Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Good finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

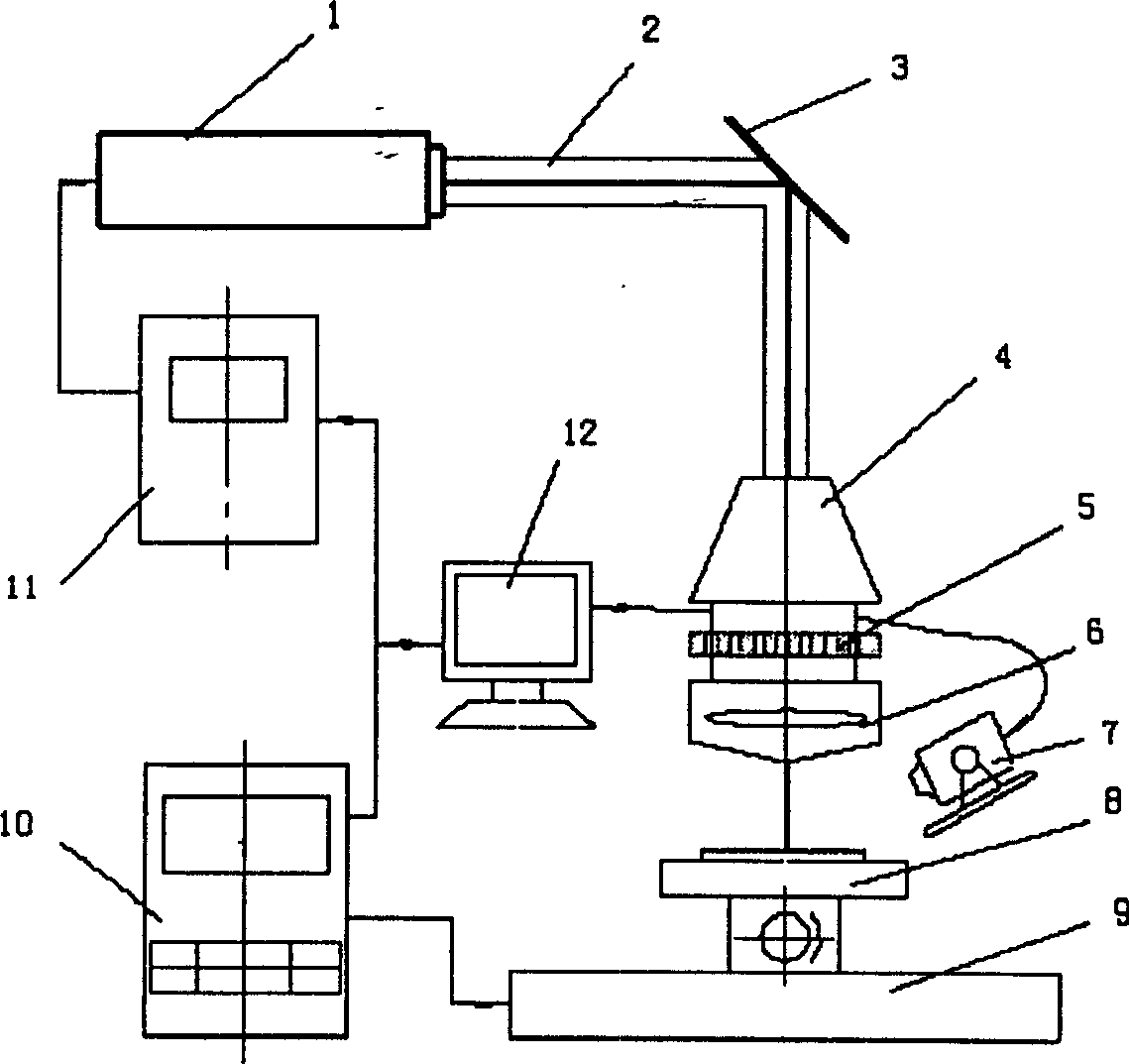

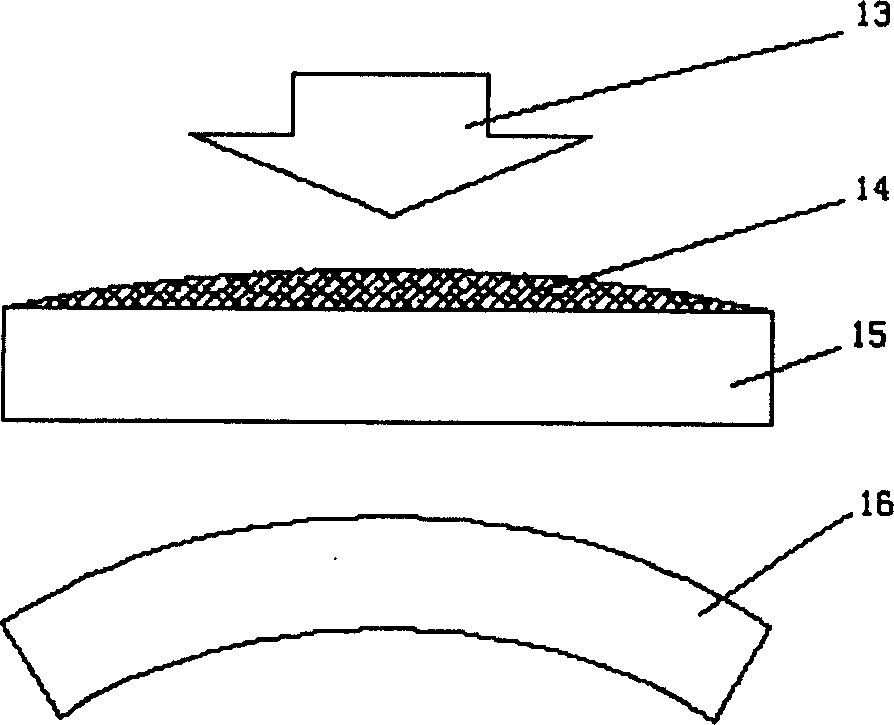

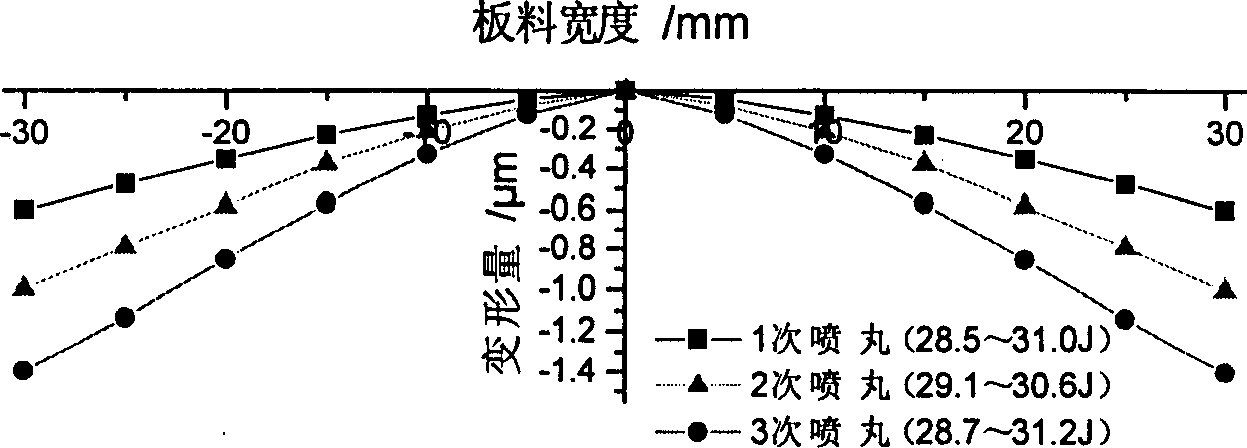

Method and equipment for forming plate of moderate thickness through laser shot blast

InactiveCN1695873AReduce surface roughness valueGood finishComputer controlNumerical controlShock waveEngineering

A laser blasting apparatus for shaping on the surface of medium-thick plate is composed of laser device, optical guide system, laser blasting head, fixture system for workpiece, and control system. Its shaping process includes computer simulation of the stress field distribution according to the curved surface shape to be processed, optimizing it to obtain the distribution of shock wave pressure and blasting tracing on the surface of plate, automatically choosing the parameters of laser pulse optical beam converte and optical mask, writing control program, generating strong short laser pulses, covering them to several pulse clusters, passing through optical mask, acting on energy converting body on the surface of workpiece to obtain shock waves, acting on the surface of workpiece for shaping.

