Cavitation erosion-erosion wearing cooperative test device

A technology of experimental testing and synergy, applied in the direction of testing wear resistance, etc., can solve the problems such as the inability to accurately describe the weight loss of metal materials, the lack of in-depth research on the synergistic mechanism of multiphase flow cavitation-erosion wear, and the long testing time. , to achieve the effect of extending the safe and stable operation cycle and avoiding unplanned shutdown accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

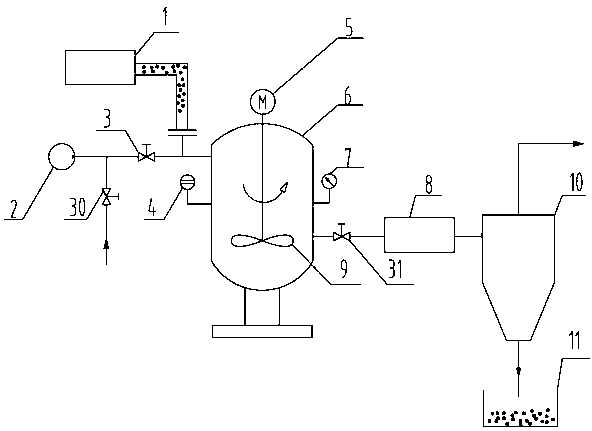

[0019] Such as figure 1 As shown, the present invention comprises a feeder 1, a compressor 2, a motor 5, a slurry tank 6, a cavitation-erosion wear test valve 8, a separator 10, a recovery tank 11, a first shut-off valve 3, and a second shut-off valve 30. The third cut-off valve 31; the inlet of the slurry tank 6 is composed of three branches converging, the gas in the first branch (such as nitrogen, air) is connected to the slurry tank 6 through the compressor 2 and the first stop valve 3 through pipelines The inlet of the upper side, the water inlet of the second branch is connected with the pipeline between the compressor 2 and the first stop valve 3 through the second stop valve 30, and the solid particles of the third branch (such as coal powder, fine sand, carbon dioxide Silicon) through the feeder 1, the flange is connected with the pipeline at the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com