Wear-resistant easy-to-cut brass pipe material and method of using same to manufacture brass pipe

A manufacturing method and technology for brass pipes, applied in the field of non-ferrous metal processing, can solve the problems of insufficient surface finish, large eccentricity of pipes, easy to scratch friction pairs, etc., and achieve the elimination of metal transverse crack defects, high strength and toughness, The effect of stable wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

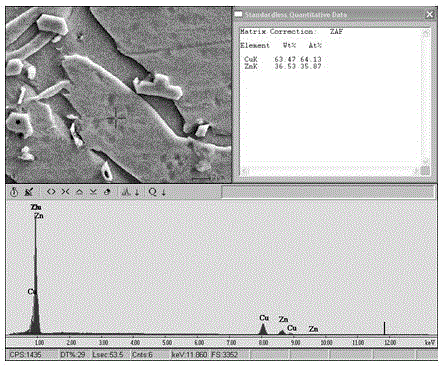

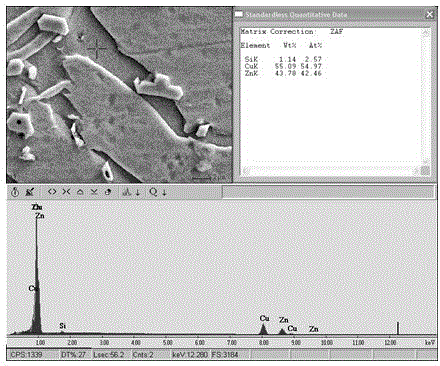

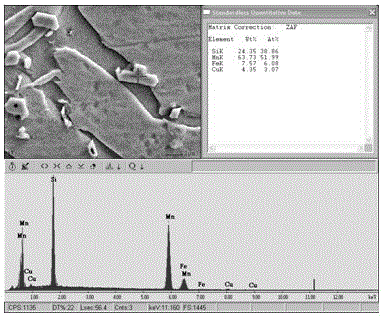

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with embodiment.

[0029] First prepare manganese Mn, iron Fe, and silicon Si master alloys to ensure that the weight ratio of Mn and Si is close to 3:1, and the manganese-copper alloy contains manganese Mn25%; the iron-copper alloy contains iron Fe10%; the silicon-copper alloy contains silicon Si20%.

[0030] The preparation method of the brass alloy tube is: 60-65wt% copper, 0.5-3.5wt% manganese, 0.5-3.5wt% silicon, 0.2-3.0wt% lead, 0.05-0.2wt% iron, 0.1-0.3wt% nickel, 0.1-0.3 wt% aluminum, the balance is zinc and unavoidable impurities, the total amount of unavoidable impurities is not more than 0.1wt% composition ratio, electrolytic copper, manganese-copper alloy, silicon-copper alloy, iron-copper alloy, lead ingot , nickel-copper, and zinc ingots are sequentially added to the induction furnace for smelting. The melting temperature is 1030-1080°C. After all the metals are melted, raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com