Owner:JIANGSU UNIV

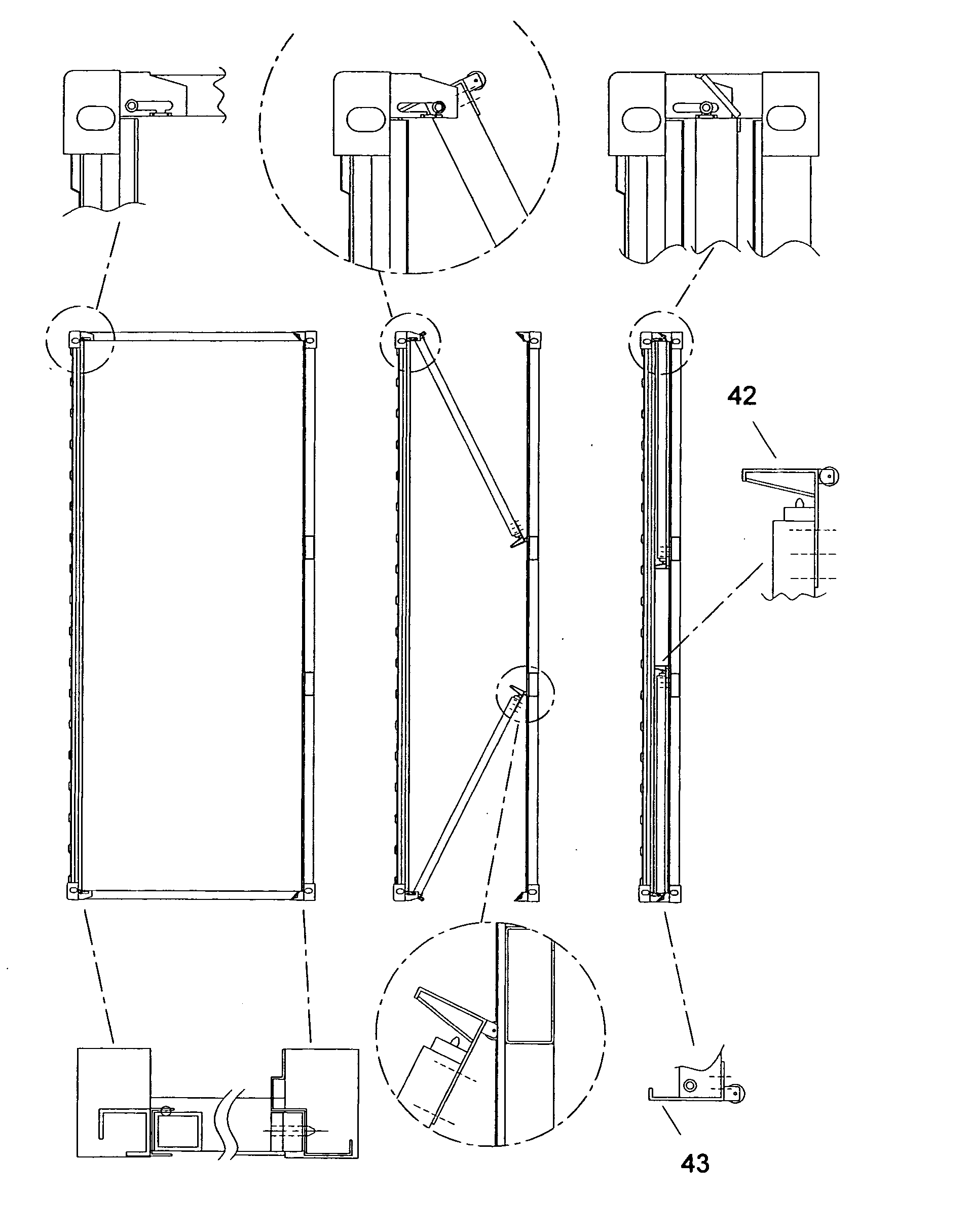

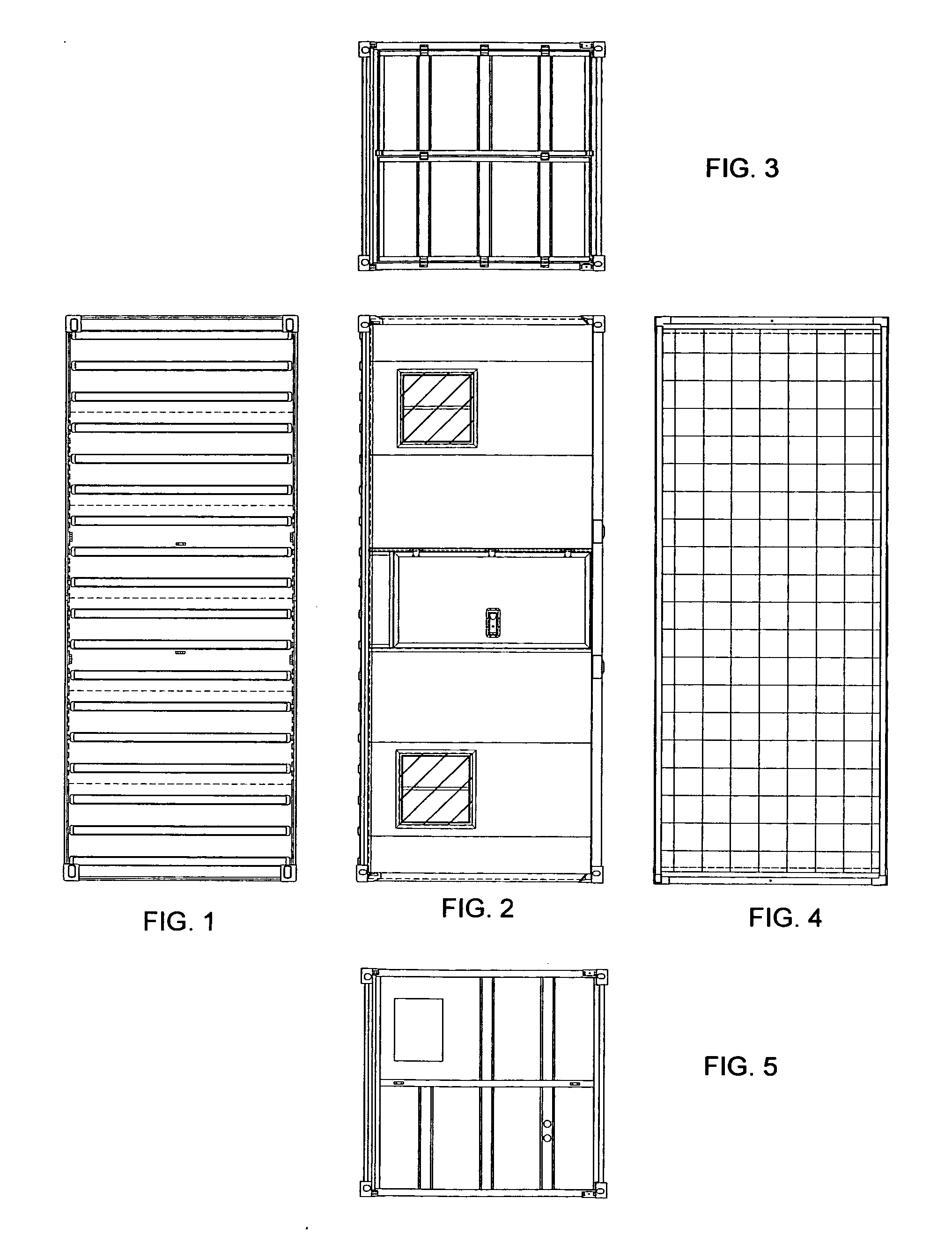

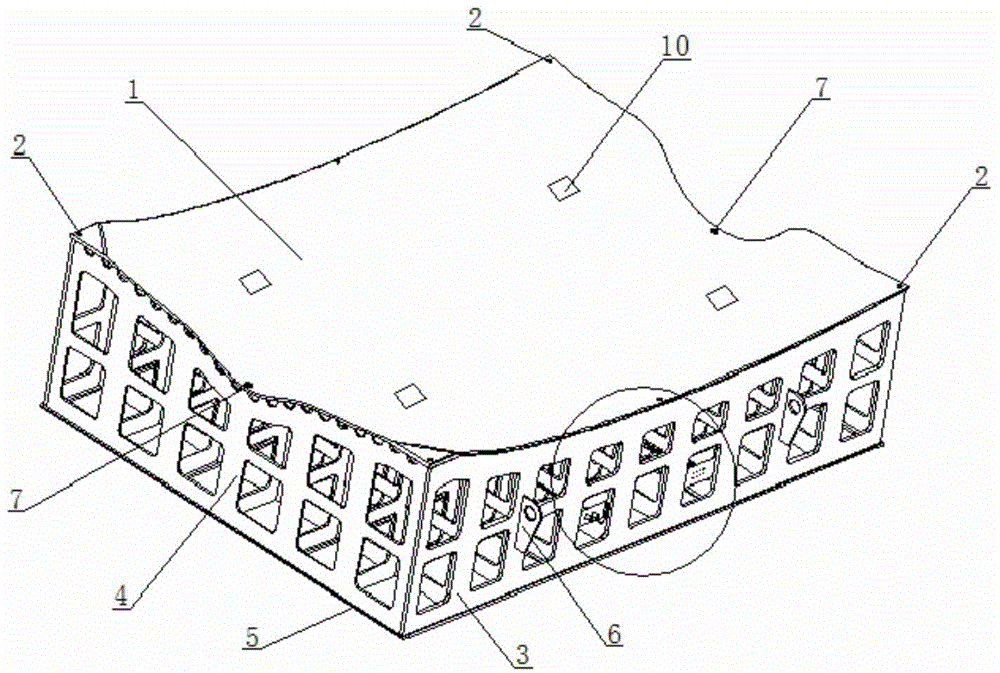

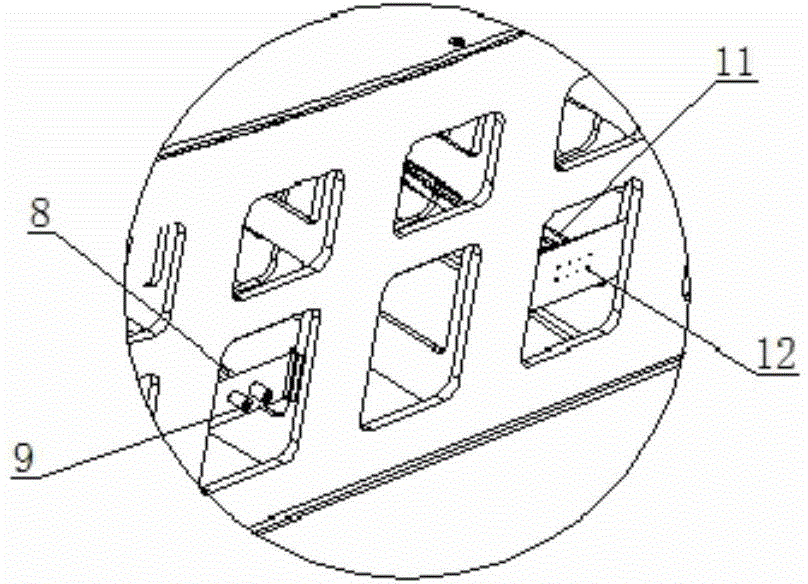

Collapsible ISO container-type modular shelter

InactiveUS20060277836A1Good insulating abilityGood finishBuilding roofsSpecial buildingModularityConstruction industry

The apparatus and method is disclosed and seek to claim exclusivity of conception of a versatile structure that follows the maritime container ISO dimensions and that is collapsible to be stored in scanty places and / or hauled together with other collapsed units, saving transportation costs. Larger surfaces may be created by simply juxtaposing one modular unit to others, side-by-side, front-to-back or stacked. In order to allow these modules to dismount in a practical manner, the inventor conceived a “Collapsibility Mechanism”, requiring minimum labor and equipment, which is based on the two frontal frames natural swing produced from hanging them by each of the two pairs of the eccentrically oblong supports. The COLLAPSIBLE ISO CONTAINER-TYPE MODULAR SHELTER also comprises original design of profiles used in the top chassis perimeter that constitute that chassis' main structural elements, as well as prevent rain-water to flow through the unit lateral and frontal sides, as gutters do. This “Structural-Gutter” concept may fit numerous other applications in the construction industry. Governments can benefit from this invention to alleviate urgent needs to shelter people domestically and abroad. Private businesses would also find it a practical and affordable solution for many of their requests of temporary housing or mobile shelters.

Owner:CHAZYN FABIO

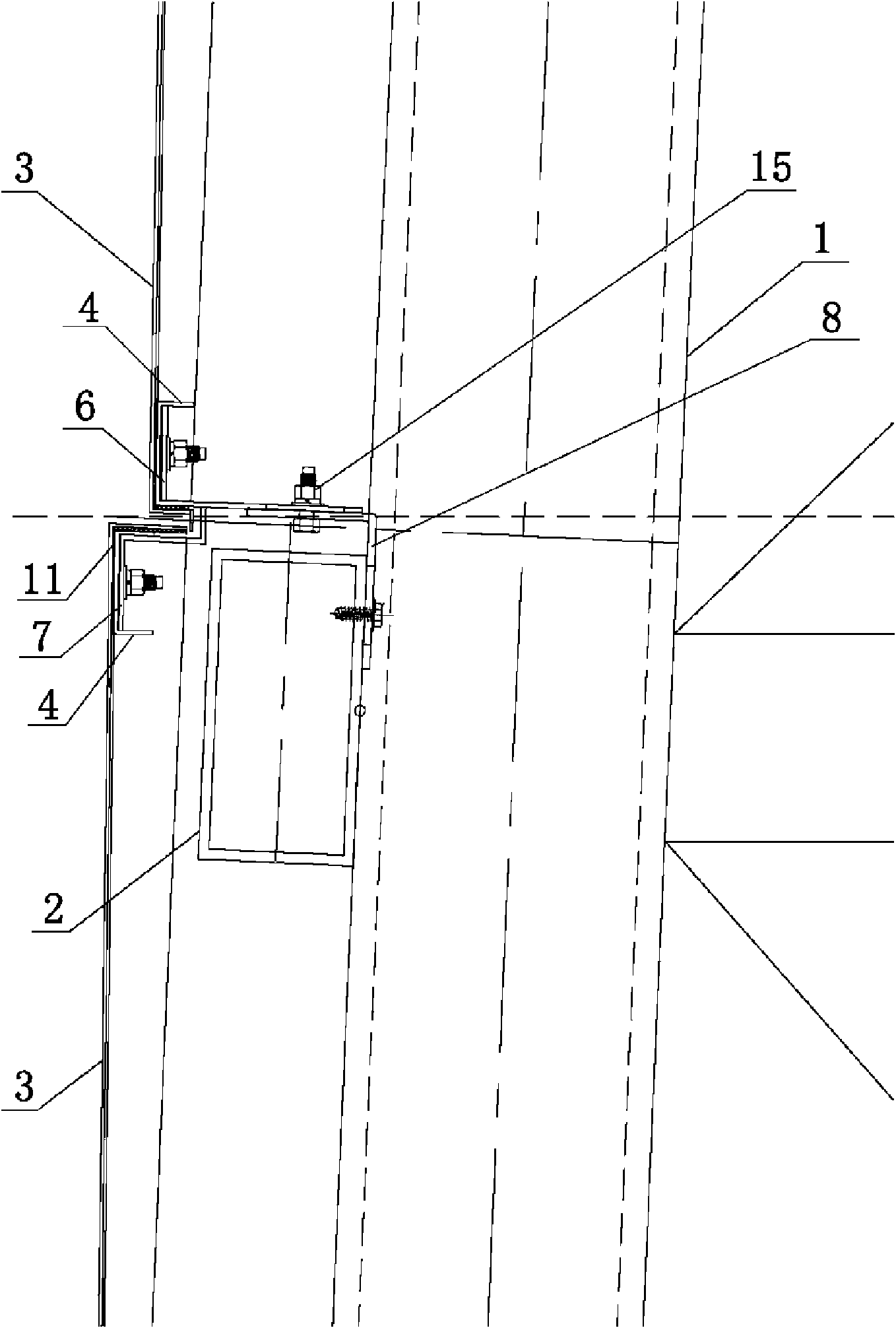

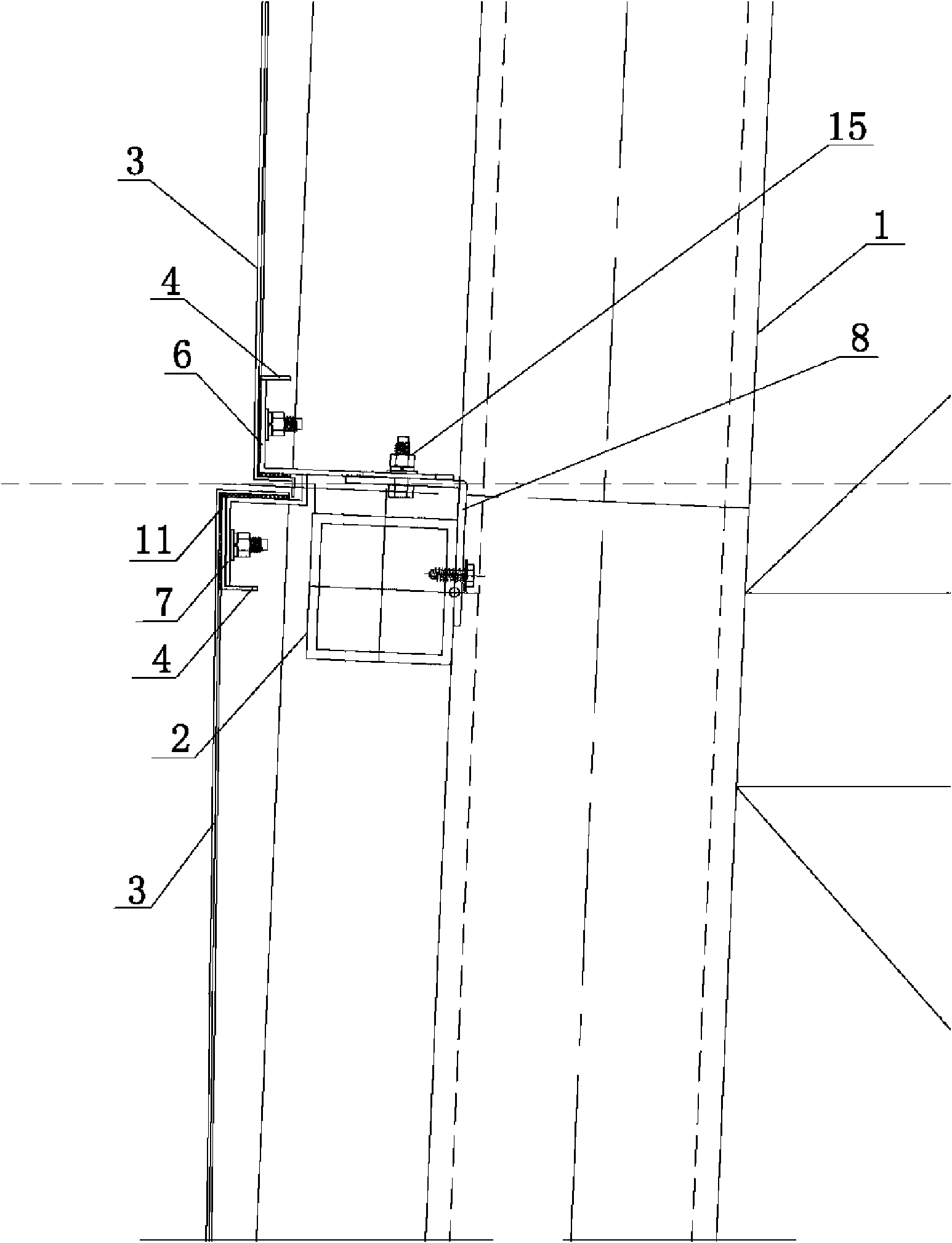

Multi-curved surface overhung copper plate curtain wall and construction method thereof

The invention provides a multi-curved surface overhung copper plate curtain wall and a construction method thereof. The primary keel thereof is a steel truss. The outer side of the main keel steel truss is connected with a transverse secondary keel. The four sides of the curtain wall panel are provided with hems. The screw of the curtain wall panel is connected with the secondary keel by a combined adjustable hanger and a bolt. The combined adjustable hanger is formed by connecting any two or three of following hangers end to end: the first hanger that is an L-shaped folded plate structure with the horizontal plate surface provided with an oblong hole along a central line and a vertical plate surface provided with a circular hole, the second hanger that is a folded plate structure with two platforms folded plate for three times with an angle of 90 degrees and an upper platform plate surface provided with an oblong hole along the central line and the vertical plate surface provided with a circular hole, and the third hanger that is an L-shaped folded plate structure with the horizontal plate surface provided with one to two oblong holes along the plate width and the vertical plate surface provided with an oblong hole along the central line. The construction error caused in the process of mounting the plates can be eliminated by the combined adjustable hanger and the variation of multi-curved surface plates in continuous curved space is satisfied. The invention solves the technical problem of mounting the multi-curved surface copper plate curtain wall.

Owner:北京市建筑工程装饰集团有限公司

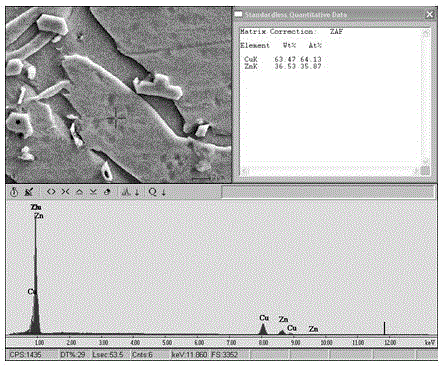

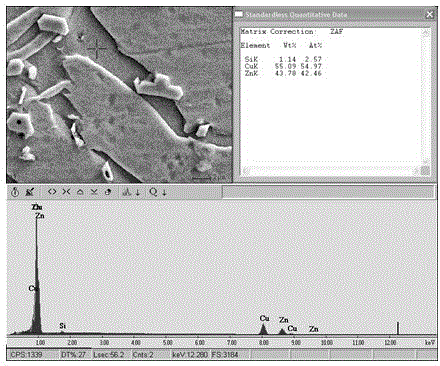

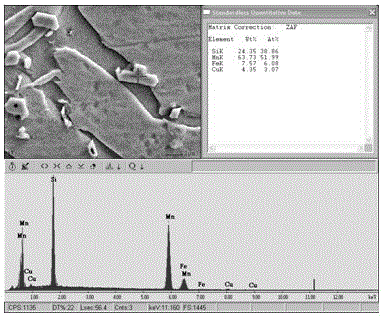

Wear-resistant easy-to-cut brass pipe material and method of using same to manufacture brass pipe

The invention discloses a wear-resistant easy-to-cut brass pipe material and a method of using the same to manufacture a brass pipe. The wear-resistant easy-to-cut brass pipe material is composed of 60-65wt% of copper, 0.5-3.5wt% of manganese, 0.5-3.5wt% of silicon, 0.2-3.0wt% of lead, 0.05-0.2wt% of iron, 0.1-0.3wt% of nickel, 0.1-0.3wt% of aluminum and the rest zinc and unavoidable impurities, wherein total amount of the unavoidable impurities is not larger than 0.1wt%. The manufacturing method includes: taking copper-zinc alloy as a base, and forming the easy-to-cut brass pipe material taking an alpha phase as a matrix and added by 15-20% beta phase and a small amount of silicon and manganese wear-resistant phase Mn5Si3 uniformly distributed on the alpha phase matrix and a beta phase matrix through alloy elements, capable of forming wear-resistant phase, like silicon, manganese and a small amount of lead. The pipe material is extruded to form the pipe, and an extruding-cold rolling process is adopted to reduce or eliminate metal transverse crack defect after uniform annealing, so that the brass pipe material is high in surface smoothness, easy to cut and machine, higher in strength and tenacity and more stable in wear resistance.

