Porous carbon fiber, and preparation method and application thereof

A technology of porous carbon fiber and pore-forming agent, which is applied in fiber treatment, fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of high cost, brittle carbon fiber, and limit the application of porous carbon fiber, and achieve low cost and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Add 0.6g of nano-calcium carbonate, a pore-forming agent with a particle size of 50nm, into 10g of organic solvent N,N-dimethylformamide, ultrasonically treat for 0.5h, and add 1.5g of high-molecular polypropylene with a number-average molecular weight of 1.5 million Nitrile, stirred at 80°C for 2 hours to form a milky white viscous solution, which is the spinning solution.

[0044] 2) The electrospinning process is carried out on a single-nozzle electrospinning device, which consists of a DC high-voltage power supply, a single capillary spinneret, a collecting plate and a ground wire. The collecting plate is made of aluminum foil, and the electrospinning temperature is 15°C.

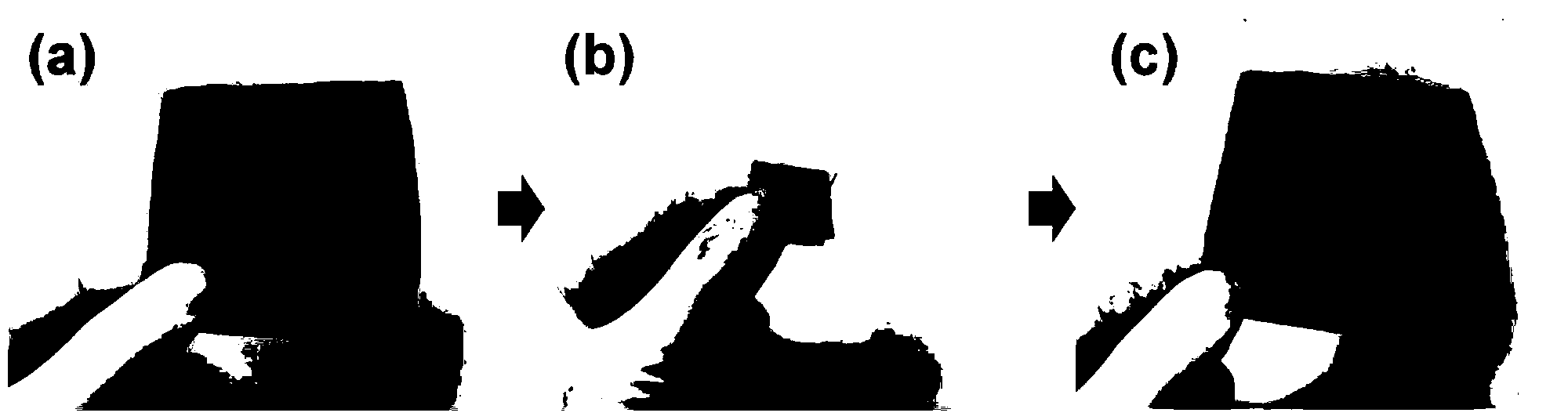

[0045] The specific preparation process is as follows: transfer the milky white precursor solution prepared above into a 10mL medical syringe, inject it into the spinneret at a flow rate of 1.0mL / h, and apply a high-voltage electric field between the spinneret and the collecting plate to make t...

Embodiment 2

[0051] 1) Add 0.6g of nano-calcium carbonate with a particle size of 20nm to 10g of N,N-dimethylformamide, ultrasonically treat it for 0.5h, add 1.5g of polymer polyacrylonitrile with a number average molecular weight of 150w, and stir at 80°C 2h to form a milky white viscous solution, which is the spinning solution.

[0052] 2) carry out electrospinning according to embodiment 1 step 2);

[0053] 3) Carry out pre-oxidation and carbonization according to step 3) of Example 1, and only replace the temperature of the carbonization step with 600°C. After cooling down to room temperature, put the black carbon fiber membrane into 2M sulfuric acid solution and wash it for 1 hour to remove CaCO 3 , and finally washed and dried to obtain porous carbon fibers.

