Method for displaying and quantitatively determining retained austenite or island martensite- austenite in TRIP steel

A quantitative detection method and technology of retained austenite, applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., can solve the problem of display and quantitative detection There are no problems such as instructions, achieving the effect of high accuracy of quantitative results, easy identification, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for displaying and quantitatively detecting retained austenite or MA islands in TRIP steel, the steps of which are as follows:

[0036] (1) After the TRIP steel sample to be inspected was intercepted according to the sampling standard, it was hot-mounted with phenolic resin inserts to prepare a metallographic sample;

[0037] (2) After the metallographic sample is ground and polished, it is lightly etched with 1% (wt.) nitric acid alcohol solution for about 8 seconds, and then lightly polished, that is, on the flannelette polishing disc Lightly throw water for 2 seconds, then use 1% (wt.) sodium bisulfite (Sodium Metabisulfite, molecular formula Na 2 S 2 o 5 ) aqueous solution and 6% (wt.) picric acid alcohol solution are uniformly mixed at a volume ratio of 1:1 to make a corrosion solution, and the metallographic sample is put into the corrosion solution and etched for 55 seconds;

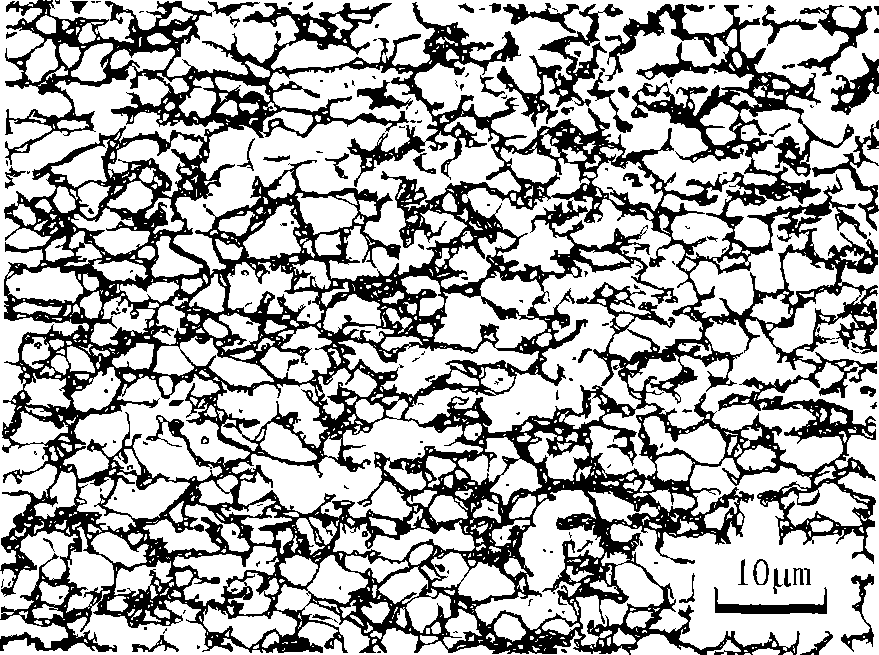

[0038] (3) observe the structure of TRIP steel under leica DM6000 M metallo...

Embodiment 2

[0049] A method for displaying and quantitatively detecting retained austenite or MA islands in TRIP steel, the steps of which are as follows:

[0050](1) After the TRIP steel sample to be inspected was intercepted according to the sampling standard, it was hot-mounted with phenolic resin inserts to prepare a metallographic sample;

[0051] (2) After the metallographic sample is ground and polished, it is lightly etched with 3% (wt.) nitric acid alcohol solution for 5 seconds, and then lightly polished, that is, on the flannelette polishing disc. Water is lightly thrown for 1 second, and then utilizes 3% (wt.) sodium metabisulfite (Sodium Metabisulfite, molecular formula Na 2 S 2 o 5 ) aqueous solution and 2% (wt.) picric acid alcohol solution in a volume ratio of 1:1 to prepare a corrosion solution, and put the metallographic sample into the corrosion solution and etch for 65 seconds;

