Jetting type liquid-solid double-phase scouring corrosion experiment apparatus

A technology for scouring corrosion and experimental equipment, which is used in measuring equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., which can solve the problems of long experimental period and difficulty in adjusting the angle of attack, and achieve the effect of short experimental period and controllable flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

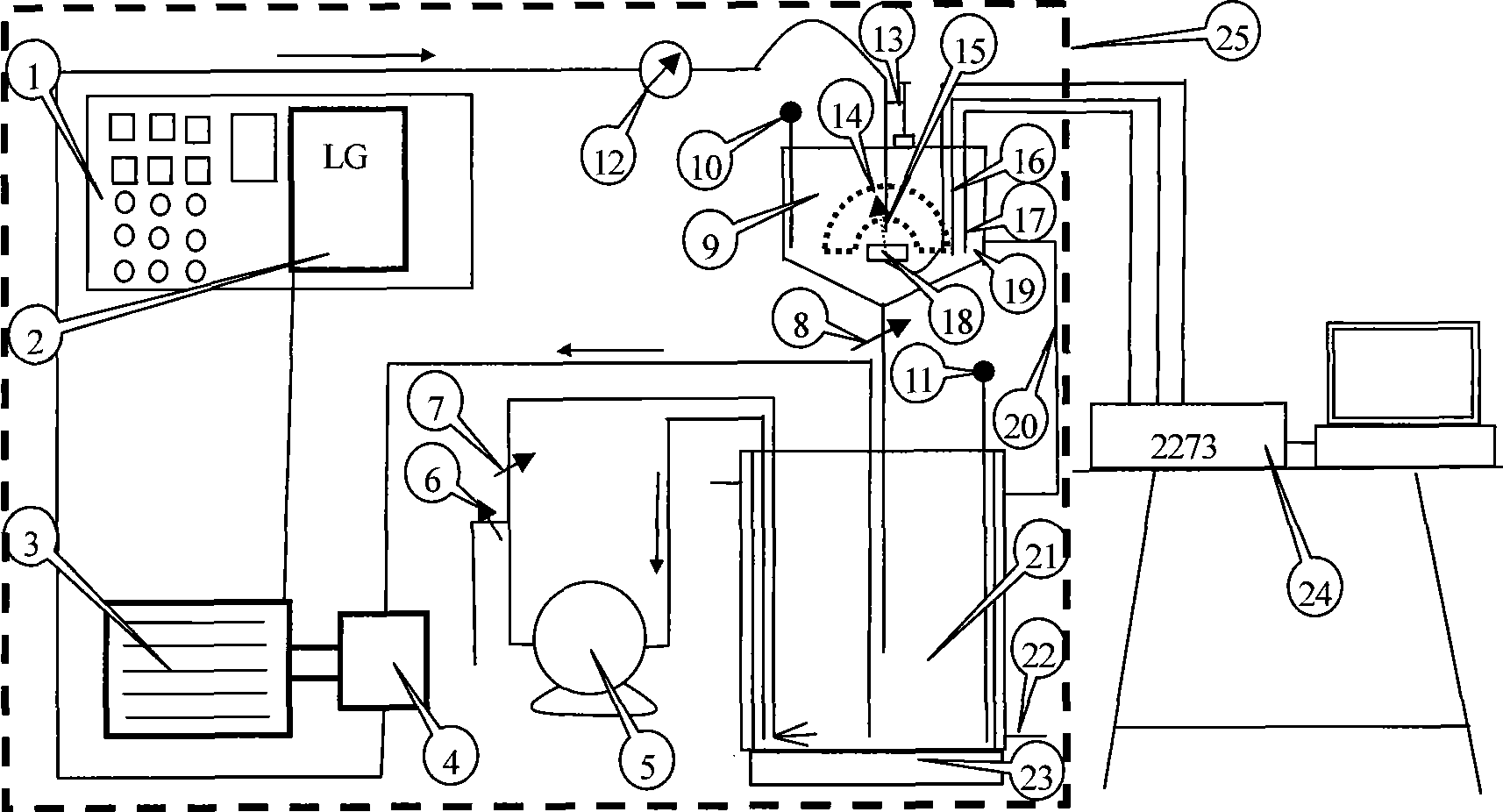

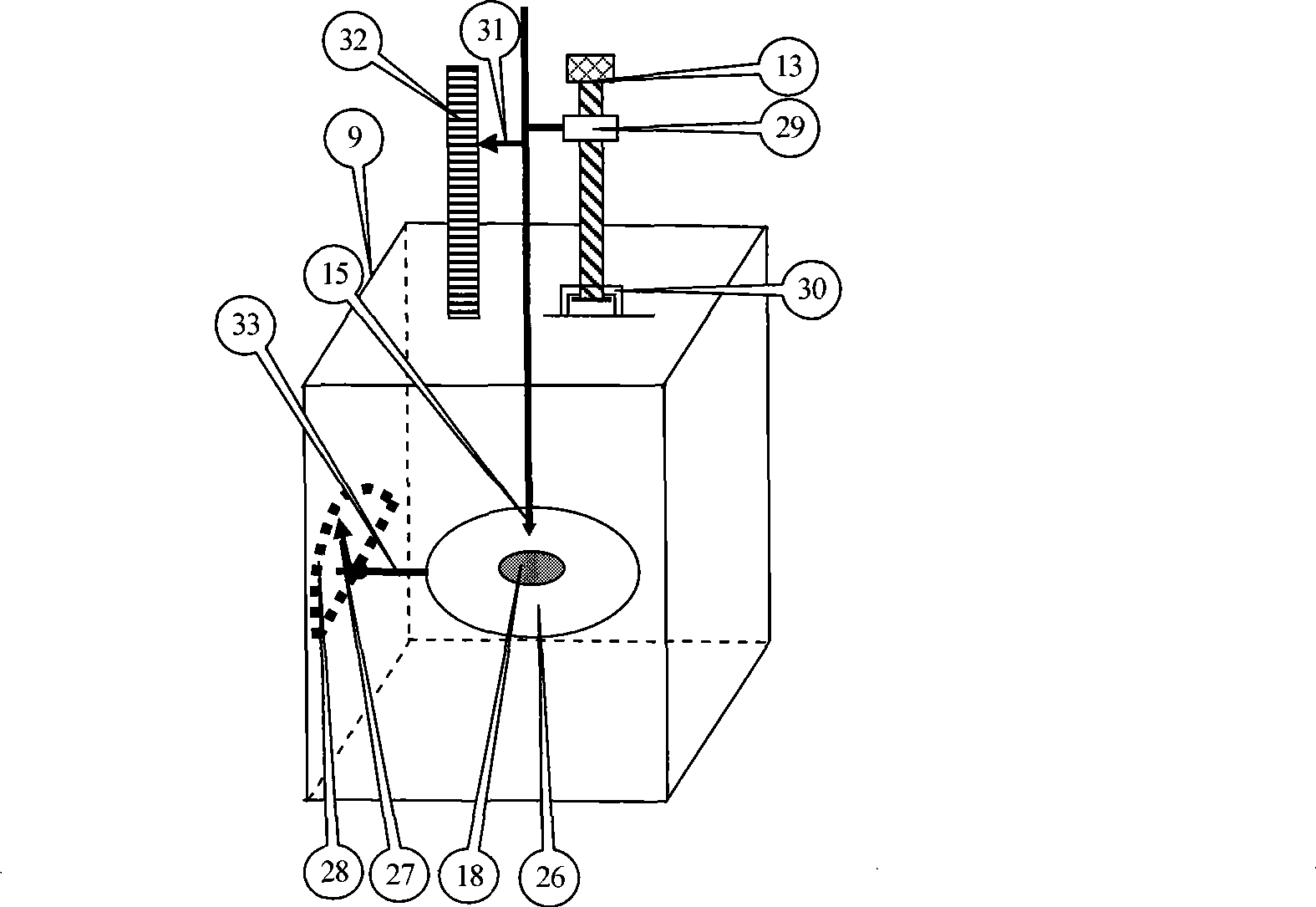

[0022] The structure and working process of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the present invention consists of control cabinet 1, frequency converter 2, motor 3, cam pump 4, stirring, discharge pump 5, ball valve I6, ball valve II7, ball valve III8, injection chamber 9, thermocouple I10, thermocouple II11, electromagnetic Flow meter 12, lifting screw 13, angle of attack adjustment device 14, nozzle 15, reference electrode 16, auxiliary electrode 17, working electrode (sample) 18, acidity meter probe 19, overflow pipe 20, slurry tank 21, The cooling water pipe 22, the heater 23, the electrochemical workstation 24, the frame 25 and the panel are composed. The cam pump 4 driven by the motor 3 equipped with the frequency converter 2 is used as the jet pump, and the electromagnetic flowmeter 12 is arranged in the pipeline, and the electromagnetic flowmeter 12 displays ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com