Owner:JINTIAN COPPER GROUP CORP NINGBO

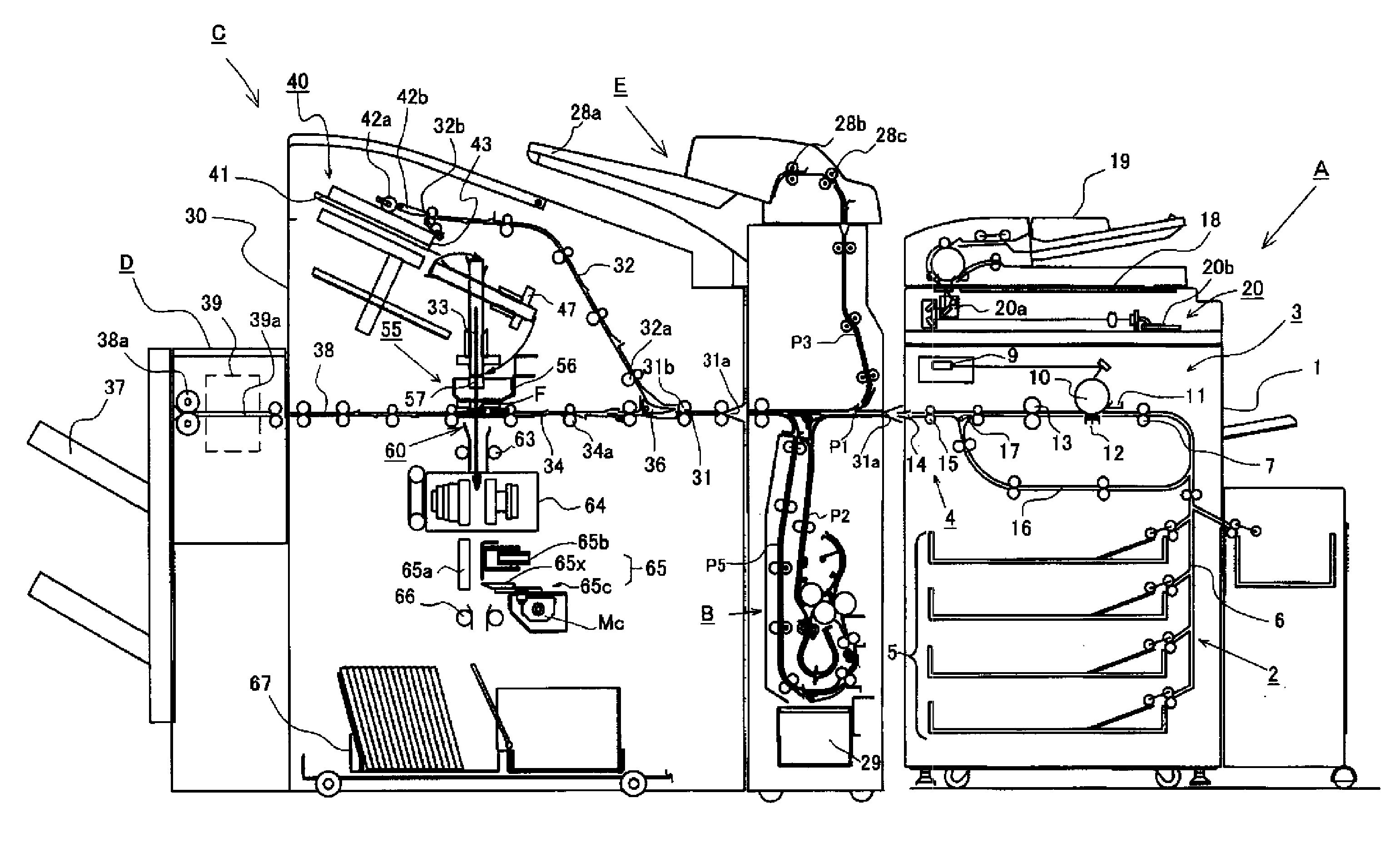

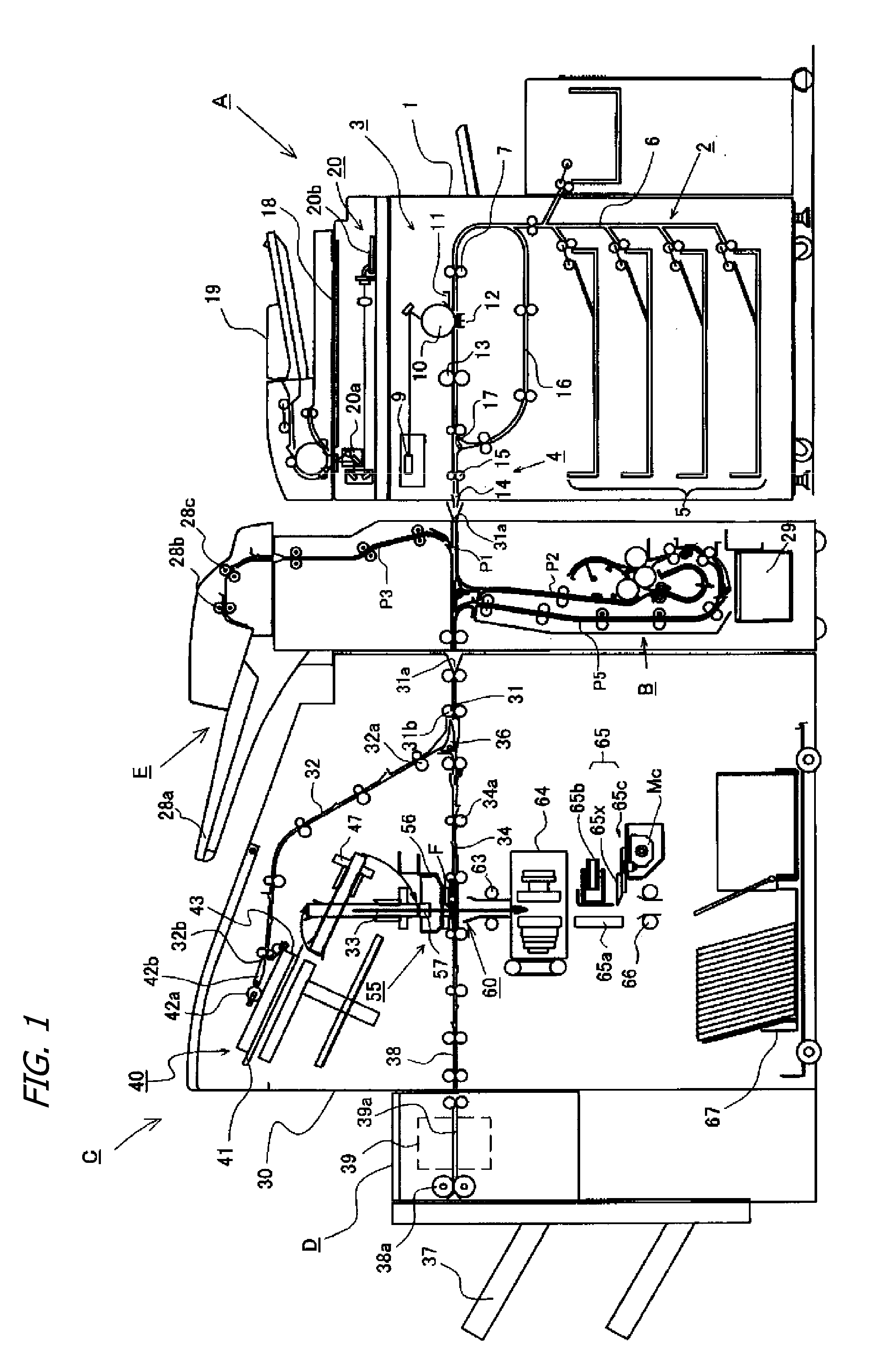

Bookbinding Apparatus and Image-Forming System Equipped with the Same

ActiveUS20080237962A1Good finishRaise the gradeRotary pressesSheet bindingControl modeBiomedical engineering

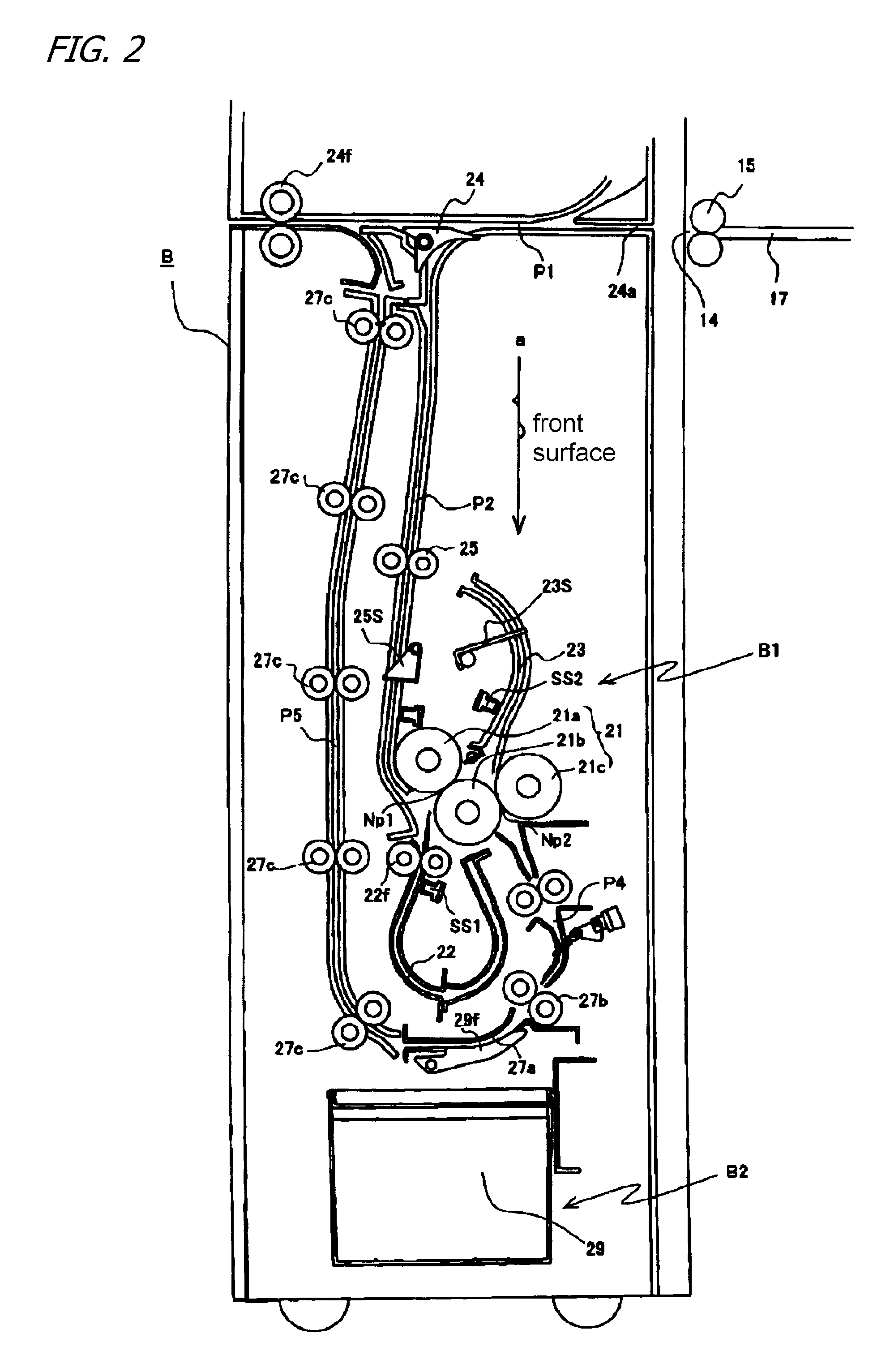

Imaging-system bookbinding apparatus avoids cutting any folded sheets mixed into booklets it trims. Furnished with: an imaging unit; a sheet-folding unit that folds imaging-unit sheets; a stacking unit that stacks sheets from the sheet-folding or image-forming units; a cover-sheet binding unit that encases stacking-unit sheet bundles with, and binds them into, cover sheets; a trimming unit that trims true the bundle fore-edge; and a fold-position computing unit that determines where a sheet is pleated by the sheet-folding unit. The sheet-folding unit has a sheet conveyance path along which folded sheets are transported elsewhere than the stacking unit, while the fold-position computing unit in a first control mode transports to the stacking unit sheets folded over by the sheet-folding unit, and in a second control mode transports them from the sheet conveyance path elsewhere than the stacking unit.

Owner:NISCA KK

Bicomponent transparent finishing fire retardant coating and preparation method thereof

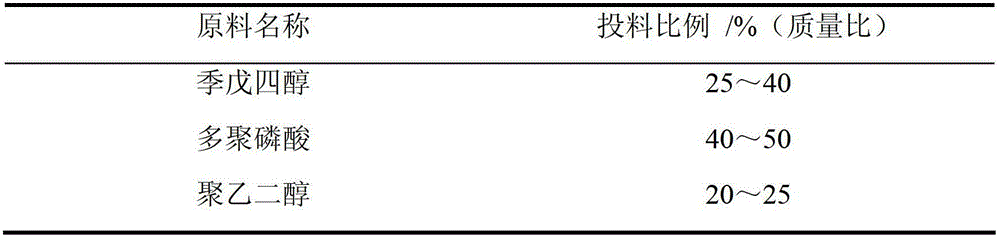

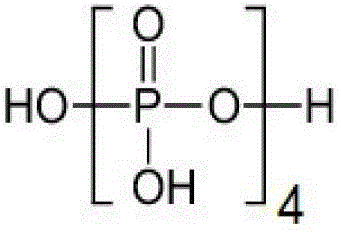

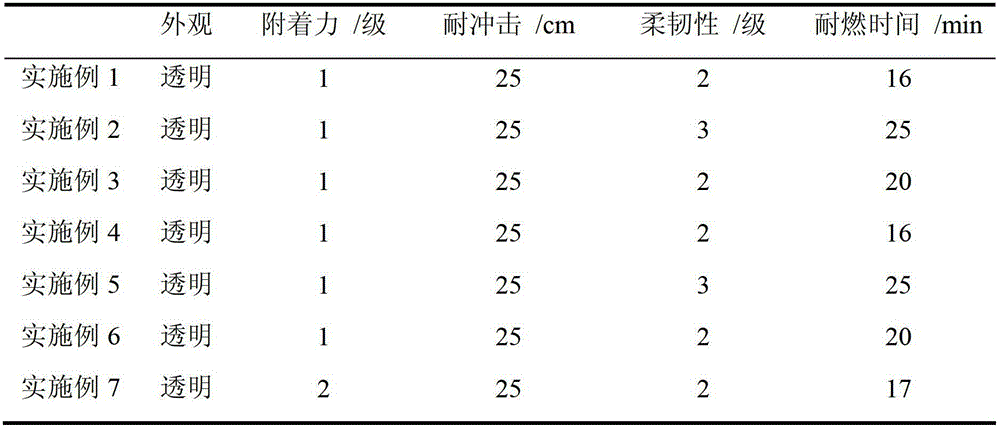

The invention relates to a bicomponent transparent finishing fire retardant coating and a preparation method thereof. The preparation method includes steps of using polyphosphoric acid, pentaerythritol and polyethylene glycol to obtain polyethylene glycol grafted polyphosphate by means of a fusion synthesis method and mixing and blending a component A and a component B to obtain the bicomponent transparent finishing fire retardant coating, wherein the component A is an aqueous solution or an absolute ethyl alcohol solution of the grafted polyphosphate, and the component B is an aqueous amino resin. According to the obtained bicomponent transparent finishing fire retardant coating, the flexibility of a coating film is greatly improved on the basis of a good fire retardant performance of the coating, and the preparation method of the bicomponent transparent finishing fire retardant coating is easy and simple to operate.

