High strength low alloy hot rolling ferrite bainite weathering resistant steel and production method thereof

A high-strength low-alloy, ferrite technology, applied in the direction of temperature control, process efficiency improvement, manufacturing converters, etc., can solve the problem of not fully meeting the service requirements of containers and railway vehicles, and not making full use of niobium precipitation strengthening and microstructure Problems such as chemical effect, weldability and low-temperature toughness decrease, to achieve the effects of shortening the production cycle, good economic benefits, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0057] The components and weight percentages of the high-strength low-alloy hot-rolled ferritic bainitic weathering steel (steel type in this example) are shown in Table 1. (Compared with steel types), the alloy does not contain molybdenum, the cost is relatively low, and the strength and elongation are higher, and it has excellent low temperature toughness. In addition, the welding cold crack sensitivity coefficient of the steel type in this embodiment is:

[0058] P cm =0.08+0.4 / 30+(1.09+0.3+0.63) / 20+0.005 / 15

[0059] +0.24 / 60+0.006 / 10=0.199

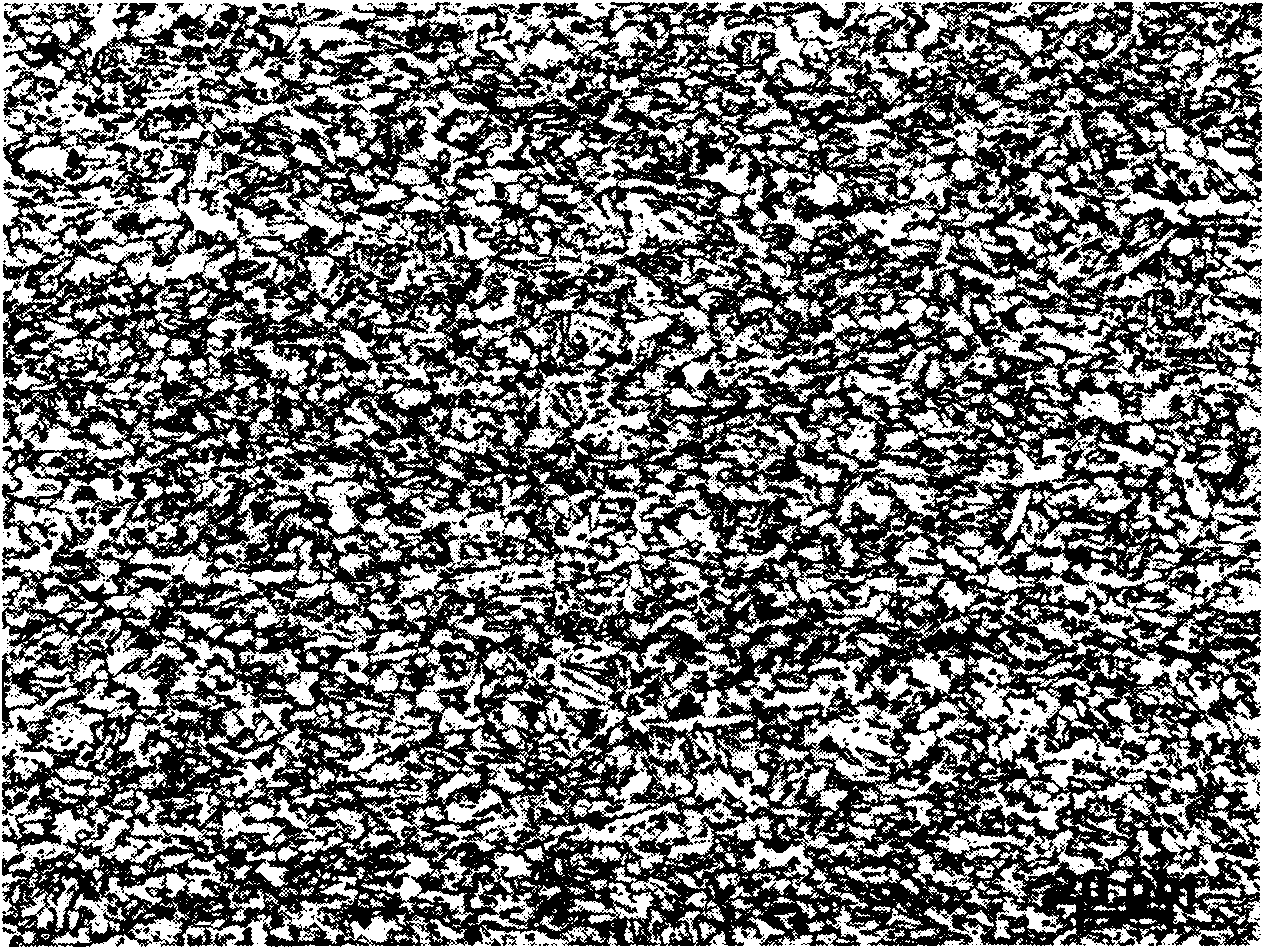

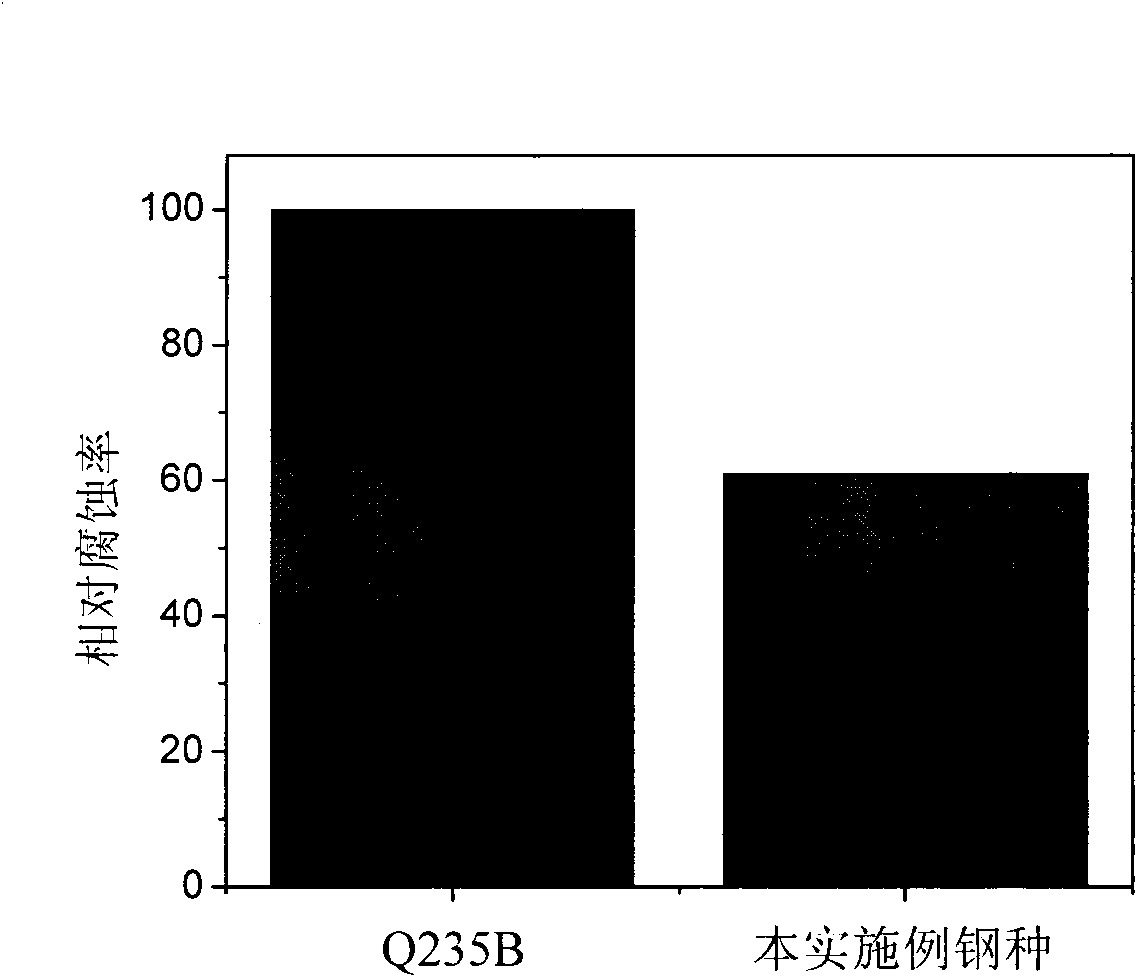

[0060] Such as figure 1 As shown, the steel type in this embodiment has a structure of acicular ferrite + bainite, which is more uniform in structure and better in weather resistance than general bainite steel.

