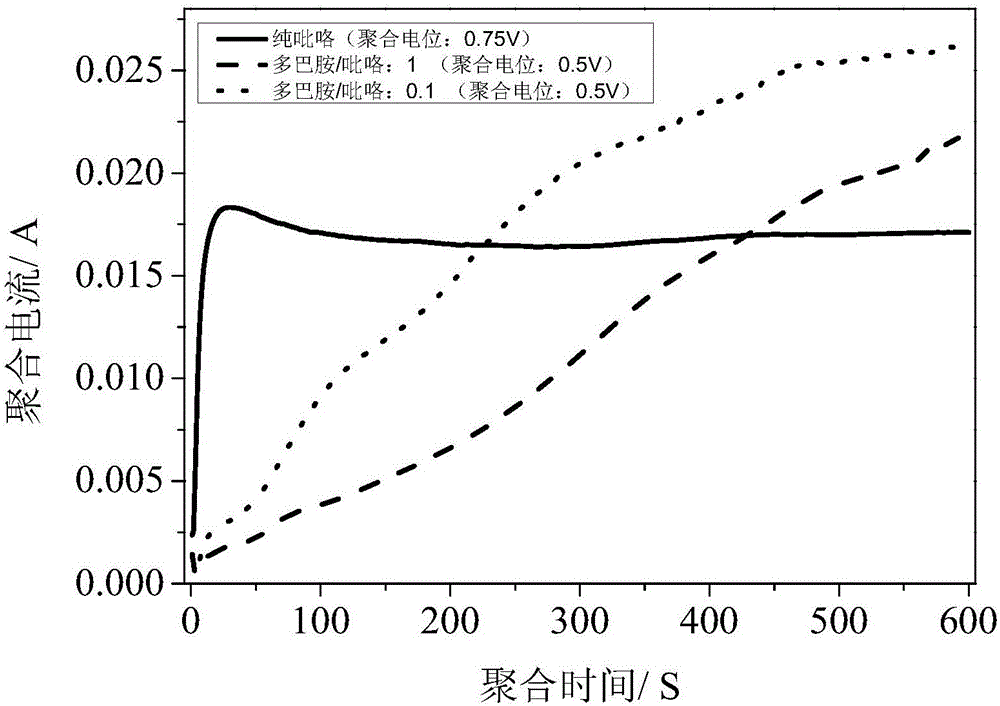

Preparation method for polypyrrole-poly-dopamine composite coating

InactiveCN106011975AShort polymerization timeProne to peroxidationElectrophoretic coatingsPaints for electrolytic applicationsPolypyrroleOxygen

The invention discloses a preparation method for a polypyrrole-poly-dopamine composite coating. The preparation method includes the following steps that (1) dopamine and a dopant are dissolved into deionized water, then a pyrrole monomer without impurities is continuously added to be dissolved, dry nitrogen is then led in to remove dissolved oxygen in a mixture, and an electrolyte with the pH ranging from 1 to 8 is obtained; and (2) in the above electrolyte, a constant potential polymerization process is adopted for conducting polymerization on the surface of one side of a pure titanium substrate to obtain the polypyrrole-poly-dopamine composite coating, and oxide, miscellaneous dirt and grease on the surface of the pure titanium substrate are removed through pretreatment. According to the method, an electrochemical method is adopted for conducting polymerization on the dopamine and the pyrrole, the polymerization time is short, polymerization can be carried out under the acidity and alkaline conditions, and meanwhile a polymerization film obtained through polymerization has some beneficial effects of the dopamine and the pyrrole; and a larger possibility is provided for potential application of the polymerization film.

Owner:XIAMEN UNIV

Method for preparing micro-sized monodisperse polyurea microsphere in static condition

The invention relates to a method for preparing micro-sized monodisperse polymer microspheres in static condition. The method comprises the steps that diisocyanate monomers and a water-acetone mixed solvent are added into a reaction bottle, wherein the mass ratio of water to acetone ranges from 20 / 80 to 60 / 40, and the diisocyanate compound accounts for 0.5-13.0% of the total mass of the polymerization system; after the reaction bottle is sealed and the mixed solvent is shaken up, the reaction bottle is placed in thermostatic waterbath of 20-80 DEG C for polymerization; after polymerization, the products are centrifugalized and dried to obtain the micro-sized monodisperse polyurea microspheres. The method for preparing micro-sized monodisperse polymer microspheres in static condition has the advantages that one monomer is used for precipitation polymerization completely in static condition without any stirring or oscillation, so that the reaction time is short, the monomer can be transformed completely, the yield of microspheres is high, and the operation is simple; the method is conducive to scale production of monodisperse microspheres; and the produced microspheres have clean surfaces and a large amount of amido, and can be used in various fields of protein adsorption and separation, enzyme immobilization, chromatographic analysis and the like..