Owner:DONGGUAN DAXING CHEM

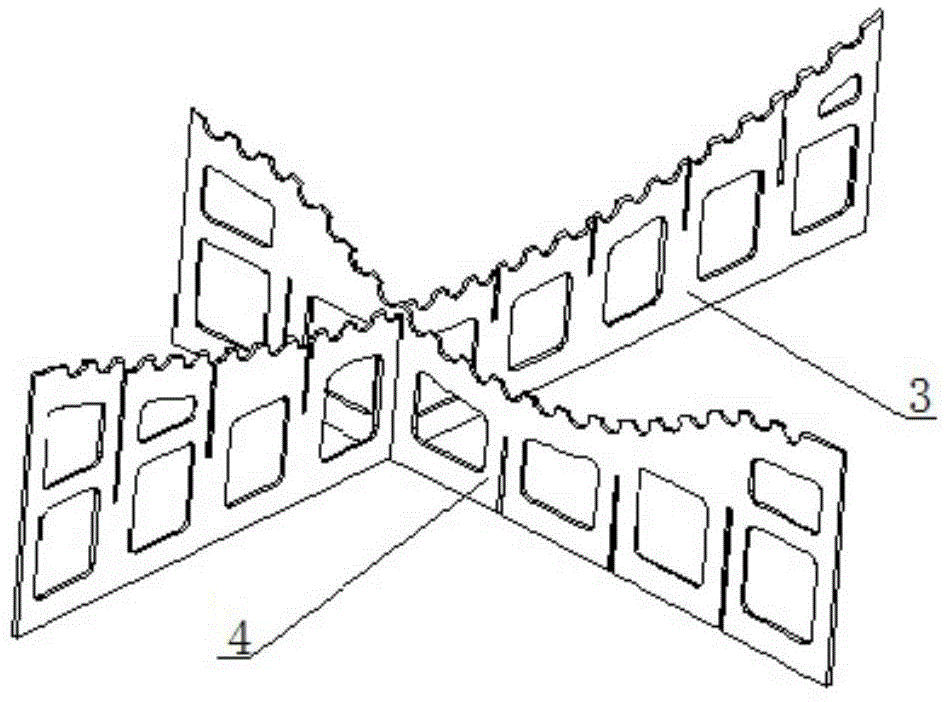

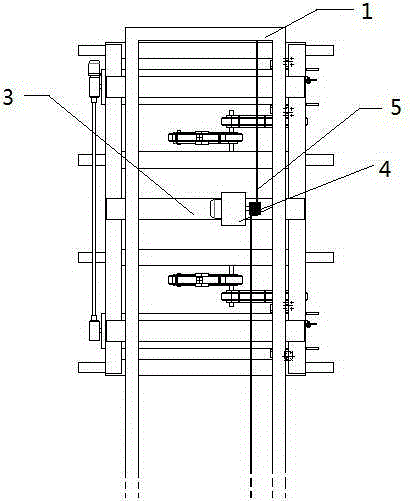

Framework type tooling for molding composite material product autoclave

The invention discloses a framework type tooling for molding a composite material product autoclave; longitudinal reinforcement ribs and transverse reinforcement ribs are in cross connection, and are welded with a molded surface to form an integrated framework structure; the bottom of the longitudinal reinforcement ribs and the bottom of the transverse reinforcement ribs are fixedly welded with a bottom flat plate; four corner edges of the molded surface are each provided with a processing and testing datum hole of a process device, and both sides of the framework are each fixed with a hanging device; a suction nozzle is located in a central axis of both ends of the molded surface, and a suction pipe is connected with the suction nozzle and forms a pressurized gas pumping system with a suction connector; the bottom surface area of the molded surface is provided with a plurality of temperature sensors, and the temperature sensors are connected with temperature monitoring connectors by wires to form a temperature monitoring system. The surface smoothness of the tooling molded surface is good, air tightness and manufacturability are good, the service life is long, the deformation is small, temperature rising and dropping are uniform when the tooling is used in the autoclave, the tooling has good thermal conductivity and thermal stability and meets the process technology requirements of the composite material product autoclave molding, and the quality of the molded composite material product is stable and reliable.

