Method for preparing lactide-propylene oxide-CO2 terpolymer by using rare earth three-way catalyst

A technology of ternary catalyst and terpolymer, which is applied in the field of polymers and can solve problems such as unfavorable industrial production and long polymerization reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of rare earth three-way catalyst

[0037] Evacuate a 50mL two-necked flask under reduced pressure at 80°C to 20-40Pa, replace it with high-purity argon every 20 minutes for 5 times, and then cool to room temperature under the protection of high-purity argon;

[0038] Under the protection of high-purity argon, 0.0005mol Y(CCl 3 COO) 3 , Then add 20mL 1,3-dioxolane and 0.005mol glycerol in turn, and wait for the Y(CCl 3 COO) 3 After all is dissolved, 0.01 mol of diethyl zinc is added dropwise to the bottle. During the process of adding diethyl zinc, the reaction temperature in the bottle is controlled at 20~25℃. After the addition of diethyl zinc is completed, there will be no more After the reaction gas is released, the two-necked bottle is sealed and placed in a constant temperature water bath shaker for aging to obtain a white suspension liquid that is a rare earth three-way catalyst. The aging conditions are: constant temperature water bath temperature of 60℃, m...

Embodiment 2

[0040] Evacuate the reactor at 80℃ to 20~40Pa, and charge CO 2 Treat for 2 hours, charge CO in total 2 6 times, and then cooled to room temperature; the rare earth ternary catalyst prepared in Example 1 (0.0005mol yttrium trichloroacetate, 20mL 1,3-dioxolane, 0.005mol glycerol, 0.01mol ZnEt 2 ) In CO 2 Add into the reactor under protection, and at the same time inject 100 mL of propylene oxide with 2.06 g of recrystallized lactide dissolved in the reactor, the molar ratio of lactide to propylene oxide is 0.01431:1.431;

[0041] Place the reaction kettle in a controllable constant temperature heating bath, quickly pass the carbon dioxide pressure regulator under the condition of a stirring rate of 500 rpm to make the carbon dioxide pressure in the kettle reach 4.0 MPa, the polymerization temperature is 70° C., and the reaction time is 10 hours;