Owner:UNIV OF JINAN

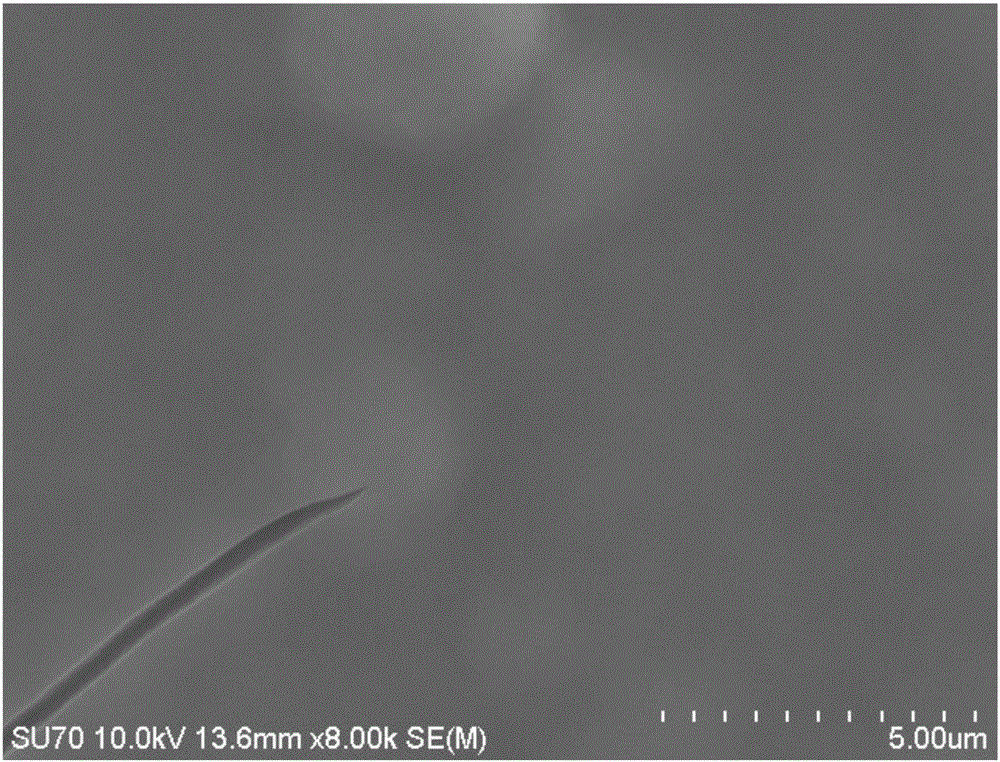

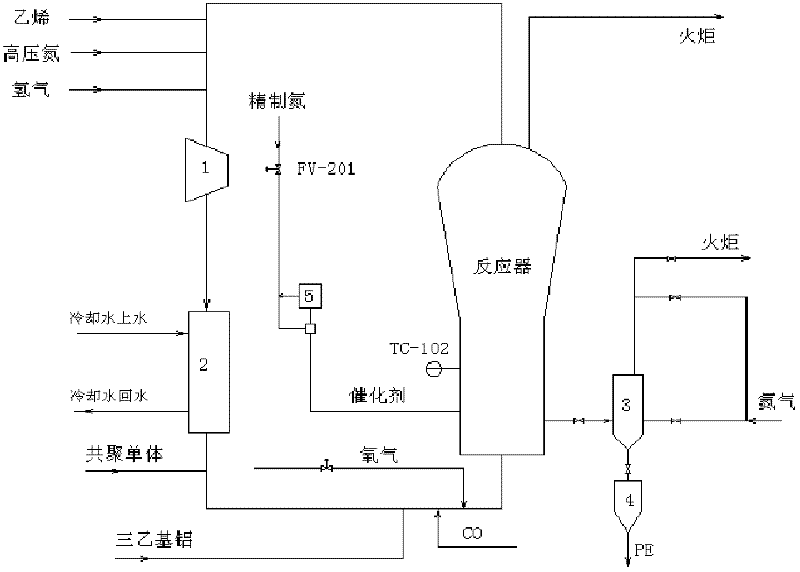

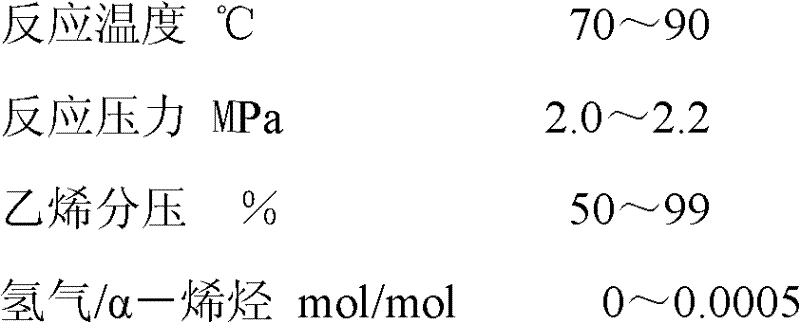

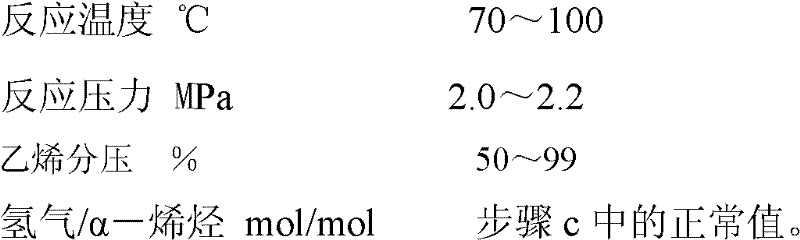

Method for quickly starting polymerization reaction in alpha-olefin gas-phase fluidized bed reactor

The invention relates to a method for quickly starting polymerization reaction in an alpha-olefin gas-phase fluidized bed reactor, belongs to a method for preparing alpha-olefin homopolymer or copolymer, and in particular relates to a method for preparing corresponding polymer by ethylene polymerization or copolymerization of ethylene and other alpha-olefins. The method is characterized by comprising the following steps of: displacing trace water in the gas-phase fluidized bed reactor by using nitrogen and ethylene, initiating to start alpha-olefin polymerization reaction or alpha-olefin copolymerization reaction by using a metallocene catalyst, switching to the conventional chromium catalyst alpha-olefin polymerization or alpha-olefin copolymerization reaction system, stopping adding the metallocene catalyst, and switching to the conventional alpha-olefin gas-phase fluidized bed reactor for polymerization reaction. By the method for quickly starting continuous polymerization reaction in the alpha-olefin gas-phase fluidized bed reactor, the trace water is quickly removed, time for establishing continuous and stable polymerization reaction is short, and the consumption of the ethylene for displacement is low; and production accidents are avoided, the consumption of the ethylene is reduced, and the production period is shortened.

Owner:CHINA PETROLEUM & CHEM CORP

Synthesis method for anionic polyacrylamide

InactiveCN102585091AInitiate polymerization time is shortShorten the polymerization initiation timeSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSolventPolyacrylamide

The invention relates to a synthesis method for anionic polyacrylamide. The synthesis method comprises the following steps of: adding a solubilizer and a chelant to three monomer aqueous solutions of acrylamide (AM), acrylic acid (AA) and 2-acryloyl-2-methyl-propyl sulfonate (AMPS); regulating the pH value of the reaction system with a buffer solution; successively adding an oxidizing agent and a reducing agent under the protection of nitrogen; introducing nitrogen for a period of time continuously; stopping introduction of the nitrogen and sealing; and initiating a polymerization reaction under the irradiation of ultraviolet light of certain wave length to generate gommures. The polymerization initiating time of the synthesis method is short, and heating or cooling control is not needed, so that the production process is simplified, the energy consumption is reduced, and the production cost is reduced.