Owner:XIAN AISHENG TECH GRP +1

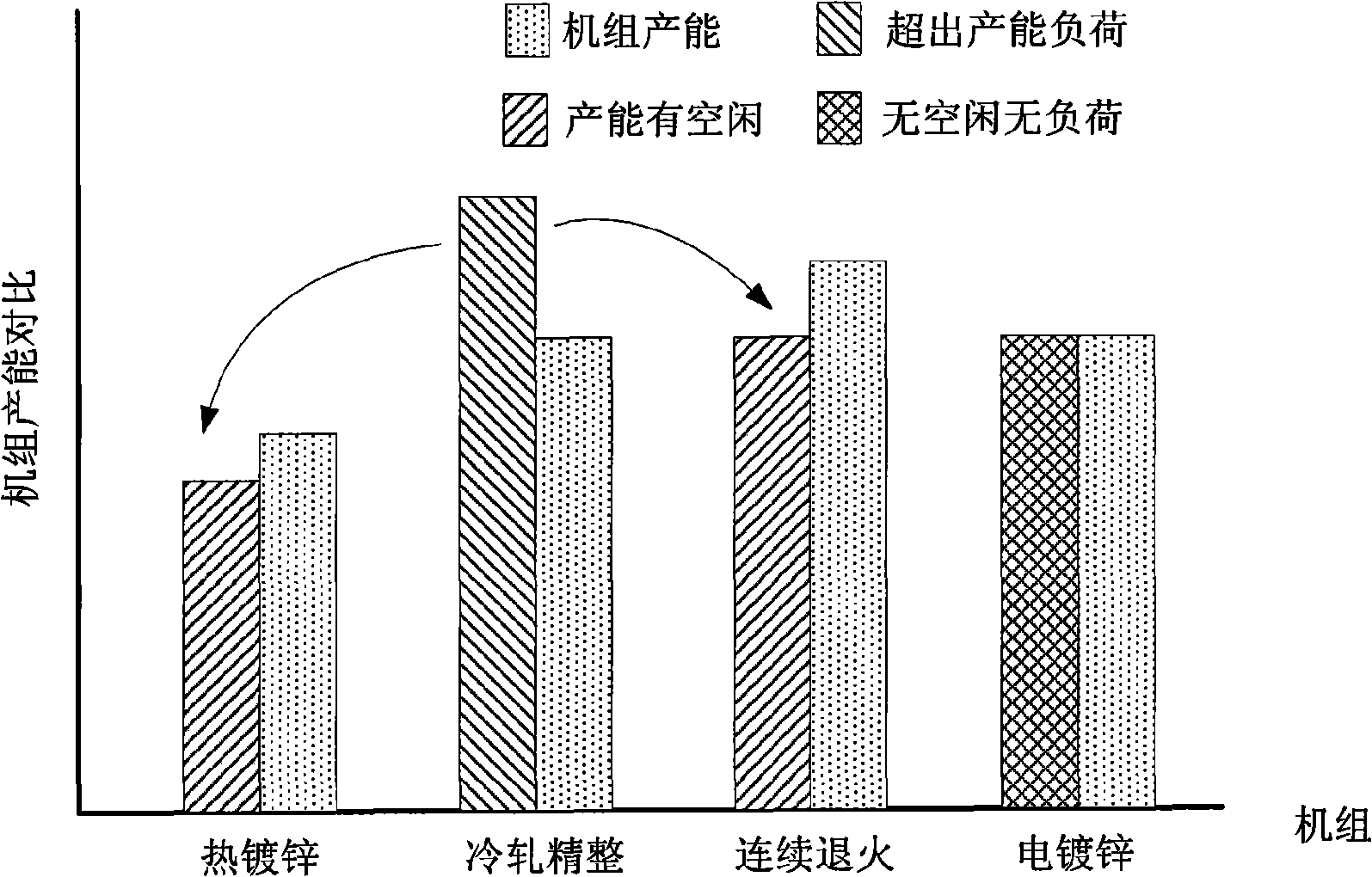

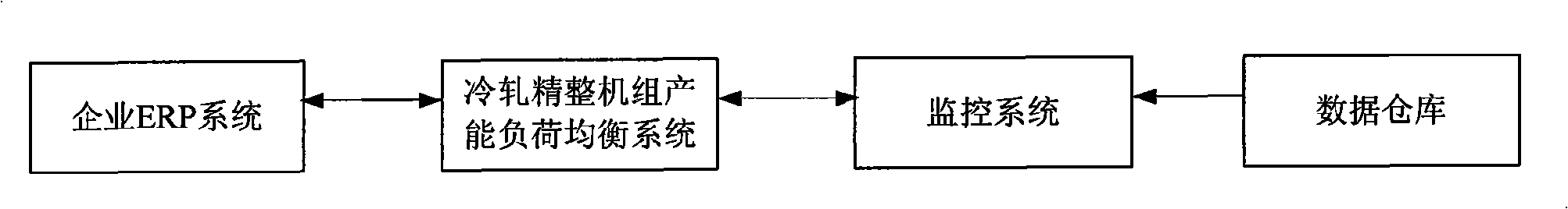

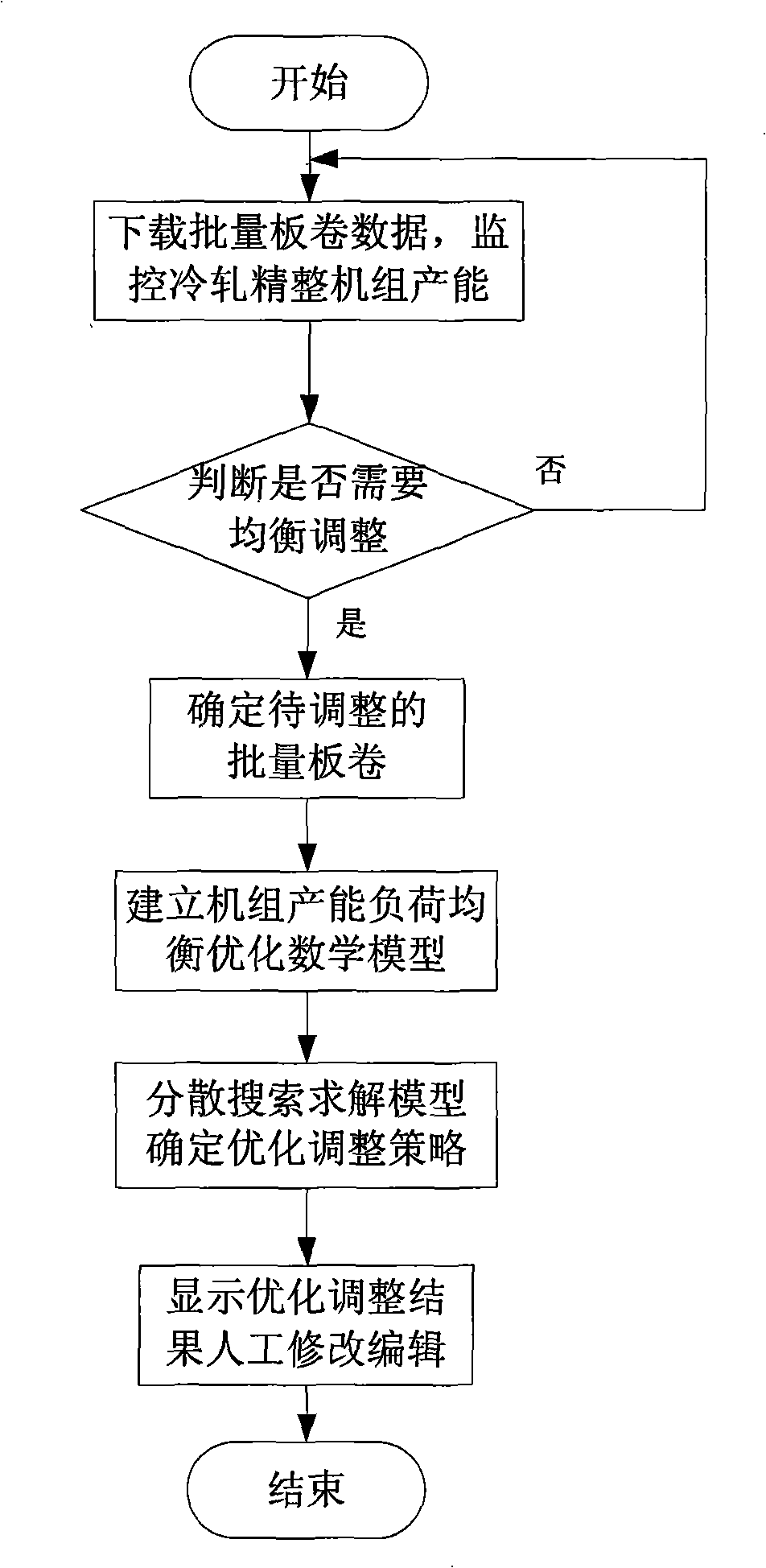

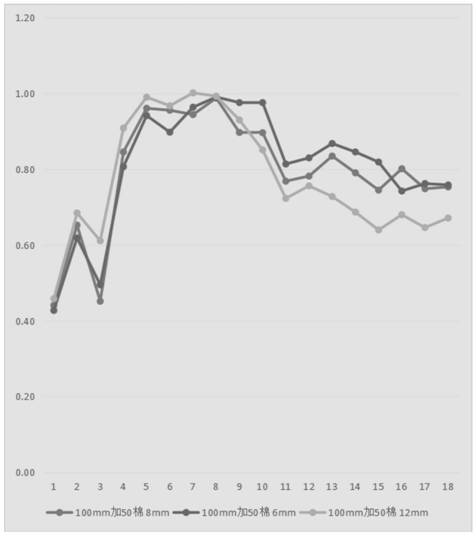

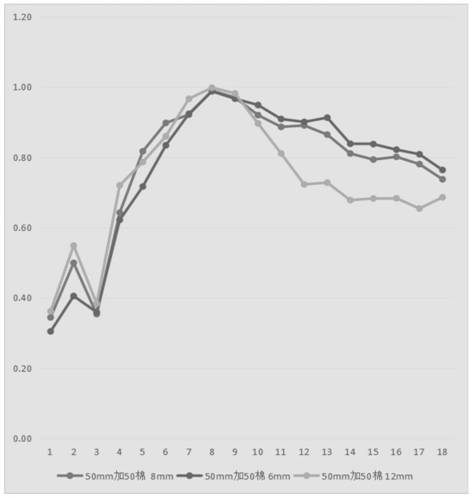

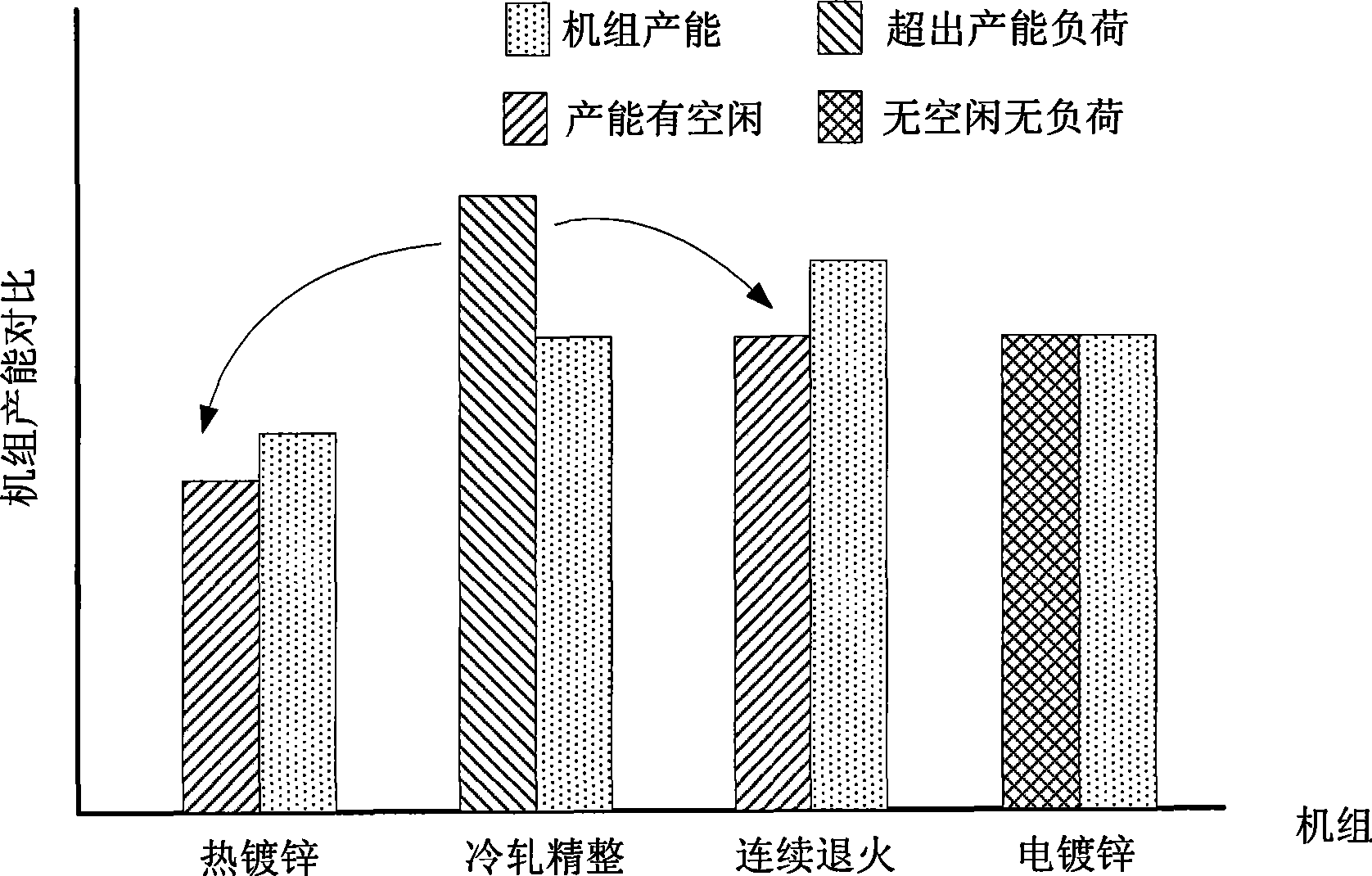

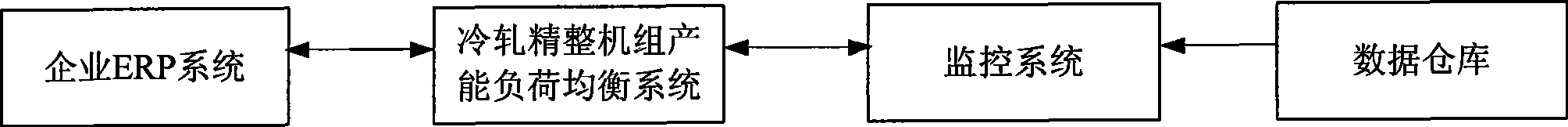

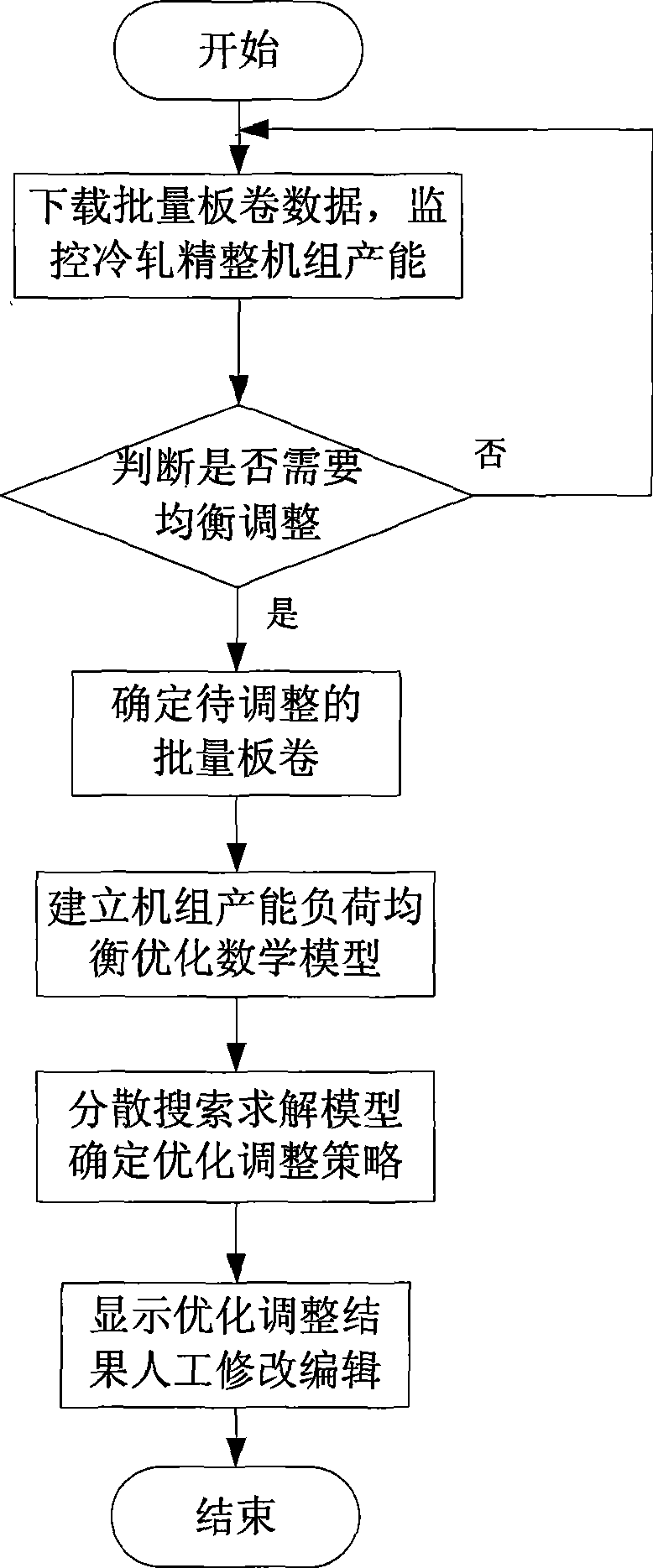

Productivity load equalization method for cold rolling final finishing units of steel enterprise

ActiveCN101403920AAccurate capacity forecastAccurate predictionRoll mill control devicesTotal factory controlGraphicsData warehouse

The invention discloses a method for balancing the capacity load of a cold rolling finishing unit in an iron and steel enterprise, and relates to the technical field of automation. The method comprises the following steps: (1) downloading the batch coiled sheet data in a data warehouse of the iron and steel enterprise; (2) judging whether the present capacity condition of the cold rolling finishing unit need balance adjustment, comparing the number of days T which is needed for producing the monthly batch coiled sheets by the cold rolling finishing unit with the remaining number of days of the month tr, and adjusting the batch coiled sheet if the T is greater than tr; (3) determining the batch coiled sheets to be adjusted based on the production technologies and the constraints of the cold rolling finishing unit and the related upstream and downstream units; (4) establishing an mathematical model for balancing and optimizing the capacity of the cold rolling finishing unit by taking the batch coiled sheets to be adjusted as objects; (5) solving the mathematical model for balancing and optimizing the capacity of the unit by a scatter search method, and determining the optimized adjustment strategy of the batch coiled sheets; and (6) displaying the optimized adjustment results by a graph mode and a data mode. The method can help find out problems in the capacity of the unit in advance, and is applied to the production process of the cold rolling finishing unit.

Owner:NORTHEASTERN UNIV

High-frequency heating cooker

InactiveCN103791529AGood finishControl supplyDomestic stoves or rangesLighting and heating apparatusCookerEngineering

The invention provides a high-frequency heating cooker. When information associated with a heating treatment inputted by an operating portion is information associated with cooking with steam, a controller controls so as to steam an object to be heated by conducting a first heating treatment in which a water vapor generator is driven to supply water vapor into a heating chamber to heat the object to be heated placed on a cooking dish with the water vapor, and a second heating treatment in which after the first heating treatment, a microwave generator is driven to heat a high-frequency heating element of the cooking dish and the object to be heated placed on the cooking dish with microwaves.

Owner:PANASONIC CORP

Powder injection molding method for silicon carbide ceramic sand-blasting nozzle

InactiveCN102172960AGood wear resistanceGood finishCeramic shaping apparatusDrawing ratioCarbonization

The invention discloses a powder injection molding method for a silicon carbide ceramic sand-blasting nozzle, relating to a method for manufacturing a ceramic sand-blasting nozzle and solving the problems that the existing method for manufacturing the sand-blasting nozzle has a complicated process, high production cost, low efficiency, and difficulty in molding a micro-runner with a draw ratio. The method comprises the steps as follows: 1. preparing a feed; 2. preparing injection blanks; 3. preparing blanks; and 4. placing the blanks in a sintering furnace for sintering, grinding and polishing, thus obtaining the silicon carbide ceramic sand-blasting nozzle. The silicon carbide ceramic sand-blasting nozzle manufactured in the invention has good wear resistance, the compactness can reach over 98 percent through tests, the pore path of the sand-blasting nozzle is small and has the diameter of 0.5-3.0mm, the internal smoothness of the pore path is good, the blasting effect is ideal, the draw ratio can achieve (50-150): 1, the production efficiency is high and the cost is low. The method is applicable to manufacturing pure-carbonization silicon carbide adding additives, and silicon carbide composite sand-blasting nozzles with low cost in bulk.

Owner:HARBIN INST OF TECH

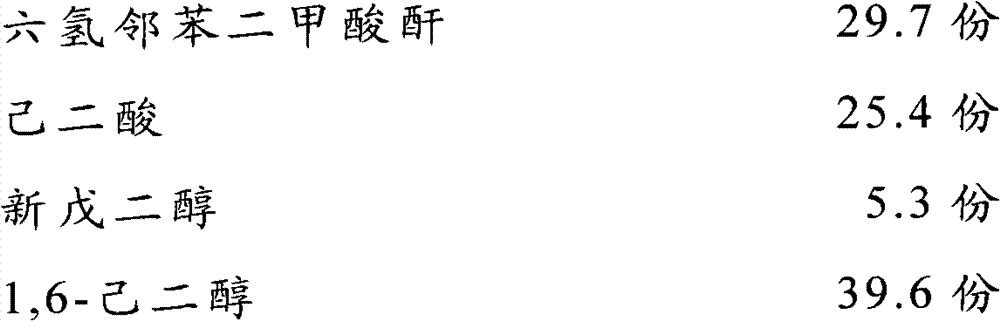

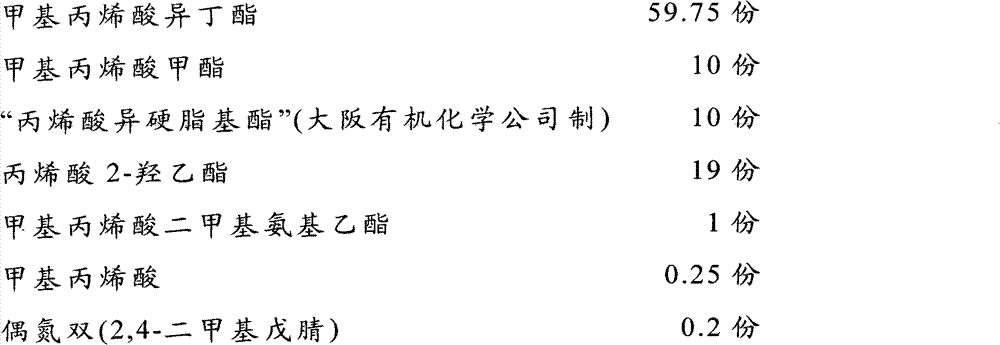

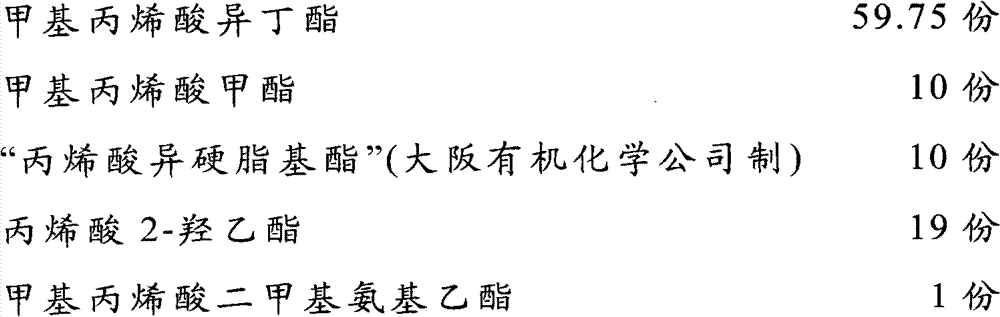

Multi-component ground coating, toning method, and coating repairing method

InactiveCN102952445AGood painting workabilityGood finishPolyester coatingsMetal coatingPolyester resin

The invention provides a multi-component ground coating, the toning method of using the coating, and the coating repairing method as well. The multi-component ground coating features excellent coating performance and is capable of forming a repairing coating film which does not generate unevenness and is consistent with the known coating film in color. The multi-component ground coating is formed by combining the metal coating composition (I) and the thickening agent composition (II) together, wherein the metal coating composition (I) comprises cellulose derivative (A1), crylic acid resinoid (B1), polyester resin (C1), and bright pigment (D1); the thickening agent composition (II) comprises cellulose derivative (A2), crylic acid resinoid (B2), polyester resin (C2), and thickening agent (E); and the thickening agent (E) in the thickening agent composition (II) comprises an amides thickening agent (E1) as part of its components.

Owner:KANSAI PAINT CO LTD

Color masterbatch and manufacturing method

The invention relates to a color masterbatch and a manufacturing method, specifically to pigmentation of a variety of plastics. The color masterbatch provided by the invention is composed of deionized water, polyvinyl butyral, ethanol, an antifoaming agent, a stabilizer, a plasticizer, a dispersant, polyethylene wax, ethylene oxide wax, a leveling agent, a coupling agent, plastic pigment powder, an anti-ultraviolet agent and an anti-ageing agent. The color masterbatch provided by the invention is prepared from a variety of raw materials in reasonable proportion, has excellent dispersion uniformity, smoothness, flexibility and low-temperature resistance, and significantly improves the quality of a product; the color masterbatch provided by the invention has two shapes of powder and granule, thereby meeting different addition requirements of powdered resins (like PVC) and granular resins (like PMMA) and achieving the effect of uniform pigmentation; and the color masterbatch provided by the invention is applicable to pigmentation of resins like PVC, ABS, PMMA, PS, polyurethane and epoxy resin.

Owner:李勇军

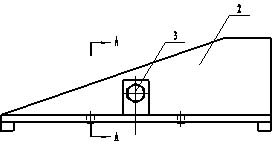

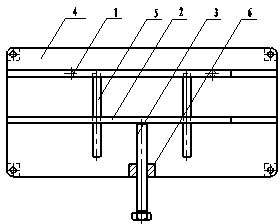

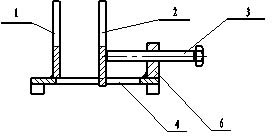

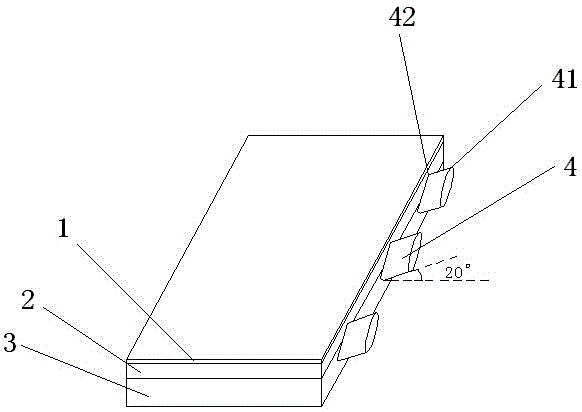

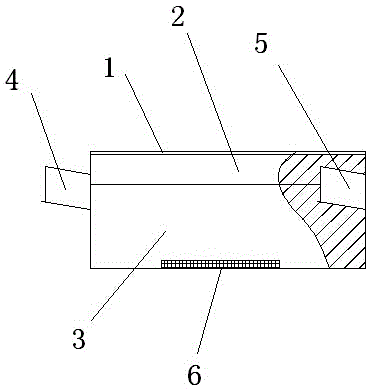

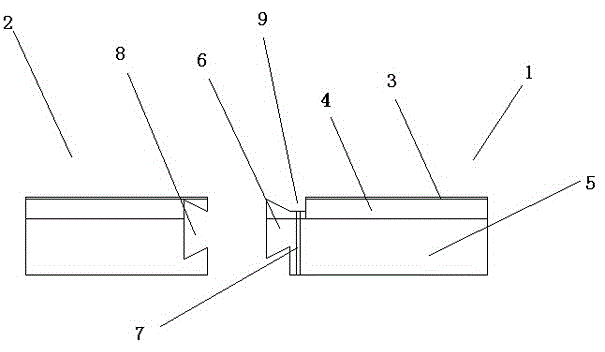

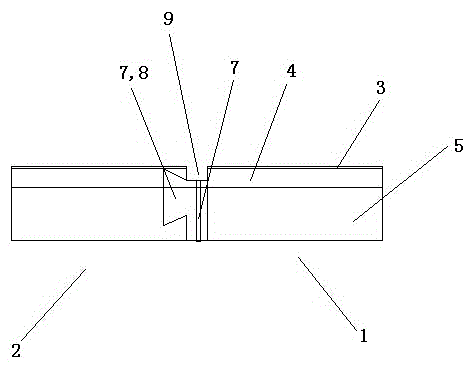

Cutting tool for butt joint grooves of sealing glue tapes or glue sticks

InactiveCN102554956AEasy and fast cuttingGood finishMetal working apparatusGlue stickPower equipment

A cutting tool for butt joint grooves of sealing glue tapes or glue sticks comprises a base. At least two slide grooves are arranged on the base, a fixed plate with a triangular upper portion is arranged at one end of each slide groove, the cutting tool is provided with at least one movable plate capable of reciprocating along the slide grooves, the size and the shape of each movable plate are completely identical to those of the fixed plate, a bolt seat is disposed on the base and positioned on one sides of the movable plates, and a fastening bolt is fastened in the bolt seat. The slide grooves are manufactured on a bottom plate, the movable plates are disposed in the slide grooves and match with the fixed plate at the other ends of the slide grooves, accordingly, the cutting tool can precisely cut the glue tapes or glue sticks in a field, minimum precision can reach 1mm, and the tool is safe and reliable and can be molded at one step. In addition, the butt joint grooves are cut simply, conveniently and quickly and are fine in smoothness. Furthermore, when the cutting tool is applied to the power industry, leakage of oil-filled equipment can be reduced, and running reliability of power equipment is improved.

