Gas-conducting pressure measuring intermittent producing oil exploitation device

A technology of gas conduction and oil extraction, which is applied in the direction of extraction fluid, measurement, earthwork drilling, etc., can solve the problems that it is difficult to realize the cost of intermittent extraction, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

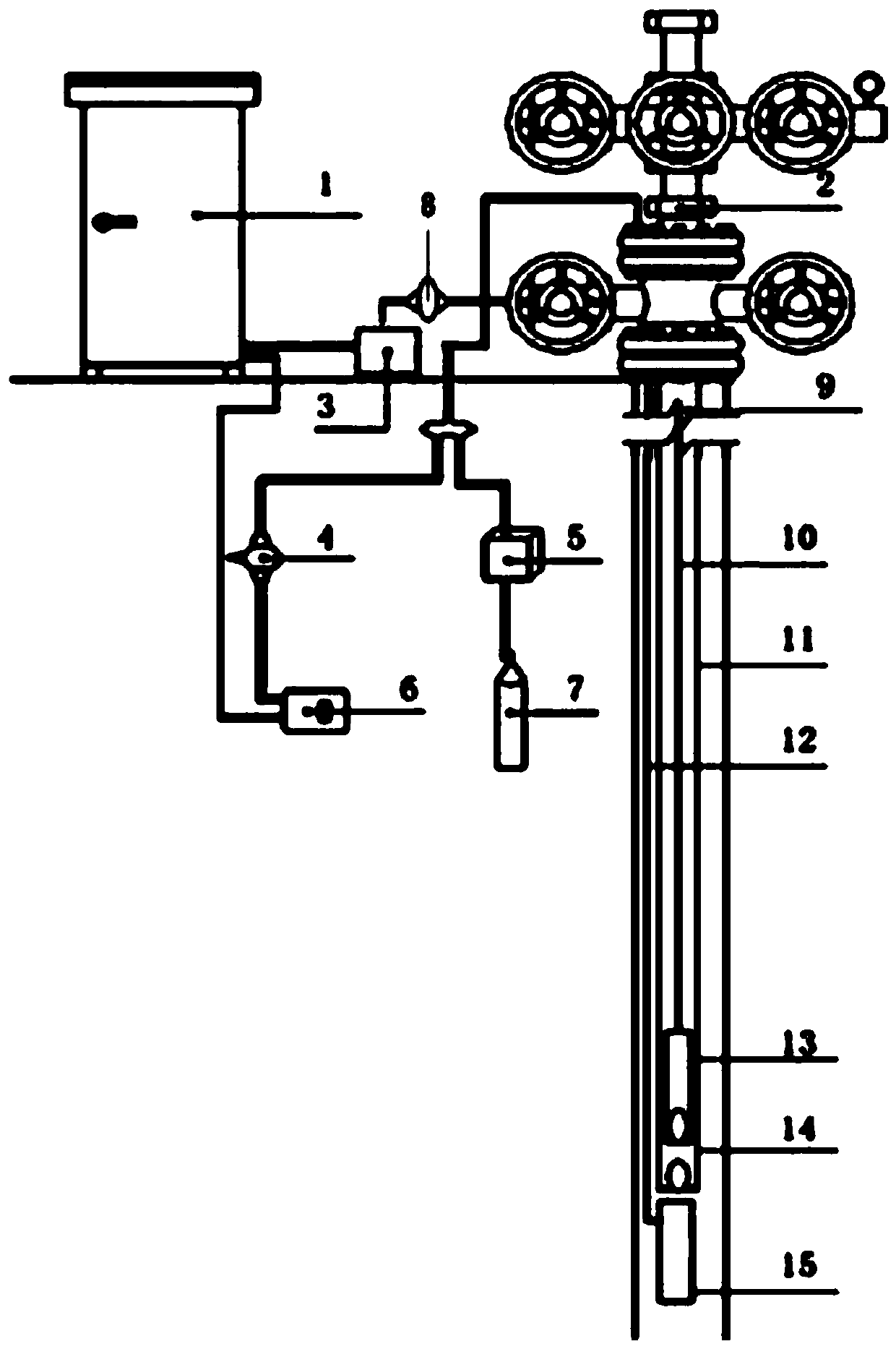

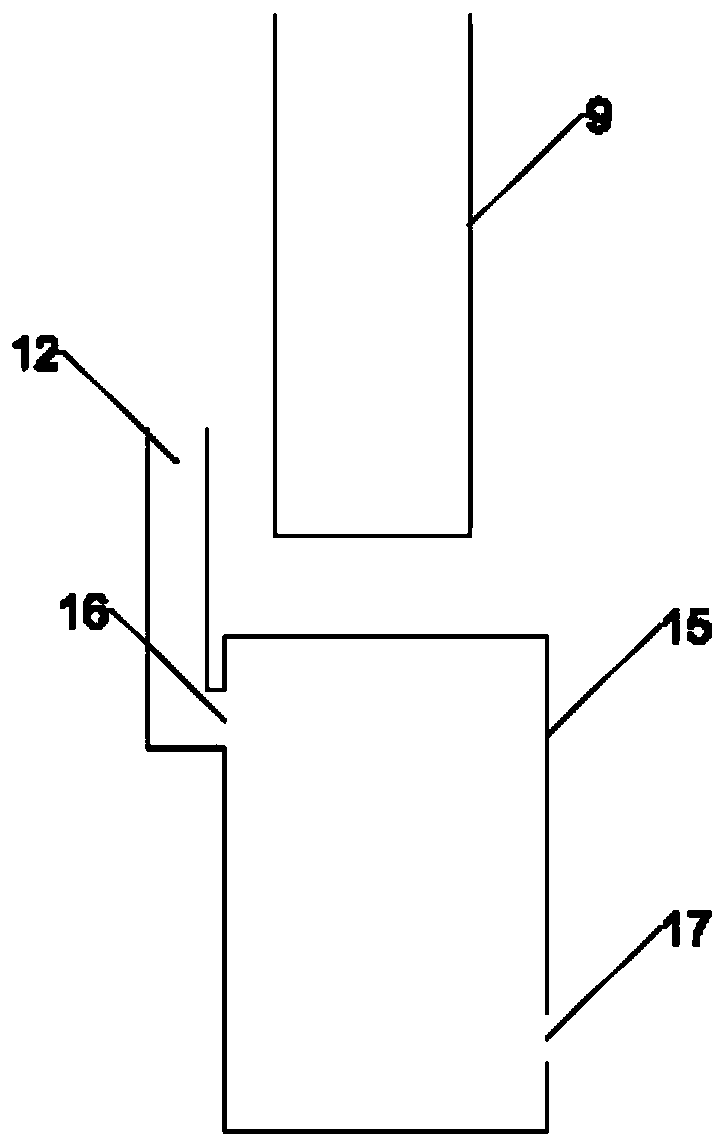

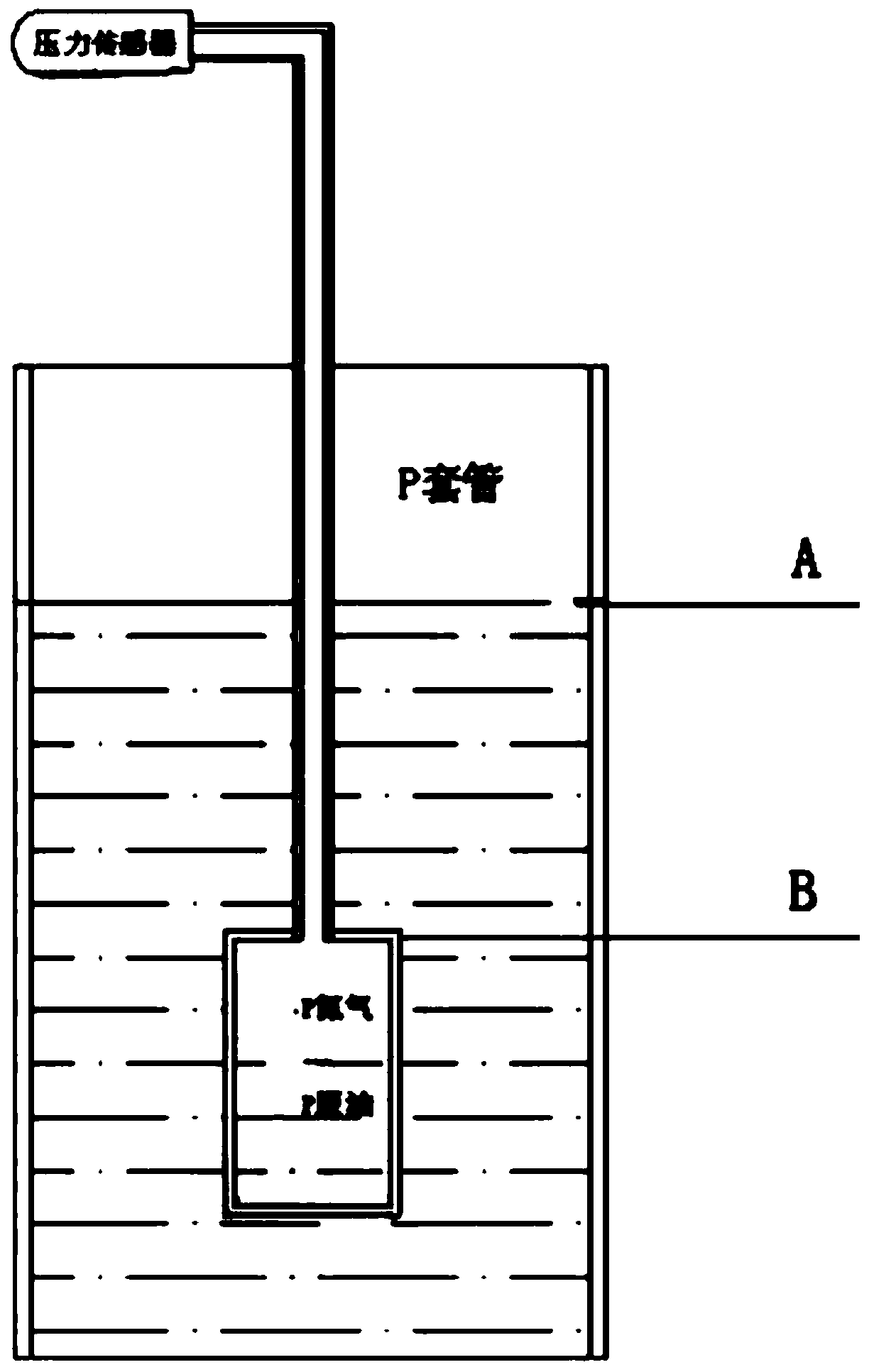

[0016] Such as figure 1 and image 3 As shown in Fig. 1, a gas conduction pressure measuring room oil recovery device can realize the effect of intermittent oil recovery in well fluid. The oil extraction device includes oil pumping equipment, control equipment and gas conduction pressure measuring equipment. The oil pumping equipment is directly in contact with the well fluid for oil extraction. Air conduction manometric equipment measures the pressure data of the hydrostatic column and feeds back to the control equipment. The control equipment combines the pressure data of the hydrostatic column with the descending height of the pumping equipment to calculate the depth of the well fluid where the pumping equipment is located. The control equipment judges whether the pumping equipment is working or how often it works through the calculated well fluid depth. The setting of control equipment and gas conduction pressure measurement equipment reduces the situation that the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com