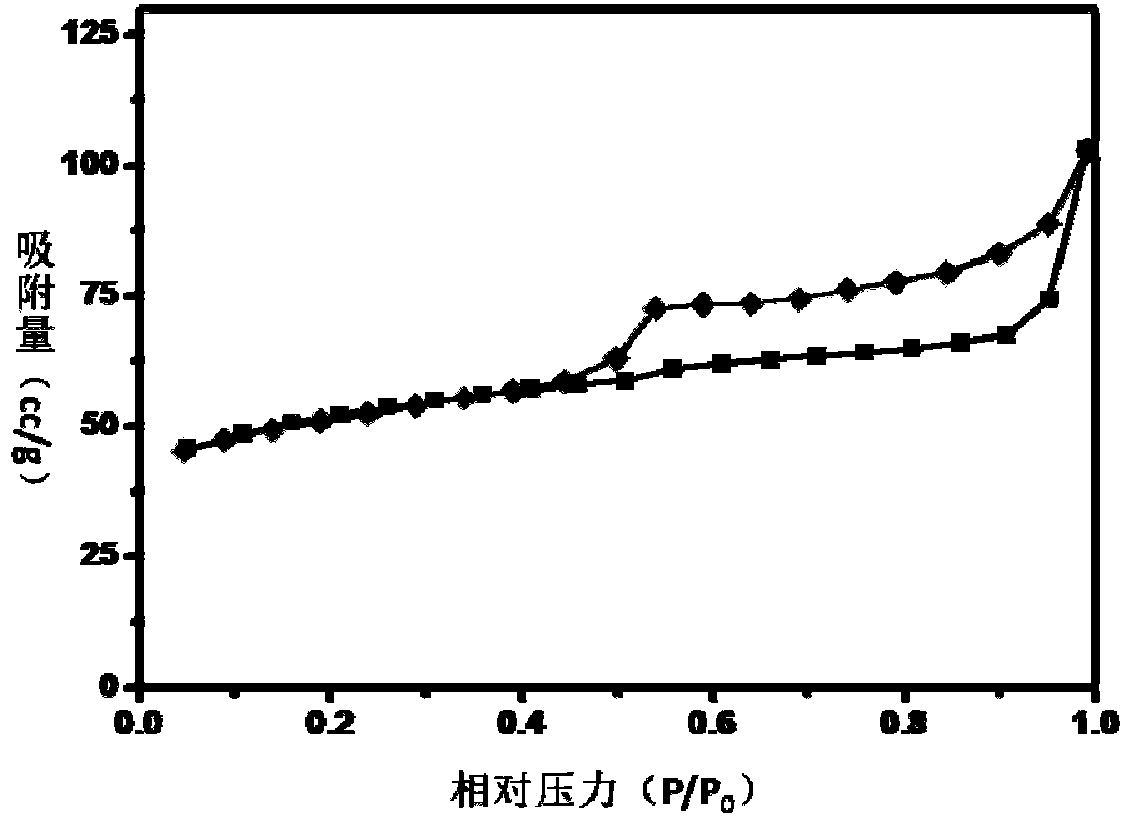

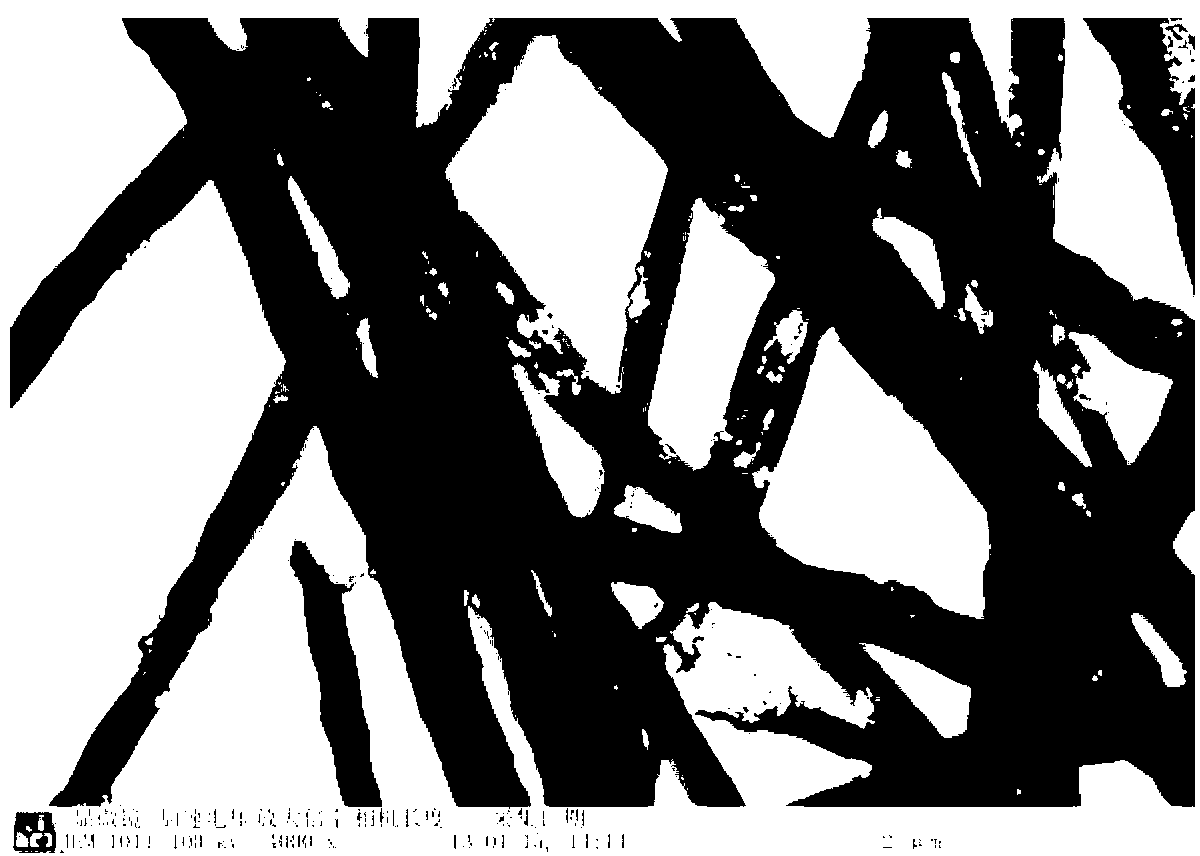

[0054] Figure 4 It is the nitrogen adsorption-desorption curve of porous carbon fiber, only in the range of macropores between 0.8 and 1.0, there is adsorption amount and accompanied by the appearance of hysteresis loop, whi...

Embodiment 3

[0058] 1) Add 1.5g of nano-calcium carbonate with a particle size of 80nm to 10g of N,N-dimethylformamide, ultrasonically treat it for 0.5h, add 1.5g of polymer polyacrylonitrile with a number average molecular weight of 150w, and stir at 80°C 2h to form a milky white viscous solution, which is the spinning solution.

[0059] 2) Perform electrospinning according to step 2) of Example 1, only the electrospinning temperature is replaced by 30°C, the flow rate is replaced by 1.5mL / h, and the working voltage is replaced by 30kV;

[0060] 3) Perform pre-oxidation, carbonization and pickling according to step 3) of Example 1, only the pre-oxidation temperature is replaced with 230°C, and the carbonization temperature is replaced with 1000°C.

[0061] Image 6 It is the nitrogen adsorption-desorption curve of porous carbon fiber. There is a hysteresis loop in the mesopore absorption range near the relative pressure of 0.5-0.8, and there is a higher adsorption capacity in the macropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com