Owner:JINZHONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER

Two-component transparent fireproof coating material preparation method

InactiveCN106147504AWide variety of sourcesLow costFireproof paintsPhosphoric Acid EstersPolymer science

The present invention relates to a two-component transparent fireproof coating material preparation method, which specifically comprises that a polyglycol-grafted polyphosphate is prepared from polyphosphoric acid, pentaerythritol and polyethylene glycol through a solution synthesis method, an aqueous solution or absolute alcohol solution having a certain concentration is prepared from the polyglycol-grafted polyphosphate, and the obtained aqueous solution or absolute alcohol solution and an aqueous amino resin are subjected to blending stirring to obtain the two-component transparent facing fireproof coating material. According to the present invention, the preparation method is simple and feasible, and has the low in cost, and with the prepared two-component transparent facing fireproof coating material, the flexibility of the coating film is substantially improved on the basis of assurance of the excellent fire resistance of the coating material.

Owner:泉州市合创涂料科技有限公司

Preparation method of modified color master batch

The invention relates to a preparation method of a modified color master batch, and belongs to the technical field of color master batches and modified materials. The method comprises the following steps: proportioning of raw materials, grinding, mixing and heating, cooling, and extrusive granulation. Compared with the prior art, the modified color master batch disclosed by the invention has the beneficial effects that the modified color master batch is prepared from a plurality of raw materials in a reasonable ratio, so that the product has excellent dispersion uniformity, smoothness, flexibility and low-temperature resistance, and obviously improves the product quality; meanwhile, the fluorescent agent is added into the modified color master batch, so that the modified color master batch has a fluorescent function.

Owner:安徽卡洛塑业科技有限公司

Artistic paint and preparation method thereof

ActiveCN112680035AGood adhesionSolve crackingAntifouling/underwater paintsPaints with biocidesPolymer scienceWollastonite

The invention belongs to the technical field of building materials and relates to artistic paint and a preparation method thereof. The artistic paint is prepared from the following raw materials in parts by mass: 100-180 parts of emulsion; 500-700 parts of a filling material; 3-6 parts of a silane coupling agent; 3-8 parts of lignocellulose; and water. The emulsion comprises a first styrene-acrylic emulsion and a second styrene-acrylic emulsion, the Tg of the first styrene-acrylic emulsion is 20 DEG C to 45 DEG C, and the second styrene-acrylic emulsion is an oil-resistant hydrophobic emulsion; the filler is selected from at least two components selected from of barite, wollastonite and heavy calcium carbonate. The artistic paint is artistic facing paint which not only can realize various artistic patterns, but also can integrate a bottom surface (without putty leveling, a bottom surface and a cover surface), and has good stain resistance.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Forming method of annular voltage-sensitive resistor

The molding method of the ring varistor includes the following steps in sequence: (a) mixing: put the powder with binder and solvent in the kneader and mix evenly; (b) rough rolling: the above powder is mixed After training, the material is discharged to the rolling mill for the first rolling; (c) freezing: the mud obtained by rough rolling is sealed and refrigerated at 0-10°C; (d) finishing rolling: the mud obtained after refrigeration is subjected to the second rolling. Secondary rolling to make it uniform and compact; (e) Extrusion: place the finished mud in a vacuum extruder to extrude into a film belt with good uniformity, density and consistency; (f) drying; (g) stamping. The method can improve the uniformity and compactness of the green body and make the production efficiency higher.

Owner:广州新日电子有限公司

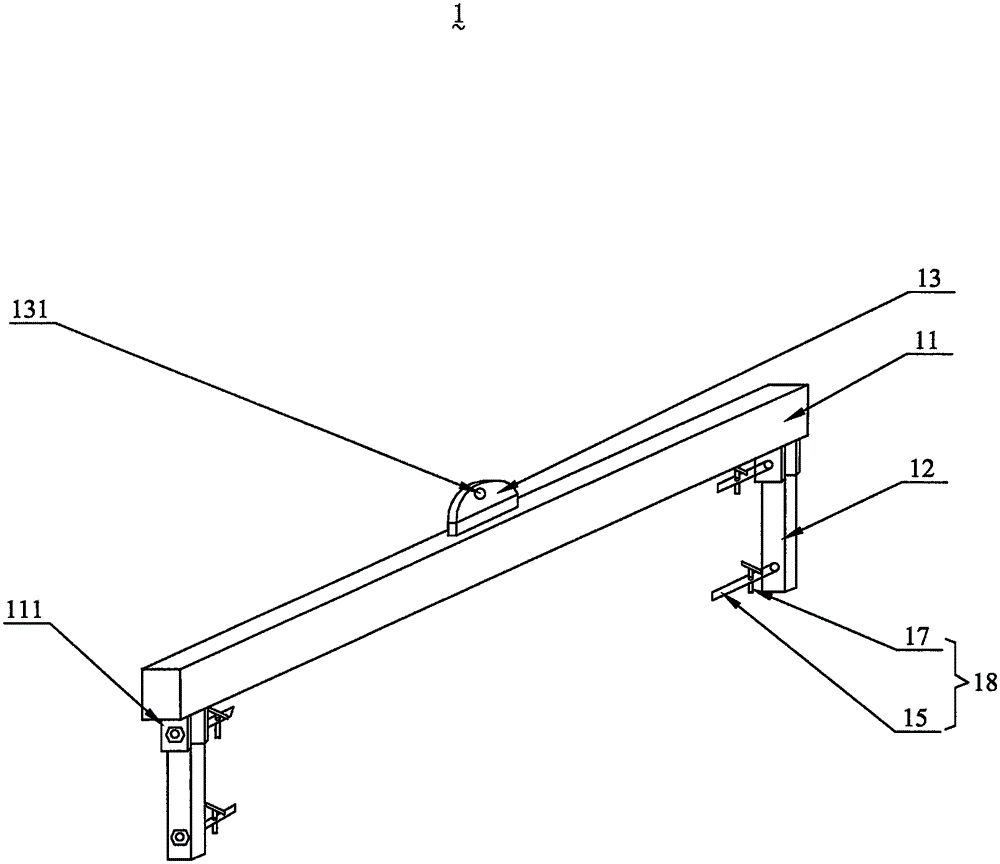

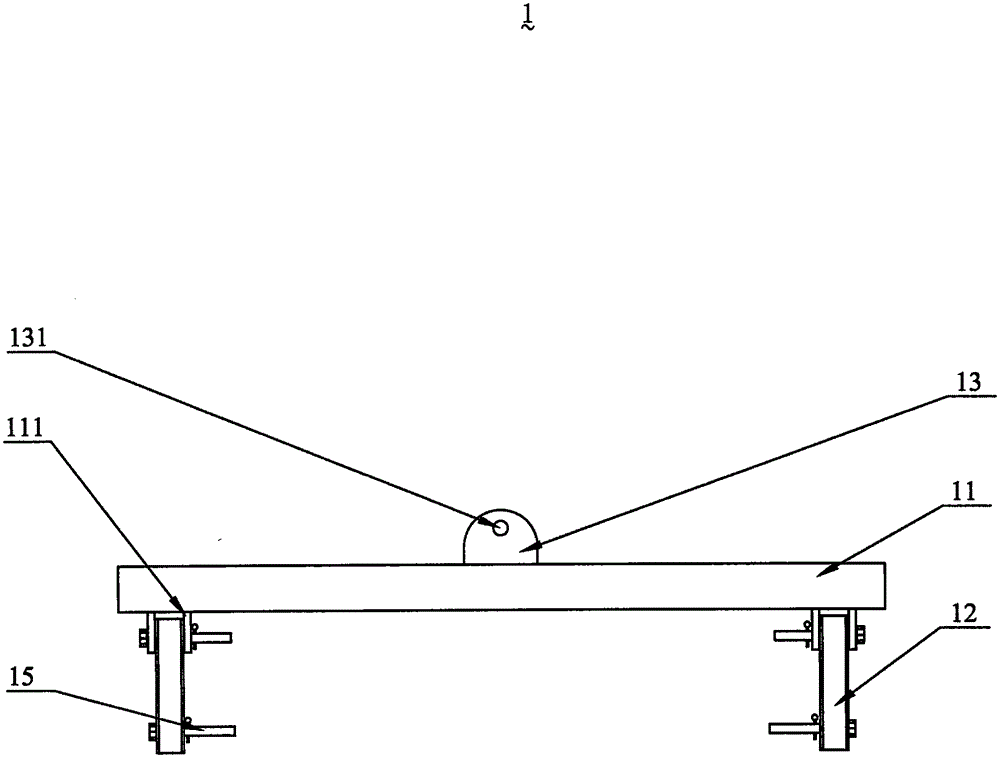

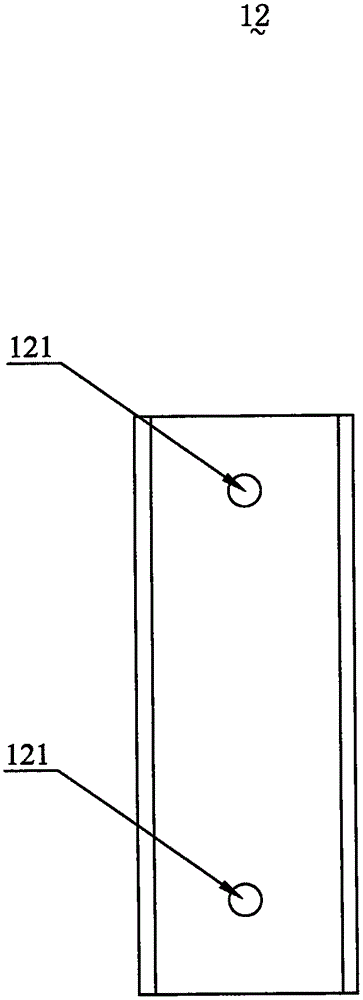

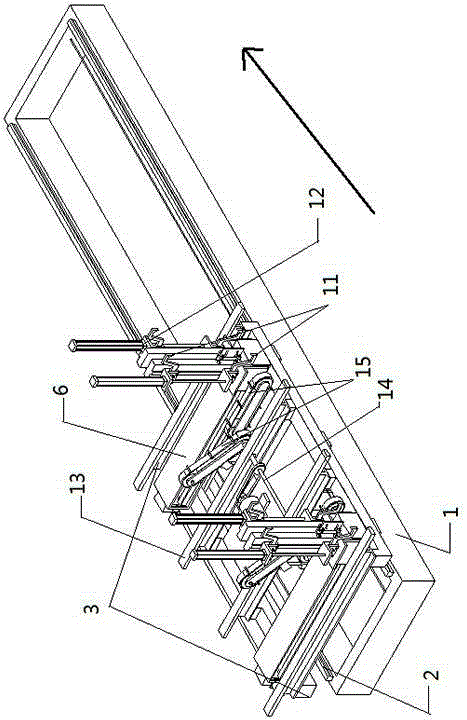

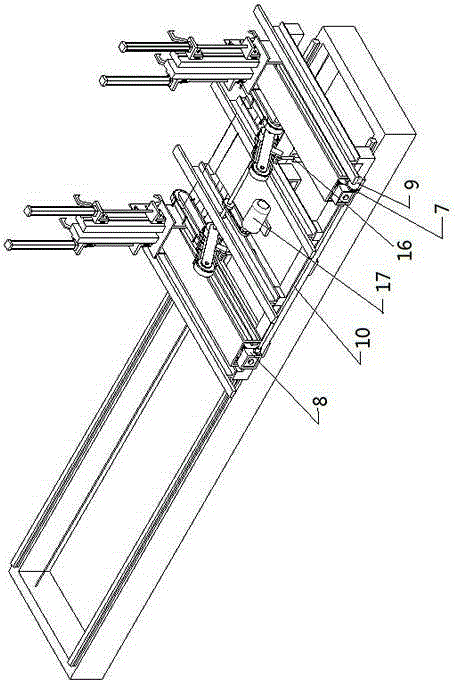

Lifting sling for prefabricated component

InactiveCN105384057AGood finishSmall amount of workLoad-engaging elementsMechanical engineeringEngineering

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

Production process of precision seamless steel tubes

InactiveCN109604369AStable and stable mechanical propertiesStable mechanical propertiesPunchingHardness

The invention relates to a production process of precision seamless steel tubes. The production process includes the following steps of feeding, wherein steel tube raw materials are pushed into a pushing machine; heating, wherein steel tube blanks are heated through a natural gas hot blast furnace, and the heating temperature is 1,180-1,200 DEG C; punch-forming, wherein the steel pipe blanks are punched through a punching machine, and steel tubes are obtained; finish rolling, wherein the steel tubes are rolled through a three-roller finish rolling machine, and the sizes of the internal diameters and the external diameters of the steel tubes are machined into designated sizes; quenching, wherein water serves as a quenching medium, the water temperature is 20-40 DEG C, and the temperatures of the quenched steel tubes are 830-850 DEG C; tempering, wherein the steel tubes are fed into a tempering furnace, the tempering temperature is 550-620 DEG C, and the time is 20-30 min; and straightening, wherein the steel tubes are straightened through a straightener. Diameter reducing and wall thickening of the seamless steel tubes are achieved in the finish rolling production procedure of the process, the production process is suitable for the steel tube blanks and waste steel tubes, and stable mechanical performance and better treatment smoothness are achieved; and compared with the existing seamless steel tubes, the precision seamless steel tubes are more durable, the hardness, plasticity and toughness are all improved, and machining is better facilitated.

Owner:山东庆云三友机械电器有限公司

Automatic feeding and sawing device

The invention provides an automatic feeding and sawing device which comprises a rack fixed to the ground. Longitudinal rails are arranged on the surface of the rack. The automatic feeding and sawing device further comprises a workbench capable of sliding on the longitudinal rails. A first motor is connected to the lower portion of the workbench and connected with a rolling wheel, a groove is formed in the surface of the rolling wheel and sleeved with a steel wire rope, and the two ends of the steel wire rope are fixed to the two ends of the rack respectively; the first motor drives the rolling wheel to rotate so as to enable the steel wire rope to drive the workbench to move on the longitudinal rails to a sawing position. A horizontal moving platform is further arranged on the upper portion of the workbench and provided with a material clamping device. According to the automatic feeding and sawing device, after wood or bamboo integrated materials are fixed, the materials can be automatically pushed back and forth to be sawn, and the pushing speed can be kept consistent; the surface smoothness of plates is good, the widths of the plates can be kept consistent, manual participation is avoided, and production efficiency and safety performance are improved.