Owner:CHONGQING UNIV

Polyitaconic acid and preparation method thereof

ActiveCN102108111AReduce residualSimple production processScale removal and water softeningPolyethylene oxideItaconic acid

The invention relates to polyitaconic acid and a preparation method thereof, in particular to the polyitaconic acid and a method for preparing the polyitaconic acid quickly and effectively. The polyitaconic acid comprises an itaconic acid monocarboxylate monomer unit and an itaconic acid dicarboxylate monomer unit, the molecular weight range of the polyitaconic acid, which is determined by a gel permeation chromatograph through standard polyethylene oxide (PEO) is 1000-10000, and a polymer is light yellow or dark red liquid which belongs to an environment-friendly product. The polyitaconic acid takes itaconic acid monomers which are partially neutralized as raw materials and is polymerized in water phase through the radical polymerization method. The method has simple process, few residues of the monomers, high conversion rate, high polymerization time, low energy consumption, and no emission of three wastes. The polyitaconic acid salt has a high-efficient inhibition role for formation and adhesion of calcium carbonate scale in seawater. The polyitaconic acid can be used as a scale inhibitor, a dispersing agent and a corrosion inhibitor in a seawater utilization (seawater circulating cooling, seawater desalting and the like) system, as well as a detergent additive, a chelating agent and the like.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Unimodal radial block copolymer possessing random graded chain and its preparation method

InactiveCN1569914AGood light transmissionImprove mechanical propertiesPolymer scienceOptical transmittance

The invention provides a unimodal radial block copolymer possessing random graded chain and its preparation method, wherein the structure is illustrated by formula R-XB#-[3]-(B#-[2]-S#-[3])B#-[1] / S#-[2]-S#-[1]]#-[3], wherein the weight portion of the single vinyl aromatic hydrocarbon monomer in the copolymer is between 30-95%, wherein the weight portion of the conjugated diolefin hydrocarbon monomer is between 5-70%. This polymer has very high transmittance and fine shock resistant intensity.

