Heat dissipation substrate for led

A heat-dissipating substrate, heat-resistant technology, applied in circuit thermal devices, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low machinability, inability to three-dimensional processing, and the inability of LED heat-dissipating substrates to bend, and achieve excellent heat dissipation performance , the effect of low thermal resistance, excellent mechanical workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

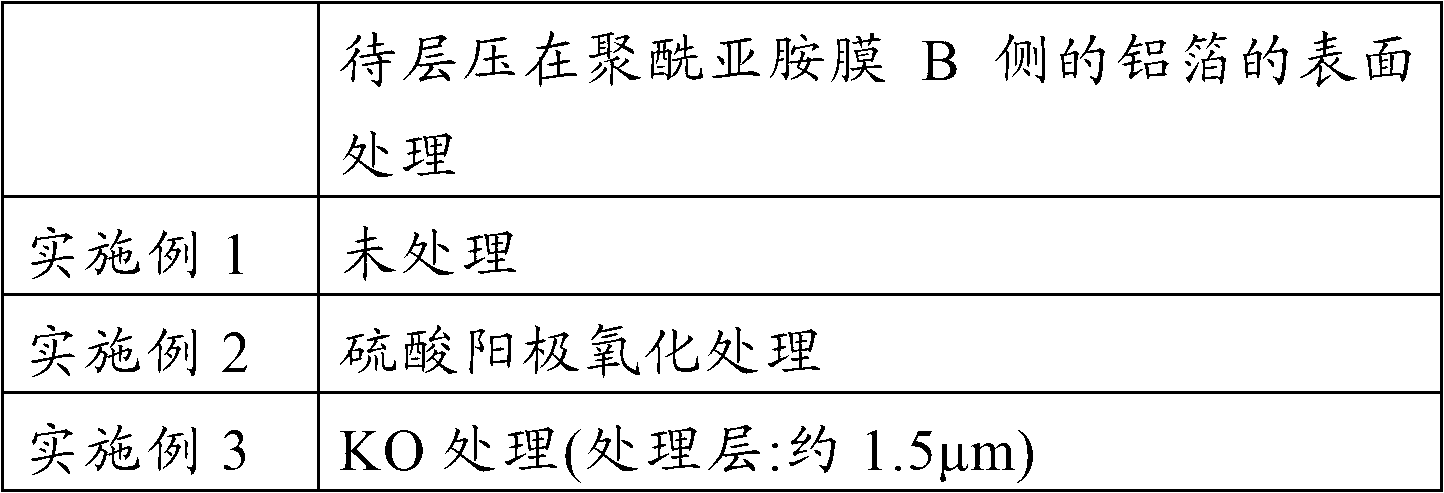

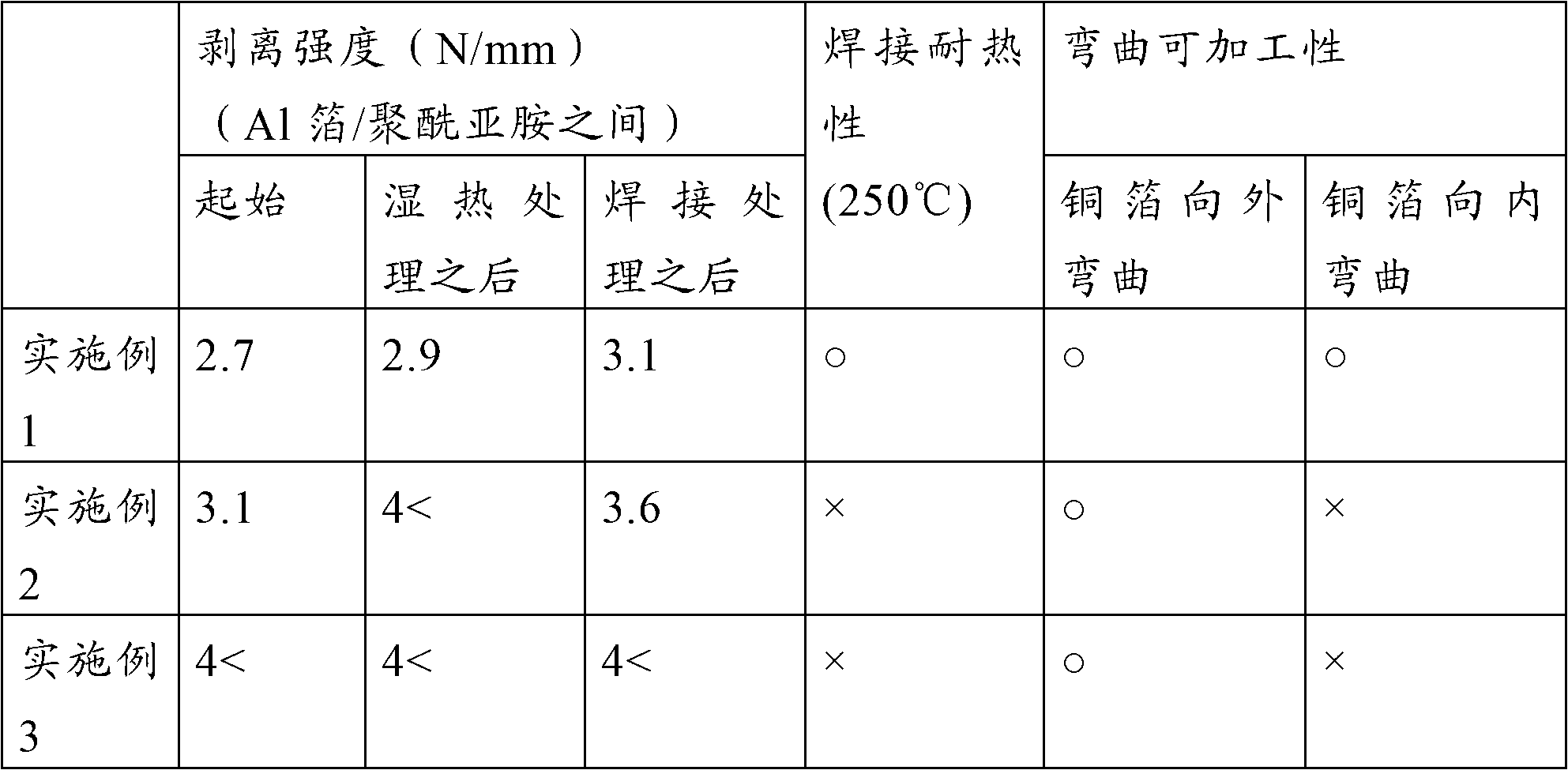

Examples

Embodiment 1

[0167] (Reference Example 1: Preparation of jelly of heat-resistant polyimide S1)

[0168] To N-methyl-2-pyrrolidone, add p-phenylenediamine (PPD) and 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA) at a molar ratio of 1000:998, so that the monomer concentration is 18% (by weight, the same applies below). Subsequently, the mixture was reacted at 50°C for 3 hours. The polyamic acid solution thus obtained had a solution viscosity of about 1680 poise at 25°C.

Embodiment 2

[0169] (Reference Example 2: Preparation of jelly for heat-resistant bonding polyimide S2)

[0170] To N-methyl-2-pyrrolidone, add 1,3-bis(4-aminophenoxy)benzene (TPE-R) and 2,3,3',4' in a molar ratio of 1000:200:800 - Biphenyltetracarboxylic dianhydride (a-BPDA) and 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA) so that the monomer concentration was 18%. Subsequently, 0.5% by weight of triphenyl phosphate was added thereto with respect to the monomer, and the mixture was reacted at 40° C. for 3 hours. The polyamic acid solution thus obtained had a solution viscosity of about 1680 poise at 25°C.

