Bi-continuous-phase composite friction material of foaming silicon carbide/metal, its member and preparation

A technology of composite friction material and foamed silicon carbide, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of failure to perform the function of composite material friction parts normally, reducing the mechanical properties and thermal conductivity of materials, and the foam ceramics are prone to damage, etc. problems, to achieve the effect of improving mechanical strength and heat transfer capacity, good designability, enhancing material friction performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

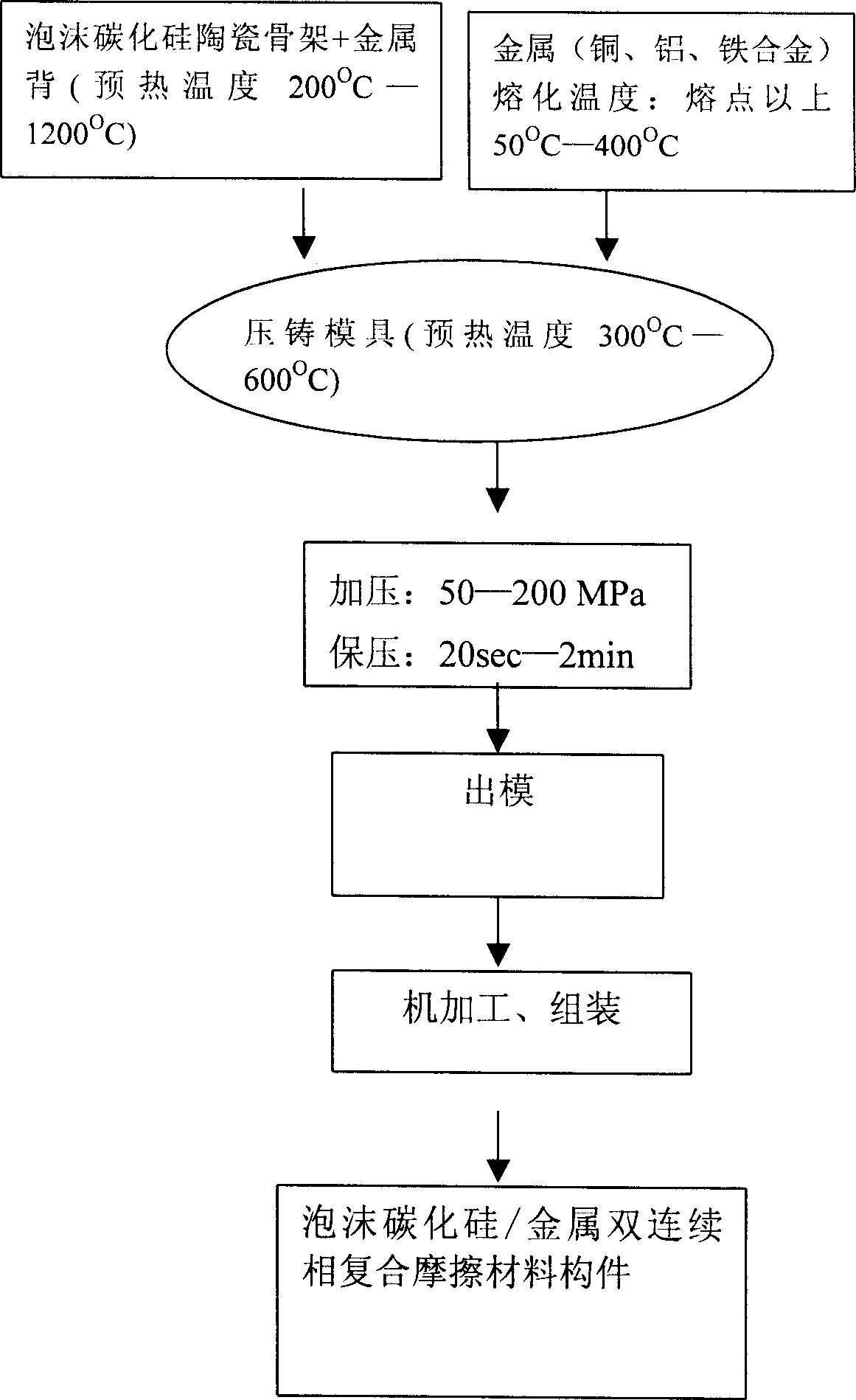

Method used

Image

Examples

Embodiment 1

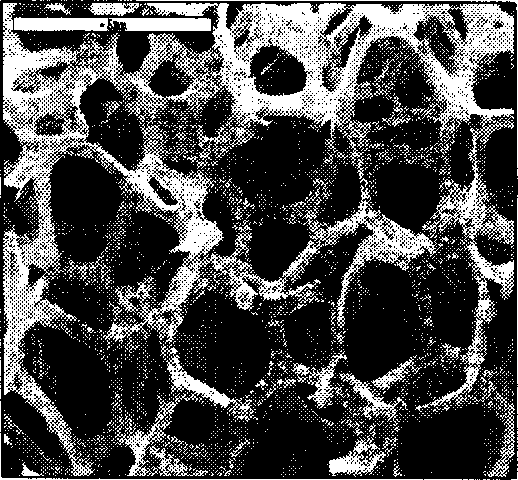

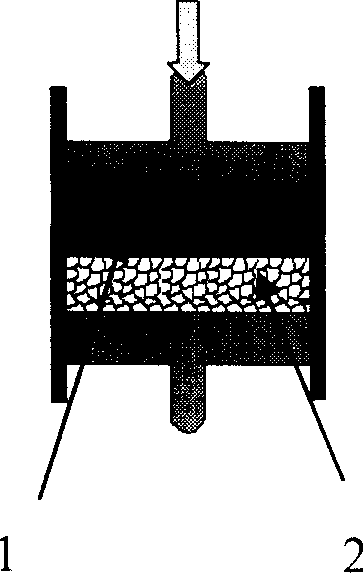

[0101] First prepare the foamed silicon carbide ceramic skeleton according to the method provided by the patent application number 03134039.3, the size is as Figure 8a , Figure 9 . Wherein the thickness of foamed silicon carbide ceramics is 4mm, and the size of the mesh (aperture of foamed silicon carbide ceramics) is 0.5mm. In the foamed silicon carbide ceramics / metal double continuous phase composite material, the volume fraction of foamed silicon carbide ceramics is 15%. The center hole is fixed on the stainless steel mesh of the same size with screws, heated to 300°C and put into a Φ100mm mold.

