Framework type tooling for molding composite material product autoclave

An autoclave forming and composite material technology, which is applied in the field of frame type process equipment structure, can solve the problems of cumbersome processing, different shapes, complicated welding work, etc., and achieves the effects of good finish, small deformation, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

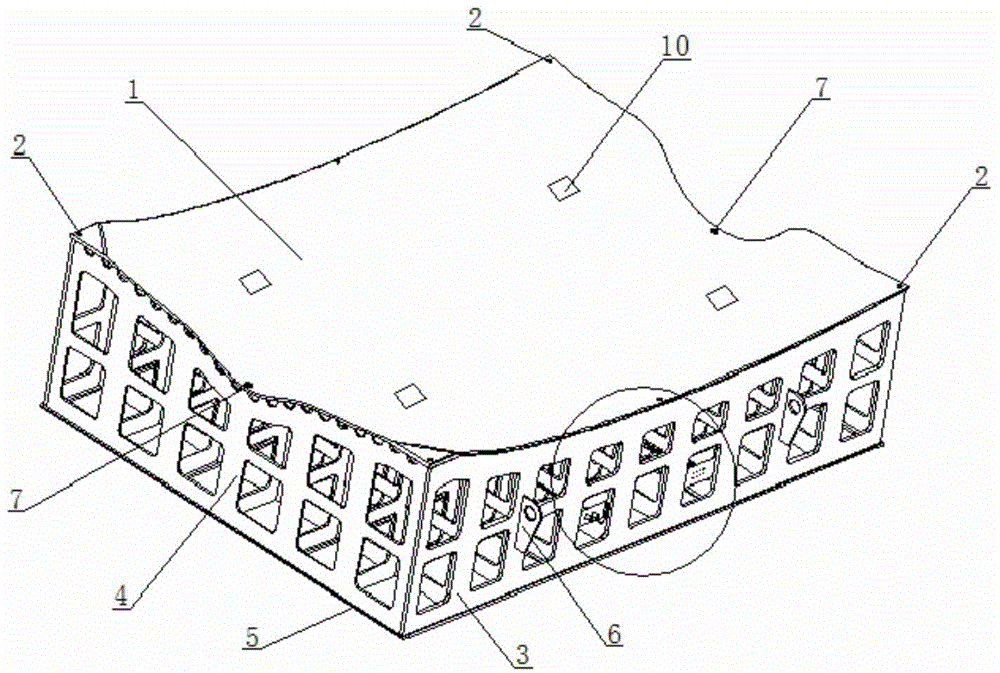

[0017] This embodiment is a frame-type tooling used for autoclave molding of composite material parts.

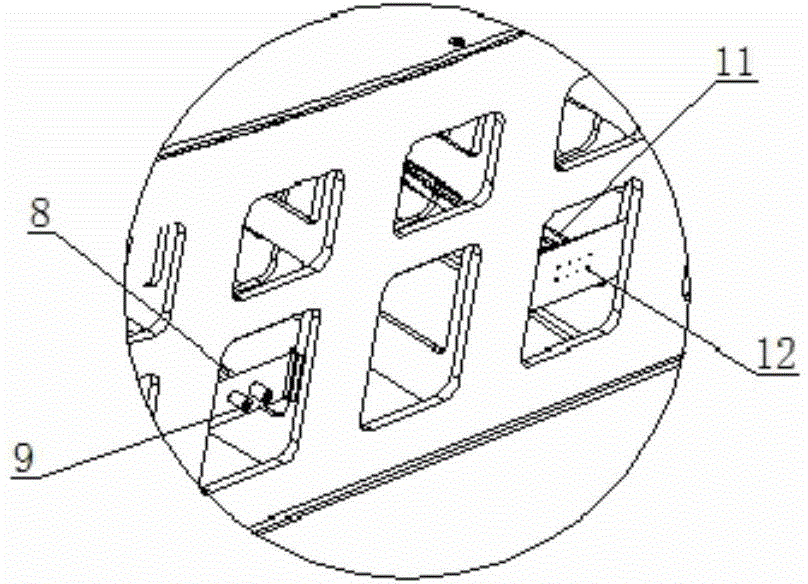

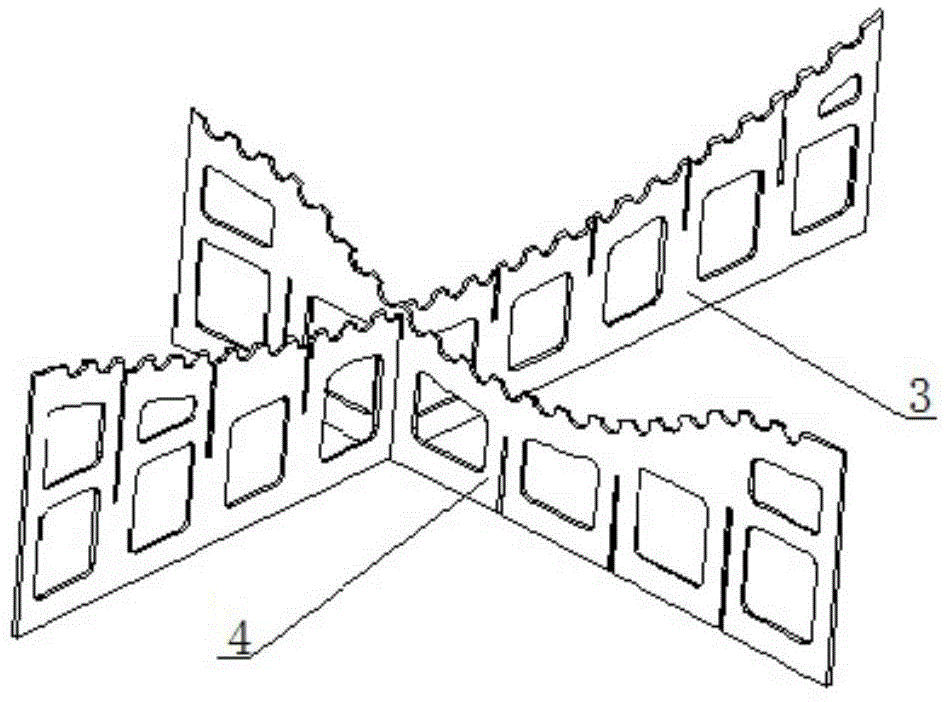

[0018] refer to figure 1 , figure 2 , image 3 , this embodiment is used for the frame-type process equipment of autoclave molding of composite material parts, which consists of profile 1, longitudinal rib 3, transverse rib 4, bottom plate 5, hanging device 6, reference hole 2, air extraction Mouth 7, air extraction pipe 8, air extraction pipe joint 9, temperature sensor 10, wire 11, temperature monitoring joint 12. The longitudinal rib 3 and the transverse rib 4 are cross-connected, and the profile 1 is welded to the longitudinal rib 3 and the transverse rib 4 to form a frame structure; the longitudinal rib 3 and the transverse rib 4 are fixedly welded on the bottom plate 5, and the four hangers The hanging devices 6 are evenly distributed and fixed on both sides of the frame, the reference hole 2 is set on the four corners of the profile 1, and the air nozzle 7 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com