Owner:PETROCHINA CO LTD

Method for preparing lactide-propylene oxide-CO2 terpolymer by using rare earth three-way catalyst

The invention discloses a method for preparing lactide-propylene oxide-CO2 terpolymer by using a rare earth three-way catalyst. The method comprises the following steps of: adding the rare earth three-way catalyst, lactide, propylene oxide and CO2 into a reaction kettle, and performing polymerization on the lactide, the propylene oxide and the CO2 under the action of the rare earth three-way catalyst to obtain the lactide-propylene oxide-CO2 terpolymer, wherein the rare earth three-way catalyst consists of trichloroacetic acid yttrium, diethyl zinc, glycerol and 1,3-dioxolane; a molar ratio of the trichloroacetic acid yttrium to the diethyl zinc to the glycerol is 1:20:10; and the concentration of the diethyl zinc in the 1,3-dioxolane is 0.5*10<-3>mol / mL. Compared with the prior art, the method has the advantages that: the polymerization of the lactide, the propylene oxide and the CO2 is catalyzed by the rare earth three-way catalyst, so the polymerization time is short; and the prepared terpolymer has the ether block content of less than 2 percent, and the method is suitable for industrial production.

Owner:中科应化(长春)科技有限公司

Furan dicarboxylic acid copolyester and preparation method thereof

ActiveCN109810248AHigh tensile modulusHigh tensile strengthMonocomponent copolyesters artificial filamentFuranMechanical property

The invention relates to furan dicarboxylic acid copolyester and a preparation method thereof. The preparation method comprises the following steps: mixing a first component, a second component and athird component with the mole ratio of 1 to (1.1 to 2.0) to (0.0001 to 0.02) with an esterification catalyst to obtain a first intermediate product, wherein the first component comprises at least oneof furan dicarboxylic acid and a furan dicarboxylic acid ester compound, the second component comprises at least one of aromatic diol and aliphatic diol, and the third component comprises polyhydric alcohol with hydroxyl number being greater than or equal to 3; performing prepolymerization reaction and polycondensation on the first intermediate product to obtain the furan dicarboxylic acid copolyester. In the preparation method, the polyhydric alcohol with hydroxyl number being greater than or equal to 3 serves as a connection point of chain segments, so that the chain segment structure of thefuran dicarboxylic acid copolyester is expanded to a network structure, thereby obtaining the colorless or lightcolor furan dicarboxylic acid copolyester with excellent mechanical property and air barrier property and high molecular weight.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of composite metal oxide and synthesis method of alcohol ether carboxylate

ActiveCN104707587AHigh catalytic activityIncrease the degree of mixingOrganic compound preparationCarboxylic acid esters preparationProduct typeAlcohol

The invention relates to a preparation method of a composite metal oxide. The preparation method comprises the following steps of 1, composite metal hydroxide preparation, 2, reaction of the composite metal hydroxide and fatty acid, and 3, roasting of the treated compound at a temperature of 300 DEG C or less. The invention also relates to a catalytic synthesis method of alcohol ether carboxylate. The catalytic synthesis method utilizes the composite metal oxide as a catalyst. The preparation method of the composite metal oxide utilizes fatty acid to realize modification and utilizes a roasting temperature far below the existing technology roasting temperature. The composite metal oxide has obviously strong activity in catalytic oxyalkylation, is suitable for alcohol ether carboxylate synthesis, and has wide and easily controlled product polymerization degree distribution. The synthesis method increases alcohol ether carboxylate product types and simplifies a preparation technology.

Owner:武汉奥克化学有限公司

Soil water retaining agent

InactiveCN103131423AGuaranteed normal growthShort polymerization timeAgriculture tools and machinesOrganic fertilisersSalt resistanceGrowth plant

A soil water retaining agent comprises the following raw materials by weight: 100-200 parts of hydroxyethyl acrylate, 200-320 parts of an alkaline solution, 50-160 parts of acrylamide, 1-3 parts of talcum powder, 3-6 parts of deionized water, 0.01-0.1 part of an initiator, and 0.1-0.3 part of a foaming agent. The soil water retaining agent of the invention is short in polymerization time, simple in process, good in water absorption stability, good in salt resistance, low in cost, and suitable for soil improvement and desert drought resistance, and can completely guarantee plant growth.

Owner:凯姆勒科技发展(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com