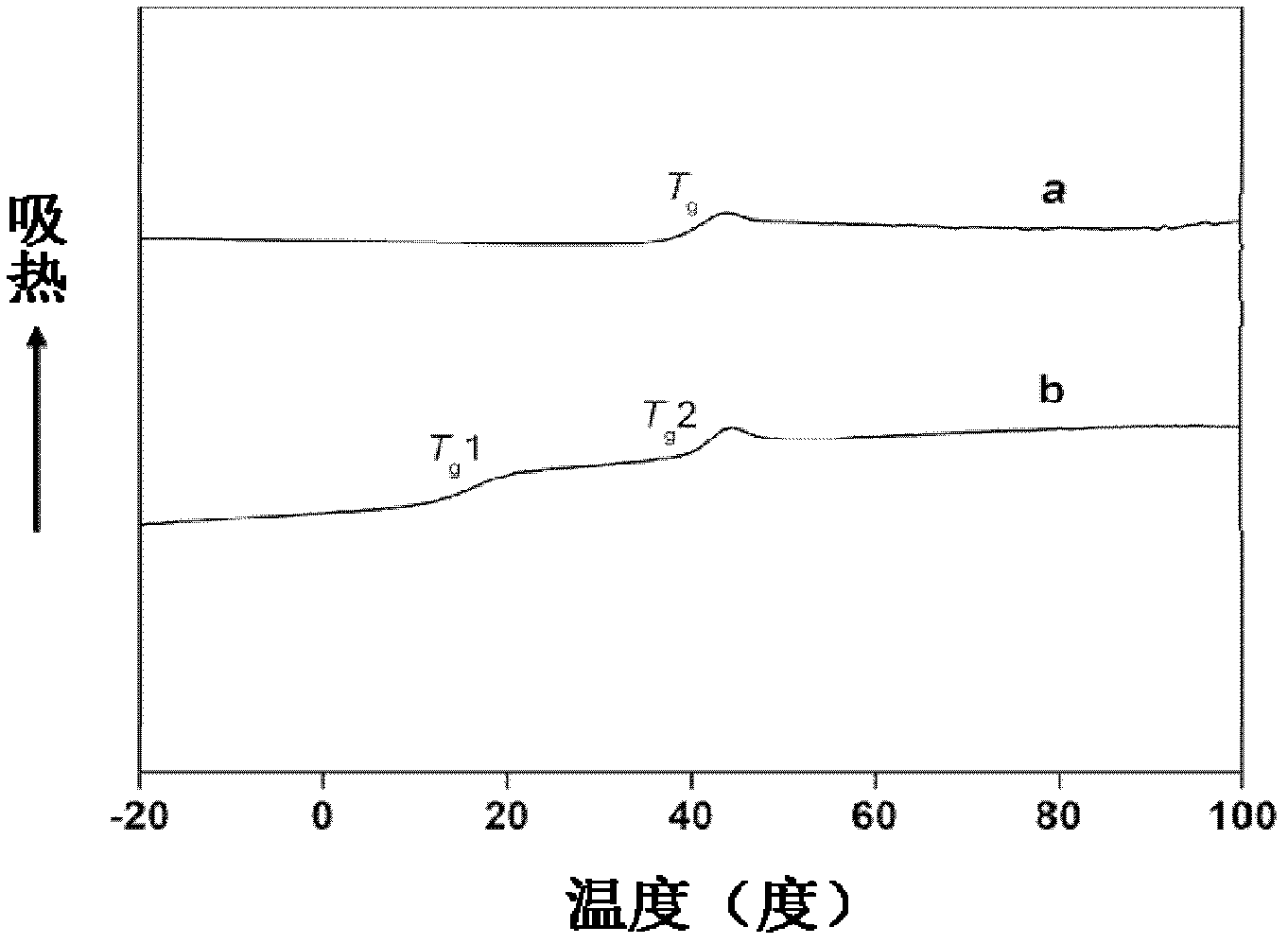

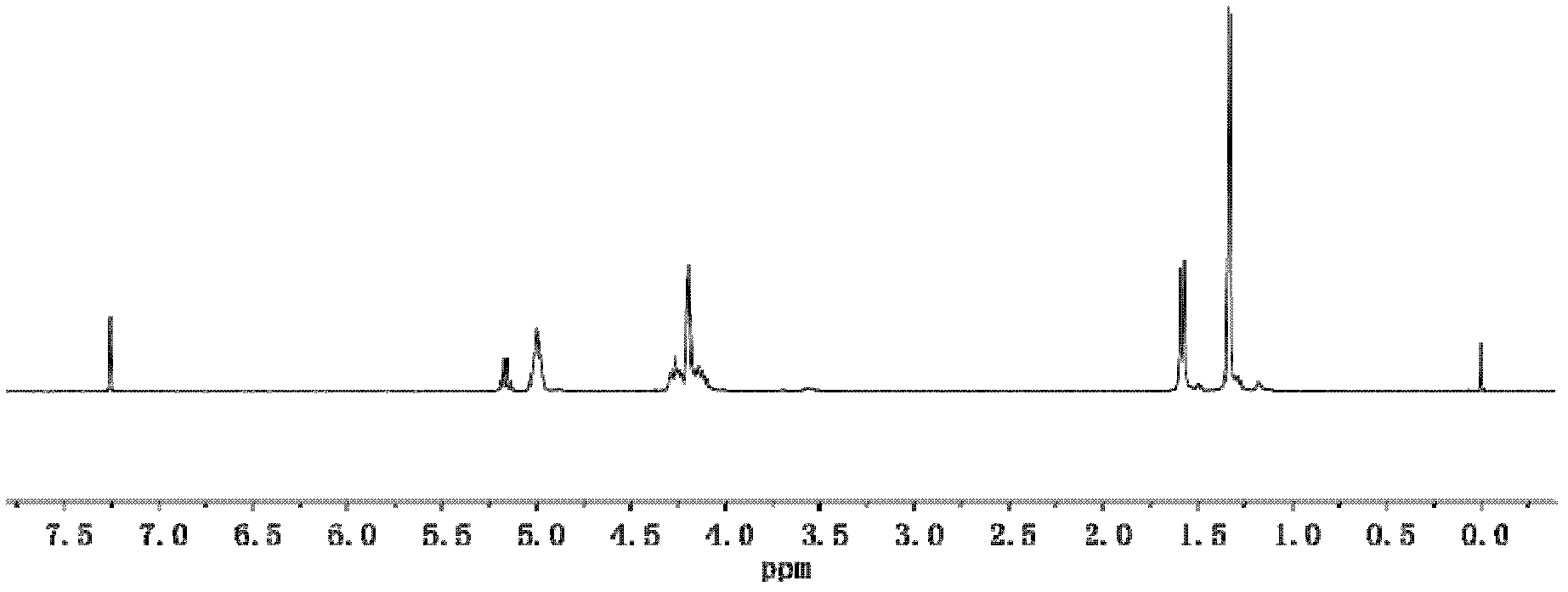

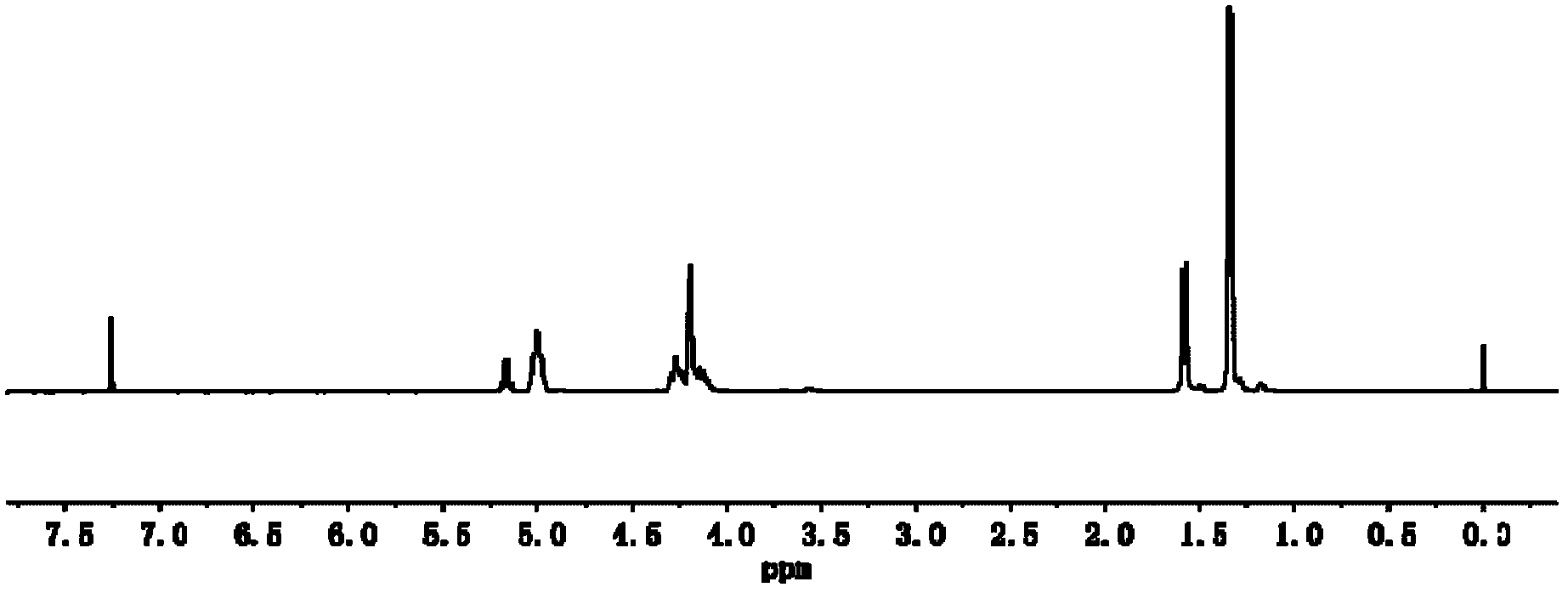

[0042] After the polymerization reaction is over, the reactor is cooled to room temperature with a cold water bath at a temperature of 12-15...

Embodiment 3

[0045] Evacuate the reactor at 80℃ to 20~40Pa, and charge CO 2 Treat for 2 hours, charge CO in total 2 6 times, and then cooled to room temperature; the rare earth ternary catalyst prepared in Example 1 (0.0005mol yttrium trichloroacetate, 20mL 1,3-dioxolane, 0.005mol glycerol, 0.01mol ZnEt 2 ) In CO 2 Put it into the reactor under protection, and at the same time inject 100 mL of propylene oxide containing 4.12 g of recrystallized lactide into the reactor, the molar ratio of lactide to propylene oxide is 0.02862:1.431;

[0046] Place the reaction kettle in a controllable constant temperature heating bath, quickly pass the carbon dioxide pressure regulator under the condition of a stirring rate of 500 rpm to make the carbon dioxide pressure in the kettle reach 4.0 MPa, the polymerization temperature is 70° C., and the reaction time is 10 hours;

[0047] After the polymerization reaction is over, the reactor is cooled to room temperature with a cold water bath at a temperature of 12-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com