Owner:安吉奥吉竹木机械有限公司

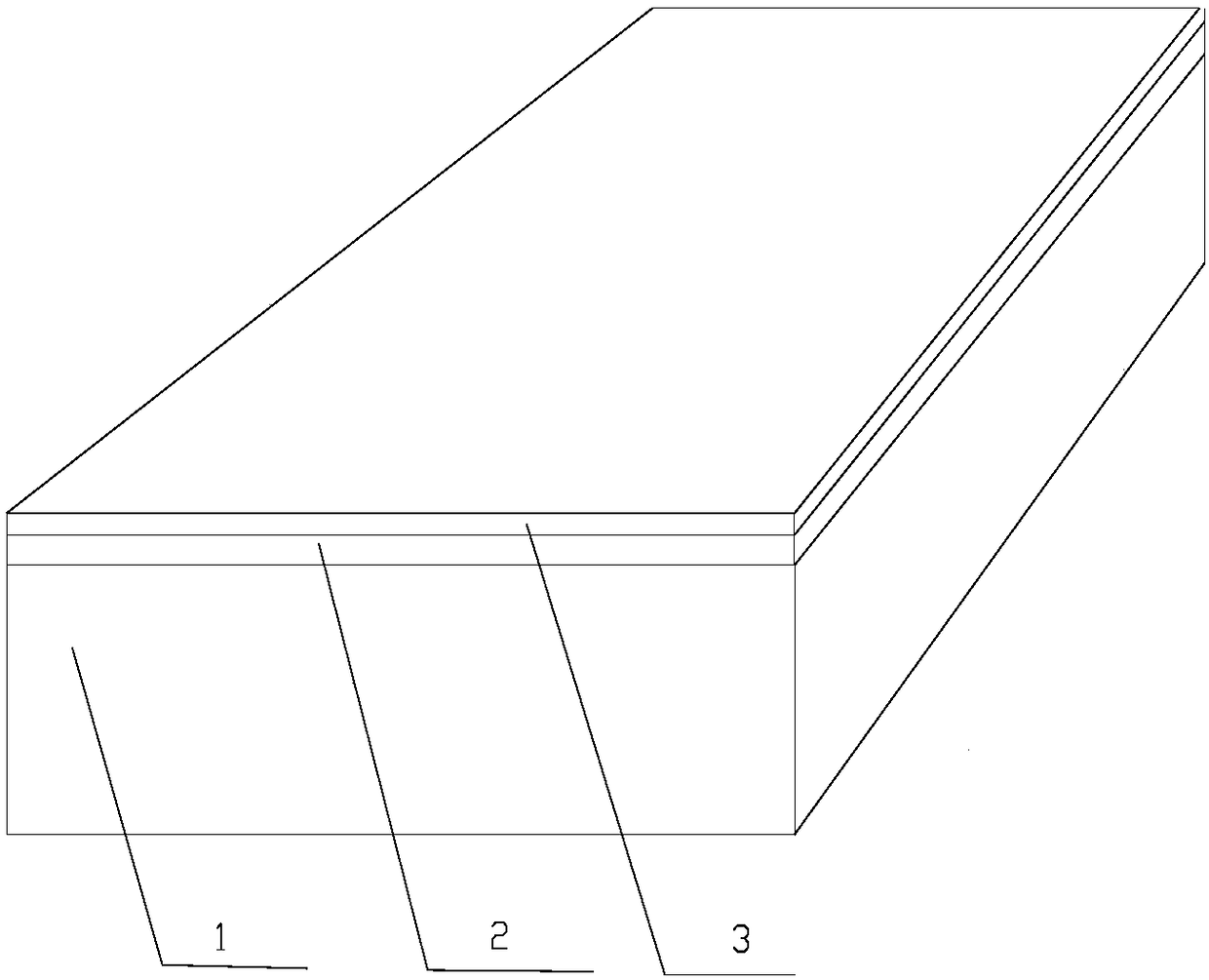

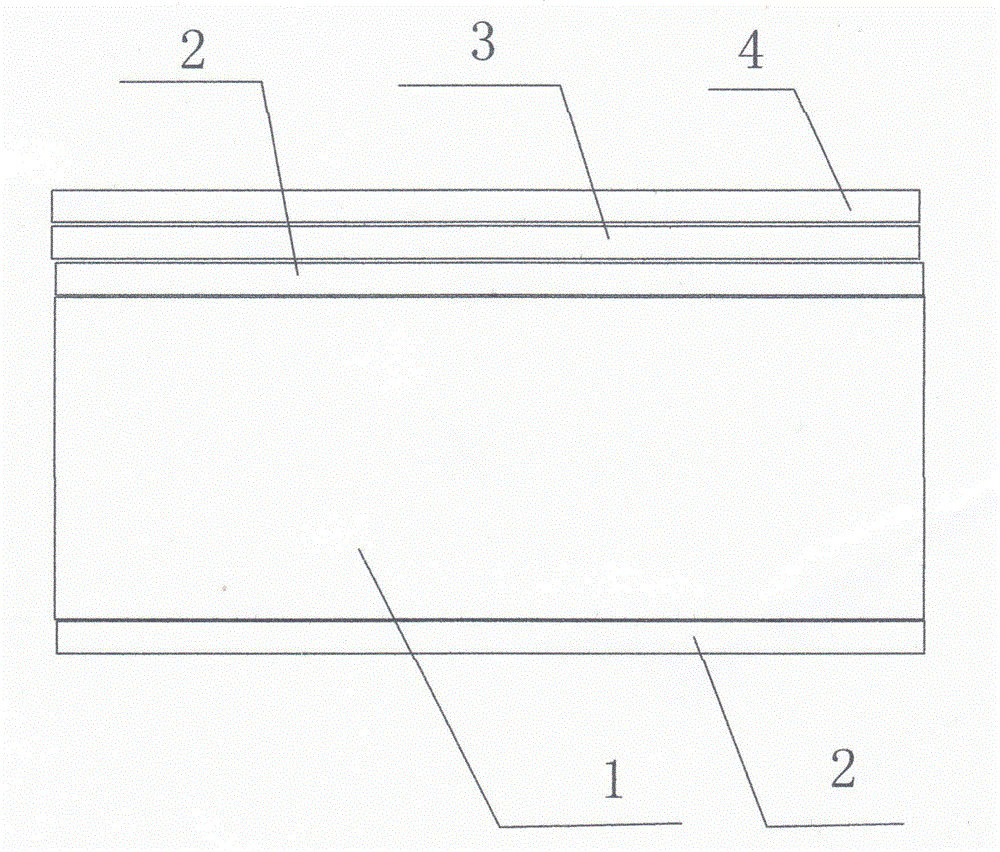

Compound fireproof decoration plate

The invention discloses a compound fireproof decoration plate. The compound fireproof decoration plate comprises a base plate and a decoration layer, the decoration layer is pasted to the front or thefront and back of the base plate, the outer surface of the decoration layer is coated with a coating layer, and the coating layer can be oil paint or other coatings. By means of the compound fireproof decoration plate, the smooth and finish degree of an existing fireproof decoration plate can be greatly increased, patterns are more attractive, and the decoration effect is greatly improved.

Owner:李石燕

Colored pottery sand acoustic board and preparation method thereof

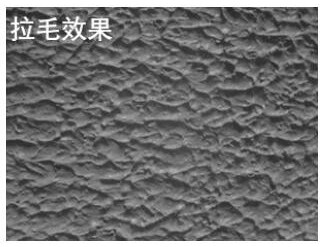

PendingCN114214977AQuality improvementIncrease market shareCovering/liningsNoise reduction constructionGlass fiberExpanded clay aggregate

The invention discloses a colored pottery sand acoustic board which comprises a nano fine sand layer, a fine sand layer and a ceramsite layer, reinforced glass fiber gridding cloth is arranged on the ceramsite layer, the fine sand layer is arranged on the reinforced glass fiber gridding cloth, and a nano fine sand layer is arranged on the fine sand layer. Different decoration effects can be achieved by adopting different methods for surface layer treatment, and the surface layer treatment is determined according to user requirements and can be freely changed. The invention can enrich the market diversification of building sound absorption materials at home and abroad, improve the quality, market occupancy and utilization rate of the building sound absorption materials and meet the requirements of modern living standard of people, and provides a novel updating product which can be directly attached to a wall for installation, has a better sound absorption effect without a cavity, achieves A1-level fire prevention and adopts a sintering principle of a processing flow. The invention has the characteristics of no pollution, moisture resistance, collision resistance, zero emission of harmful gas, no secondary pollution, good surface layer effect and the like.

Owner:上海彩滨实业发展有限公司

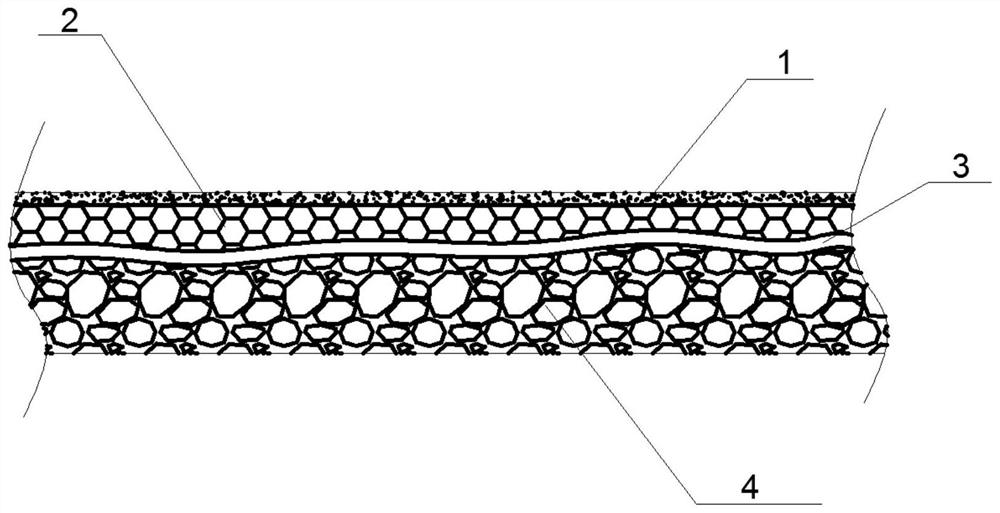

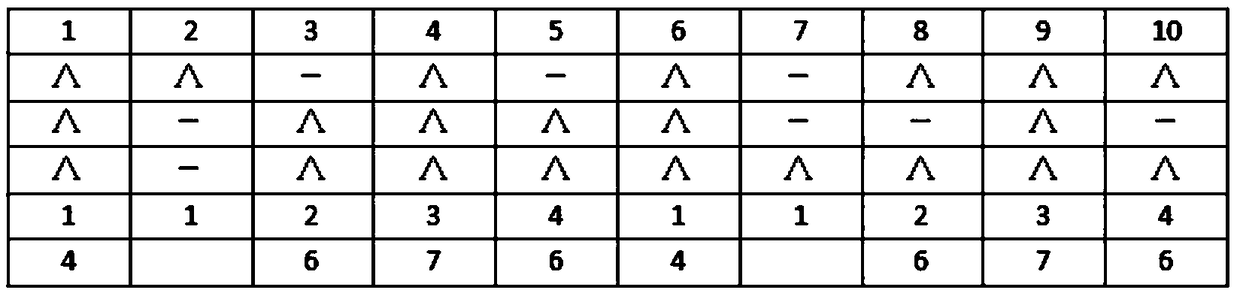

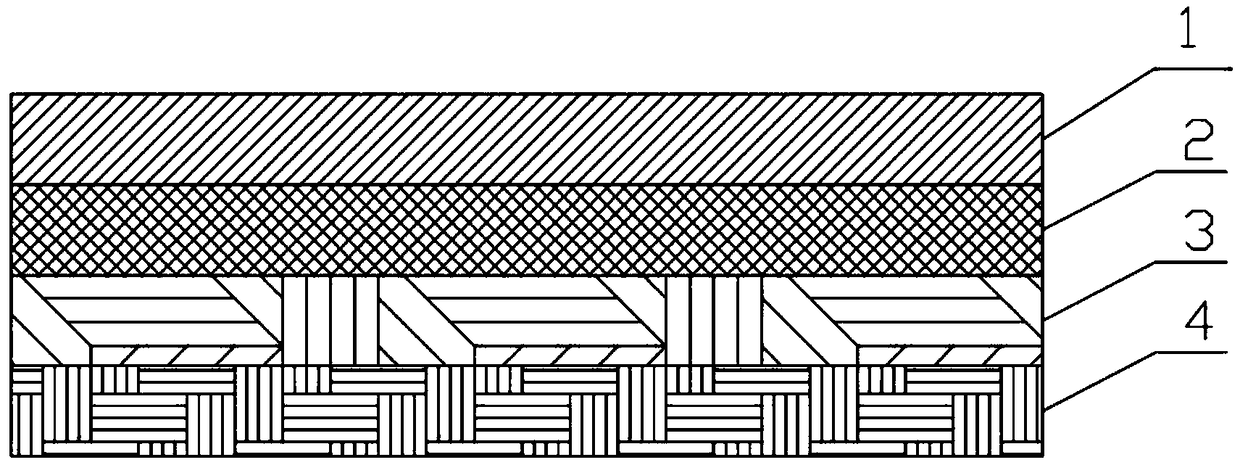

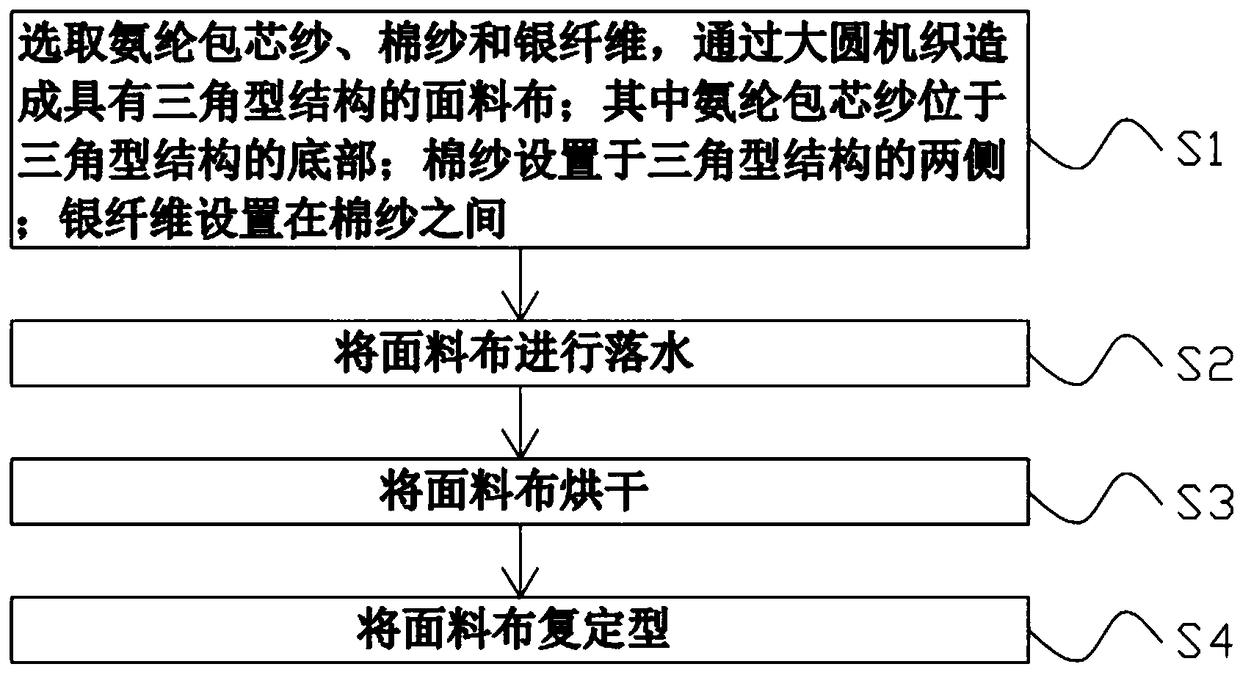

Composite triangular multicolor silk-like knitted fabric and preparation method thereof

PendingCN108708057ALess hairyGood finishSucessive textile treatmentsWeft knittingAgricultural engineeringWoven fabric

The invention discloses composite triangular multicolor silk-like knitted fabric and a preparation method thereof. The preparation method comprises the steps of 1, selecting spandex corn-spun yarns, cotton yarns and silver fibers, and using a circular knitting machine to weave fabric of triangular structure, wherein the spandex core-spun yarns are positioned at the bottom of the triangular structure, the cotton yarns are arranged on the two sides of the triangular structure, and the silver fibers are arranged between the cotton yarns; 2, soaking the fabric; 3, drying the fabric; 4, reshaping the fabric. The composite triangular multicolor silk-like knitted fabric employs cotton yarns and spandex core-spun yarns treated with silicone oil so that the fabric is less hairy and good in glossiness; the spandex core-spun yarns are of better elasticity so that the fabric rarely deforms; the silver fibers allow the fabric gains better color effect when drawn to change color.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Productivity load equalization method for cold rolling final finishing units of steel enterprise

ActiveCN101403920BAccurate capacity forecastAccurate predictionRoll mill control devicesTotal factory controlGraphicsData warehouse

The invention discloses a method for balancing the capacity load of a cold rolling finishing unit in an iron and steel enterprise, and relates to the technical field of automation. The method comprises the following steps: (1) downloading the batch coiled sheet data in a data warehouse of the iron and steel enterprise; (2) judging whether the present capacity condition of the cold rolling finishing unit need balance adjustment, comparing the number of days T which is needed for producing the monthly batch coiled sheets by the cold rolling finishing unit with the remaining number of days of the month tr, and adjusting the batch coiled sheet if the T is greater than tr; (3) determining the batch coiled sheets to be adjusted based on the production technologies and the constraints of the cold rolling finishing unit and the related upstream and downstream units; (4) establishing an mathematical model for balancing and optimizing the capacity of the cold rolling finishing unit by taking the batch coiled sheets to be adjusted as objects; (5) solving the mathematical model for balancing and optimizing the capacity of the unit by a scatter search method, and determining the optimized adjustment strategy of the batch coiled sheets; and (6) displaying the optimized adjustment results by a graph mode and a data mode. The method can help find out problems in the capacity of the unit in advance, and is applied to the production process of the cold rolling finishing unit.

