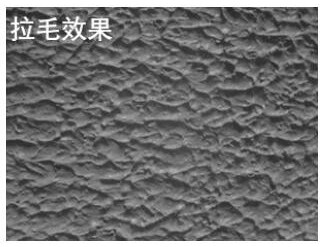

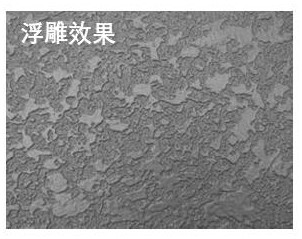

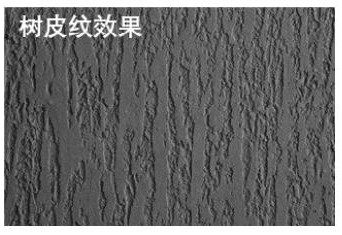

Artistic paint and preparation method thereof

An art paint and raw material technology, applied in antifouling/underwater paints, coatings, paints containing biocides, etc. Reduce the pressure of manufacturers' production and storage, smooth texture and feel, and reduce waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] A preparation method for art paint, comprising the following steps:

[0101] Add filler, lignocellulose, emulsion and silane coupling agent to water, stir to disperse;

[0102] The mass parts of the emulsion are 100-180 parts; the mass parts of the filler are 500-700 parts; the mass parts of the silane coupling agent are 3-6 parts; the mass parts of the lignocellulose are 3- 8 copies;

[0103] The emulsion includes a first styrene-acrylic emulsion and a second styrene-acrylic emulsion, the glass transition temperature of the first styrene-acrylic emulsion is 20°C-45°C, and the second styrene-acrylic emulsion is oil-resistant and hydrophobic styrene-acrylic emulsion ;

[0104] The filler is at least two selected from barite, wollastonite and heavy calcium.

[0105] The raw materials are added sequentially according to the formula, the preparation operation is simple, and the construction is convenient.

[0106] In a preferred embodiment, the amount of water required ...

Embodiment 1

[0111] This embodiment provides a stain-resistant multi-model art paint and its preparation method and construction method. Proceed as follows:

[0112] 1) Weigh the following raw materials: water-based broad-spectrum preservative 1.5kg, ester compound 6kg, dispersant 2.2kg, defoamer 3kg, antifreeze 5kg, wollastonite 200kg, barite 500kg, silane coupling agent 3.6kg , lignocellulose 5kg, emulsion 100kg, hydroxyethyl cellulose 3.2kg, stabilizer 0.5kg, tap water 170kg, total 1000kg.

[0113] 2) Add tap water into the stirring tank, turn on the stirring tank, stir at 700r / min, add the weighed water-based broad-spectrum preservative, ester compound, dispersant, defoamer, antifreeze, wollastonite in sequence while stirring , lignocellulose, emulsion, stir and disperse for 5 minutes, then add barite, hydroxyethyl cellulose, silane coupling agent in turn, stir and disperse for 10 minutes, then increase the speed to 1200r / min, add stabilizer, stir 5-10 minutes, until the mixed slurry...

Embodiment 2

[0116] This embodiment provides a stain-resistant multi-model art paint and its preparation method and construction method. Proceed as follows:

[0117] 1) Weigh the following raw materials: water-based broad-spectrum preservative 1.5kg, ester compound 7.2kg, dispersant 2.3kg, defoamer 3kg, antifreeze 6kg, wollastonite 300kg, barite 400kg, silane coupling agent 3.6 kg, lignocellulose 5kg, emulsion 120kg, hydroxyethyl cellulose 3.0kg, stabilizer 0.5kg, tap water 147.9kg, total 1000kg.

[0118] 2) Add tap water into the stirring tank, turn on the stirring tank, stir at 700r / min, add the weighed water-based broad-spectrum preservative, ester compound, dispersant, defoamer, antifreeze, wollastonite in sequence while stirring , lignocellulose, emulsion, stir and disperse for 5 minutes, then add barite, hydroxyethyl cellulose, silane coupling agent in turn, stir and disperse for 10 minutes, then increase the speed to 1200r / min, add stabilizer, stir 5-10 minutes, until the mixed sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com