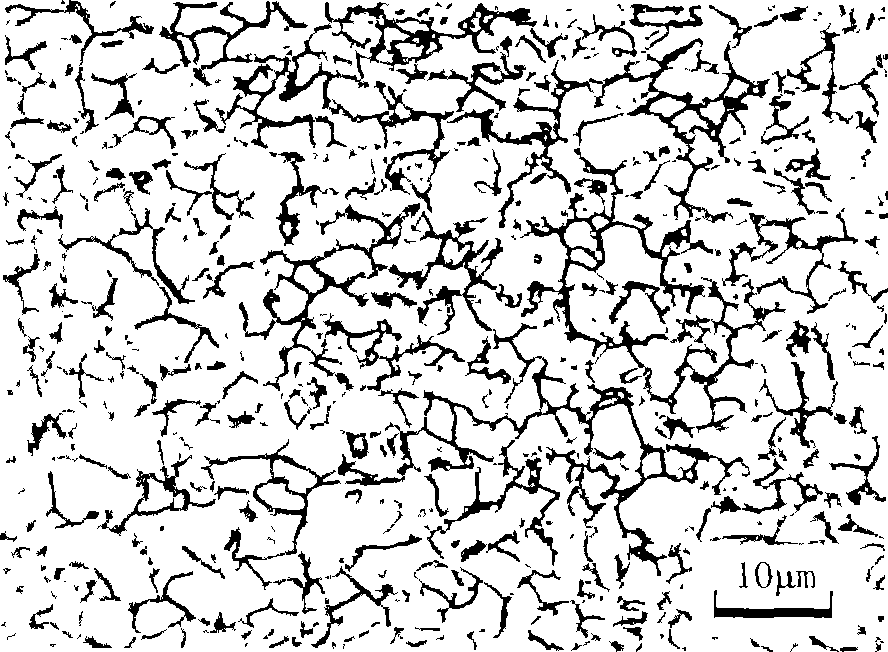

[0052] (3) Observe the structure of TRIP steel under a metallographic microscope: ferri...

Embodiment 3

[0055] A method for displaying and quantitatively detecting retained austenite or MA islands in TRIP steel, the steps of which are as follows:

[0056] (1) After the TRIP steel sample to be inspected was intercepted according to the sampling standard, it was hot-mounted with phenolic resin inserts to prepare a metallographic sample;

[0057] (2) After the metallographic sample is ground and polished, it is lightly etched with 2% (wt.) nitric acid alcohol solution for 6 seconds, and then lightly polished, that is, on the flannelette polishing disc. The water is lightly thrown for 1.5 seconds, and then 2% (wt.) sodium bisulfite (Sodium Metabisulfite, molecular formula Na 2 S 2 o 5 ) aqueous solution and 4% (wt.) picric acid alcohol solution are uniformly mixed at a volume ratio of 1:1 to make an etching solution, and the metallographic sample is put into the etching solution and etched for 60 seconds;

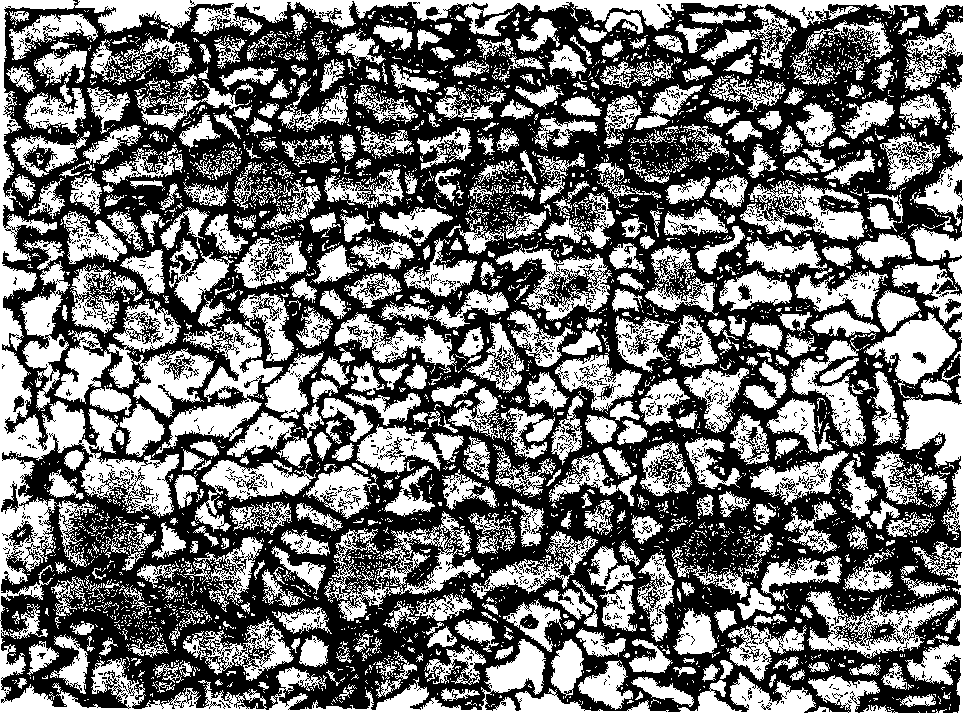

[0058] (3) Observe the structure of TRIP steel under a metallographic mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com