Metal foil laminate

A metal foil and laminate technology, applied in the direction of metal layered products, layered products, synthetic resin layered products, etc., can solve the problems of reduced folding resistance, abnormality, difficulty in obtaining molded products, etc., and achieves excellent flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

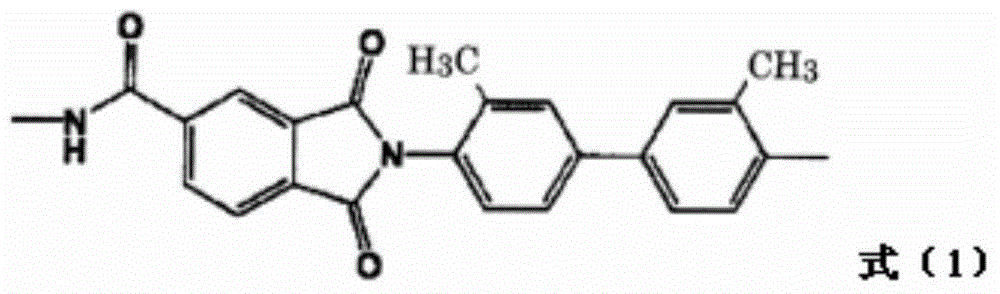

[0257] Under nitrogen flow, 211.3 g (1.10 mol) of trimellitic anhydride, 132.1 g (0.05 mol) of o-tolidine diisocyanate, 125.3 g (0.05 mol) of 4,4'-diphenylmethane diisocyanate, and fluorine were added to the reaction vessel under nitrogen flow. 0.6 g of potassium sulfide and 2500 g of N-methyl-2-pyrrolidone (purity: 99.9%) were heated to 100°C and reacted directly for 5 hours. Then, it was made to react at 130 degreeC for 3 hours, N-methyl-2-pyrrolidone was added to adjust the concentration so that the solution viscosity became 400 dPa·s, and it was cooled to room temperature. The obtained polyamideimide resin (denoted as polyamideimide composition A) was dissolved in a polymerization solvent, and the characteristics of each resin of logarithmic viscosity, acid value, and number average molecular weight are shown in Table 1.

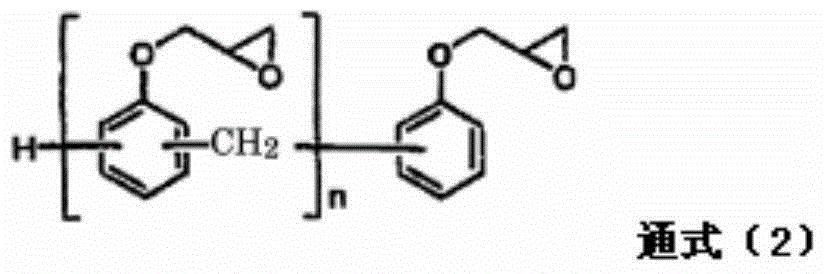

[0258] Then, 24 g of a phenol novolak type epoxy resin (JER154 manufactured by Mitsubishi Chemical Corporation) (6% by mass relative to the total solid con...

Embodiment 2

[0260] Only trimellitic anhydride which is an acid component of Example 1 was changed to 1.02 mol, and it adjusted to the logarithmic viscosity and molecular weight of Table 1 suitably, and the polyamide-imide resin varnish was produced. The polyamideimide resin varnish obtained in Example 2 was all dissolved in the solvent, and the resin characteristics of the resin varnish obtained are shown in Table 1.

[0261] Then, 12 g of a phenol novolak type epoxy resin (JER154 manufactured by Mitsubishi Chemical Corporation) (3% by mass relative to the total solid content) was mixed to produce a casting varnish. Then, the prepared casting varnish was used to produce a metal foil laminate, and a flexible printed wiring board for evaluation of folding resistance, as well as insolubility, Gurley-style bending stiffness (an index of low resilience), and evaluation of mounting properties were produced. Evaluation of the characteristics of each substrate film. The characteristic evaluation re...

Embodiment 3

[0266] Under nitrogen flow, 161.4 g (0.84 moles) of trimellitic anhydride, 50.8 g (0.16 moles) of 3,3',4,4'-benzophenone tetracarboxylic dianhydride, 3,3' were added to the reaction vessel, 4,4'-biphenyltetracarboxylic dianhydride 15.5g (0.05mol), o-tolidine diisocyanate 264.3g (1.00mol), potassium fluoride 0.6g, and N-methyl-2-pyrrolidone (purity 99.9 %) 2230, the temperature was raised to 100°C, and it was directly reacted for 6 hours. Then, it was made to react at 130 degreeC for 4 hours, and N-methyl-2-pyrrolidone was added to adjust the concentration so that the solution viscosity became 300 dPa·s, and it was cooled to room temperature. The obtained polyamideimide resin (denoted as polyamideimide composition B) was dissolved in a solvent, and the resin characteristics of logarithmic viscosity, acid value, and number average molecular weight are shown in Table 1.

[0267] Then, 12 g of a phenol novolak type epoxy resin (JER154 manufactured by Mitsubishi Chemical Corporation)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com