[0102] Using the die-casting method, heat the iron brass Hfe59-1-1 to the melting point (901°C) above 200°C, remove the covering agent, deoxidize, and slag, and then pour it into the mold. The pressure is 50MPa, and the holding time is 20 seconds. Press it into the foamed silicon carbide ceramic skeleton, and machine it to the required size to obtain the foamed silicon carbide...

Embodiment 2

[0104] The difference from Example 1 is:

[0105] Foamed silicon carbide ceramics were prepared according to Example 1. Under the conditions of temperature 1800° C., vacuum 2 Pa, and holding time of 1 hour, the residual silicon inside the framework ribs of the foamed ceramics was removed to obtain porous foamed silicon carbide ceramics. The relative density of porous foam silicon carbide ceramic bars is 90%, the equivalent diameter of pores is 2 μm, and the porosity is 10%.

Embodiment 3

[0107] The difference from Example 1 is:

[0108] Adopt the method for adding pore forming agent (silicon powder) to prepare porous foamed silicon carbide ceramics, in the ceramic slurry prepared by the method provided in the patent application number 03134039.3, according to the formula of the embodiment 1 component in this application Porous foamed silicon carbide ceramics were prepared by adding 20g of silicon powder. The relative density of porous foam silicon carbide ceramic bars is 85%, the equivalent diameter of pores is 10 μm, and the porosity is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com