Weather-resistant and high thermal conductive coating, radiating solar rear panel and efficient solar cell panel

A solar backplane, high thermal conductivity technology, applied in coating, circuit, photovoltaic power generation, etc., can solve the problem of low power generation of modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

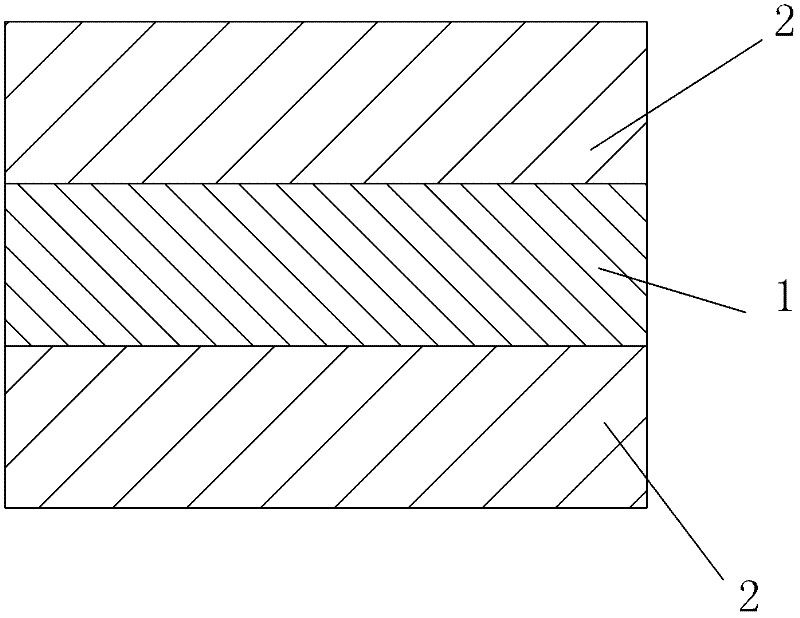

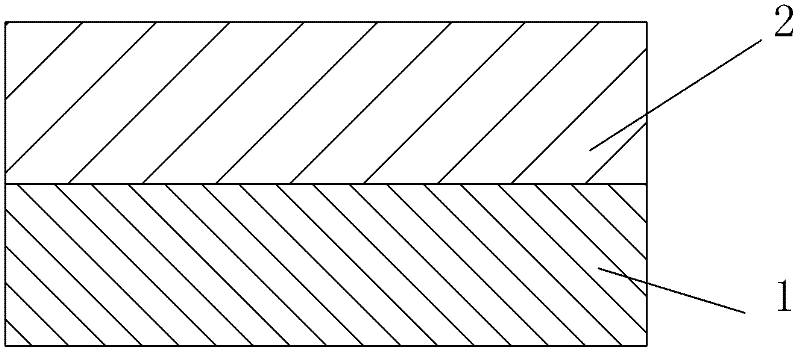

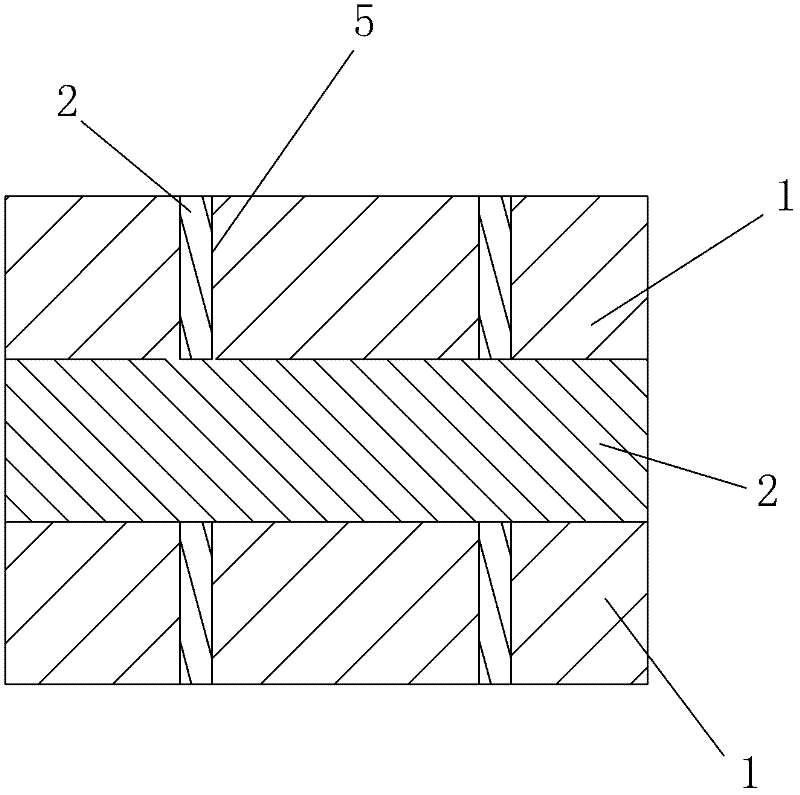

Image

Examples

Embodiment 1

[0040] The weather-resistant high thermal conductivity coating of the present invention consists of the following components by weight:

[0041] 30 parts epoxy resin

[0042] Amine curing agent 1 part

[0043] 2-Hydroxy-4-methoxybenzophenone 0.1 parts

[0044] Aluminum nitride 100 parts

[0045] Acetone 50 parts.

Embodiment 2

[0047] The weather-resistant high thermal conductivity coating of the present invention consists of the following components by weight:

[0048] Mixture of amino resin and epoxy resin 30 parts

[0049] Anhydride curing agent 5 parts

[0050] 5 parts of polyhindered phenol

[0051] Silicon carbide 80 parts

[0052] Butanone 100 parts.

Embodiment 3

[0054] The weather-resistant high thermal conductivity coating of the present invention consists of the following components by weight:

[0055] Acrylic resin 40 parts

[0056] 2 parts isocyanate

[0057] Carbodiimide 4 parts

[0059] 80 parts of benzene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com