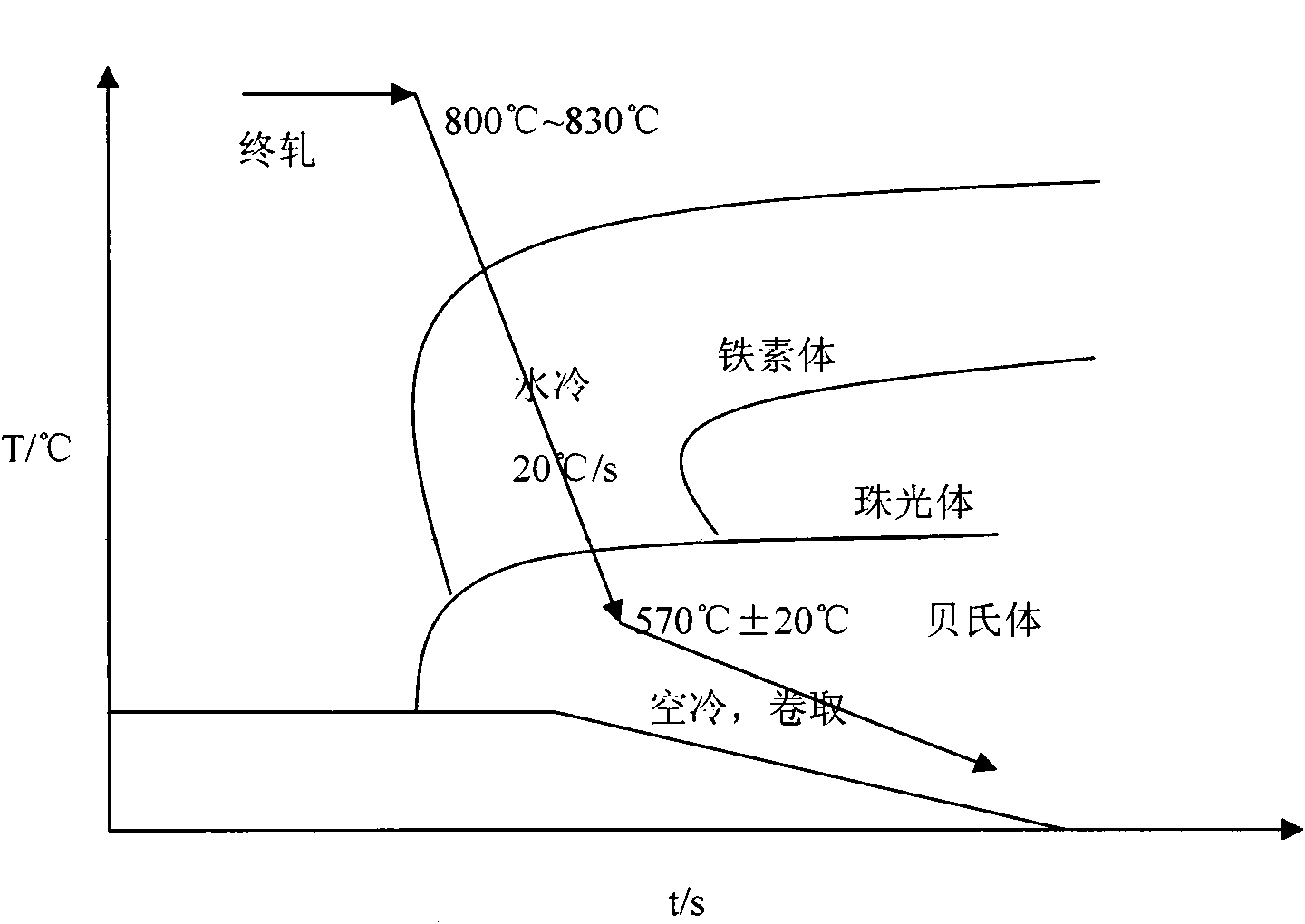

[0061] The preparation process of the high-strength low-all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com