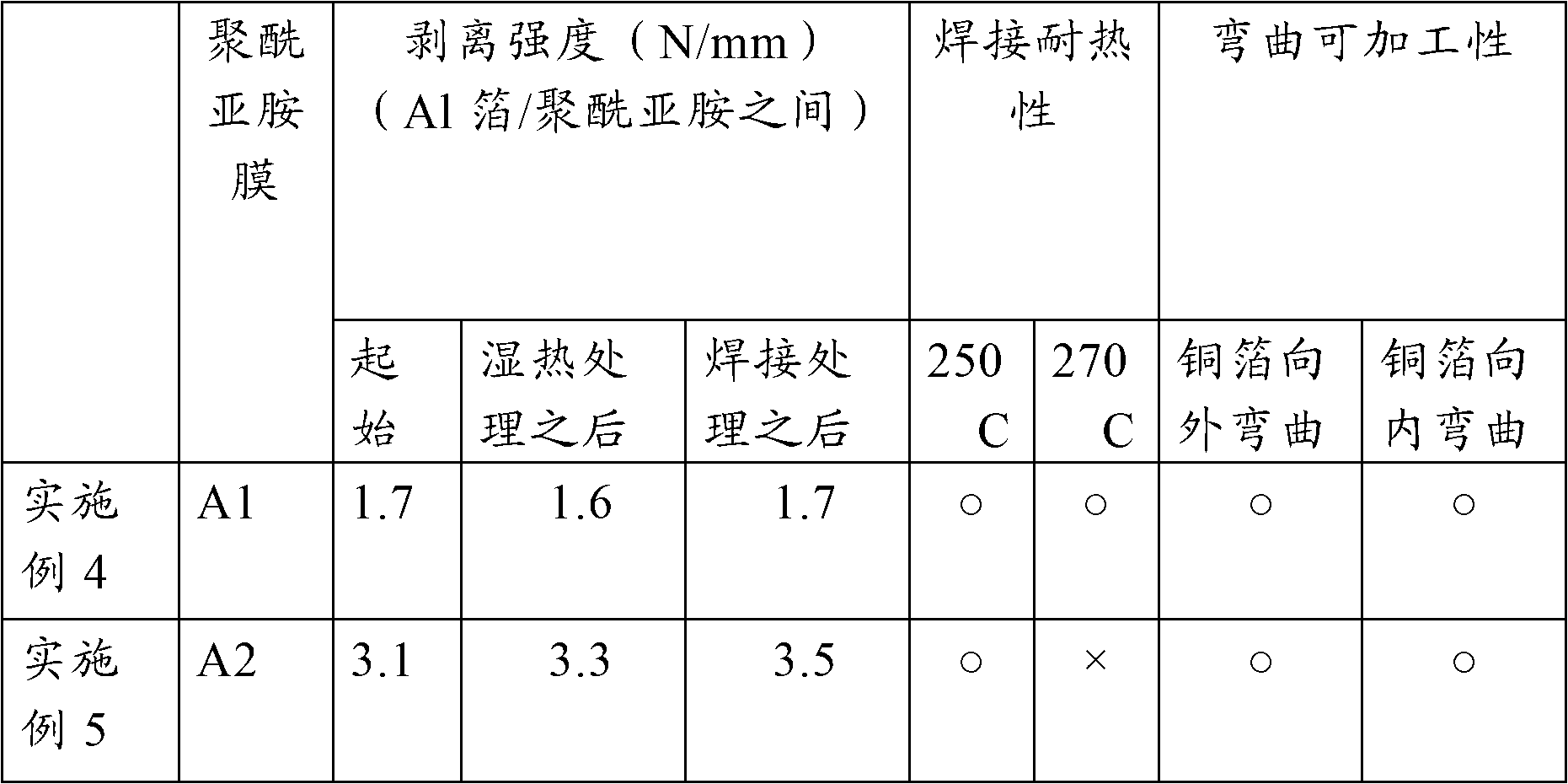

Embodiment 3 and 4

[0171] (Reference Examples 3 and 4: Preparation of thermocompression bonding multilayer polyimide films A1 and A2)

[0172] Use the film-forming machine that three-layer extrusion die (multi-flow channel die) is equipped with, cast the polyamic acid solution that reference example 1 and 2 make with the thickness casting of different three-layer extrusion dies on metal support body, then Continuously dried under hot air at 140°C, and peeled off the support to form a self-supporting film. The self-supporting film peeled off from the support was gradually heated in a furnace from 150°C to 450°C to remove the solvent and carry out the imidization reaction. Thus, three-layer long polyimide films of two different thicknesses were prepared and wound into rolls.

[0173] The properties of the thus obtained three-layer polyimide film (layer configuration: S2 / S1 / S2) were evaluated, and the results are as follows.

[0174] (Thermal compression bonding multilayer polyimide film A1)

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com