Owner:NORTHEASTERN UNIV LIAONING

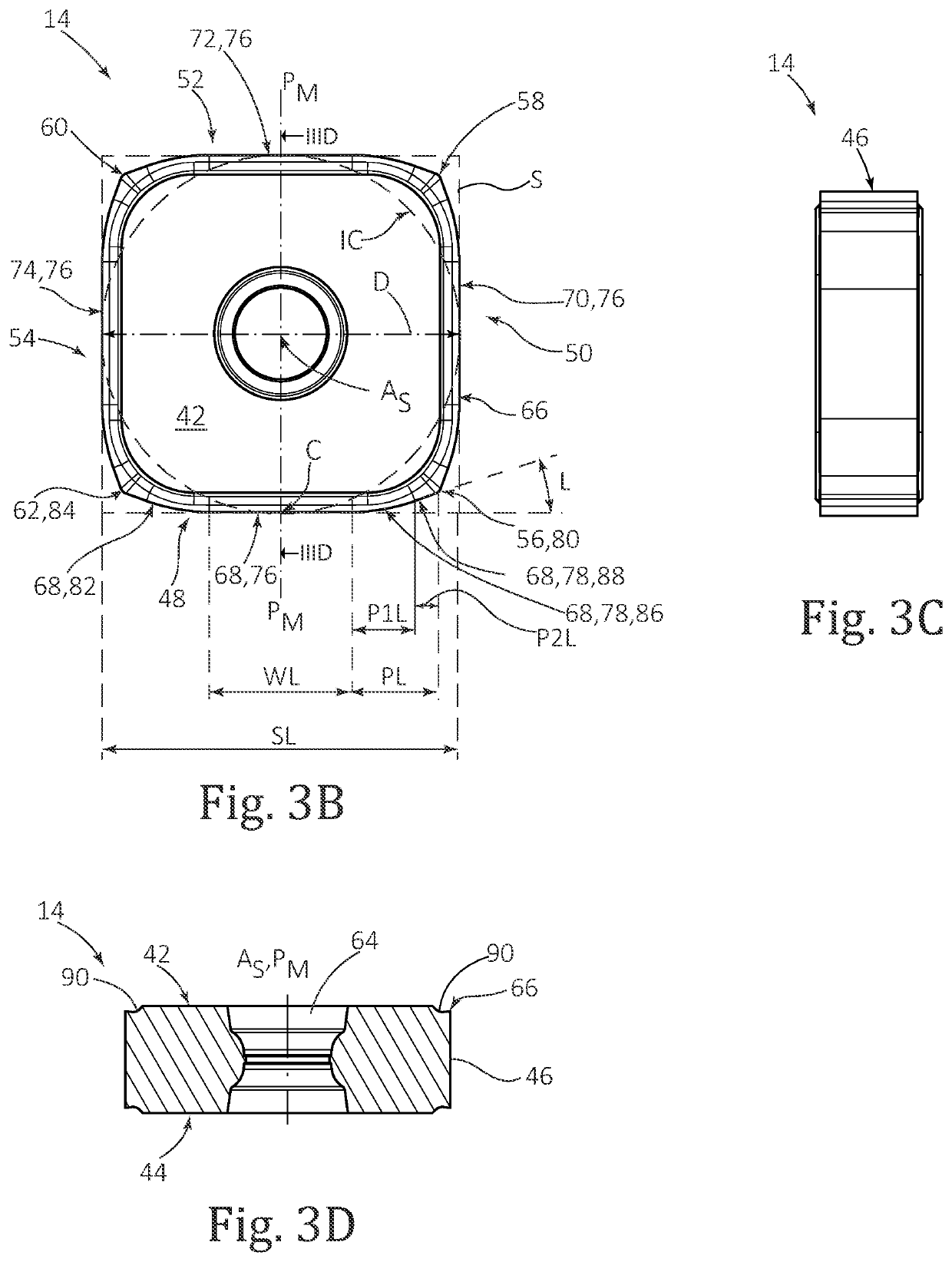

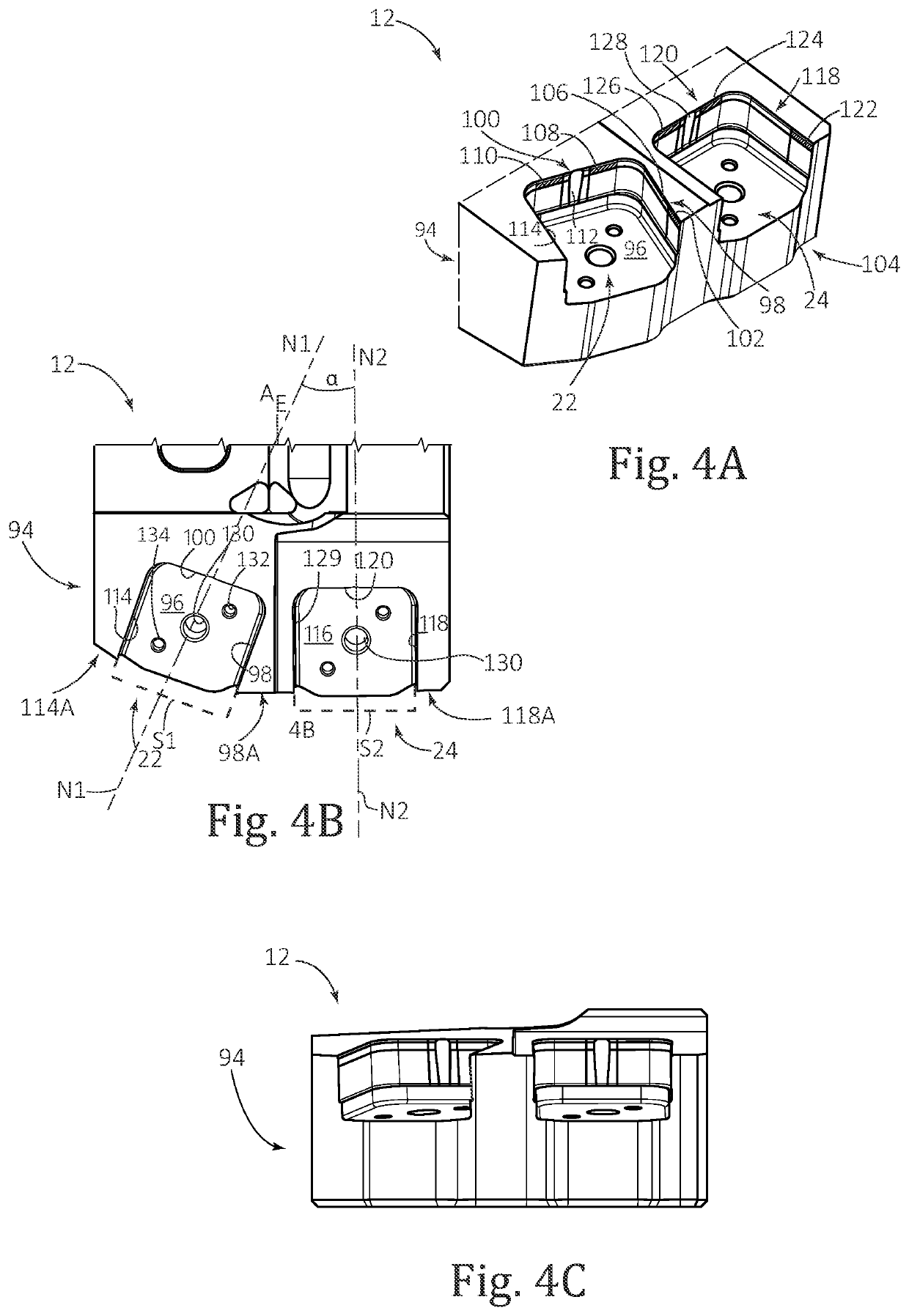

Square-shaped insert for bar-peeling and insert-holder tool for same

PendingUS20210245258A1Good finishImprove versatilityCutting insertsTurning toolsSquare ShapeMechanical engineering

A square-shaped bar-peeling insert and insert-holder designed with pockets to hold two such square-shaped inserts. Each insert has four peripheral sub-surfaces and corners. Between each adjacent pair of corners is a cutting edge which includes a straight wiper sub-edge and two at least partially curved peeling sub-edges respectively located on opposing sides of the wiper sub-edge. The corners of the insert are inwardly disposed relative to an imaginary square formed by the sub-edges.

Owner:ISCAR LTD

Heat-preserving and decorative board

The invention discloses a heat-preserving and decorative board which sequentially comprises a heat-preserving combined coating, a panel layer and a heat-preserving core material layer from outside to inside. Inclined kidney-shaped round tenons are arranged at one end of the board, and mortises matched with the inclined kidney-shaped round tenons are arranged at the other end of the board. Each inclined kidney-shaped round tenon comprises a connection end and a free end, and the connection ends connect the panel layer and the heat-preserving core material layer. The heat-preserving combined coating sequentially comprises a putty layer, a primer layer, a decorative coating and a finish paint layer from outside to inside. The board is long in service life, the finishing effect is good, and boards are easily and firmly matched. During use of the heat-preserving and decorative board, when the boards are assembled and used in pairs, combination between the boards is firmer through cooperation of the inclined kidney-shaped round tenons and the mortises beside traditional anchoring elements and wet sticky fixation. Besides, matching is easy and convenient, the inclined kidney-shaped round tenons connect the panel layer and the heat-preserving core material layer, and fixation of the whole board is enhanced.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Furniture decorative plastic-wood plate and preparation method thereof

InactiveCN106273919AGood finishBeautiful graphicsSynthetic resin layered productsFurniture partsMelamine resinEngineering

The invention discloses a furniture decorative plastic-wood plate and a preparation method thereof. The furniture decorative plastic-wood plate comprises a base material plate layer, melamine resin layers, a decoration layer and a fireproof coating layer, wherein the melamine resin are pressed and attached to the upper surface and the lower surface of the base material plate via high temperature and high pressure; the decoration layer is pasted on the front face or the front face and the reverse face of the base material plate layer which is provided with the melamine resin layers on the surfaces; the external surface of the decoration layer is coated with the fireproof coating layer. The furniture decorative plastic-wood plate and the preparation method thereof provided by the invention have the advantages that the smooth finish of a conventional fireproof decoration plate is greatly improved, and patterns and texts are more beautiful, so that the decoration effect is greatly improved.

Owner:王松亚

Stainless steel seamless steel tube with precise inner diameter for hydraulic and pneumatic cylinder

The invention relates to a stainless steel seamless steel tube with a precise inner diameter for a hydraulic and pneumatic cylinder, which is mainly used for manufacturing and processing hydraulic and pneumatic elements or being directly processed into cylinder pipes. The stainless steel seamless steel tube with the precise inner diameter for the hydraulic and pneumatic cylinder is made of an austenite stainless steel material instead of a common carbon steel material, the inner surface roughness thereof completely adopts the precision of more than 0.8mum of a nominal value Ra, and the allowable precision deviation of the outer diameter size thereof is improved by one time than that of the steel pipe product made of the common carbon steel material. The stainless steel seamless steel tube with the precise inner diameter for the hydraulic and pneumatic cylinder enhances corrosion resistance and wear resistance of the product, enables the product to adapt to severe and special working environment, has the characteristics of good inner-surface finish, high precision, no need of grinding machining and the like, and further improves the installation precision of the product.

Owner:常州市联谊特种不锈钢管有限公司

Heat-preserving and decorative board assembly

InactiveCN105089240AExtended service lifeGood finishCovering/liningsLayered productsTongue and grooveEngineering

The invention discloses a heat-preserving and decorative board assembly. The assembly comprises a first heat-preserving board and a second heat-preserving board spliced with the first heat-preserving board into a whole. A dovetail tenon is arranged at one end of a first composite board, and a groove is formed between the dovetail tenon and the first composite board. The groove is provided with a connection through hole. The second heat-preserving board is provided with a mortise matched with the dovetail tenon. During use of the assembly, when boards are assembled and used in pairs, combination between the boards is firmer and more compact through cooperation of the dovetail tenon and the mortise beside traditional wet sticky fixation; besides, the groove between the dovetail tenon and the first composite board is provided with the connection through hole, the boards are fixed to a wall through the through hole by means of an anchoring element, the boards can be sealed through sealants after being fixed, a panel layer and a heat-preserving core material layer are connected through the dovetail tenon, and the situation that because of long-time use, the panel layer breaks away from the heat-preserving core material layer is avoided.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

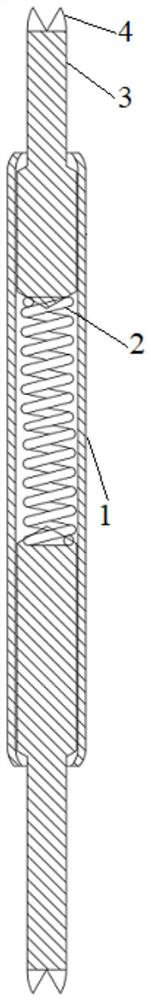

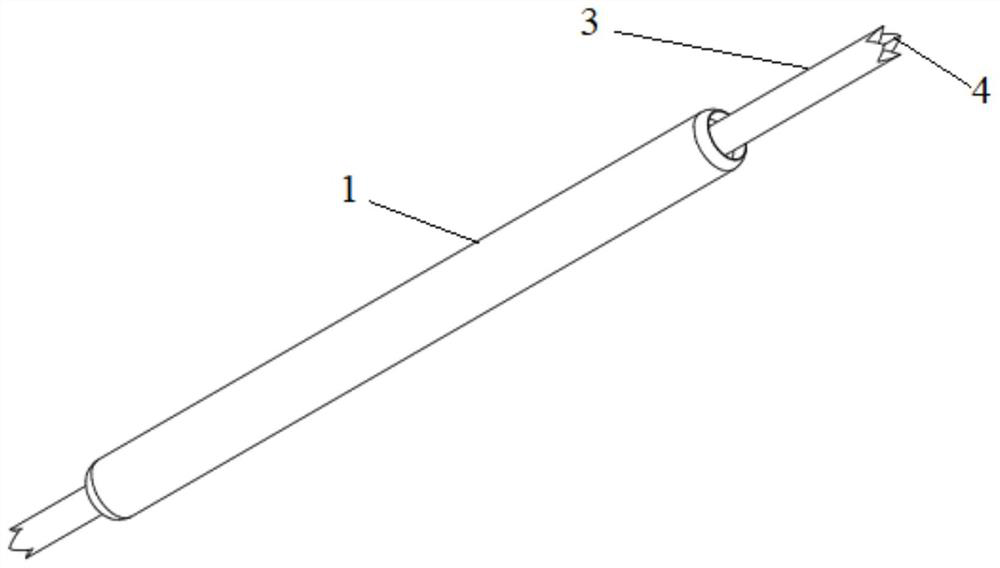

Mirror cutting needle type probe and processing method

PendingCN114778903AReduce roughnessGood finishElectrical measurement instrument detailsElectrical testingPhysicsCutting needle

The invention discloses a mirror cutting needle type probe which comprises a needle tube, an elastic piece is arranged in the needle tube, needle heads are inserted into the two ends of the needle tube respectively, the tail portions of the two needle heads abut against the two ends of the elastic piece respectively, a plurality of sawteeth are arranged on the head portion of each needle head in a claw shape, and the surface of each sawtooth is subjected to mirror polishing. The invention relates to a mirror cutting needle type probe, which solves the problems that the needle of the existing probe is large in roughness and is easy to stain after being used for a long time. The invention further discloses a machining method of the mirror cutting needle type probe.

Owner:渭南木王智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com